Introduction

Are you looking for efficient and reliable solutions for valve control in your industrial operations? Look no further than part-turn electric valve actuators, which offer precision and flexibility in managing flow control. With the increasing demand for high-quality actuators, companies like Haisen are leading the way with their innovative part-turn valve electric actuator.

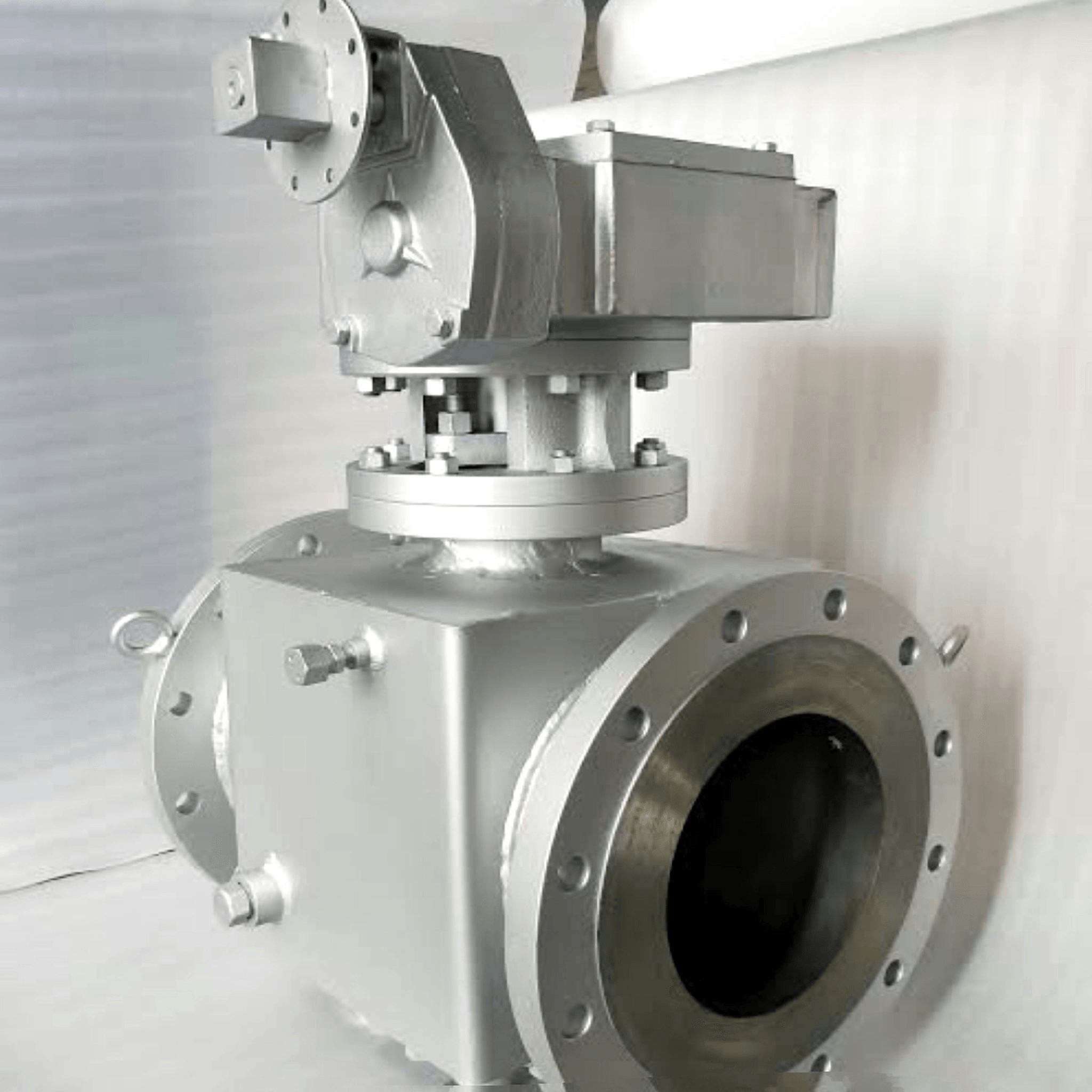

Overview of Part-turn Electric Valve Actuators

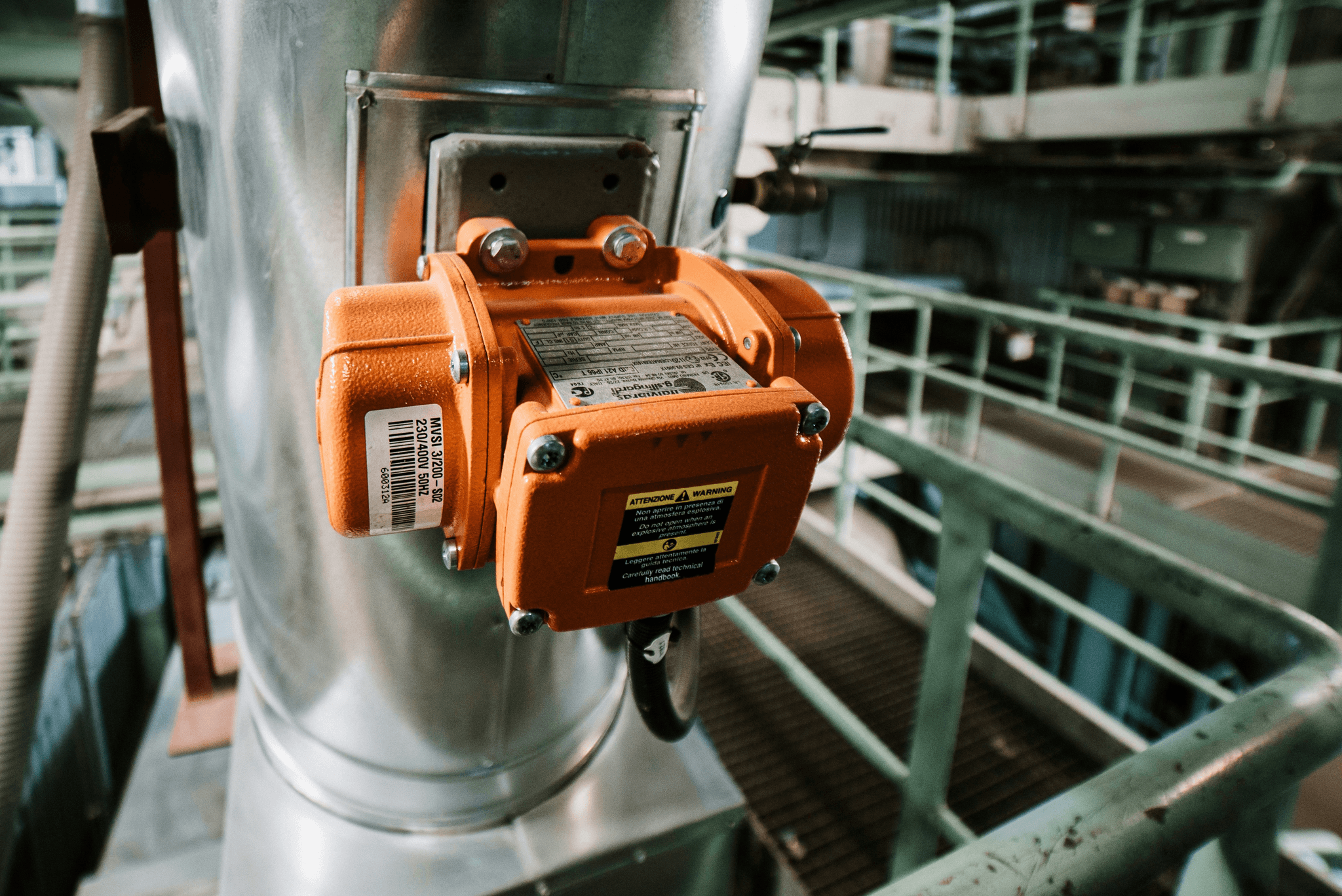

Part-turn electric valve actuators are designed to provide precise and smooth operation in controlling the flow of liquids or gases through valves. These actuators are essential components in various industrial processes, ensuring seamless performance and optimal efficiency.

Importance of High-Quality Actuators

High-quality part turn electric valve actuators play a crucial role in maintaining the reliability and safety of industrial systems. With robust construction and advanced technology, these actuators offer long-term durability and consistent performance, making them a valuable investment for any operation.

Introducing Haisen's Part-Turn Valve Electric Actuator

Haisen's part-turn valve electric actuator is at the forefront of innovation, offering superior functionality and precision control. With a focus on quality and reliability, Haisen's actuators are designed to meet the diverse needs of industrial applications, providing unmatched performance and efficiency.

Understanding Rotork Part Turn Actuators

Rotork part turn actuators are renowned for their exceptional features and benefits in the industrial valve control sector. With robust construction, precise engineering, and advanced technology, these actuators offer unparalleled performance and reliability.

Features and Benefits of Rotork Actuators

The Rotork part turn actuators boast a compact and lightweight design, making them easy to install and maintain. Their high torque output ensures efficient operation, while their corrosion-resistant materials guarantee durability in harsh environments. Additionally, their modular design allows for easy customization to suit specific application requirements.

Furthermore, the Rotork part turn actuators are designed with a range of mounting options, allowing for flexible installation in various industrial settings. This versatility enables them to be easily integrated into existing systems without the need for extensive modifications, saving both time and resources. Their user-friendly interface and intuitive controls also simplify operation and maintenance, reducing downtime and enhancing overall productivity.

Applications in Various Industrial Fields

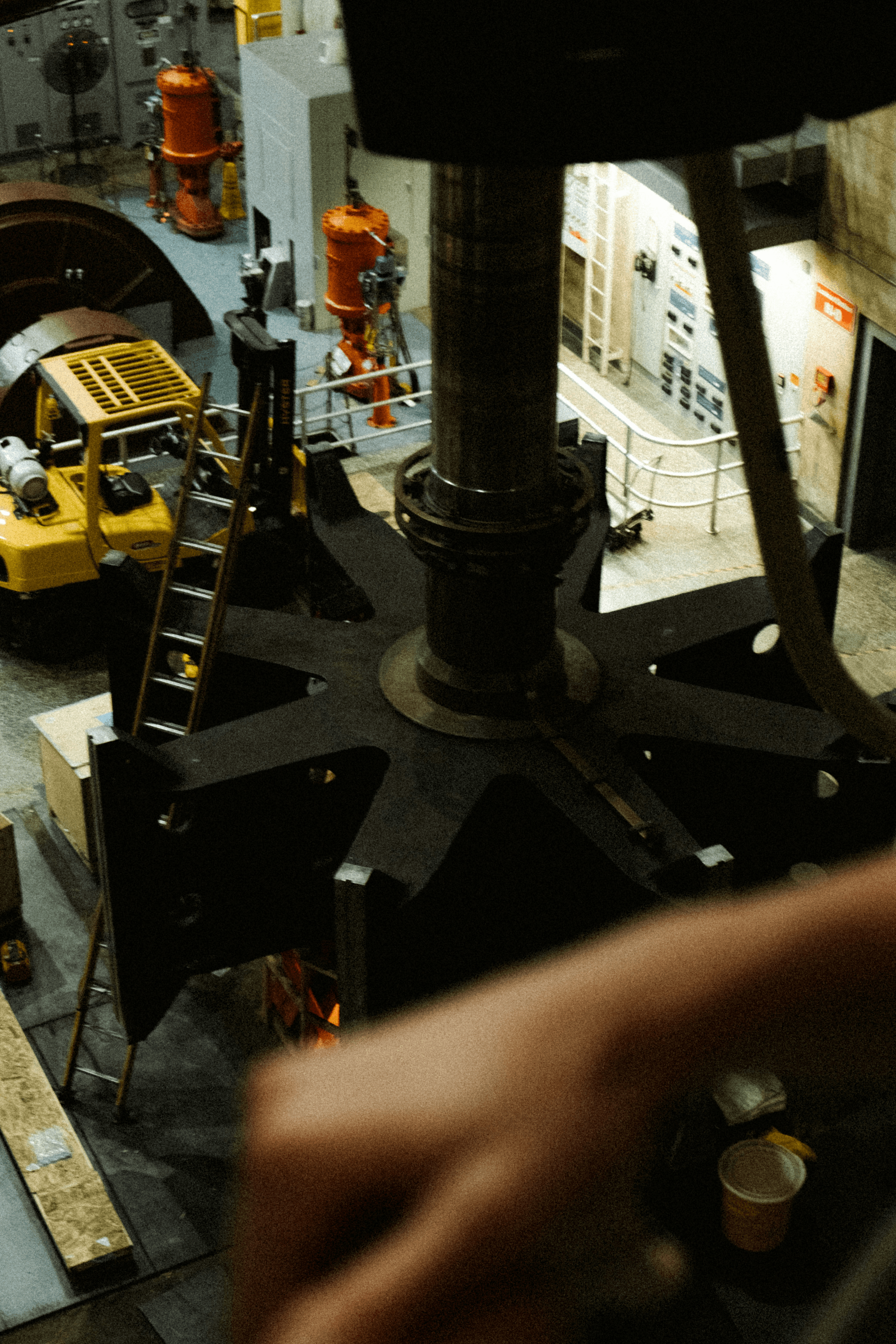

These versatile actuators find applications across a wide range of industrial fields, including oil and gas, water treatment, power generation, and chemical processing. Their ability to handle varying valve sizes and types makes them indispensable in diverse operational settings where precise valve control is essential.

Furthermore, Rotork part turn actuators are designed to withstand harsh environmental conditions, making them ideal for use in oil and gas operations where exposure to extreme temperatures and corrosive materials is common. Their robust construction and reliable performance ensure that valves can be operated efficiently and safely in these demanding settings.

Advantages of Using Rotork Part Turn Actuators

The advantages of using Rotork part turn actuators are manifold. They offer seamless integration with existing control systems, enabling streamlined operation and maintenance processes. Their exceptional reliability minimizes downtime, while their energy-efficient performance contributes to cost savings over the long term.

In addition to their seamless integration and exceptional reliability, Rotork part turn actuators also offer precise and accurate control over valve positioning. This level of precision ensures that the valves operate exactly as intended, reducing the risk of errors or malfunctions. This accuracy is crucial in industries where precise control over fluid flow is essential, such as oil and gas, water treatment, and chemical processing.

Key Considerations When Choosing an Actuator

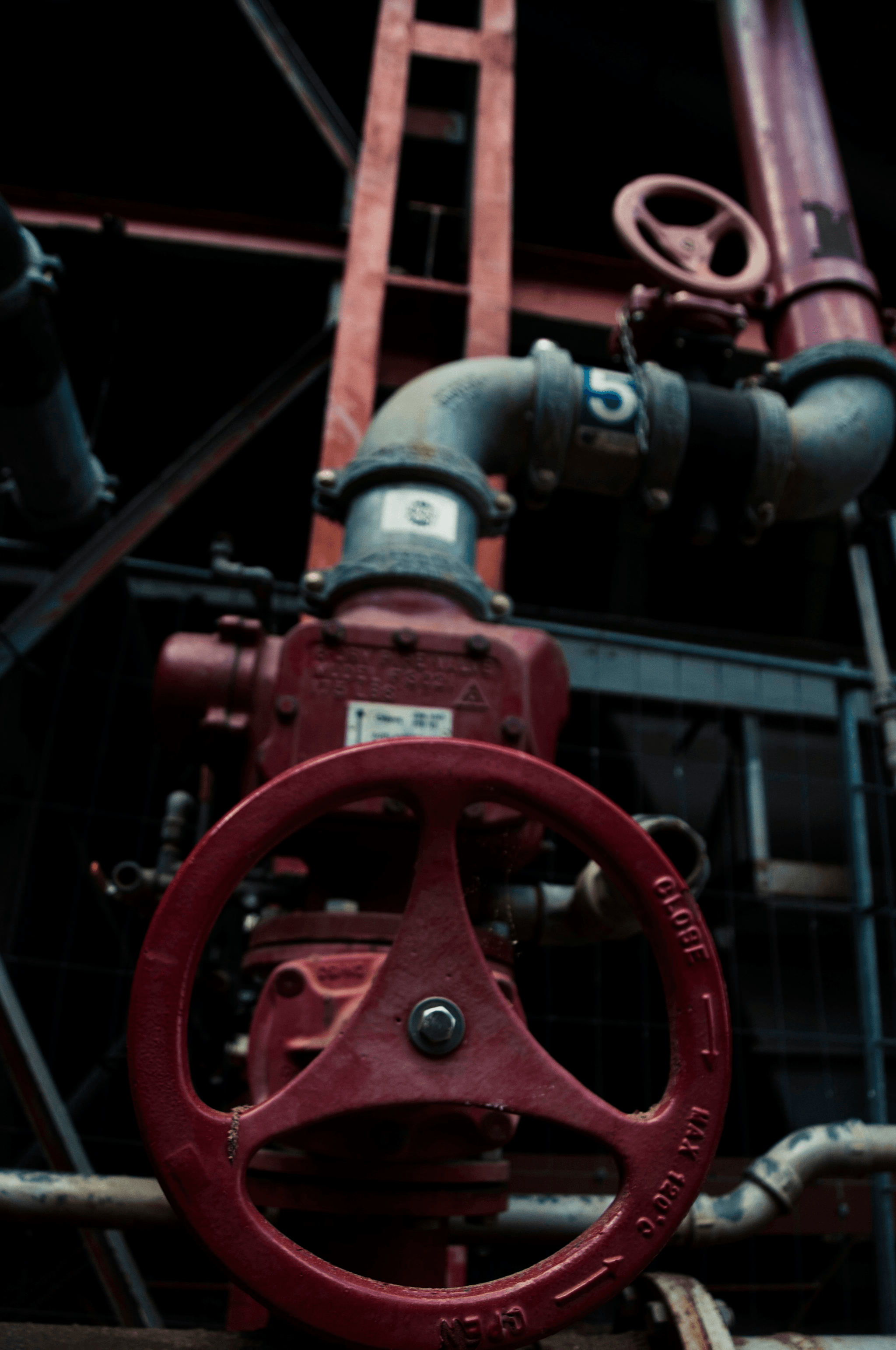

When selecting a Part-turn Electric Valve Actuator, it's crucial to consider the specific factors related to valve control. Understanding the torque requirements, operating speed, and control options for your application is essential in ensuring optimal performance and efficiency.

Factors to Consider for Valve Control

The selection of the right Part-turn valve actuator is heavily influenced by the type of valve it will be controlling. Different valves require different torque and operating speeds, so it's important to match the actuator's capabilities with the valve's requirements for precise and reliable control.

It is also important to consider the quality and reliability of the part-turn valve actuator. Investing in a high-quality actuator can help ensure that the valve control system operates smoothly and efficiently, reducing the risk of downtime or malfunctions. Reliability is crucial in industrial settings where valves are used for critical processes, so choosing a reputable brand known for producing durable and dependable actuators is essential.

Importance of Quality and Reliability

Quality and reliability are paramount when choosing an actuator for your industrial applications. Rotork part turn actuators are known for their robust construction, durability, and long-term performance, making them a trusted choice for critical valve automation needs.

In addition to their reputation for durability and long-term performance, Rotork part turn actuators also offer advanced technology features that enhance their reliability and precision. With state-of-the-art control systems and intelligent monitoring capabilities, these actuators provide real-time feedback and diagnostics, allowing for proactive maintenance and minimizing downtime. This technological edge ensures that your industrial processes can operate smoothly and efficiently, even in the most demanding conditions.

The Role of Technology in Actuator Selection

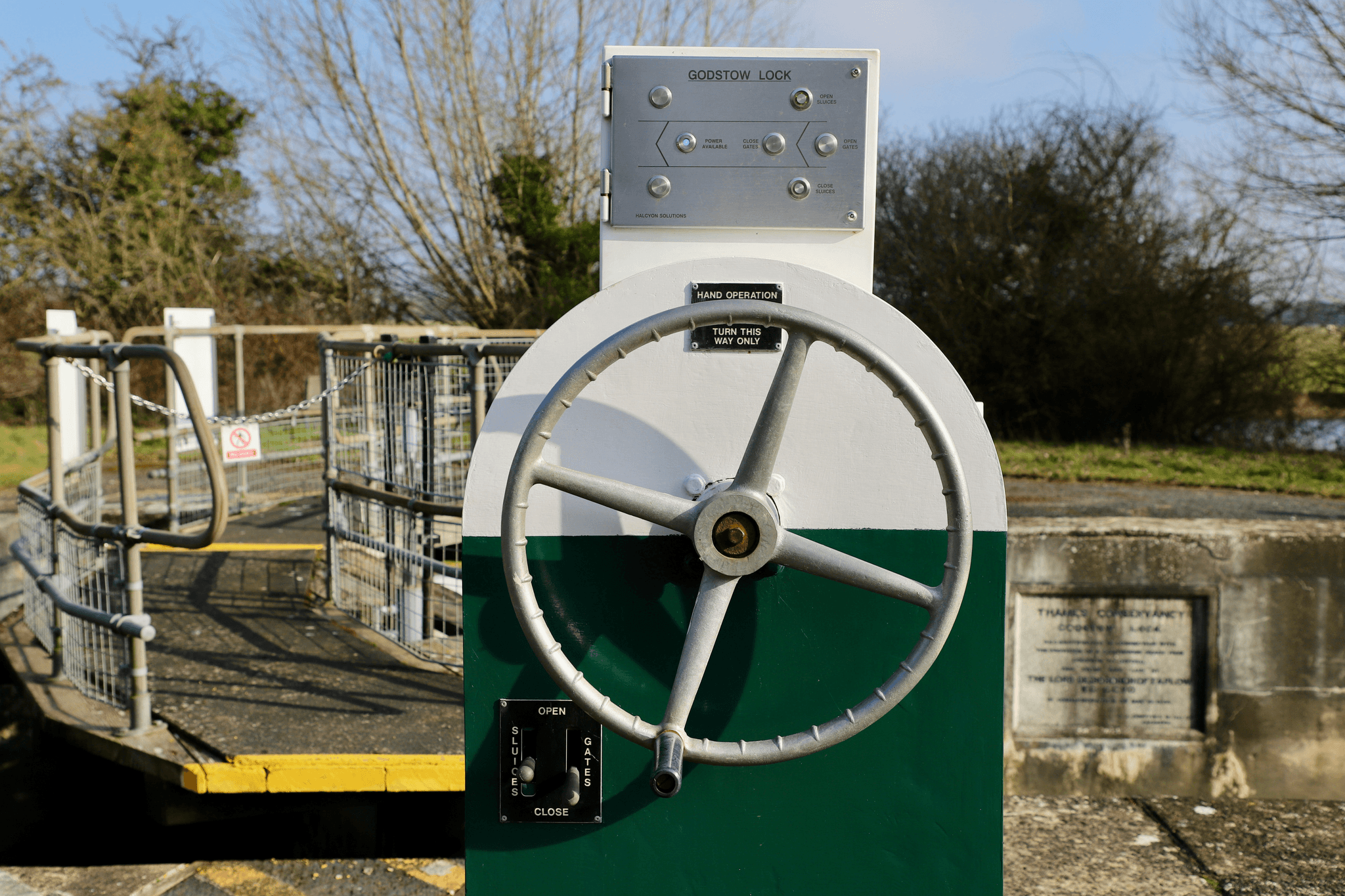

With advancements in technology, the role of innovation in actuator selection cannot be overstated. Rotork actuators incorporate cutting-edge technologies such as digital control interfaces and remote monitoring capabilities, offering enhanced functionality and ease of operation for various industrial settings.

Exploring Pro Part-turn Electric Valve Actuator

Pro Part-turn Electric Valve Actuators are designed with innovative features to provide precise and reliable valve control in industrial settings. With advanced technology and robust construction, these actuators offer superior performance and efficiency, making them a preferred choice for various applications.

Innovative Features of Pro Part-turn Actuators

The Pro Part-turn Electric Valve Actuator is equipped with cutting-edge features such as intelligent position control, torque sensing, and self-diagnostics, ensuring accurate and smooth valve operation. These actuators also incorporate fail-safe mechanisms and advanced communication protocols for seamless integration with control systems, enhancing overall functionality.

In addition to these advanced features, the Pro Part-turn Electric Valve Actuator is designed for optimal performance and efficiency. With its high-speed operation and low power consumption, this actuator offers cost-effective and reliable valve automation. Its compact and lightweight design also makes installation and maintenance hassle-free, saving time and resources for the end user. Furthermore, the actuator's robust construction ensures durability and longevity, making it a dependable choice for various industrial applications.

Performance and Efficiency of Pro Actuators

Pro Part-turn Electric Valve Actuators deliver exceptional performance and efficiency in controlling the flow of fluids or gases through valves. With precise positioning capabilities and rapid response times, these actuators optimize process control while minimizing energy consumption, resulting in cost savings and improved operational efficiency.

Pro Part-turn Electric Valve Actuators are designed to withstand harsh industrial environments, ensuring reliable performance and longevity. Their robust construction and durable materials make them ideal for use in demanding applications, providing peace of mind to operators and maintenance teams. This reliability translates to reduced downtime and maintenance costs, further contributing to overall operational efficiency.

Case Studies and Success Stories

Numerous industries have benefited from the reliability and durability of Pro Part-turn Electric Valve Actuators. From petrochemical plants to water treatment facilities, these actuators have demonstrated consistent performance in demanding environments, earning recognition for their contribution to enhanced productivity and safety.

Now that we've explored the innovative features, performance benefits, and real-world success stories of Pro Part-turn Electric Valve Actuators, it's evident that these actuators play a crucial role in optimizing industrial operations across diverse sectors.

Benefits of Part Turn Electric Valve Actuators

Part-turn electric valve actuators, such as the renowned Rotork part turn actuators, offer a multitude of benefits for industrial applications. These advanced actuators provide precise control and smooth operation, ensuring optimal performance for valve systems.

Improving Valve Control and Operation

Rotork part turn actuators excel in improving valve control and operation, offering accurate positioning and reliable torque output. With their advanced technology and intelligent design, these actuators ensure seamless control over valve mechanisms, enhancing overall system efficiency.

Enhancing Safety and Security

Part-turn electric valve actuators play a crucial role in enhancing safety and security within industrial settings. The precision and reliability of Rotork actuators contribute to the safe operation of valves, minimizing the risk of potential hazards or accidents in industrial environments.

Maximizing Efficiency and Productivity

By utilizing Rotork part turn actuators, industries can maximize efficiency and productivity in their operations. These high-performance actuators streamline valve control processes, reducing downtime and optimizing overall system performance to boost productivity.

With their exceptional features and capabilities, Rotork part turn actuators are undeniably essential for improving valve control, enhancing safety, and maximizing operational efficiency in diverse industrial applications.

The Future of Part-turn Valve Actuators

As technology continues to advance, the future of part-turn valve actuators looks promising. With the increasing demand for automation and efficiency, emerging trends and technologies are shaping the way these actuators function in industrial settings. Companies like Rotork are at the forefront of this innovation, constantly pushing the boundaries of what is possible with part-turn electric valve actuators.

Emerging Trends and Technologies

One of the emerging trends in part-turn valve actuators is the integration of IoT (Internet of Things) technology, allowing for remote monitoring and control. This not only improves efficiency but also enables predictive maintenance, reducing downtime and maintenance costs. Additionally, advancements in materials and construction methods are making actuators more durable and reliable, meeting the demands of harsh industrial environments.

Innovations in Actuator Design

Innovations in actuator design are focused on enhancing performance and functionality. Rotork part turn actuators are incorporating advanced control algorithms to optimize valve positioning and response time, resulting in more precise control over fluid flow. Furthermore, compact designs with higher torque outputs are being developed to accommodate space constraints while delivering superior performance.

Potential Impact on Industrial Operations

The potential impact of these advancements on industrial operations is significant. With improved reliability and efficiency, companies can expect reduced operational costs and increased productivity. The integration of smart technologies also allows for better decision-making through real-time data analysis, leading to enhanced safety protocols and streamlined processes.

Conclusion

When it comes to choosing the right actuator for your needs, it's important to consider the specific requirements of your industrial applications and the benefits offered by different options such as Rotork Part Turn Actuators. Investing in quality and reliability is crucial to ensure smooth operations and minimize downtime. By maximizing performance with Rotork actuators, you can enhance efficiency and productivity while ensuring reliable valve control.

Choosing the Right Actuator for Your Needs

Selecting the right part-turn electric valve actuator is a critical decision that can significantly impact the performance of your industrial processes. With options like Rotork Part Turn Actuators and Pro Part-turn Electric Valve Actuators available, it's essential to carefully evaluate your requirements and choose an actuator that aligns with your specific needs.

Investing in Quality and Reliability

Investing in high-quality part-turn electric valve actuators, such as those offered by Rotork, is an investment in the reliability and efficiency of your operations. By prioritizing quality, you can minimize the risk of malfunctions or breakdowns, ensuring smooth and uninterrupted operation of your valves.

Maximizing Performance with Rotork Actuators

Rotork actuators are designed to deliver exceptional performance, offering precise control over part-turn valve operations in various industrial settings. By leveraging the advanced features and capabilities of Rotork Part Turn Actuators, you can optimize efficiency, enhance safety, and maximize productivity across your operations.