Introduction

When it comes to industrial automation and safety, explosion-proof electric actuators play a crucial role. These specialized devices are designed to operate in hazardous environments where the risk of explosion is high, making them essential for various industries. One of the key aspects to consider is the ATEX Approved Explosion Proof Electric Actuator, which adheres to strict European Union regulations for equipment used in potentially explosive atmospheres. But what exactly makes an electric motor explosion proof? Let's delve into the intricacies of these critical components and their significance in industrial settings.

Understanding Explosion Proof Electric Actuators

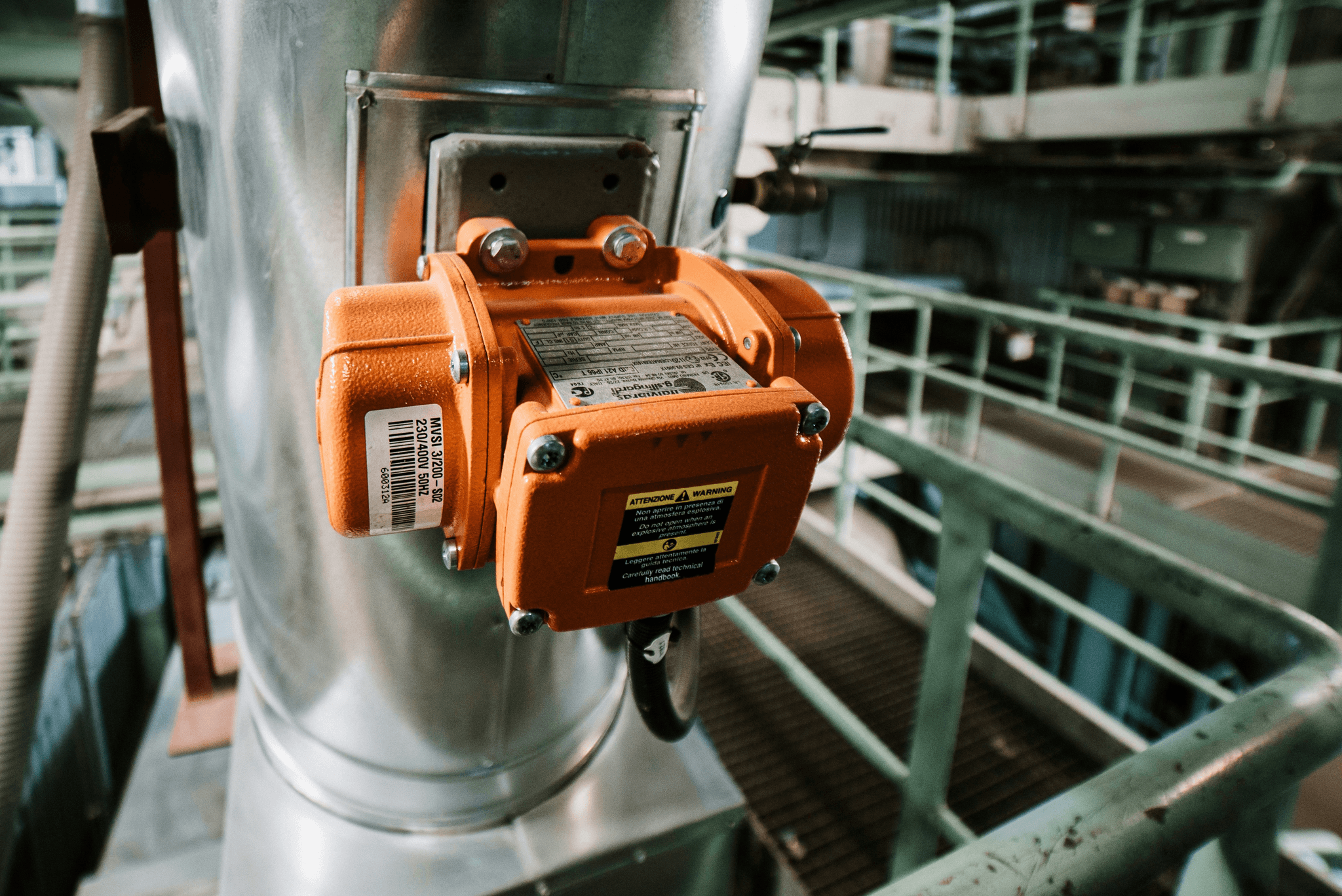

Explosion-proof electric actuators are specifically engineered to prevent ignition of flammable gases, vapors, or dust within their enclosures. This is achieved through robust construction and sealing techniques that contain any potential sparks or heat generated by the motor inside the unit. As a result, these actuators can safely operate in environments where traditional electric motors would pose a significant risk.

ATEX Approved Explosion Proof Electric Actuator

The ATEX directive sets stringent requirements for equipment intended for use in explosive atmospheres, ensuring that they meet high safety standards. An ATEX Approved Explosion Proof Electric Actuator undergoes rigorous testing and certification processes to ensure its suitability for hazardous areas where combustible substances may be present. This certification provides peace of mind to industries operating in such environments.

What Makes an Electric Motor Explosion Proof?

An electric motor is deemed explosion proof when it is designed and constructed in a way that prevents internal sparks or arcs from igniting surrounding flammable gases or dust. This often involves features such as sealed enclosures, robust housing materials, and protective measures against potential sources of ignition within the motor itself.

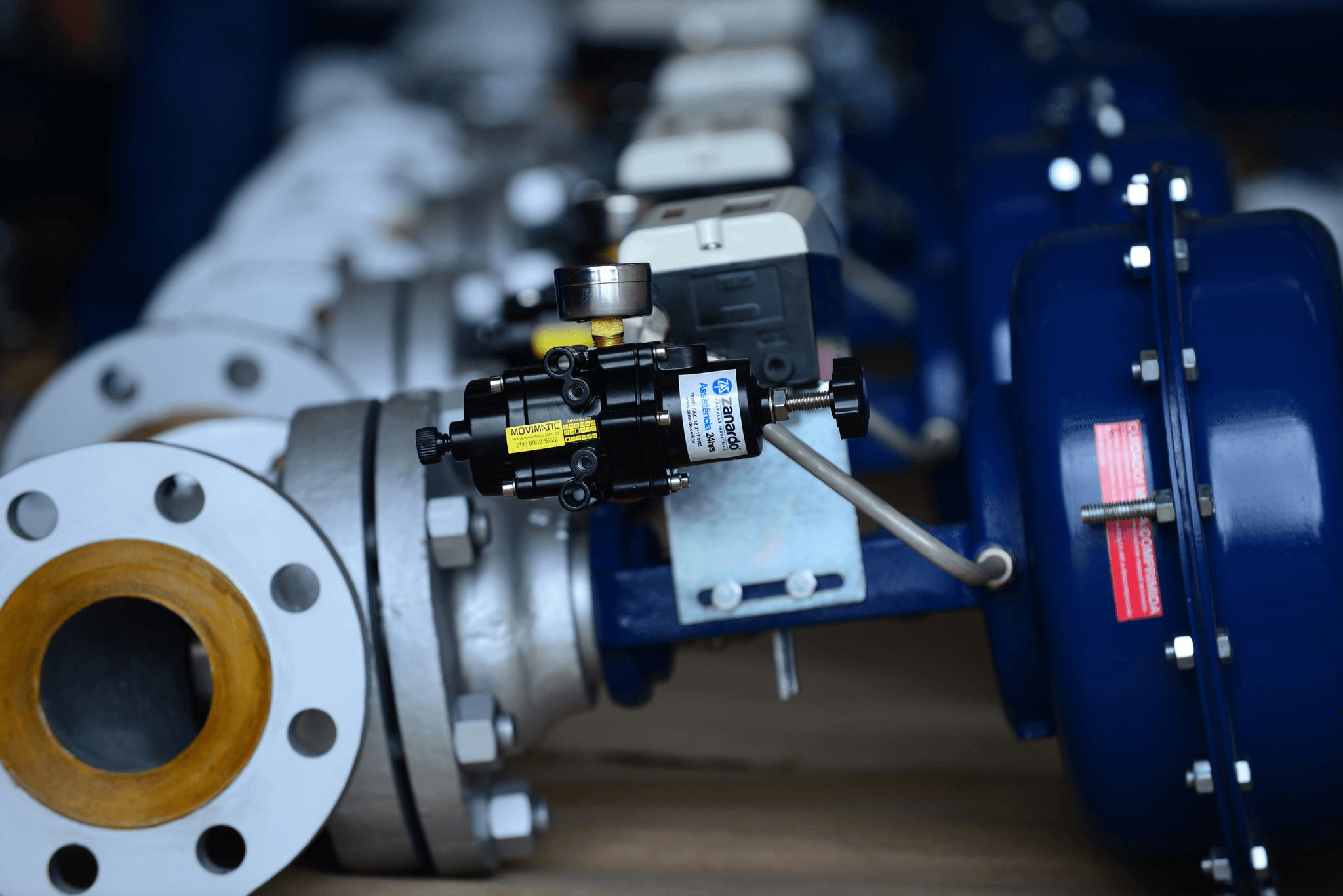

The Core Features of Haisen's Part-Turn Valve Electric Actuator

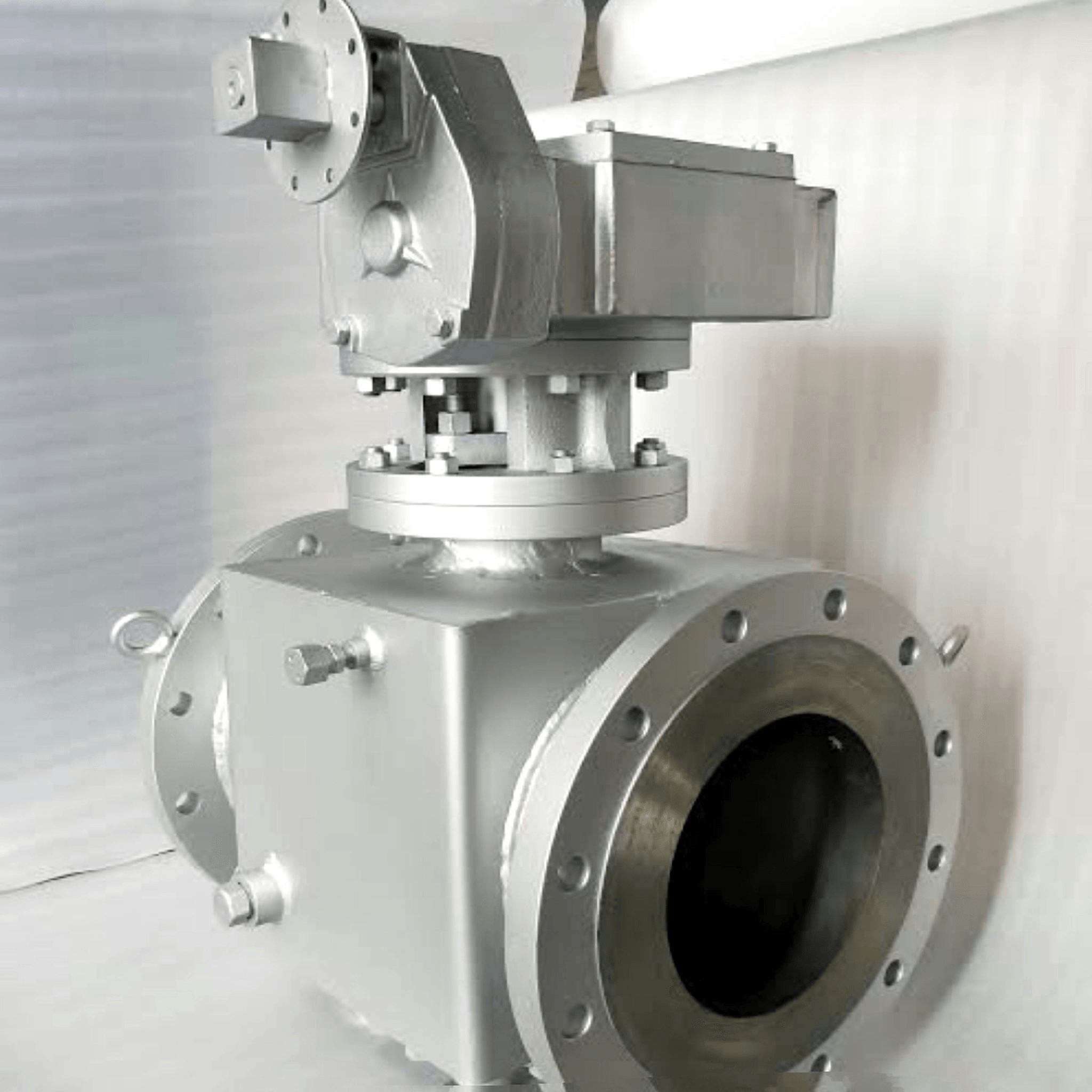

Haisen's Part-Turn Valve Electric Actuator is designed with high-quality materials and construction, ensuring durability and reliability in challenging industrial environments. The use of robust components and precision engineering make it a top choice for applications requiring explosion-proof electric actuators.

High-Quality Materials and Construction

The electric actuator is constructed using premium-grade materials such as stainless steel and aluminum, providing resistance to corrosion, extreme temperatures, and harsh chemicals. This ensures the longevity of the actuator in demanding settings where ATEX Approved Explosion Proof Electric Actuators are essential for safety.

The use of high-quality materials and construction techniques not only ensures the longevity of the electric actuator but also contributes to its reliable performance in challenging environments. By utilizing premium-grade stainless steel and aluminum, the actuator is able to withstand corrosion, extreme temperatures, and harsh chemicals, making it an ideal choice for industries where safety and durability are paramount. This level of resilience is particularly crucial in settings where ATEX Approved Explosion Proof Electric Actuators are necessary, providing peace of mind for operators and ensuring the smooth operation of critical equipment.

Remote Control Capabilities

Haisen's Part-Turn Valve Electric Actuator offers remote control capabilities, allowing users to operate valves from a safe distance. This feature enhances efficiency while minimizing exposure to hazardous conditions, making it an ideal choice for applications that require remote operation of explosion-proof electric actuators.

Industrial Applications and Versatility

With its ability to handle various valve types and sizes, Haisen's Part-Turn Valve Electric Actuator is suitable for a wide range of industrial applications. Whether it's in oil and gas, petrochemical, or water treatment facilities, this versatile actuator provides reliable performance in heavy-duty environments.

Remember that safety should always be your top priority when choosing an explosion-proof electric actuator!

The Importance of Electronic Fail Safe Actuators

Fail safe actuators play a crucial role in ensuring safety in industrial settings, especially in hazardous environments where the risk of explosion is high. These actuators are designed to quickly and automatically shut down in the event of a power failure or emergency situation, preventing potential accidents and damage to equipment. By incorporating fail safe actuators into your system, you can effectively minimize the risks associated with operating heavy-duty machinery and ensure compliance with industry safety standards.

How Fail Safe Actuators Ensure Safety

Fail safe actuators are equipped with advanced electronic systems that constantly monitor power supply and control signals. In the event of a failure or abnormal condition, these actuators are programmed to automatically revert to a safe position or shut down completely, preventing any potential hazards from occurring. This ensures that critical processes are safeguarded and minimizes the impact of unexpected events on operations.

Another benefit of fail safe actuators is their ability to reduce risks in hazardous environments. By automatically reverting to a safe position or shutting down completely in the event of a failure, these actuators help prevent potential hazards from occurring, such as leaks or explosions. This proactive safety measure not only protects personnel and equipment but also minimizes the likelihood of costly damage to the surrounding environment. In this way, fail safe actuators play a crucial role in ensuring safety and peace of mind in high-risk industrial settings.

Reducing Risks in Hazardous Environments

In environments where explosive gases, vapors, or dust particles are present, fail safe actuators provide an additional layer of protection against potential ignition sources. By promptly responding to emergency situations and shutting down equipment as needed, these actuators help reduce the likelihood of accidents and mitigate the impact of any unforeseen events on personnel safety and asset integrity.

In addition to fail safe actuators, regular maintenance and inspection of equipment in hazardous environments is crucial for ensuring ongoing safety. By adhering to industry standards and best practices, organizations can minimize the risk of accidents and maintain a safe working environment for their personnel. This proactive approach not only protects against potential ignition sources but also helps to prevent costly downtime and damage to critical assets.

Compliance with Industry Standards

The use of fail safe actuators is essential for meeting stringent industry regulations and standards related to safety in hazardous environments. Whether it's ATEX Approved Explosion Proof Electric Actuator for use in potentially explosive atmospheres or other industry-specific requirements, incorporating fail safe technology ensures that your systems adhere to the necessary guidelines for safe operation.

Exploring the Strength of Electric Actuators

When it comes to power and performance, explosion-proof electric actuators are designed to deliver exceptional torque and speed, making them suitable for a wide range of industrial applications. The ATEX Approved Explosion Proof Electric Actuator, in particular, is engineered to operate in hazardous environments without compromising on its performance capabilities. This ensures that even in high-risk settings, the actuator can maintain its power and efficiency, providing reliable operation when it matters most.

Power and Performance

The ATEX Approved Explosion Proof Electric Actuator is built with robust motors and precision-engineered components, allowing it to generate high levels of torque to operate valves and other equipment effectively. This ensures that the actuator can handle heavy-duty tasks with ease, making it a reliable choice for demanding industrial settings where strong performance is essential. Whether it's controlling flow rates or managing process pressures, the actuator's power capabilities make it a standout choice for critical operations.

The ATEX Approved Explosion Proof Electric Actuator is not only powerful but also highly reliable and long-lasting. Its robust construction and precision engineering ensure that it can withstand the rigors of industrial environments, providing consistent performance over an extended period. This durability minimizes downtime and maintenance costs, making it a cost-effective choice for businesses looking to optimize their operations. With the actuator's longevity, you can trust that it will continue to deliver exceptional results, making it a valuable asset for any industrial setting.

Reliability and Longevity

In addition to its impressive power output, the explosion-proof electric actuator also boasts exceptional reliability and longevity. With durable construction and high-quality materials, these actuators are built to withstand the rigors of industrial environments while maintaining consistent performance over an extended lifespan. This reliability ensures that operations can continue uninterrupted, minimizing downtime and enhancing overall productivity in various industrial applications.

Furthermore, the explosion-proof electric actuator is designed to adapt to a wide range of environmental conditions, making it suitable for use in various industrial settings. Whether it's extreme temperatures, high humidity, or exposure to corrosive substances, these actuators are engineered to withstand the harshest environments without compromising performance. This adaptability ensures that they can be deployed in diverse applications with confidence, providing a versatile solution for industrial automation needs.

Environmental Adaptability

One of the key strengths of explosion-proof electric actuators lies in their environmental adaptability. Designed to operate in challenging conditions where explosive atmospheres may be present, these actuators are equipped with features that protect them from potential hazards such as dust or gas ignitions. This level of environmental adaptability makes them well-suited for heavy-duty applications where safety and performance go hand in hand.

Now we have explored the strength of electric actuators by highlighting their power and performance capabilities, reliability and longevity, as well as their environmental adaptability in challenging industrial environments. These features make explosion-proof electric actuators ideal for heavy-duty applications where safety is paramount.

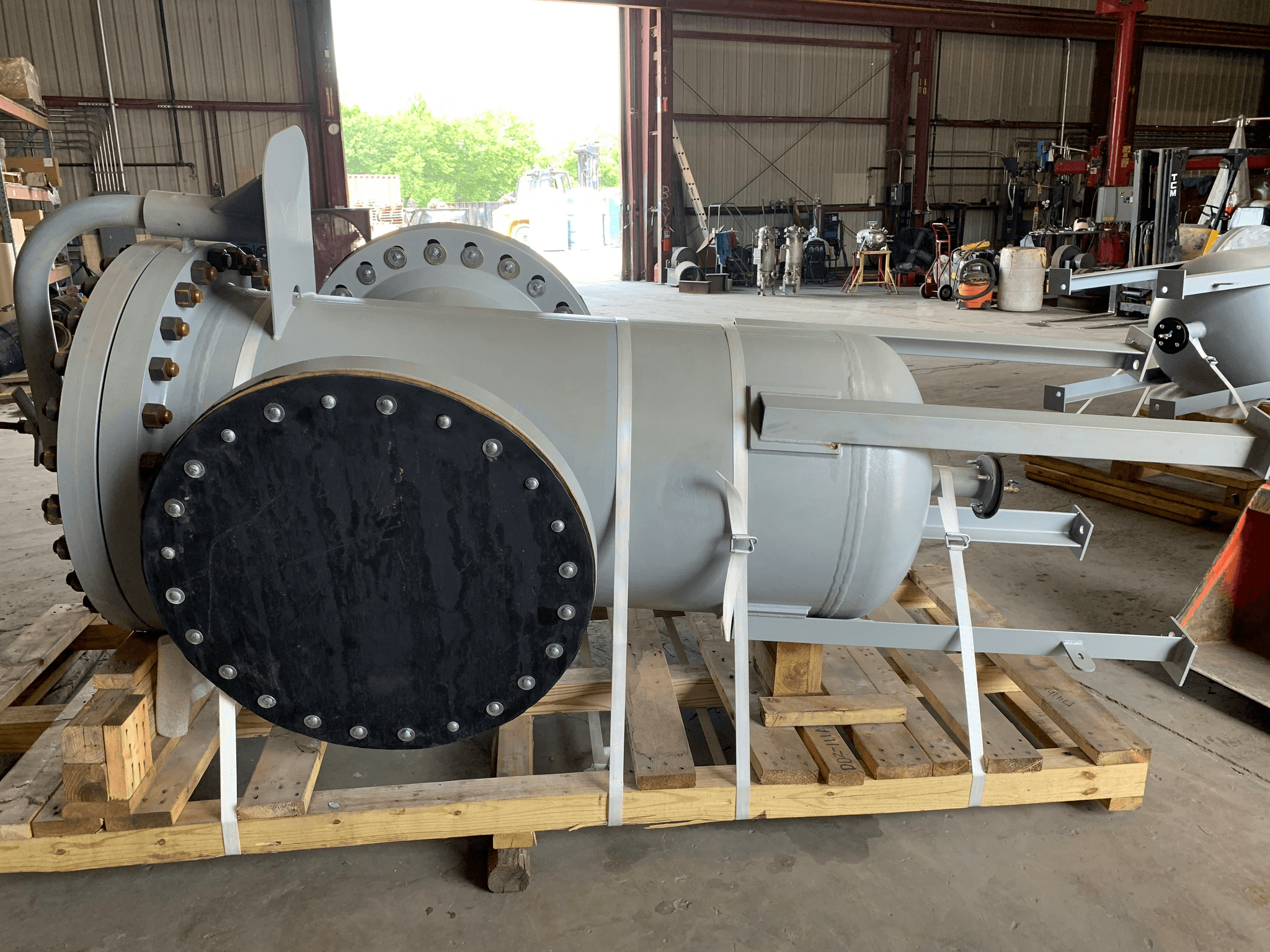

Understanding Explosion Proof Actuators for Heavy Duty Applications

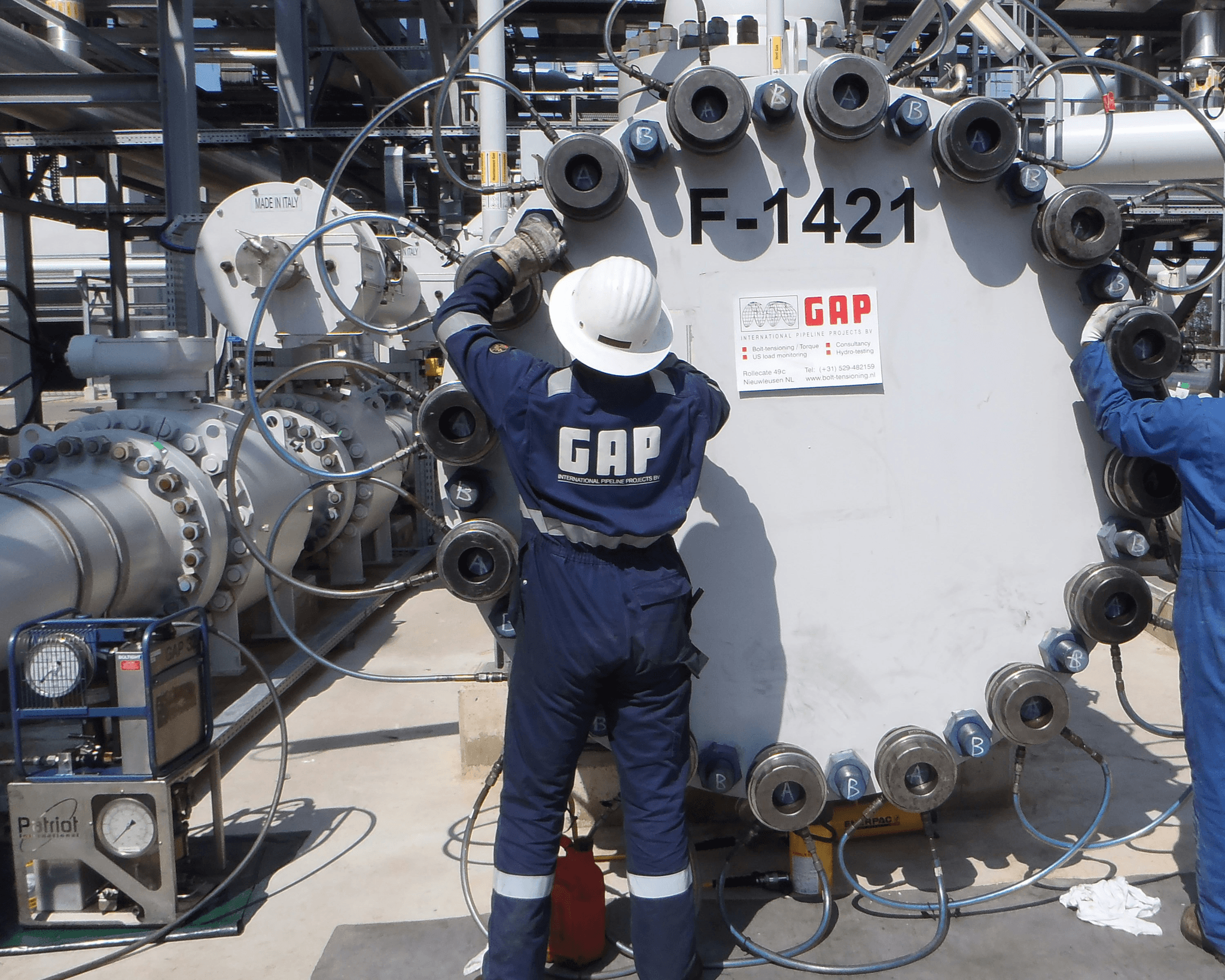

When it comes to heavy-duty applications in industrial and commercial settings, the need for reliable and safe equipment is paramount. Explosion-proof electric actuators, such as the ATEX Approved Explosion Proof Electric Actuator, are designed to withstand harsh conditions and provide seamless operation in demanding environments. These actuators are commonly used in oil and gas refineries, chemical plants, and other hazardous locations where the risk of explosion is a constant concern.

Industrial and Commercial Use Cases

Explosion-proof electric actuators are widely utilized in various industries due to their ability to operate safely in potentially explosive atmospheres. They are commonly employed in valve automation systems for controlling the flow of liquids and gases in critical processes. These actuators play a crucial role in ensuring the efficient and safe operation of industrial equipment, making them indispensable for heavy-duty applications.

Protection Against Ignition Sources

One of the key features of explosion-proof electric actuators is their capability to protect against ignition sources that could trigger an explosion. These actuators are specifically designed to contain any internal explosion and prevent it from igniting the surrounding atmosphere. This level of protection is achieved through robust construction, specialized seals, and advanced engineering that mitigate the risk of sparking or overheating.

Meeting Rigorous Safety Regulations

In high-risk environments where flammable gases, vapors, or dust particles are present, stringent safety regulations must be adhered to at all times. Explosion-proof electric actuators are engineered to comply with these regulations by undergoing rigorous testing and certification processes. This ensures that they meet industry standards for safety and performance, providing peace of mind for operators working in hazardous areas.

What Sets Haisen's Part-Turn Valve Electric Actuator Apart

Haisen's Part-Turn Valve Electric Actuator stands out due to its innovative technology and design, offering cutting-edge features that ensure optimal performance and safety in industrial settings. With a focus on precision engineering and advanced materials, this electric actuator is at the forefront of the industry.

Innovative Technology and Design

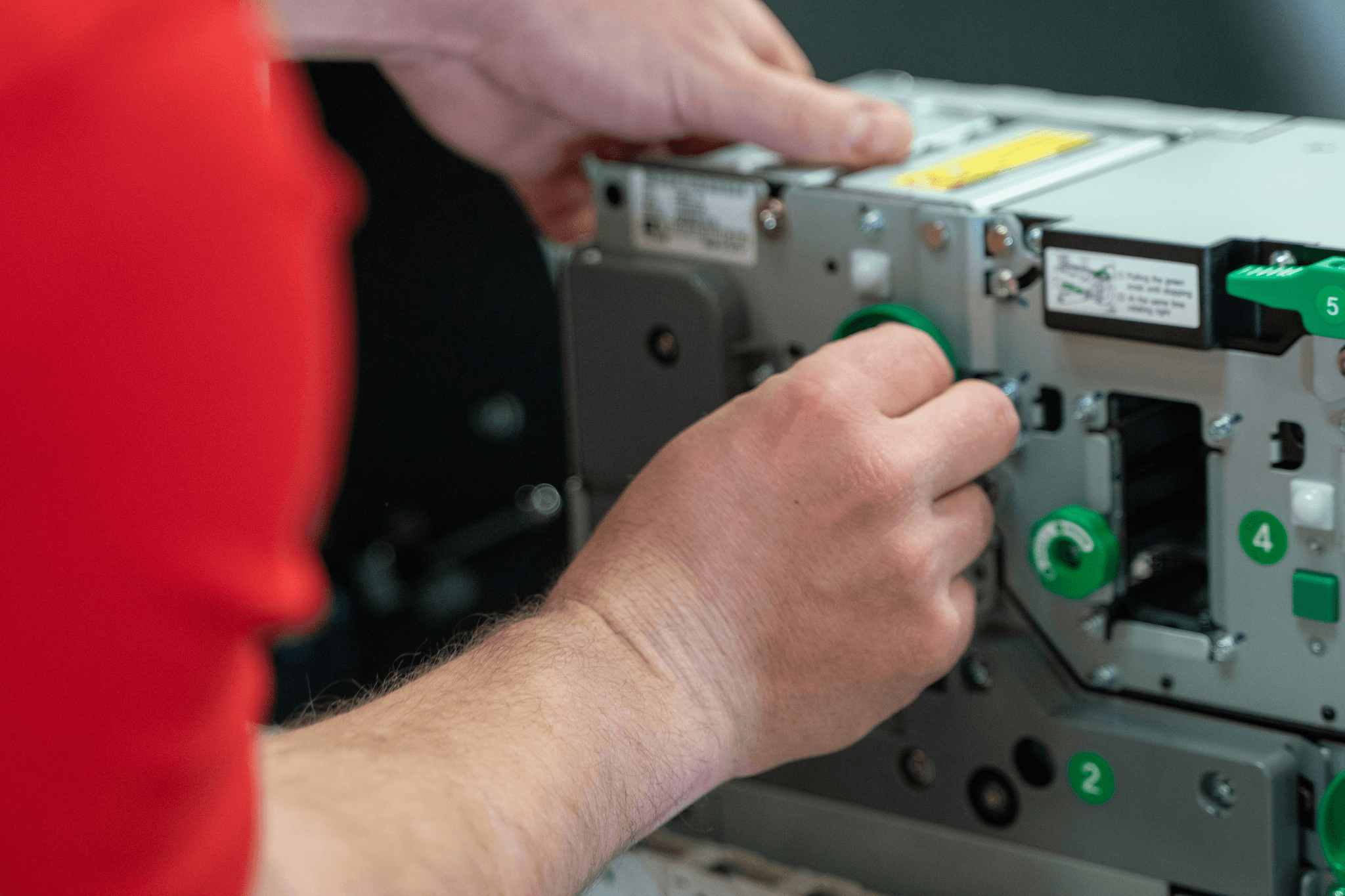

Haisen's electric actuator incorporates state-of-the-art technology, such as advanced control systems and intelligent monitoring capabilities, to provide seamless operation and precise control over valve movements. The design is sleek and compact, making it easy to install in various industrial environments without compromising on functionality.

Customer Satisfaction and Trust

With a strong emphasis on customer satisfaction, Haisen's electric actuators are built to exceed expectations in terms of reliability, durability, and overall performance. The brand has earned the trust of numerous industries by consistently delivering high-quality products that meet the most stringent requirements.

Competitive Advantage in the Market

Haisen's Part-Turn Valve Electric Actuator offers a competitive advantage in the market with its superior features, exceptional build quality, and reliable performance. It has set a new standard for explosion-proof electric actuators by providing unmatched value for industrial applications.

Conclusion

Explosion-proof electric actuators, such as the ATEX Approved Explosion Proof Electric Actuator, offer unparalleled versatility in industrial settings. These robust devices enhance safety and efficiency by providing reliable performance in hazardous environments. When choosing the right electric actuator for your needs, consider the strength of explosion-proof actuators and their ability to meet heavy-duty requirements.

The Versatility of Explosion Proof Electric Actuators

Explosion-proof electric actuators are incredibly versatile, suitable for a wide range of industrial applications. Whether it's in oil and gas, chemical processing, or wastewater treatment plants, these actuators provide reliable and safe operation in potentially explosive atmospheres.

Enhancing Safety and Efficiency in Industrial Settings

The use of explosion-proof electric actuators significantly reduces the risk of ignition sources leading to catastrophic accidents in industrial settings. Their fail-safe capabilities and compliance with industry standards ensure that operations run smoothly without compromising safety.

Choosing the Right Electric Actuator for Your Needs

When selecting an electric actuator for your specific needs, consider factors such as power and performance, reliability, environmental adaptability, and compliance with safety regulations. The Haisen Part-Turn Valve Electric Actuator stands out for its innovative technology and design, customer satisfaction, and competitive advantage in the market.

With their exceptional versatility and safety features, explosion-proof electric actuators are essential components for enhancing operational efficiency while prioritizing worker safety in hazardous environments. Choose wisely to ensure that you have the right electric actuator to meet your specific industrial needs!