Introduction

Are you familiar with motorized actuator valves? These devices are crucial components in various industries, ensuring the smooth operation of control systems. When it comes to electric actuator specialists, it's essential to understand their role in maintaining and optimizing these valves. But what exactly is a motorized valve actuator, and how does it work? Let's dive into the world of motorized actuator valves to uncover their significance and functionality.

Understanding Motorized Actuator Valves

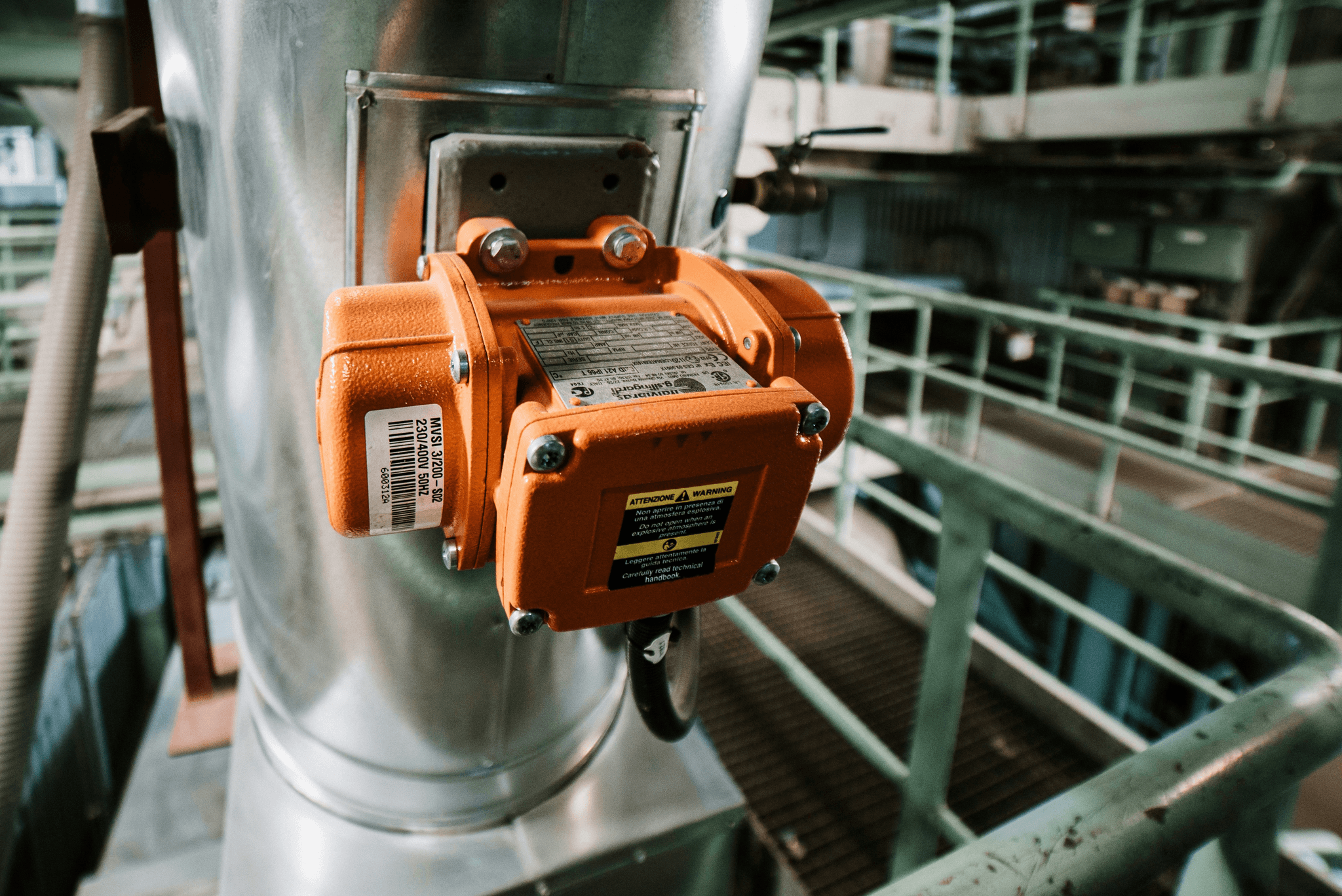

In the realm of industrial automation, motorized actuator valves play a vital role in regulating the flow of fluids and gases within pipelines and systems. These valves are equipped with electric actuators that provide precise control over the valve's position, allowing for seamless adjustments based on operational requirements. Whether it's for HVAC systems or manufacturing processes, motorized actuator valves offer unparalleled efficiency and reliability.

Electric Actuator Specialists: What You Need to Know

When dealing with motorized actuator valves, seeking assistance from electric actuator specialists is crucial for ensuring optimal performance and longevity. These experts possess in-depth knowledge of various types of actuators and their applications, offering valuable insights into selecting, installing, and maintaining these critical components. With their expertise, you can rest assured that your motorized actuator valves will operate at peak efficiency.

What is the Working of Motorized Actuator?

Understanding the working principles of a motorized actuator is essential for grasping its functionality within a valve system. Essentially, a motorized actuator utilizes electrical energy to drive mechanical motion, translating electrical signals into precise movements that control valve positions. This enables automated regulation of fluid or gas flow through the valve, providing unparalleled accuracy and responsiveness in diverse industrial settings.

The Basics of Motorized Actuator Valves

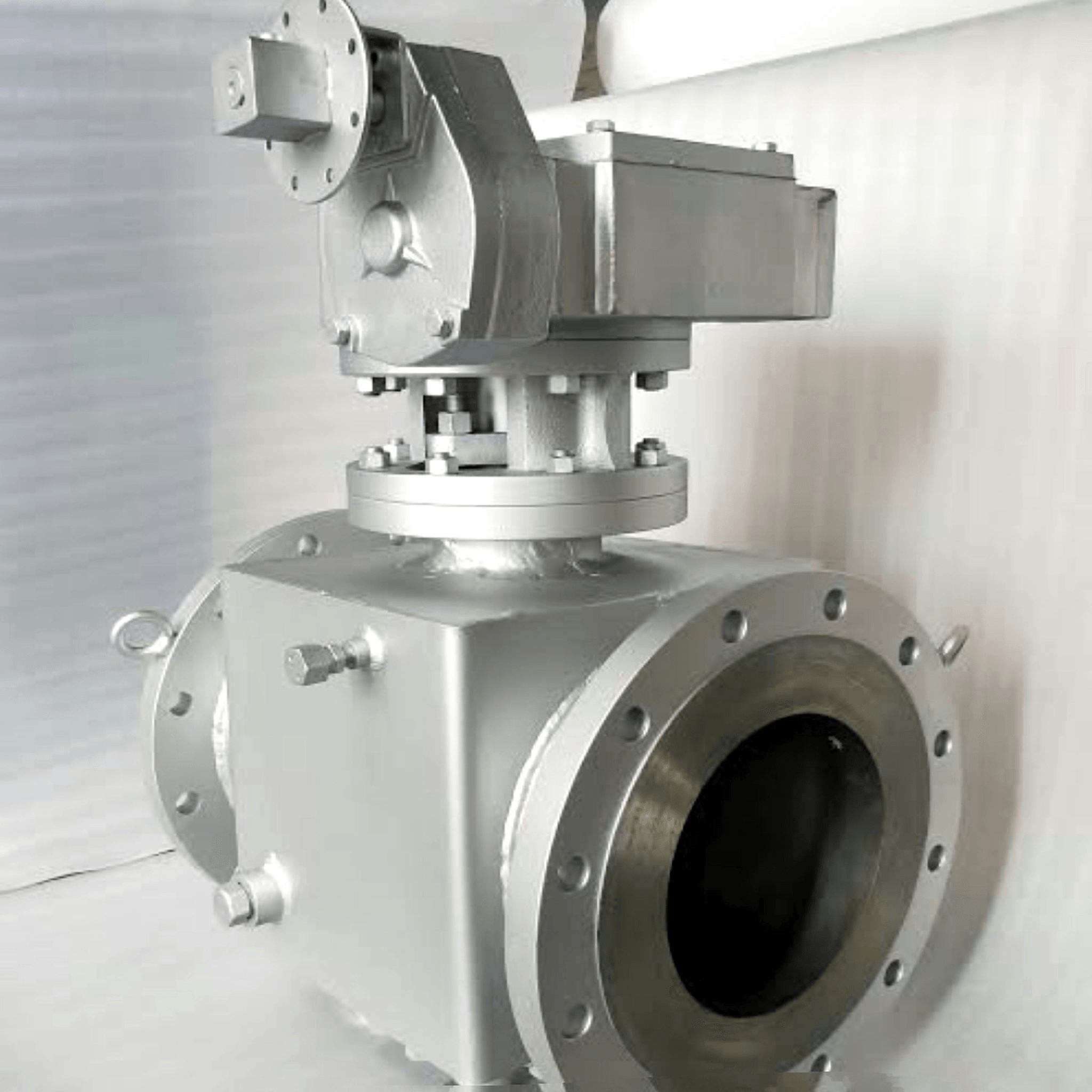

When it comes to motorized actuator valves, understanding the basics is crucial. A power valve actuator is an essential component that provides the force necessary to operate a valve, allowing for precise control of fluid flow. This type of actuator is commonly used in industrial settings, where accurate and reliable valve operation is essential for safety and efficiency.

What does an actuator do on a valve? Well, simply put, an actuator is responsible for converting energy into mechanical motion to open or close a valve. It acts as the driving force behind the movement of the valve, ensuring that it operates according to the desired parameters. Whether it's controlling the flow of water in a municipal water treatment plant or regulating the flow of gas in a manufacturing facility, actuators play a crucial role in maintaining operational control.

Haisen's Part-Turn Valve Electric Actuator is a prime example of cutting-edge technology in this field. This type of actuator is designed to provide precise and reliable performance for part-turn valves, offering seamless integration with various control systems. With features such as intelligent torque control and advanced diagnostics, Haisen's electric actuator ensures smooth and efficient operation while minimizing maintenance requirements.

Troubleshooting Motorized Actuator Valves

When it comes to troubleshooting motorized actuator valves, there are a few common issues that can arise. These include issues with power supply, mechanical failures, and control signal problems. Identifying these issues early on is crucial to prevent any major disruptions in operation.

Common Issues with Motorized Actuator Valves

Common issues with motorized actuator valves often stem from electrical or mechanical failures. These can include power supply problems leading to the actuator not functioning properly, mechanical wear and tear causing the valve to stick or not close properly, and control signal issues resulting in erratic valve behavior.

How to Identify Valve Actuator Problems

Identifying valve actuator problems involves conducting regular inspections and tests to ensure everything is functioning as it should. This includes checking for any unusual sounds coming from the actuator, inspecting for leaks around the valve, and testing the responsiveness of the actuator to control signals.

After identifying any potential issues with the valve actuator, it is important to thoroughly inspect the electrical connections and wiring to ensure there are no loose connections or damaged wires that could be causing the problem. Additionally, checking the power supply to the actuator and ensuring it is within the specified voltage range is crucial for optimal performance. It's also recommended to examine the condition of the actuator's mechanical parts, such as gears and bearings, as wear and tear in these components can lead to malfunctions.

Solutions for Faulty Actuators

Solutions for faulty actuators often involve addressing the root cause of the issue. This may include replacing worn-out parts, recalibrating the actuator, or even upgrading to a more reliable system if necessary. Regular maintenance and prompt attention to any issues are key in ensuring smooth operation of motorized actuator valves.

Regular maintenance and prompt attention to any issues are key in ensuring smooth operation of motorized actuator valves. This includes scheduling regular inspections and tune-ups to catch potential problems before they escalate into major malfunctions. By staying ahead of maintenance, you can prolong the lifespan of your actuators and minimize the risk of unexpected failures. Additionally, investing in high-quality parts and components can also contribute to the overall reliability and performance of your actuator system.

Maintenance and Care for Motorized Actuator Valves

Proper Maintenance of Motorized Actuators

To ensure the longevity and optimal performance of motorized actuator valves, it is crucial to conduct regular maintenance. This includes checking for any signs of wear and tear, lubricating moving parts, and cleaning the actuators to prevent dust accumulation. Proper maintenance will help in avoiding unexpected breakdowns and costly repairs.

In addition to regular maintenance, it is also important to calibrate the actuators periodically to ensure accurate and precise performance. Calibration helps to maintain the correct positioning of the valves, which is essential for their proper functioning. This step can help in preventing malfunctions and ensuring that the actuators operate within the specified parameters.

Tips for Extending the Lifespan of Actuators

One effective way to extend the lifespan of motorized actuators is by ensuring that they are operated within their specified limits. Avoiding overloading or overworking the actuators can significantly reduce wear and tear. Additionally, investing in high-quality actuators from reputable manufacturers can also contribute to their longevity.

Another important factor in extending the lifespan of motorized actuators is to conduct regular inspections and maintenance. By inspecting the actuators for any signs of wear, damage, or malfunctions, potential issues can be identified and addressed before they escalate into more serious problems. This proactive approach can help prevent unexpected breakdowns and costly repairs, ultimately prolonging the lifespan of the actuators.

Importance of Regular Inspections

Regular inspections play a vital role in identifying potential issues with motorized actuator valves before they escalate into major problems. By conducting routine checks on the actuators, any signs of malfunction or deterioration can be detected early on, allowing for timely repairs or replacements as needed.

Regular inspections also help in preventing unexpected downtime and costly repairs by addressing any issues proactively. By staying ahead of potential problems, businesses can avoid interruptions in their operations and maintain productivity. Additionally, regular maintenance can contribute to a safer working environment by minimizing the risk of accidents or equipment failures.

Choosing the Right Motorized Actuator Valve

When selecting a motorized actuator valve, there are several factors to consider. The size and type of valve, the operating environment, and the required torque and speed are all essential considerations. Additionally, it's important to assess the power supply available and whether the valve will be used for on/off or modulating control.

Factors to Consider When Selecting an Actuator Valve

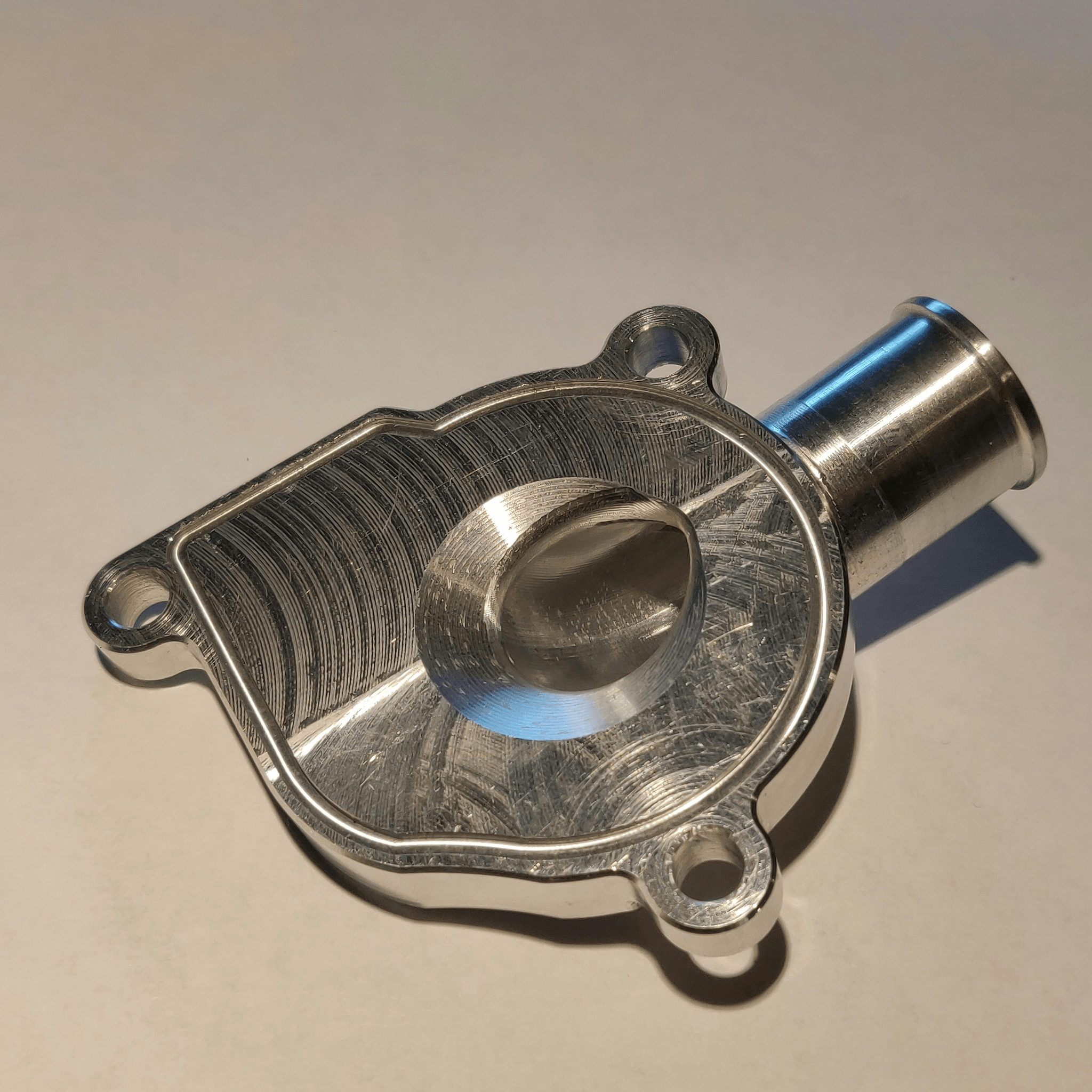

One crucial factor when choosing a motorized actuator valve is the type of valve it will be paired with. Different valves require different types of actuators to operate effectively. Additionally, considering the environmental conditions in which the actuator will operate is essential for ensuring its longevity and performance. It's important to assess factors such as temperature, humidity, and exposure to corrosive materials when selecting an actuator valve. For instance, if the actuator will be used in a harsh chemical processing plant, it's imperative to choose a valve that can withstand such conditions without compromising its functionality.

Understanding Different Types of Actuators

There are various types of actuators available, each with its own unique features and benefits. Electric actuators, pneumatic actuators, hydraulic actuators, and manual actuators are some of the most common options. Understanding how each type functions and their respective advantages can help in making an informed decision.

Electric actuators are powered by electricity and are known for their precise and efficient operation. They are ideal for applications that require accurate control and positioning, making them a popular choice in industries such as manufacturing, automotive, and aerospace. Additionally, electric actuators offer the advantage of easy integration with digital control systems, allowing for seamless automation of processes.

Electric Valve Manufacturer Insights

Electric valve manufacturers play a crucial role in providing valuable insights into selecting the right motorized actuator valve. Their expertise in designing and producing high-quality electric actuators can offer valuable guidance in choosing the most suitable option for specific applications.

Electric valve manufacturers also offer valuable insights into the maintenance and care of motorized actuator valves. Their expertise can provide guidance on best practices for ensuring the longevity and efficient operation of electric actuators. By understanding the manufacturer's recommendations for maintenance, users can maximize the performance and lifespan of their valves, ultimately saving time and resources in the long run.

Now that we've covered factors to consider when choosing a motorized actuator valve, let's delve deeper into understanding different types of actuators and gain insights from electric valve manufacturers to make informed decisions for optimal performance.

Conclusion

Motorized actuator valves play a crucial role in various industries, and understanding their operation and maintenance is essential for smooth functionality. Electric Actuator Specialists can provide valuable insights into selecting the right actuator valve for your specific needs. By choosing the right motorized control valves and actuators, you can ensure efficient and reliable performance in your systems.

Ensuring Smooth Operation of Motorized Actuator Valves

Regular maintenance and proper care are key to ensuring the smooth operation of motorized actuator valves. By addressing any issues promptly and conducting regular inspections, you can prevent potential problems that may disrupt the functioning of your systems. Additionally, working with reputable electric valve manufacturers can provide you with high-quality products that are designed for optimal performance.

Advantages of Using Motorized Control Valves and Actuators

The use of motorized control valves and actuators offers numerous advantages, including precise control over flow rates, improved efficiency, and reduced energy consumption. These advanced technologies allow for automated operation, enhancing overall system performance while minimizing manual intervention. With the right selection and maintenance, motorized actuator valves can significantly contribute to the success of your operations.

Tips for Maximizing the Efficiency of Actuators

To maximize the efficiency of actuators, it's important to consider factors such as environmental conditions, load requirements, and compatibility with existing systems. Proper installation and regular inspections are essential for identifying potential issues early on and implementing solutions to maintain optimal efficiency. By following these tips and working closely with electric actuator specialists, you can ensure that your actuators continue to operate at peak performance.

In addition to installation and regular inspections, it's also important to consider the maintenance of actuators. Regular lubrication and cleaning can help prevent wear and tear, ensuring that the actuators continue to function smoothly. Additionally, keeping an eye on the performance metrics of the actuators can help identify any potential issues before they escalate into larger problems. By staying proactive with maintenance, you can maximize the lifespan and efficiency of your actuators.