Introduction

In a world where safety and efficiency are paramount, the importance of coefficient of friction testing cannot be overstated. Understanding and measuring the friction between surfaces is crucial for ensuring safety and compliance with industry standards, whether on the road or at the airport. As technology advances, so does the need to upgrade equipment to keep up with the latest models that offer enhanced accuracy and precision.

Importance of Coefficient of Friction Testing

Friction is a fundamental force in physics that significantly impacts vehicle safety and performance. A coefficient of friction meter, or friction tester, measures this crucial factor across industries like transportation and aviation. Precise testing equipment ensures surfaces provide adequate grip for safe vehicle operation.

Key applications of friction testers include:

- Road surface analysis: Determining the grip of different road conditions for optimal tire design.

- Brake system evaluation: Assessing brake pad and rotor friction for efficient stopping power.

- Aircraft runway inspection: Verifying runway conditions for safe takeoff and landing.

These devices contribute to safer and more efficient transportation systems by accurately measuring friction.

Understanding the Latest Model

The latest friction test equipment, such as the Sarsys friction tester, offers advanced features that cater to the evolving needs of industries reliant on accurate friction measurements. These include high-precision components, specialized tires for compliance, computer control with Chinese Windows OS, and an external electronic calibration device for added reliability.

Benefits of Upgrading Equipment

Upgrading to the latest coefficient of friction testing machine presents numerous benefits, including increased safety measures, enhanced accuracy and precision in measurements, improved testing efficiency, and extended capabilities for various aviation and road maintenance industries.

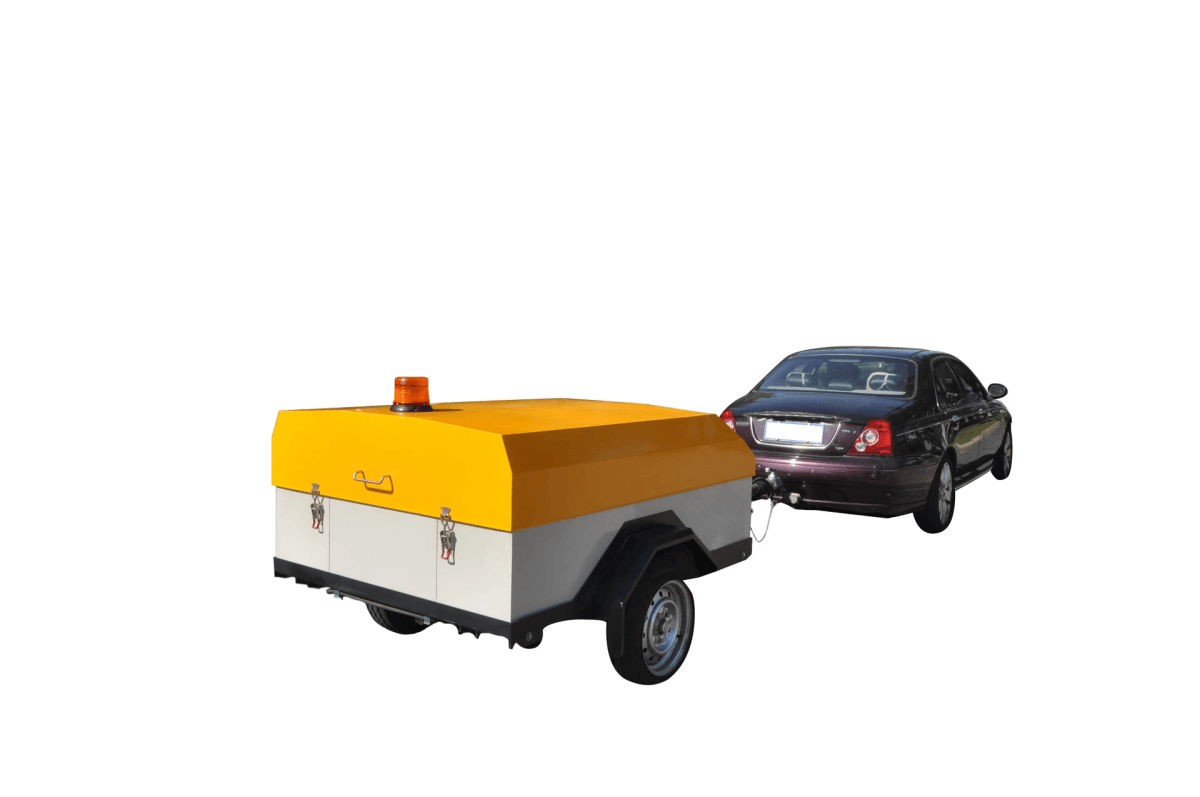

Features of Haisen's BHM01/02 Surface Friction Tester

Regarding the latest friction testing equipment, Haisen's BHM01/02 Surface Friction Tester stands out with its innovative features. The safety design for vehicle systems ensures that testing is conducted with the utmost precaution, preventing potential accidents. This friction tester's reliability is unmatched, thanks to its high-precision components that guarantee accurate and consistent results.

Safety Design for Vehicle Systems

The safety design for vehicle systems in Haisen's BHM01/02 Surface Friction Tester prioritizes the well-being of operators and vehicles during testing. With advanced safety measures, such as emergency stop buttons and protective barriers, users can conduct tests with confidence and peace of mind.

Reliability with High-Precision Components

The high-precision components integrated into Haisen's BHM01/02 Surface Friction Tester ensure that every test yields reliable and consistent results. From the sensors to the data acquisition system, each component is carefully calibrated to deliver accurate measurements of friction coefficients on various surfaces.

Acceleration Capability of Tested Vehicles

One of the standout features of Haisen's BHM01/02 Surface Friction Tester is its ability to accommodate a wide range of vehicles with varying acceleration capabilities. Whether testing high-performance sports cars or heavy-duty trucks, this friction tester can accurately assess their traction on different road surfaces.

External Electronic Calibration Device

Haisen's BHM01/02 Surface Friction Tester has an external electronic calibration device to maintain precision and accuracy over time. This allows operators to calibrate the equipment regularly, ensuring it delivers reliable results throughout its lifespan.

Specialized Tires for Compliance

Haisen's BHM01/02 Surface Friction Tester is designed to accommodate specialized tires that comply with industry standards for friction testing. This ensures that tests using tires accurately represent real-world driving conditions, leading to more meaningful and applicable results.

Computer Control with Chinese Windows OS

Integrating a computer control system with Chinese Windows OS in Haisen's BHM01/02 Surface Friction Tester provides users a user-friendly interface for seamless operation and data management. This allows for easy control over test parameters and efficient data analysis.

Water System for Extended Testing

With a built-in water system, Haisen's BHM01/02 Surface Friction Tester enables extended testing on wet surfaces, simulating realistic driving conditions in various weather scenarios.

Achievements and Implementation

The achievements made possible by Haisen's BHM01/02 Surface Friction Tester have been instrumental in advancing friction testing capabilities across industries such as transportation, automotive engineering, and civil infrastructure development.

Advantages of Upgrading to the Latest Model

Upgrading to the latest model of a coefficient of friction testing machine offers numerous benefits for various industries. The advanced safety measures incorporated into the new equipment ensure a secure testing environment, reducing the risk of accidents or mishaps during testing procedures. Enhanced accuracy and precision guarantee reliable and consistent results, allowing for more informed decision-making based on accurate data. Furthermore, the improved testing efficiency enables quicker turnaround times and increased productivity when conducting friction tests.

Increased Safety Measures

The latest coefficient of friction meter model prioritizes safety with state-of-the-art features such as automatic emergency shut-off systems and enhanced protective enclosures to prevent potential hazards during testing. With built-in safety protocols and fail-safes, operators can conduct tests with peace of mind, knowing that the equipment is designed to prioritize their well-being and safety above all else.

Enhanced Accuracy and Precision

One key advantage of upgrading to the latest friction coefficient tester is its unparalleled accuracy and precision. With cutting-edge sensor technology and high-performance components, the new equipment ensures that test results are consistently reliable, providing invaluable data for research, development, and compliance purposes across different industries.

Improved Testing Efficiency

Upgrading to the latest model of a coefficient of friction tester offers substantial benefits beyond safety and accuracy. Advanced automation significantly enhances testing efficiency. Streamlining processes and reducing manual labor can achieve higher productivity without compromising quality or reliability.

Key advantages of upgrading include:

- Accelerated testing cycles: Automated features expedite test procedures, allowing more tests to be conducted in less time.

- Improved data accuracy: Modern models often incorporate precision sensors and advanced algorithms for enhanced data reliability.

- Cost savings: Reduced labor requirements and increased efficiency contribute to overall cost reduction.

Incorporating these advancements into your testing operations can substantially improve productivity, data quality, and cost-effectiveness.

By understanding the critical role of a reliable coefficient of friction tester in various industries, you can make informed decisions to optimize your testing processes and ensure compliance with safety standards.

Applications in Aviation Industry

Using coefficient of friction testing equipment in airports is crucial for ensuring the safety and efficiency of runway operations. With the advanced technology of a friction coefficient tester, airports can accurately measure the friction between the runway surface and aircraft tires, allowing for informed decision-making regarding takeoff and landing conditions. This contributes to aviation safety by minimizing the risk of skidding or hydroplaning during critical moments.

Importance of Friction Testing in Airports

The importance of friction testing in airports cannot be overstated, as it directly impacts the safety and performance of aircraft operations. By utilizing specialized road friction testers, airport authorities can assess and monitor runway conditions to ensure optimal levels of grip for aircraft tires. This proactive approach significantly reduces the likelihood of accidents caused by inadequate friction, ultimately safeguarding passengers and crew members.

Compliance with Aviation Standards

Friction test equipment plays a vital role in helping airports comply with stringent aviation standards set forth by regulatory bodies such as the International Civil Aviation Organization (ICAO) and the Federal Aviation Administration (FAA). By utilizing a Sarsys friction tester or runway friction testing equipment, airport authorities can demonstrate adherence to these standards by consistently measuring and maintaining appropriate levels of friction on runways.

Impact on Runway Safety and Maintenance

The impact of using advanced coefficient of friction testing machines extends to runway safety and maintenance practices within airports. Regular testing allows for early identification of potential hazards, such as rubber deposits or contaminants on runways, enabling prompt intervention to mitigate risks. Additionally, data obtained from these tests informs maintenance schedules, leading to improved longevity and performance of runway surfaces.

Impact on Road Safety and Transportation

Friction testing is crucial in road maintenance, ensuring that road surfaces are safe and durable for vehicles. Using advanced friction test equipment such as the Sarsys friction tester, road authorities can accurately measure the friction coefficient of different road surfaces, identifying areas requiring maintenance or improvement.

Role of Friction Testing in Road Maintenance

The use of a coefficient of friction meter is essential in road maintenance, as it allows for the identification of low-friction areas prone to skidding and accidents. Regularly conducting friction tests, road authorities can proactively address issues such as worn-out surfaces, oil spills, or water accumulation, ensuring that roads remain safe for drivers and pedestrians.

Contribution to Vehicle Safety and Performance

Friction testing equipment benefits road maintenance and contributes to vehicle safety and performance. Manufacturers can develop tires with optimal grip levels by accurately measuring the friction coefficient of different surfaces, enhancing vehicle stability and control. This ultimately improves overall driving safety and performance in various road conditions.

Influence on Traffic Management

Friction testing significantly influences traffic management by providing valuable data on road surface conditions. With this information, traffic authorities can make informed decisions regarding speed limits, lane closures, or detours during adverse weather conditions or construction work. This proactive approach helps minimize accidents and traffic congestion.

Future of Friction Testing Equipment

The future of friction testing equipment is poised for significant technological advancements, with the development of more sophisticated and precise coefficient of friction testing machines. These machines will incorporate cutting-edge sensor technology, advanced data analysis capabilities, and improved user interfaces to provide more accurate and reliable test results.

Technological Advancements

The next generation of coefficient of friction meters will revolutionize surface analysis by integrating advanced technologies. These cutting-edge devices will feature:

- State-of-the-art sensors and measurement techniques for real-time monitoring and analysis of surface friction properties.

- Sophisticated software algorithms for precise calculation of the coefficient of friction, enhancing accuracy and reliability.

- Artificial intelligence and machine learning integration for optimized performance and efficiency.

- It has advanced data visualization capabilities for comprehensive and user-friendly presentation of friction data.

These meters will empower users to make informed decisions in the automotive, aerospace, and manufacturing industries by providing clear and actionable insights. Ultimately, the enhanced understanding of surface friction properties will drive product design and performance advancements.

Trends in

the Friction Testing Industry

As industries prioritize safety and compliance, there is a growing trend toward adopting advanced friction test equipment such as the Sarsys friction tester. This trend reflects a shift towards more sophisticated testing methods that provide comprehensive data on surface friction characteristics, enabling better decision-making in road maintenance, airport runway safety, and vehicle performance optimization.

Potential for Further Innovation

With ongoing research and development efforts in surface friction testing, this area has vast potential for further innovation. Future advancements may include integrating unmanned aerial vehicles (UAVs) for aerial friction testing and developing portable handheld devices for on-the-go friction measurements. These innovations can potentially revolutionize how surface friction is assessed across various industries.

Advanced Testing Capabilities for Various Industries

Investing in friction testing equipment is essential for industries prioritizing safety and compliance. Upgrading to the latest model, such as the Haisen BHM01/02 surface friction tester, ensures enhanced accuracy and precision in measuring road and runway friction. This investment guarantees safety and advances testing capabilities across various sectors.

Investing in Friction Testing Equipment

Industries can significantly enhance their testing processes by investing in a high-quality coefficient of friction testing machine like the Haisen BHM01/02. This equipment offers several key benefits:

- Improved Efficiency and Accuracy: Advanced features such as external electronic calibration devices and specialized tires ensure precise and reliable test results.

- Long-Term Cost Savings: By preventing costly errors and reducing the need for retesting, industries can optimize resource allocation.

- User-Friendly Operation: The equipment's intuitive design minimizes training requirements and human error.

Industries can substantially improve testing performance and overall productivity by incorporating the Haisen BHM01/02 into their operations.

Ensuring Safety and Compliance

Using a reliable friction coefficient tester is crucial in ensuring safety and compliance with industry standards. Upgrading to the latest model increases safety measures, impacting road safety, transportation, and aviation industry standards. This investment guarantees all necessary precautions to maintain safe operating conditions for vehicles on roads and runways.

Upgrading to the latest friction coefficient tester model also allows for more efficient and accurate testing, resulting in improved data collection and analysis. This enhanced capability benefits various industries by providing valuable insights into the performance of different types of surfaces under varying conditions. With this advanced testing technology, organizations can make informed maintenance, construction, and design decisions, ultimately contributing to overall safety and compliance with industry regulations.

Implementing cutting-edge friction test equipment like the Haisen BHM01/02 surface friction tester has far-reaching effects across multiple industries. Its impact on road maintenance, vehicle performance, traffic management, airport operations, and runway safety cannot be overstated. By advancing testing capabilities with this equipment, industries can elevate their standards and ensure optimal safety measures are met.

Furthermore, the Haisen BHM01/02 surface friction tester provides real-time data and analysis, allowing industries to make informed decisions regarding maintenance schedules, vehicle design improvements, and traffic flow optimization. This level of precision and accuracy can lead to significant cost savings by identifying potential safety hazards before they become major issues. Additionally, using this cutting-edge equipment demonstrates a commitment to excellence and innovation within each respective industry.