Introduction

In the world of aviation, one of the unsung heroes is the truck refueling plane, a vital component in ensuring that aircraft are ready for takeoff without delay. These specialized vehicles play a crucial role in streamlining the refueling process, making it efficient and effective for various types of aircraft. Understanding how these trucks operate and their importance can provide valuable insights into the overall efficiency of air travel.

Understanding Truck Refueling Planes

Truck refueling planes, often referred to as aviation refuelers, are equipped with advanced systems designed to deliver fuel quickly and safely to commercial and military aircraft. They consist of several key components such as a chassis, piping system, pneumatic control system, hydraulic system, and electrical system. For instance, Haisen's Aircraft Pipeline Refueling Truck is known for its high flow rate capabilities while ensuring that impurities are filtered out during the fueling process.

The Importance of Efficient Refueling Techniques

Efficient refueling techniques are essential for maintaining flight schedules and minimizing downtime at airports. A well-executed refuel can significantly reduce turnaround times for commercial planes, allowing airlines to maximize their operational efficiency. Additionally, understanding how do commercial planes refuel helps highlight the importance of utilizing both ground-based civilian fuel trucks and aerial methods to meet varying needs.

Overview of Aircraft Refueling Methods

There are multiple methods used in aircraft refueling which include gravity feed systems and pump-based techniques; each has its own advantages depending on the situation at hand. Ground operations often involve civilian fuel trucks that supply fuel directly to an aircraft's tank through specialized hoses or nozzles designed for safe transfer. Meanwhile, innovations in tow trucks—what is a plane tow truck called?—and other support vehicles continue to evolve alongside advancements in aviation technology to enhance overall operational effectiveness.

What is a Truck Refueling Plane?

A truck refueling plane is an essential piece of equipment in the aviation industry, designed specifically for efficiently refueling aircraft on the ground. Unlike traditional fuel trucks, these specialized vehicles are equipped to deliver fuel directly to various types of aircraft, enhancing the speed and effectiveness of the refueling process. Understanding how these trucks operate provides insight into their critical role in ensuring that commercial planes remain operational and ready for flight.

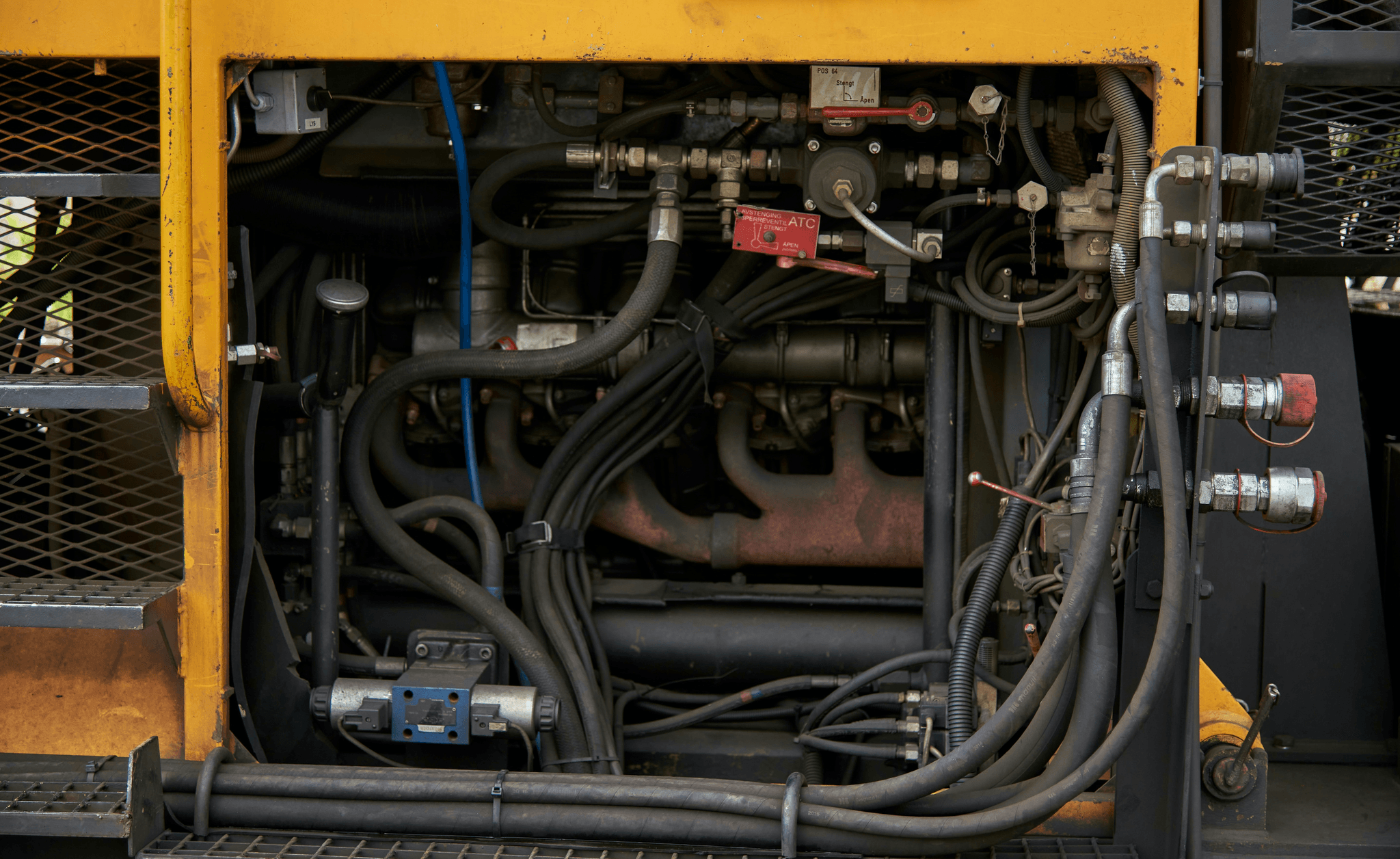

Components of a Truck Refueling Plane

The components of a truck refueling plane include several key systems that work together to ensure efficient fuel delivery. Haisen's Aircraft Pipeline Refueling Truck, for instance, features a robust chassis, an advanced piping system, and pneumatic as well as hydraulic control systems to manage fuel flow effectively. Additionally, it incorporates an electrical system that allows for precise monitoring and filtration during refueling operations—ensuring that impurities are removed from the fuel before it reaches the aircraft.

How Truck Refueling Planes Enhance Operations

Truck refueling planes significantly enhance operations at airports by streamlining the fueling process and reducing turnaround times for commercial planes. By utilizing high flow rates—often measured in gallons per minute—these trucks can fill up large aircraft quickly, minimizing delays between flights. Furthermore, their ability to perform underwing refueling services makes them versatile enough to accommodate various sizes of aircraft while maintaining safety and efficiency standards.

Examples of Truck Refueling Planes in Use

Several examples illustrate how truck refueling planes are utilized across different airports worldwide. For instance, many major international airports employ Haisen’s Aircraft Pipeline Refueling Trucks due to their ability to deliver high flow rates while maintaining strict quality control measures during fueling operations. Other notable examples include civilian fuel trucks that support smaller regional airlines or charter services—demonstrating how this technology can adapt across various sectors within aviation.

Techniques Used in Truck Refueling

Gravity vs. Pump Refueling Methods

In the world of aircraft refueling, two primary methods dominate: gravity and pump refueling. Gravity refueling relies on natural force to transfer fuel from a higher point to an aircraft's tank, making it a straightforward yet slower process. On the other hand, pump refueling utilizes powerful pumps to deliver fuel at a controlled flow rate—this method is particularly advantageous for larger commercial planes due to its speed and efficiency.

When asking How do commercial planes refuel? one must consider that most modern operations favor pump systems for their ability to handle high volumes quickly. This means that while gravity-fed systems may still be utilized in certain scenarios, they often fall short in meeting the demands of busy airports where time is money. Ultimately, choosing between these two methods can significantly impact how effectively a truck refueling plane operates during peak hours.

The Role of Aviation Refuelers in Efficiency

Aviation refuelers play an indispensable role in ensuring that aircraft are fueled efficiently and safely. These professionals are trained not only in operating complex machinery but also in adhering to stringent safety protocols while handling flammable materials like aviation fuel. The question “Is aircraft fueler a hard job?” often arises; indeed, it requires precision under pressure as they ensure timely service without compromising safety standards.

Moreover, aviation refuelers directly influence turnaround times at airports by coordinating with ground crews and pilots during fueling operations. Their expertise helps streamline processes that can otherwise become bottlenecks if not managed properly—this is where their experience truly shines as they work alongside civilian fuel trucks or other support vehicles on-site. By optimizing workflows and maintaining communication with flight crews, aviation refuelers enhance operational efficiency across all types of truck refueling planes.

Key Technologies in Aircraft Refueling Trucks

Modern aircraft refueling trucks are equipped with advanced technologies designed for maximum efficiency and safety during fueling operations. For example, Haisen's Aircraft Pipeline Refueling Truck features sophisticated components such as pneumatic control systems and hydraulic mechanisms that facilitate rapid fueling at high flow rates—essential for minimizing downtime between flights. These innovations allow for effective service across various types of aircraft while ensuring that impurities like dust and moisture are filtered out before reaching an airplane’s tanks.

Another critical aspect is monitoring flow rates—understanding What is the flow rate of an aircraft fuel truck? helps operators gauge performance levels during each operation cycle effectively. High flow rate systems reduce waiting times considerably compared to traditional methods; thus they play a pivotal role in maintaining airport schedules tight-knit while keeping costs manageable for airlines relying heavily on timely departures and arrivals alike. With continuous advancements being made, it's clear that technology will continue shaping how we approach fueling operations with truck refueling planes.

How Do Commercial Planes Refuel?

Overview of the Refueling Process

The typical refueling process starts with the arrival of an aircraft at the gate or designated fueling area. Ground crew members connect hoses from either a truck refueling plane or a civilian fuel truck to the aircraft's fuel tanks, ensuring that everything is secure and leak-proof before starting the flow of fuel. This procedure often includes checks on fuel quality and quantity, ensuring that what goes into the aircraft meets strict aviation standards.

During this process, aviation refuelers play a critical role in monitoring flow rates and managing any potential hazards. For example, Haisen's Aircraft Pipeline Refueling Truck is designed with advanced filtration systems to remove impurities while accurately measuring flow rates during filling. This attention to detail helps maintain safety standards while optimizing efficiency.

Comparing Ground and Aerial Refueling Methods

While ground refueling using truck refueling planes is standard for commercial flights, aerial refueling also exists but serves different purposes—typically military operations or long-haul flights where ground access is limited. Ground-based methods allow for quicker turnaround times as they can be performed at airports equipped with civilian fuel trucks ready to go when needed. In contrast, aerial refueling requires specialized tanker aircraft and trained personnel, making it less common in commercial aviation.

One key difference lies in efficiency; ground operations can generally handle higher flow rates compared to aerial methods due to advanced technologies employed in aircraft fueling trucks like those from Haisen. These trucks can deliver significant amounts of fuel quickly while maintaining safety protocols—a necessity when dealing with large passenger jets that require substantial amounts of jet fuel before takeoff.

The Role of Civilian Fuel Trucks in Refueling

Civilian fuel trucks serve an indispensable role in commercial aviation by providing flexible and efficient fueling solutions at airports worldwide. Equipped with state-of-the-art technology, these trucks can adapt to various types of aircraft while ensuring rapid service through high flow rate systems—essential for busy airports where time is money!

In addition to their primary function as mobile fueling stations, civilian fuel trucks often act as backup support for larger truck refueling planes during peak times or emergencies when rapid service is needed most urgently. Their versatility allows them to operate smoothly alongside other fueling methods while making sure every plane gets what it needs without delay.

What is a Plane Tow Truck Called?

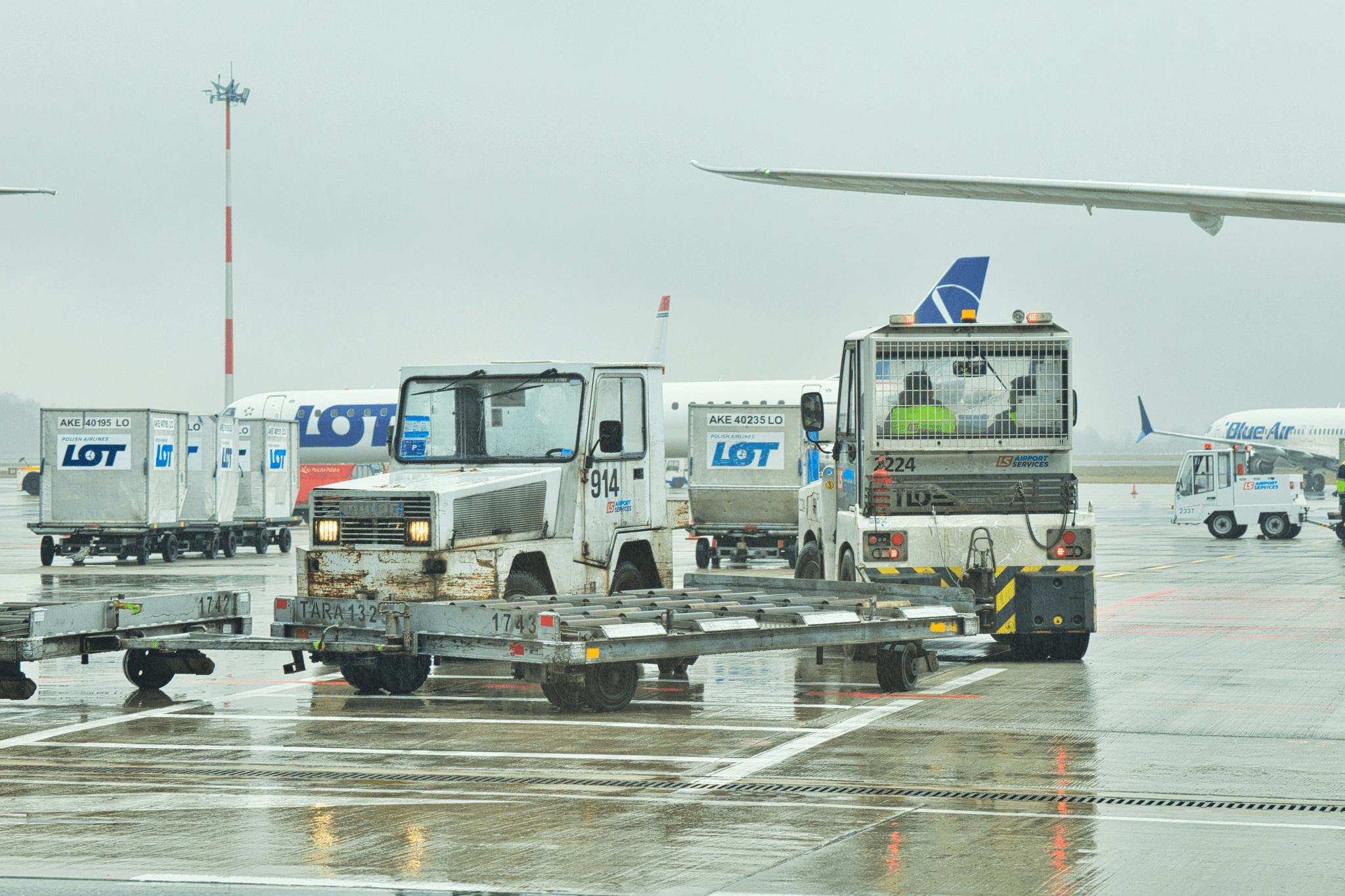

When discussing aircraft operations, the terminology can sometimes be as complex as the machinery itself. A plane tow truck, more formally known as an aircraft tow vehicle or tug, plays a crucial role in managing aircraft movement on the ground. These vehicles are specifically designed to maneuver planes safely and efficiently, ensuring that they are positioned correctly for takeoff or maintenance.

Defining Aircraft Tow Vehicles

Aircraft tow vehicles are specialized machines engineered to transport airplanes from one location to another on the airport tarmac. Unlike traditional trucks, these vehicles feature unique designs that allow them to connect seamlessly with various types of aircraft. The power and precision of these tow trucks make them indispensable in both commercial and military aviation sectors.

Functions and Importance of Tow Trucks

The functions of plane tow trucks extend beyond simple transportation; they also play a vital role in maintaining airport efficiency. By facilitating quick repositioning of aircraft between gates, runways, and maintenance areas, these vehicles help minimize downtime during busy flight schedules. Their importance cannot be overstated; without reliable aircraft tow vehicles, the logistics of air travel would quickly become chaotic.

Notable Tow Truck Innovations in Aviation

Innovation in aviation has led to remarkable advancements in aircraft tow vehicles over the years. For instance, modern electric tugs have emerged as eco-friendly alternatives that reduce emissions while still providing robust towing capabilities. Additionally, some advanced models come equipped with automated systems that enhance operational efficiency—an essential factor when considering how do commercial planes refuel effectively while managing ground traffic.

Flow Rates and Efficiency

When it comes to aircraft refueling, flow rates play a crucial role in determining how quickly and efficiently a truck refueling plane can deliver fuel. The flow rate of aircraft fuel trucks refers to the volume of fuel that can be transferred within a specific time frame, typically measured in gallons per minute (GPM). A higher flow rate not only speeds up the refueling process but also minimizes downtime for commercial planes, allowing them to get back in the air faster.

What is the Flow Rate of Aircraft Fuel Trucks?

The flow rate of aircraft fuel trucks can vary significantly depending on their design and intended use. Generally, modern aircraft refueling trucks are capable of achieving flow rates ranging from 300 to over 1,000 gallons per minute. For instance, Haisen's Aircraft Pipeline Refueling Truck stands out with its efficient design that enables high flow rates while ensuring cleanliness through advanced filtration systems during fueling operations.

Factors Affecting Refueling Speed and Efficiency

Several factors influence the speed and efficiency of refueling processes for both civilian fuel trucks and dedicated aviation refuelers. These include the type of fuel being used, environmental conditions like temperature and wind, as well as the specific equipment employed during the operation. Additionally, proper training for personnel—such as those working as aviation refuelers—is essential; if they are not well-versed in handling equipment or understanding protocols, it could lead to delays or inefficiencies.

Benefits of High Flow Rate Systems in Refueling

High flow rate systems offer numerous benefits when it comes to aircraft refueling operations. First and foremost, they significantly reduce turnaround times for commercial planes by allowing quicker fueling processes—this is especially critical during peak travel seasons when every minute counts. Furthermore, efficient systems minimize fuel wastage by ensuring precise measurements throughout the transfer process; thus enhancing overall operational effectiveness for truck refueling planes.

The Job of Aviation Refuelers

Aviation refuelers play a critical role in ensuring that aircraft are ready for takeoff, but is being an aircraft fueler a hard job? The answer is a bit nuanced. While the tasks can be physically demanding and require meticulous attention to detail, many refuelers find the work fulfilling and integral to aviation operations.

Is Aircraft Fueler a Hard Job?

Being an aircraft fueler can indeed be challenging due to the high-stakes environment of airports. Refueling requires precision and adherence to safety protocols, as any mistake could have serious repercussions for both personnel and aircraft. Additionally, working in various weather conditions or during irregular hours adds another layer of difficulty; however, many aviation refuelers thrive on the excitement of being part of fast-paced airport operations.

Skills and Training Required for Refuelers

To excel as an aviation refueler, individuals must possess specific skills and undergo rigorous training. Knowledge about how commercial planes refuel is crucial; understanding the mechanics behind truck refueling planes helps ensure that they perform their duties effectively and safely. Moreover, training programs often cover safety practices, equipment operation—including aircraft refueling trucks—and emergency procedures to prepare them for real-world scenarios.

Challenges Faced by Aviation Refuelers

Aviation refuelers encounter several challenges on the job that test their skills and adaptability. For instance, they must manage time efficiently while maintaining high flow rates of fuel from civilian fuel trucks or specialized aircraft fueling systems like Haisen's Aircraft Pipeline Refueling Truck. Moreover, they often deal with tight schedules where delays can have cascading effects on flight operations, making it essential for them to stay focused amidst pressure.

Conclusion

In the fast-paced world of aviation, maximizing efficiency in aircraft refueling is crucial for maintaining schedules and minimizing downtime. The integration of advanced technologies and techniques in truck refueling planes enhances operational effectiveness, ensuring that commercial planes can be ready for takeoff as quickly as possible. By understanding the nuances of how commercial planes refuel, stakeholders can make informed decisions that improve overall efficiency.

Maximizing Efficiency in Aircraft Refueling

To maximize efficiency in aircraft refueling, it’s essential to focus on both speed and accuracy. Utilizing high-flow rate systems found in modern truck refueling planes allows for quicker turnaround times, which is vital during busy flight schedules. Additionally, training aviation refuelers to handle equipment like civilian fuel trucks proficiently ensures that each refueling operation runs smoothly and without unnecessary delays.

Key Takeaways on Truck Refueling Techniques

Several key takeaways emerge when considering truck refueling techniques used today. First, understanding the distinction between gravity and pump methods can greatly affect the speed at which a plane is fueled; pump systems often provide higher flow rates than gravity-fed options. Furthermore, knowing what a plane tow truck is called—an aircraft tow vehicle—highlights its importance in moving planes into position for efficient fueling operations.

Future Innovations in Aircraft Refueling Systems

Looking ahead, future innovations in aircraft refueling systems are poised to revolutionize the industry even further. Emerging technologies may include automated fueling systems that reduce human error and increase safety during operations—a significant consideration given the question: Is an aircraft fueler a hard job? As advancements continue to unfold, we can expect enhanced designs for aircraft refueling trucks that improve both functionality and efficiency.