Introduction

In industrial automation, electrical actuators are crucial in controlling valves and ensuring seamless operation of various processes. These versatile devices are essential for regulating the flow of liquids and gases in various applications, from manufacturing plants to power generation facilities.

Understanding the Basics of Electrical Actuators

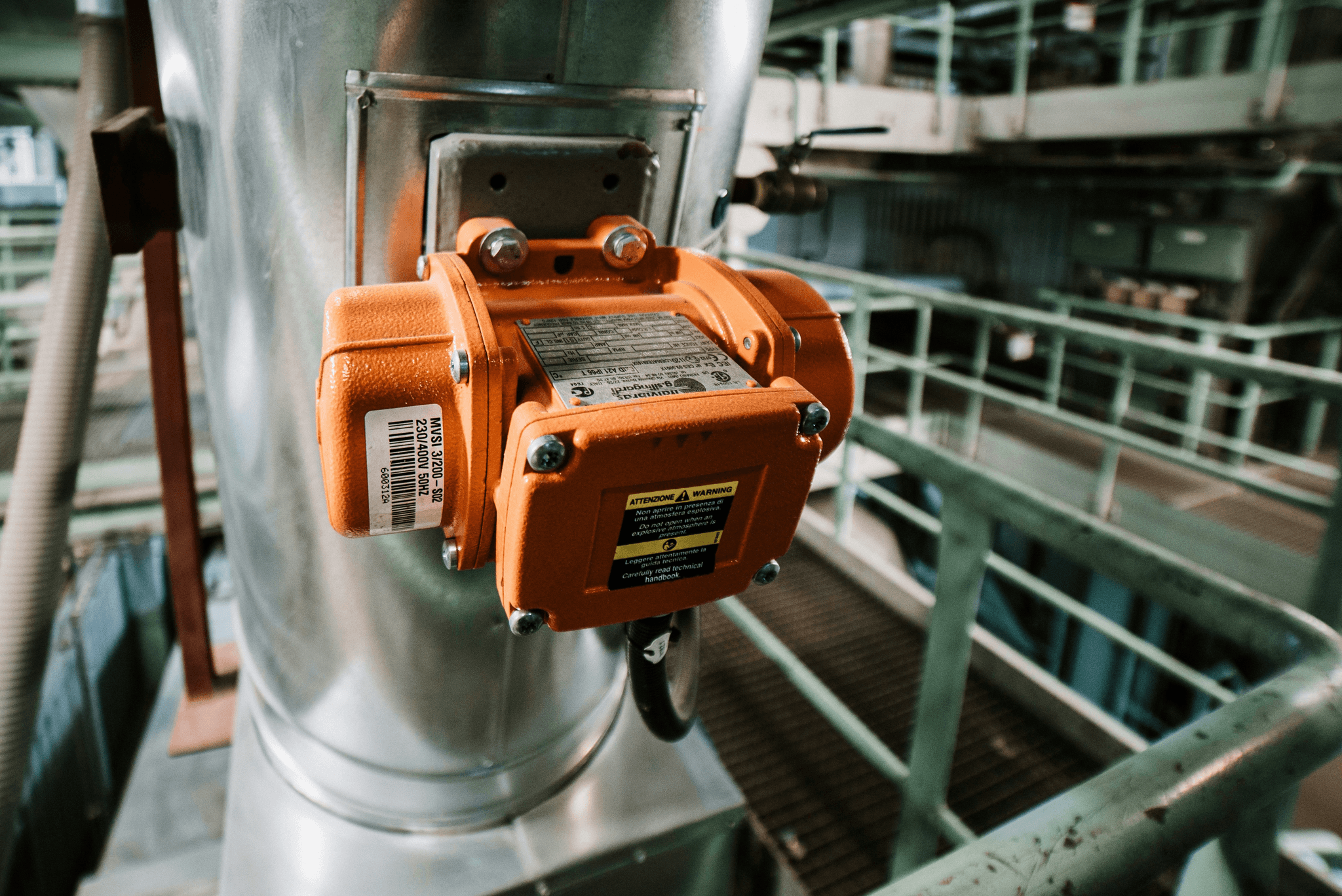

Electrical actuators are designed to convert electrical energy into mechanical motion, allowing precise control over valve operation. These actuators offer smooth and accurate positioning by utilizing an electric motor to drive the valve stem, making them ideal for applications requiring high precision and reliability. In addition to their precision, electrical actuators offer fast response times, allowing quick adjustments to changing process conditions. This makes them well-suited for industries where rapid and precise control is essential, such as oil and gas or chemical processing.

Exploring the Benefits of Actuator Valves

Actuator valves enable precise and efficient fluid flow control in modern industrial processes.

- Improved Process Efficiency: Actuator valves allow quick and accurate fluid flow control, leading to streamlined operations and reduced waste.

- Reduced Downtime: By minimizing manual intervention, actuator valves increase system reliability and decrease maintenance requirements.

- Enhanced Safety: Actuator valves can be integrated with safety systems to prevent hazardous conditions and protect personnel.

Actuator valves offer a valuable solution for industries seeking to optimize fluid flow control, improve efficiency, and enhance safety. By carefully selecting the appropriate actuator type, businesses can tailor their systems to meet specific needs and achieve optimal performance.

The Importance of Proper Actuator Selection

Selecting the right actuator for a specific application is paramount to achieving optimal performance and longevity. Factors such as torque requirements, environmental conditions, and valve compatibility must be carefully considered to ensure that the chosen actuator meets the system's unique needs.

When selecting an actuator, it is also important to consider the application's speed and precision requirements. Some applications require quick response times and precise control, while others prioritize smooth, steady operation. Understanding these requirements will help choose the right actuator to ensure optimal performance.

Types of Actuators

Understanding the differences between electrical and pneumatic actuators is crucial when controlling valves. Electrical actuators are powered by electricity and provide precise control over valve positioning, making them ideal for applications that require accuracy and reliability. On the other hand, pneumatic actuators use compressed air to operate valves, offering quick response times and cost-effective solutions for certain industrial settings.

Electric Actuator vs Pneumatic Actuator

Electric actuators are popular for their ability to deliver consistent and precise control over valve operation, making them suitable for various applications, including process control, water treatment, and power generation. In contrast, pneumatic actuators are known for their quick response times and simplicity in design, making them a cost-effective choice for applications where speed is essential.

Motorized Actuator vs Manual Actuator

Motorized actuators utilize an electric motor to drive valve movement, offering efficient and reliable performance in various industrial settings. They are often preferred for their ability to automate valve operation and integrate with control systems seamlessly. On the other hand, manual actuators require human intervention to operate valves, making them suitable for smaller-scale applications that do not require frequent adjustments.

Introducing Haisen's Part-Turn Valve Electric Actuator

Haisen's Part-Turn Valve Electric Actuator from the QT series is a cutting-edge product designed to provide precise control over butterfly, ball, and plug valves with a 90° rotation. This innovative actuator can be operated locally or remotely, offering flexibility in various industrial fields such as petrochemical, metallurgy, shipbuilding, light industry, food processing, papermaking, construction, municipal engineering, thermal power generation, and hydropower.

Factors to Consider

When selecting an electrical actuator for your control valve, it's crucial to consider several factors to ensure optimal performance. First and foremost, valve compatibility is key. Not all actuators are suitable for all types of valves, so it's important to choose one that is specifically designed for your particular valve type. Additionally, torque and thrust requirements must be carefully evaluated to ensure that the actuator can provide the necessary force to operate the valve effectively. Finally, environmental considerations such as temperature, humidity, and potential exposure to corrosive substances should also be considered to ensure the actuator's longevity.

Valve Compatibility

Ensuring that your electrical actuator is compatible with your specific type of control valve is essential for seamless operation. For instance, Haisen's Part-Turn Valve Electric Actuator is designed to control butterfly, ball, and plug valves with a 90° rotation. This ensures the actuator is perfectly suited for these valves, providing reliable and efficient control.

In addition to valve compatibility, it is crucial to consider the torque and thrust requirements of your specific control valve. Haisen's Part-Turn Valve Electric Actuator is equipped with the necessary torque and thrust capabilities to efficiently operate butterfly, ball, and plug valves with a 90° rotation. This ensures that the actuator can effectively handle the pressure and resistance of these valves, contributing to smooth and reliable operation.

Torque and Thrust Requirements

Different valves require different levels of torque and thrust to operate effectively. Accurately assessing your application's torque and thrust requirements is crucial to selecting an electric actuator that can deliver the necessary force. The QT series part-turn valve electric actuator from Haisen can provide precise torque and thrust control, making it suitable for various industrial applications.

In addition to torque and thrust requirements, it's important to consider the environmental conditions in which the electric actuator will operate. Factors such as temperature, humidity, and exposure to corrosive substances can all impact the actuator's performance and longevity. The QT series part-turn valve electric actuator from Haisen is designed to withstand various environmental conditions, making it a reliable choice for industrial applications in challenging settings. With its durable construction and advanced sealing technology, this electric actuator is built to deliver consistent performance even in harsh environments.

Environmental Considerations

Haisen's Part-Turn Valve Electric Actuator is a reliable and durable solution for demanding industrial applications. Its robust design and advanced features suit various environments and operating conditions.

- Superior Temperature Resistance: Withstands extreme temperature variations, ensuring optimal performance in harsh conditions.

- Moisture and Chemical Protection: Resists corrosion and degradation, even in the presence of moisture and chemicals.

- Mechanical Strength: Built to withstand mechanical stresses and vibrations, ensuring long-term reliability.

- Customizable Options: Available with various torque outputs, speeds, and control interfaces to meet specific application requirements.

Choose Haisen's Part-Turn Valve Electric Actuator for a reliable and durable solution that can withstand the challenges of your industrial environment. Its advanced features and customizable options make it the ideal choice for demanding applications.

Selecting the Right Actuator

When evaluating control options for your valves and actuators, it's crucial to consider your application's specific requirements. Whether you're looking for precise control over flow rates or quick response times, the right electrical actuator can make all the difference. With Haisen's Part-Turn Valve Electric Actuator, you can operate your valves locally or remotely, giving you full control over your system.

Evaluating Control Options

When selecting the right actuator for your control valve, considering the different control options available is essential. An electric actuator provides precise and accurate control over valve positioning, allowing seamless integration into automated systems. Haisen's Part-Turn Valve Electric Actuator allows you to easily adjust and monitor valve positions to ensure optimal performance in any industrial setting.

Ensuring Reliable Performance

Reliability is key when choosing an actuator motor for your valves and actuators. It would help if you had a solution that consistently delivers smooth and efficient operation without compromising performance. Haisen's Part-Turn Valve Electric Actuator is designed to meet these demands, offering reliable performance in controlling butterfly, ball, and plug valves with a 90° rotation.

Optimizing Efficiency

Optimizing efficiency is another critical aspect of selecting the right actuator for your application. A motorized actuator can offer improved energy efficiency compared to manual actuators, reducing operational costs and environmental impact. With Haisen's Part-Turn Valve Electric Actuator, you can optimize efficiency by utilizing its remote control capabilities to minimize downtime and maximize productivity.

By carefully evaluating control options, ensuring reliable performance, and optimizing efficiency with Haisen's Part-Turn Valve Electric Actuator, you can confidently select the right actuator for your specific needs and maximize the performance of your valves and actuators in any industrial application.

Installation and Maintenance

Proper Installation Techniques

When installing electrical actuators for control valves, it's crucial to ensure that the actuator is securely mounted to the valve and that all electrical connections are properly wired. For example, Haisen's Part-Turn Valve Electric Actuator requires precise alignment with the valve stem to ensure optimal performance. It's also essential to follow the manufacturer's wiring and power supply guidelines to prevent any potential issues.

Additionally, it's important to regularly inspect the actuator and valve for any signs of wear and tear, corrosion, or damage. This can help prevent potential malfunctions and extend the lifespan of the equipment. Routine lubrication of moving parts is also essential to ensure smooth operation and prevent friction-related issues. Following a proactive maintenance schedule can minimize downtime and avoid costly repairs in the long run.

Routine Maintenance Practices

Regular maintenance is crucial to ensure your actuator valves' optimal performance and longevity.

- Regular inspections and lubrication: Check for wear, damage, and ensure proper lubrication of moving parts.

- Haisen's Part-Turn Valve Electric Actuator: Conduct routine gearbox and motor component inspections.

- Cleaning and maintenance: Remove debris from the actuator housing to prevent premature wear.

- Environmental considerations: Protect actuators from extreme temperatures, humidity, and corrosive substances.

- Maintenance schedules and records: Implement a regular maintenance plan and keep detailed records of inspections and repairs.

By following these maintenance guidelines, you can significantly extend the lifespan of your actuator valves and minimize downtime in your operations.

Extending the Lifespan of Actuators

To extend the lifespan of electrical actuators, it's important to address any issues promptly and conduct preventive maintenance regularly. This includes monitoring the performance of the actuator valves and addressing any unusual noises or vibrations. With Haisen's Part-Turn Valve Electric Actuator, implementing a proactive maintenance schedule can help prevent unexpected downtime and ensure long-term reliability.

Regular maintenance of electrical actuators is essential to ensure optimal performance and prevent costly breakdowns. By conducting routine checks on the actuator valves and addressing any issues promptly, you can avoid potential malfunctions that could disrupt operations. With Haisen's Part-Turn Valve Electric Actuator, implementing a proactive maintenance schedule can help you avoid any potential problems and keep your equipment running smoothly for years.

Make the Right Choice for Your Application

When selecting the right actuator for your application, consider factors such as valve compatibility, torque and thrust requirements, and environmental considerations. By evaluating control options and ensuring reliable performance, you can maximize your system's efficiency. With Haisen's Part-Turn Valve Electric Actuator, you can benefit from a versatile product suitable for various industrial fields.

By understanding the basics of electrical actuators and exploring the benefits of actuator valves, you can make an informed decision that suits your needs. Whether a motorized or a manual actuator, selecting the right one is crucial for optimal performance.

Maximizing Performance with Actuator Selection

Choosing the appropriate electric or pneumatic actuator based on your application requirements is key to maximizing performance. Haisen's Part-Turn Valve Electric Actuator's versatility makes it a valuable asset in industries such as petrochemicals, metallurgy, shipbuilding, and more. With its robust construction and reliable performance, this electric actuator is designed to withstand harsh environmental conditions, ensuring long-term success in various industrial settings. Additionally, its precise control and quick response time improve operational efficiency and reduce downtime, further enhancing overall performance.

Ensuring Long-Term Success with the Right Actuator

Proper installation techniques and routine maintenance practices are essential for extending the lifespan of actuators. By ensuring long-term success with the right actuator, you can optimize efficiency and reliability in your industrial processes. Investing in high-quality materials and advanced technology can further enhance your actuators' performance and durability. This proactive approach minimizes downtime and reduces overall operating costs, providing a competitive advantage in the market.