Introduction

Electric valve actuators are devices used to control the opening and closing of valves in various industrial applications. They are powered by electricity and designed to automate valve operation. They play a crucial role in regulating the flow of liquids and gases in pipelines, making them essential components in many industries.

What are Electric Valve Actuators?

Electric valve actuators are motorized devices attached to valves to control their movement. They use an electric motor to open or close the valve, eliminating the need for manual operation. This automation improves efficiency and enhances safety by allowing remote control of valve operation.

Electric valve actuators are also known for their precision and reliability. By using electric motors, these actuators can provide precise control over the valve's movement, allowing for accurate adjustments and positioning. This level of precision is crucial in industries where even a small deviation can lead to significant consequences. Electric valve actuators are also known for their durability and long lifespan, making them a cost-effective solution in the long run.

Benefits of Electric Valve Actuators

Electric valve actuators are becoming increasingly popular in industrial automation due to their numerous benefits over traditional pneumatic or hydraulic actuators.

- Improved precision and accuracy: Electric valve actuators offer precise and accurate control of valve movement, ensuring optimal process performance.

- Reduced manual labor: These actuators eliminate manual intervention, leading to cost savings and increased productivity.

- Enhanced monitoring and feedback: Electric valve actuators provide real-time monitoring and feedback, enabling operators to make informed decisions and optimize process efficiency.

- Greater flexibility and integration: These actuators are easy to install and integrate with existing systems, allowing seamless upgrades and modifications.

- Advanced diagnostic features: Many electric valve actuators have built-in diagnostic capabilities, enabling proactive maintenance and minimizing downtime.

Electric valve actuators offer a compelling solution for industries seeking to improve process control, reduce costs, and enhance overall operational efficiency. Their precision, reliability, and versatility make them an ideal choice for various applications.

Key Considerations when Choosing Electric Valve Actuators

When selecting electric valve actuators, it is important to consider factors such as torque requirements, speed of operation, environmental conditions, and compatibility with different valves. Understanding these key considerations is essential for ensuring that the chosen actuator meets the application's specific needs. Another important factor is the power supply available at the installation site. It's crucial to ensure the actuator can be powered properly to operate efficiently and reliably. Additionally, it's important to consider the control options available for the electric valve actuator, such as on/off control, modulating control, or proportional control, to ensure compatibility with the existing control system.

Understanding Electric Valve Actuators

Electric valve actuators are devices used to control the opening and closing of valves in various industrial applications. These actuators are powered by electricity and can be operated remotely or locally, making them convenient and efficient for controlling valve operations.

How Electric Valve Actuators Work

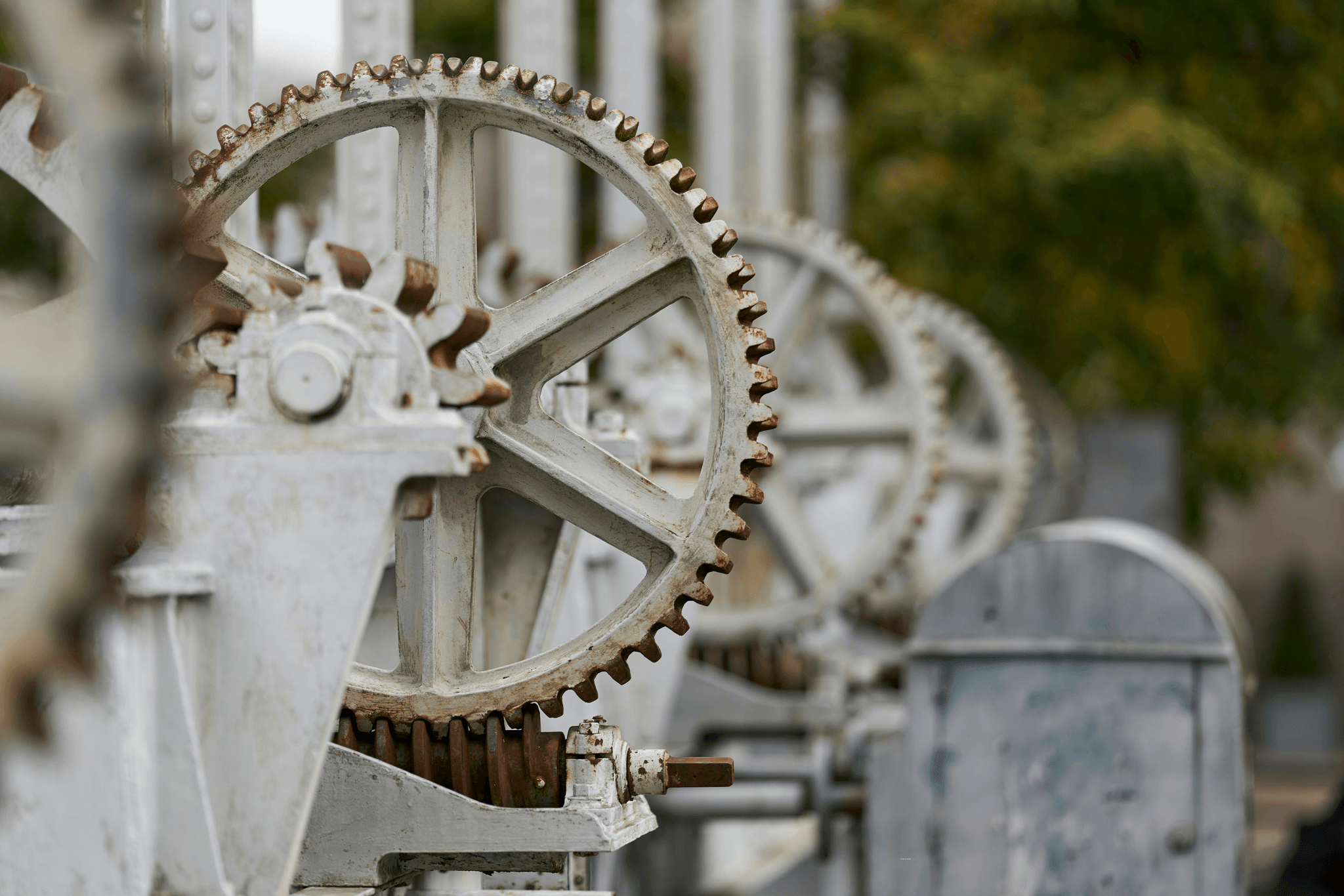

Electric valve actuators convert electrical energy into mechanical motion to open or close valves. When an electrical signal is received, the actuator's motor drives a series of gears or a screw mechanism to rotate the valve stem, thus controlling the flow of media through the valve.

Electric valve actuators come in various types, including electric motor, pneumatic, and hydraulic-electric actuators. Electric motor actuators are the most common type and use an electric motor to drive the valve's motion. Pneumatic-electric actuators combine the power of compressed air with an electric motor to operate the valve, while hydraulic-electric actuators use hydraulic power in addition to electrical energy. Each type has advantages and is suitable for different applications, providing flexibility in choosing the right actuator for specific needs.

Types of Electric Valve Actuators

Several types of electric valve actuators exist, including quarter-turn and multi-turn actuators. Quarter-turn actuators, such as ball and butterfly valves, are suitable for valves requiring a 90° rotation. In contrast, multi-turn actuators are designed for valves requiring multiple open or close rotations.

Quarter-turn electric valve actuators are commonly used in industrial applications where quick and efficient valve operation is required. These actuators are often preferred for their simplicity and reliability, making them a popular choice for controlling the flow of fluids in various processes. Additionally, quarter-turn actuators can be easily automated and integrated into existing control systems, providing a cost-effective solution for valve actuation.

Applications of Electric Valve Actuators

Electric valve actuators are widely used in petrochemicals, metallurgy, shipbuilding, food processing, and power generation industries. They are commonly employed in processes where precise control over fluid flow is essential, making them crucial components in various industrial systems.

Electric valve actuators are also utilized in wastewater treatment plants, which play a crucial role in regulating water flow and other fluids. These actuators help ensure that the treatment process runs smoothly and efficiently, ultimately contributing to the plant's overall effectiveness. Electric valve actuators are often integrated into HVAC systems to control airflow and maintain optimal temperature and humidity levels in commercial and industrial buildings.

Choosing the Right Electric Valve Actuator

Factors to Consider when Selecting Electric Valve Actuators

When selecting electric valve actuators, it's crucial to consider factors such as the type of valve being controlled, the torque and speed requirements, environmental conditions, and control options. The type of valve being controlled will determine the torque and speed requirements, while environmental conditions such as temperature and humidity will impact the choice of actuator materials. Additionally, considering control options like local or remote operation is essential for seamless integration with existing systems.

In addition to the factors mentioned above, it is important to consider the power supply available for the electric valve actuators. Some actuators may require a specific voltage or power source, so understanding the electrical requirements is crucial for proper installation and operation. Furthermore, evaluating the maintenance and support options provided by different brands is essential. Look for brands that offer easy access to spare parts and technical support to ensure smooth operation and minimal downtime in case of any issues.

Comparison of Leading Electric Valve

Actuator Brands

When comparing leading electric valve actuator brands, it is important to assess reliability, durability, ease of installation, and customer support. Some well-known brands include Rotork, Auma, and Emerson Electric Co., each offering different features and benefits. By evaluating these factors, you can make an informed decision based on your specific application requirements.

When comparing leading electric valve actuator brands, it's important to assess reliability, durability, ease of installation, and customer support. Some well-known brands include Rotork, Auma, and Emerson Electric Co., each offering different features and benefits. By evaluating these factors, you can make an informed decision based on your specific application requirements. In addition to these factors, it's also essential to consider the compatibility of the electric valve actuators with existing systems and control interfaces. Seamless integration can save time and resources during installation and maintenance.

Haisen's Part-Turn Valve Electric Actuator Review

Haisen's QT series part-turn valve electric actuator is a cutting-edge product designed to control butterfly, ball, and plug valves with a 90° rotation. It can be operated locally or remotely, making it suitable for various industrial fields, including petrochemicals, metallurgy, shipbuilding, food processing, and more. Its versatility and advanced features make it a competitive option in the market.

Haisen's QT series part-turn valve electric actuator stands out for its robust construction and reliable performance. With a durable design and high torque output, this actuator ensures smooth and precise valve operation, even in harsh industrial environments. Its ability to withstand extreme temperatures and corrosive substances makes it a top choice for industries where reliability is paramount.

Installing and Maintaining Electric Valve Actuators

Proper Installation of Electric Valve Actuators

When installing electric valve actuators, it's crucial to ensure that the actuator is securely mounted to the valve and that all electrical connections are properly made. Additionally, it's important to follow the manufacturer's guidelines for wiring and calibration to guarantee optimal performance.

Maintenance Tips for Electric Valve Actuators

Regular maintenance is crucial for ensuring electric valve actuators' optimal performance and longevity.

- Inspect for wear and tear: Regularly examine the actuator for signs of damage, such as cracks, corrosion, or loose parts.

- Lubricate moving parts: Apply manufacturer-recommended lubricant to moving components to reduce friction and prevent premature wear.

- Check electrical connections: Inspect wiring and connectors for signs of corrosion, loose connections, or damage.

- Verify power source: Ensure the battery or power supply functions properly and replace it if necessary.

- Clean the actuator: Remove dirt and debris from its exterior to prevent interference with its operation.

By diligently performing these maintenance tasks, you can significantly extend the lifespan of your electric valve actuators and minimize the risk of costly repairs or malfunctions.

Troubleshooting Common Issues with Electric Valve Actuators

Common issues with electric valve actuators may include motor malfunctions, faulty wiring, or issues with the control system. Troubleshooting these problems often requires a systematic approach, including checking power sources, inspecting wiring connections, and consulting the user manual for guidance on specific error codes.

After identifying the potential issues with electric valve actuators, it is important to prioritize troubleshooting steps based on the most likely causes. A thorough motor inspection for any signs of wear and tear can help pinpoint malfunctions affecting its performance. Additionally, checking for loose or damaged wiring connections can address issues related to faulty wiring, ensuring that the electrical components are functioning as intended. By systematically addressing each potential problem area, users can effectively troubleshoot common issues and restore the optimal functionality of their electric valve actuators.

Future Trends in Electric Valve Actuators

Innovations in Electric Valve

Actuator Technology

As technology continues to advance, electric valve actuators are also seeing innovations. One key trend is the integration of smart technology into electric valve actuators, allowing for remote monitoring and control. This enables real-time data collection and analysis, improving efficiency and predictive maintenance. Additionally, advancements in materials and design are enhancing the durability and performance of electric valve actuators, making them more reliable in various industrial applications.

Potential Advancements in Electric Valve Actuators

In the future, we can expect to see advancements in the energy efficiency of electric valve actuators. With a growing focus on sustainability, manufacturers invest in developing actuators that consume less power while maintaining high performance. Furthermore, there is potential for increased customization options to meet specific industry requirements and improved safety features to ensure reliable operation even in challenging environments.

In addition to energy efficiency and sustainability, advancements in electric valve actuators may include improved connectivity and remote monitoring capabilities. As industries continue to embrace digitalization, there is a growing demand for actuators that can be integrated into smart systems for real-time monitoring and control. This could increase productivity and cost savings by enabling predictive maintenance and reducing downtime. Furthermore, remotely adjusting valve settings can enhance operational flexibility and responsiveness to changing conditions.

Impact of Electric Valve Actuators on Industry

The evolution of electric valve actuators is poised to significantly impact various industries. With enhanced automation and control capabilities, these advanced actuators can streamline processes, reduce downtime, and optimize resource utilization. This will improve productivity and cost savings across oil and gas, water treatment, manufacturing, and other sectors.

The increased efficiency and reliability of electric valve actuators will also positively impact environmental sustainability. By reducing the need for manual intervention and minimizing leaks or spills, these advanced actuators can contribute to a cleaner and safer working environment. This will align with modern industries' growing emphasis on corporate social responsibility and eco-friendly practices.

Make the Right Choice for Electric Valve Actuators

When selecting electric valve actuators, factors such as torque requirements, valve type, and environmental conditions must be considered. Whether it's a motorized ball valve or a part-turn electric actuator, choosing the right one can significantly impact system performance and longevity.

Importance of Regular Maintenance for Electric Valve Actuators

Regular maintenance is crucial for ensuring the reliable and efficient operation of electric valve actuators in industrial settings.

- Visual Inspection: Regularly inspect actuators for signs of wear, corrosion, or damage to the housing, cables, and other components.

- Lubrication: Apply appropriate lubricant to moving parts, such as gears and shafts, to reduce friction and prevent premature wear.

- Functional Testing: Periodically test the actuator's control system to verify proper operation and responsiveness.

- Calibration: If necessary, recalibrate the actuator to ensure accurate positioning and control of the valve.

- Cleaning: Remove dirt, dust, and other contaminants from the actuator to prevent interference with its operation.

By diligently following a regular maintenance schedule, you can significantly extend the lifespan of your electric valve actuators and minimize the risk of unexpected failures. This proactive approach will improve your industrial operations' safety, efficiency, and overall productivity.

Embracing the Future of Electric Valve Actuators

As technology continues to advance, so do electric valve actuators. Innovations in materials, control systems, and connectivity are shaping the future of these devices. With potential advancements in efficiency and reliability on the horizon, embracing these developments will be key to staying ahead in various industries.

With the increasing focus on sustainability and environmental impact, electric valve actuators are also expected to evolve in terms of energy efficiency and eco-friendly materials. As industries strive to reduce their carbon footprint and comply with stringent regulations, developing electric valve actuators that consume less power and operate with minimal environmental impact will be crucial. This shift towards greener technologies will benefit the planet and enhance the reputation of businesses embracing these advancements.