Introduction

In recent years, China has emerged as a powerhouse in the manufacturing of valve actuators, offering a wide range of products designed for various applications. These valve actuator manufacturers have made significant strides in technology and efficiency, catering to the growing demand for reliable automation solutions across industries. As businesses seek to enhance their operational capabilities, understanding the landscape of these manufacturers becomes essential.

Overview of Valve Actuator Manufacturers in China

China is home to some of the leading valve actuator manufacturers that specialize in producing high-quality electric actuators and actuator valves. With a focus on innovation and performance, these companies are continually developing advanced solutions tailored to meet diverse industry needs. From solenoid and valve combinations to standalone electric valve actuators, the variety available ensures that customers can find products suited to their specific requirements.

Importance of Quality in Valve Actuation

Quality plays a critical role in selecting valve control valves and actuators, as it directly impacts performance and longevity. In industrial settings, where reliability is paramount, choosing high-quality actuator valves from reputable manufacturers can prevent costly downtime and maintenance issues. Therefore, understanding the standards set by leading valve actuator manufacturers is crucial for making informed decisions that enhance operational efficiency.

Exploring Types of Valve Actuators

The market offers an array of electric actuators designed for different types of valves, each with unique functionalities tailored for specific applications. Understanding the differences between solenoid and valve actuators is vital for selecting the right device; while solenoid actuators offer quick actuation times ideal for simple tasks, electric valve actuators provide more precise control over complex systems. By exploring various types of valves and their corresponding actuator technologies, users can optimize their processes effectively.

Leading Valve Actuator Manufacturers in China

When it comes to valve actuator manufacturers, China is a powerhouse, offering a wide range of electric actuators designed to meet various industrial needs. From part-turn valve electric actuators to advanced smart technologies, the landscape is rich with options that cater to different applications. In this section, we’ll explore some of the leading manufacturers making waves in the valve control market.

Haisen's Part-Turn Valve Electric Actuator

Haisen has carved out a niche for itself with its part-turn valve electric actuators that are both reliable and efficient. These actuators are specifically designed for applications involving quarter-turn valves, making them perfect for industries like water treatment and oil refining. By focusing on quality and performance, Haisen ensures that their products stand out among other valve actuator manufacturers.

Types of Electric Actuators Available

Electric actuators are essential components in modern industrial systems, providing reliable and efficient control over various types of valves. These devices convert electrical energy into mechanical motion, allowing for precise valve operation in a range of applications. Understanding the different types of electric valve actuators is crucial for selecting the right one from the myriad of options offered by valve actuator manufacturers.

Understanding Electric Valve Actuators

Electric valve actuators are designed to operate valves automatically and can be used in both on/off and modulating applications. They come equipped with features that enhance their functionality, ensuring they meet the specific requirements of various industries. With advancements in technology, electric valve actuators have become more efficient, reducing energy consumption while increasing performance reliability.

These actuators typically consist of a motor, gearbox, and control circuitry that work together to move the valve stem or disk precisely. Unlike traditional pneumatic or hydraulic systems, electric actuators eliminate the need for additional fluid power sources, making installation simpler and maintenance easier. The versatility offered by electric valve actuators allows them to be integrated seamlessly into existing automation systems.

Differences Between Solenoid and Valve Actuators

When comparing solenoid and valve actuators, it’s essential to recognize their distinct operational mechanisms and applications. Solenoid actuators utilize electromagnetic coils to create a magnetic field that moves a plunger or armature, providing rapid actuation for simple on/off control tasks. In contrast, electric valve actuators offer more robust features suitable for both open/close operations as well as precise control over flow rates.

One key difference lies in their suitability for various types of valves; while solenoids are often used with smaller valves due to their compact size and quick response time, electric valve actuators can handle larger valves requiring greater torque and longer stroke lengths. Additionally, solenoid systems may not provide feedback on position status unless paired with sensors; however, many modern electric actuator designs include built-in feedback mechanisms to ensure accurate positioning. This makes understanding these differences vital when selecting between solenoid and valve options from reputable valve actuator manufacturers.

Key Features of Actuator Valves

Actuator valves come equipped with several key features that enhance their performance across different industrial applications. One prominent feature is their ability to provide precise control over flow rates; this is particularly important in processes requiring exact measurements or adjustments based on real-time data inputs from automated systems. Furthermore, many modern actuator designs incorporate intelligent controls that allow for remote monitoring and operation via digital interfaces.

Another noteworthy aspect is the integration of safety mechanisms within these devices; many actuator valves include fail-safe options that ensure they revert to a default position during power failures or malfunctions—this adds an extra layer of reliability crucial in critical operations such as petrochemical processing or hydropower generation. Additionally, compatibility with various communication protocols enables actuator valves to easily integrate into larger system architectures without compromising efficiency or functionality.

In summary, when exploring the world of electric actuation technology—especially among leading valve actuator manufacturers—it's clear that understanding these types will lead you toward making informed decisions tailored specifically to your operational needs.

Applications of Valve Actuators

Valve actuators are pivotal components in various industrial applications, ensuring that systems operate smoothly and efficiently. Their ability to control the flow of fluids through valves makes them indispensable in a multitude of settings, from manufacturing plants to energy production facilities. Understanding the specific use cases for valve control valves can help businesses choose the right electric actuator for their needs.

Industrial Use Cases for Valve Control Valves

In industrial environments, valve actuators are essential for managing processes that involve fluid movement and pressure regulation. These actuator valves help maintain safety standards by enabling precise control over liquid or gas flow, which is crucial in sectors like water treatment, pharmaceuticals, and food processing. The diversity of valves and types of valves available means that manufacturers can tailor solutions to meet specific operational demands.

Moreover, industries often rely on both solenoid and valve actuators to provide different functionalities based on their unique requirements. While solenoid actuators offer rapid response times suitable for on-off applications, electric valve actuators provide more nuanced control over flow rates and pressure adjustments. This versatility allows companies to optimize their operations while ensuring compliance with industry regulations.

Valve Actuators in Petrochemical Industries

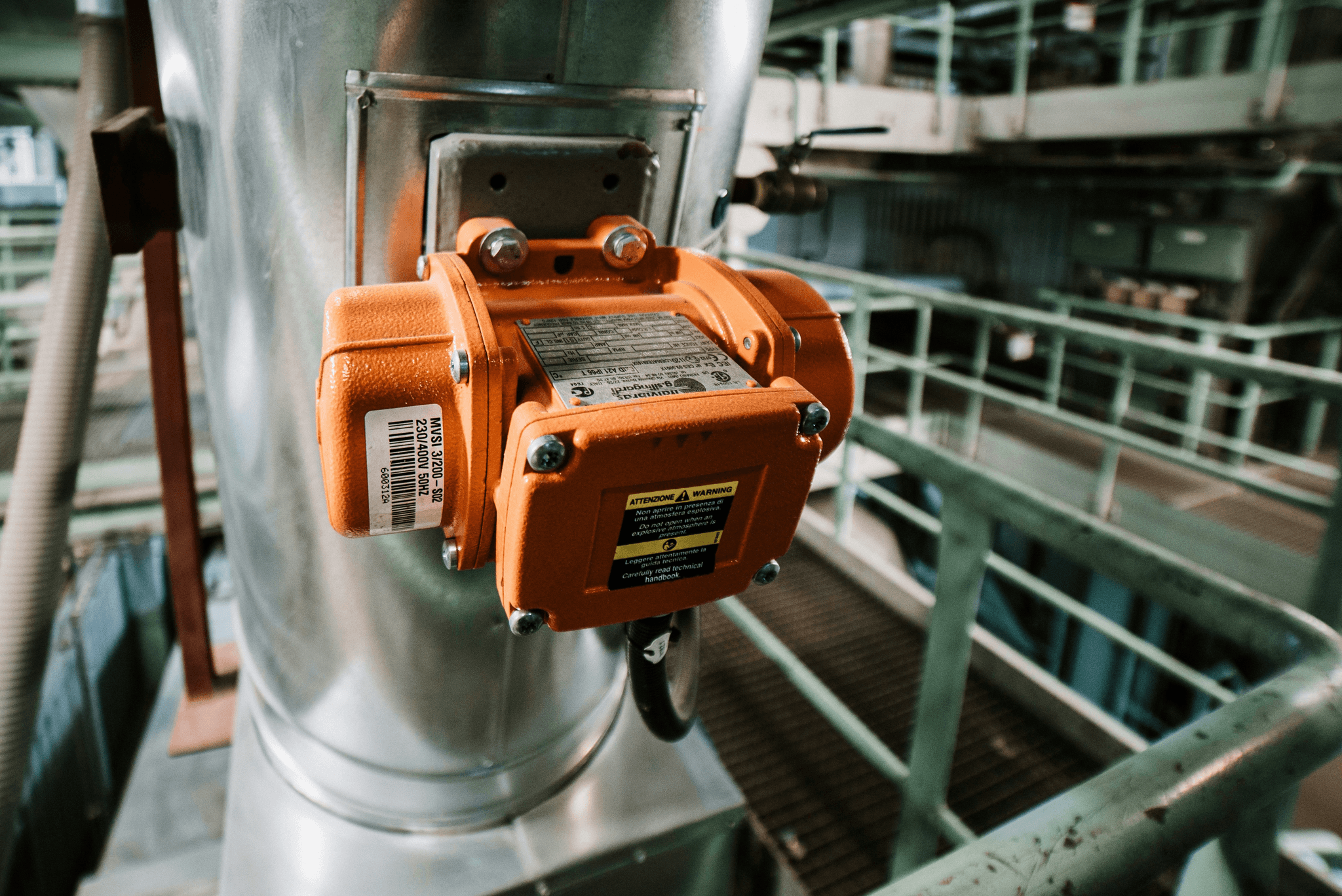

The petrochemical sector is one of the primary beneficiaries of advanced valve actuation technology due to its complex processes involving hazardous materials. Electric valve actuators play a crucial role in controlling the flow of chemicals throughout refining and processing operations, enhancing both safety and efficiency. Valve actuator manufacturers continually innovate to develop products that withstand extreme conditions while maintaining reliability.

In this industry, actuator valves must handle high pressures and corrosive substances without compromising performance or safety standards. This need has led to an increased demand for specialized electric actuators designed specifically for petrochemical applications. Furthermore, integrating smart technologies into these systems allows operators to monitor performance remotely, thus improving maintenance strategies.

Role of Actuator Valves in Hydropower

In hydropower facilities, actuator valves are vital components that regulate water flow through turbines and other machinery essential for energy generation. The precision offered by electric valve actuators ensures optimal performance while safeguarding against potential failures caused by improper fluid management. As renewable energy sources gain traction globally, the role of reliable valve actuation technology becomes even more critical.

These systems not only enhance efficiency but also contribute significantly to sustainability goals by minimizing waste during energy production processes. The integration of advanced monitoring features allows operators to make real-time adjustments based on fluctuating water levels or demand changes—an essential capability in today’s dynamic energy landscape. Consequently, understanding the nuances between solenoid and valve options enables better decision-making when selecting equipment for hydropower applications.

Choosing the Right Valve Actuator

Selecting the right valve actuator can be a pivotal decision for any operation, influencing efficiency and performance. With numerous valve actuator manufacturers in China offering a variety of products, understanding what to look for is essential. From industrial applications to specific operational needs, making an informed choice ensures that you get the best fit for your requirements.

Factors to Consider When Selecting Valve Actuators

When it comes to choosing electric actuators, there are several key factors to consider. First and foremost is the type of valve control valve you are working with; different valves and types of valves require specific actuators that match their operational characteristics. Additionally, consider the environment where the actuator will be installed—temperature extremes, humidity levels, and exposure to corrosive substances can significantly impact performance.

Another critical factor is the required torque and speed specifications of your application. Different electric valve actuators provide varying levels of force and response times; therefore, ensure that your selection aligns with your system's demands. Lastly, don’t overlook compatibility with existing systems or control mechanisms; seamless integration can save time and reduce costs.

Comparing Specifications of Valve and Solenoid

Understanding the differences between solenoid and valve actuators is crucial when making your selection. While both serve important roles in controlling flow through valves, they operate differently—solenoids typically offer quick actuation but may lack precision compared to dedicated electric valve actuators which provide more controlled movements over longer durations. This distinction can affect how effectively each option meets your operational needs.

Moreover, when comparing specifications such as power consumption or response time between solenoid and valve options, you'll find that electric actuators often deliver superior energy efficiency over extended periods of use. This efficiency translates into lower operational costs in many industrial applications where continuous operation is required. Ultimately, choosing between these technologies involves evaluating their respective strengths against your specific requirements.

The Importance of Reliability in Actuator Selection

Reliability should never be underestimated when selecting an actuator valve for critical operations. The last thing you want is an unreliable component causing downtime or failure in processes like petrochemical production or hydropower generation—where consistent performance is non-negotiable. Therefore, opting for reputable valve actuator manufacturers known for quality assurance can make all the difference.

Furthermore, consider maintenance requirements as part of reliability; some electric valve actuators may demand more frequent upkeep than others based on their design or materials used in construction. A reliable actuator minimizes unexpected failures while maximizing productivity across various applications including those involving complex systems like automated controls in manufacturing setups or energy production facilities.

In conclusion, selecting the right valve actuator involves careful consideration of various factors including compatibility with existing systems and reliability under operational conditions while weighing options between solenoid and traditional electric solutions.

Future Trends in Valve Actuation Technology

The landscape of valve actuation technology is evolving rapidly, driven by innovations that enhance performance, reliability, and efficiency. As industries increasingly rely on automation and smart technologies, valve actuator manufacturers are stepping up to meet these demands. This section delves into the latest trends shaping the future of electric actuators and their applications.

Innovations in Valve Control Technology

Innovations in valve control technology are redefining how electric valve actuators function within various systems. For instance, advancements in materials have led to lighter, more durable components that improve the longevity and performance of actuator valves. Additionally, enhanced control algorithms allow for greater precision in managing flow rates through solenoid and valve mechanisms, making them more responsive to operational needs.

Furthermore, many manufacturers are integrating sensors directly into actuator designs to monitor performance metrics like torque and position feedback in real-time. This integration not only boosts efficiency but also facilitates predictive maintenance by alerting operators before potential failures occur. As a result, the landscape of valves and types of valves is becoming increasingly sophisticated, ensuring seamless operation across diverse applications.

The Shift Towards Smart Valve Actuators

The shift towards smart valve actuators represents a significant milestone for valve actuator manufacturers eager to embrace the Internet of Things (IoT). These smart devices can communicate with other systems within industrial environments to provide data analytics that enhance decision-making processes. By employing advanced connectivity options such as wireless communication protocols, these electric actuators can be monitored and controlled remotely.

Moreover, this transition allows for improved energy management as smart actuators optimize their operations based on real-time data inputs from surrounding systems. The convergence of solenoid and valve technologies with smart capabilities means that companies can achieve better resource management while minimizing downtime caused by unexpected failures or maintenance needs. Ultimately, this trend paves the way for increased automation in industries reliant on precise control over fluid dynamics.

Sustainability and Efficiency in Actuator Design

Sustainability is becoming a critical focus among valve actuator manufacturers as they strive to design products with lower environmental impact while maintaining high efficiency levels. Modern electric actuators are being engineered not only for optimal performance but also with energy-saving features that reduce power consumption during operation. These designs often include variable speed drives that adjust motor speeds based on demand rather than running at full capacity continuously.

In addition to energy efficiency improvements, manufacturers are also exploring eco-friendly materials for building actuator valves which contribute to reduced carbon footprints during production processes. Furthermore, sustainable practices extend beyond product design; many companies are adopting circular economy principles by implementing recycling initiatives for old or damaged components used in solenoid and valve setups. This holistic approach ensures that both current operations and future developments align with global sustainability goals while enhancing overall system efficacy.

Conclusion

As we wrap up our exploration of valve actuator manufacturers, it’s clear that the landscape is rich with options tailored to various industrial needs. The importance of selecting the right actuator cannot be overstated, especially when considering the myriad types of valves and their specific applications. Whether you’re in petrochemicals or hydropower, understanding the differences between solenoid and valve actuators can make a significant difference in operational efficiency.

Key Takeaways on Actuator Manufacturers

The leading valve actuator manufacturers in China, such as Haisen and Auma, have established themselves through innovation and quality. Each manufacturer brings unique strengths to the table, offering electric actuators that cater to diverse industrial applications. By focusing on reliability and performance, these manufacturers ensure that their products meet stringent industry standards.

Navigating the World of Valve Types

When it comes to valves and types of valves, knowing your options is crucial for effective system design. Electric valve actuators provide precise control compared to traditional methods, making them a popular choice across various sectors. Understanding how solenoid and valve actuators differ can help you select the most suitable solution for your specific needs.

Ensuring Quality in Valve Control Solutions

Quality assurance in actuator selection is vital for maintaining operational efficiency and safety standards. With so many electric actuator options available, it’s essential to evaluate specifications carefully while prioritizing reliability over cost alone. Investing time into understanding your requirements will lead you toward high-quality solutions from reputable valve actuator manufacturers.