Introduction

In the world of industrial automation, rotary electric actuators play a crucial role in controlling valve operations and other mechanical processes. These innovative devices provide rotational power to valves, dampers, and other equipment, enabling precise control and manipulation. As a key component in industrial automation systems, rotary electrical actuators are essential for optimizing operational efficiency and ensuring smooth functionality.

Understanding Rotary Electric Actuators

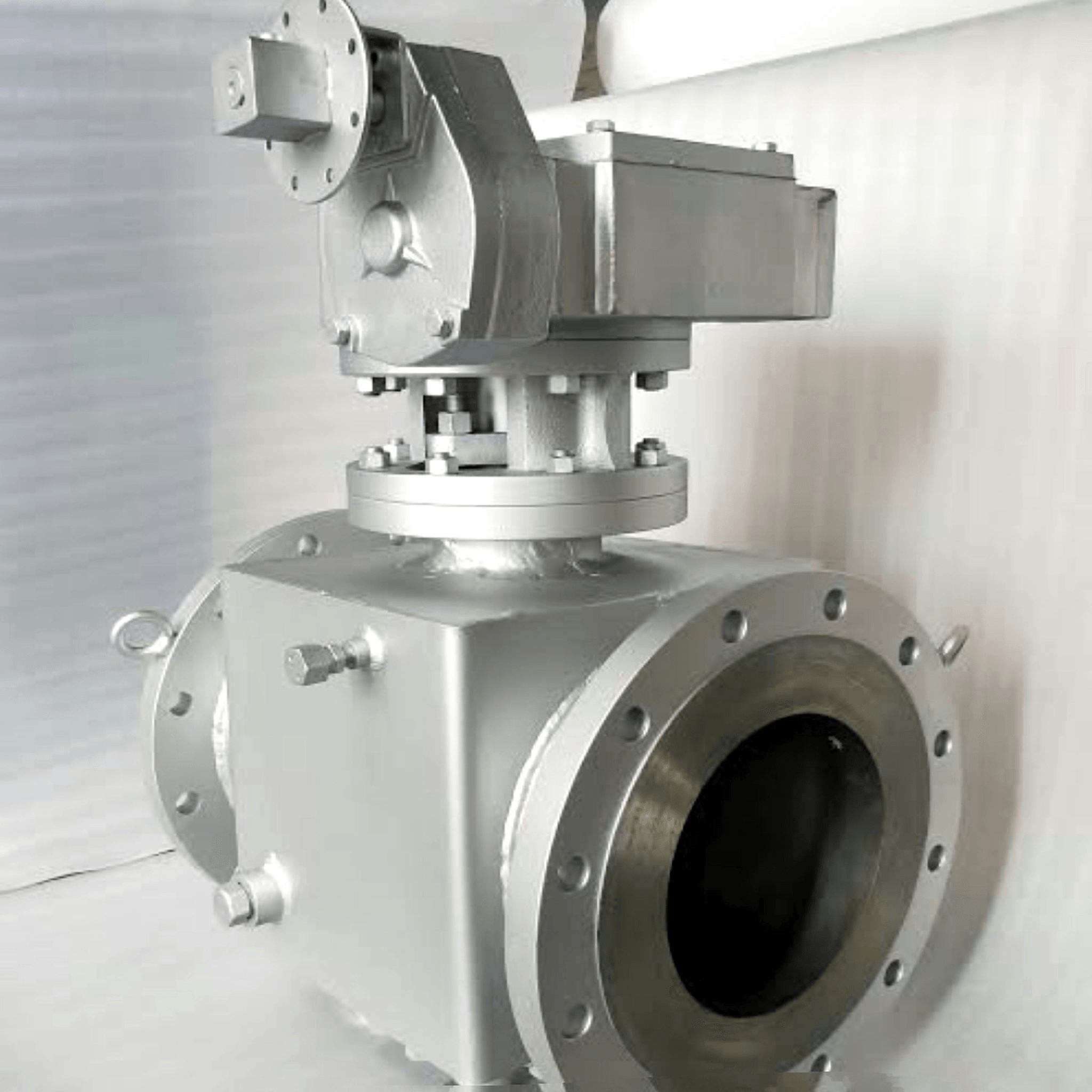

A rotary electric actuator is a type of device that converts electrical energy into rotational motion to control the position of various mechanical components such as valves, dampers, and other industrial equipment. This mechanism allows for precise positioning and adjustment of these components, offering enhanced control and flexibility in industrial processes.

Exploring the Functionality of Rotary Electrical Actuators

The functionality of rotary electric actuators lies in their ability to convert electrical energy into mechanical motion through the use of gears, motors, and other components. By harnessing this rotational power, these actuators enable precise positioning and manipulation of valves and other equipment in industrial settings.

These actuators play a crucial role in ensuring the efficiency and accuracy of industrial processes, as they can be programmed to perform specific movements with great precision. Additionally, rotary electric actuators offer a high level of reliability, making them ideal for continuous operation in demanding environments. The ability to control these actuators remotely further enhances their utility, allowing for seamless integration into automated systems and reducing the need for manual intervention.

The Importance of Rotary Electric Actuators

Rotary electric actuators play a vital role in ensuring efficient operation and control of valves in industrial processes. Their ability to provide accurate positioning and reliable performance makes them indispensable for maintaining optimal functionality in various applications. These actuators are essential for enhancing operational efficiency, improving safety, and minimizing downtime in industrial operations.

Furthermore, rotary electric actuators are designed to withstand harsh industrial environments, making them highly durable and reliable. Their robust construction and resistance to extreme temperatures, humidity, and dust ensure long-term performance and minimal maintenance requirements. This durability contributes to cost savings and increased productivity, as these actuators can operate continuously without the need for frequent replacements or repairs.

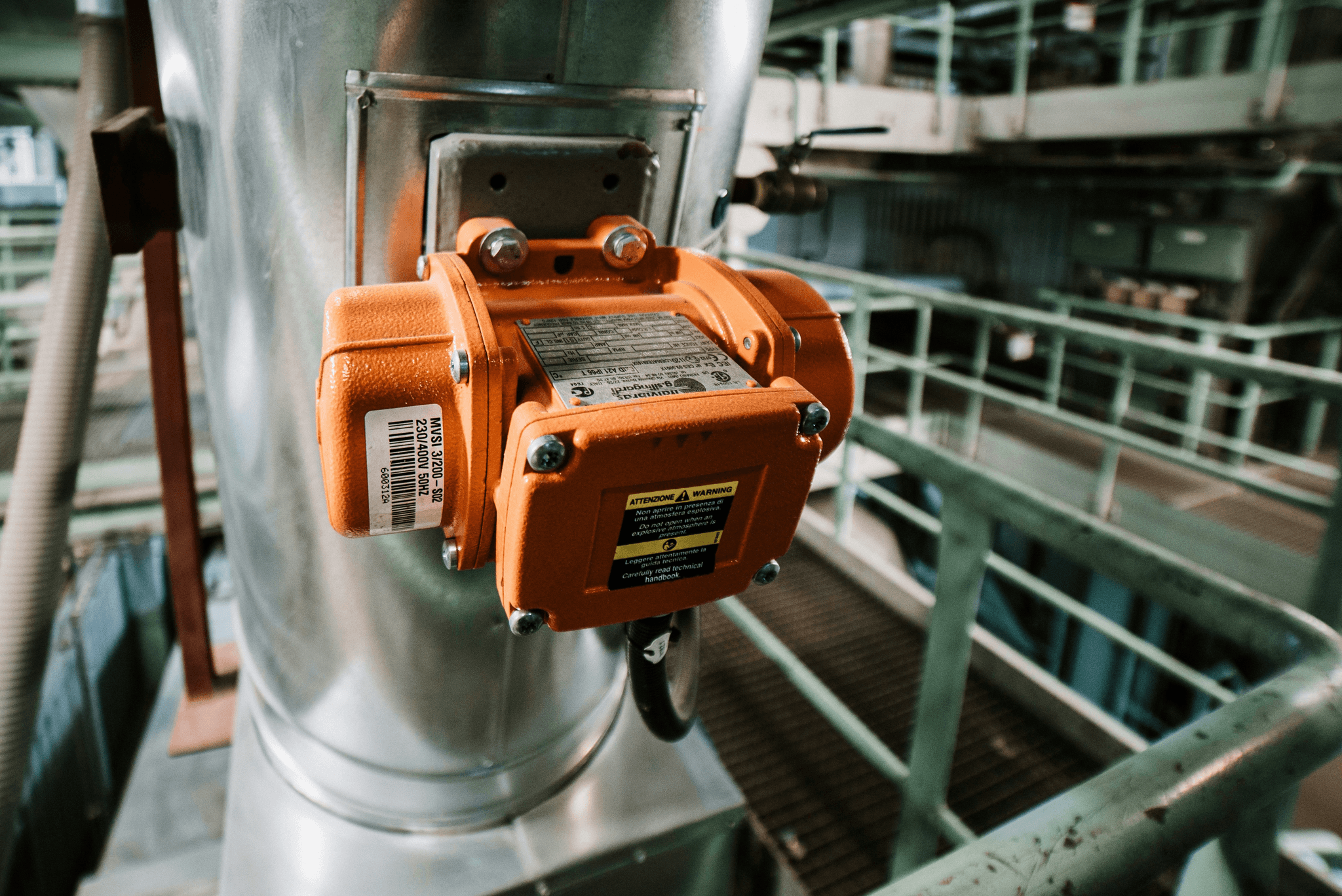

Haisen's Part-Turn Valve Electric Actuator

Haisen's Part-Turn Valve Electric Actuator is a cutting-edge rotary electric actuator designed to provide efficient and precise control over various valve types. With its robust features and capabilities, this actuator offers seamless operation in industrial environments, ensuring optimal performance and reliability.

Features and Capabilities of Haisen's Part-Turn Valve Electric Actuator

Equipped with advanced technology, Haisen's Part-Turn Valve Electric Actuator boasts features such as torque control, position feedback, and adjustable speed settings. This allows for accurate valve positioning and seamless integration with control systems, enhancing overall operational efficiency.

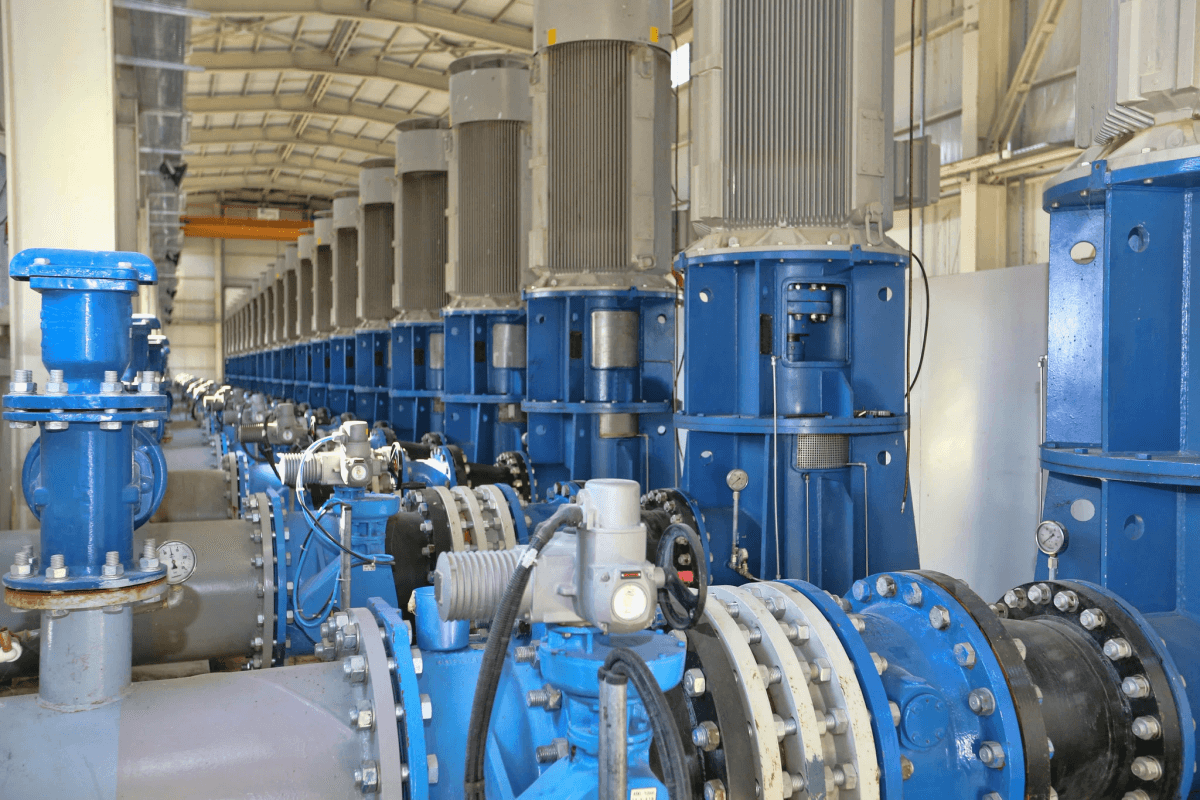

Application in Controlling Butterfly Valves, Ball Valves, and Plug Valves

This innovative actuator is versatile in its application, providing precise control over butterfly valves, ball valves, and plug valves. Its adaptability makes it a valuable asset in various industrial settings where different types of valves are utilized for fluid or gas flow regulation.

Remote and Local Operation of Haisen's Part-Turn Valve Electric Actuator

Haisen's Part-Turn Valve Electric Actuator offers the convenience of both remote and local operation, allowing operators to adjust valve positions from a central control room or directly at the valve site. This flexibility enhances operational efficiency and reduces the need for manual intervention.

Benefits of Rotary Electric Actuators

Increased Efficiency in Industrial Operations

Rotary electric actuators provide increased efficiency in industrial operations by offering precise and reliable control over valve manipulation. This leads to streamlined processes, reduced energy consumption, and improved productivity. With their ability to automate repetitive tasks, rotary electric actuators contribute to a more efficient and cost-effective operation in various industries.

Enhanced Control and Precision in Valve Manipulation

The use of rotary electric actuators ensures enhanced control and precision in valve manipulation, allowing for accurate positioning and adjustment of valves. This level of control is essential for maintaining optimal performance and preventing costly errors or inefficiencies. The ability to fine-tune valve operation with rotary electric actuators results in improved overall system reliability.

Cost-Effective Solutions for Valve Automation

Rotary electric actuators offer cost-effective solutions for valve automation by reducing the need for manual intervention and minimizing the risk of human error. This not only saves time and labor costs but also enhances safety by eliminating the need for personnel to be present in hazardous environments during valve operations.

Advantages of Using Rotary Electric Actuators

Flexibility and Adaptability in Various Industrial Environments

Rotary electric actuators offer unparalleled flexibility and adaptability, making them suitable for a wide range of industrial applications. Whether it's controlling valve operations in oil and gas refineries or managing flow rates in water treatment plants, these actuators can seamlessly integrate into diverse environments, providing efficient and reliable performance.

Minimization of Maintenance and Downtime

One of the key advantages of rotary electric actuators is their ability to minimize maintenance requirements and downtime. With their robust design and precision engineering, these actuators ensure prolonged operational efficiency, reducing the need for frequent maintenance interventions. This ultimately translates to cost savings and enhanced productivity for industrial facilities.

Improvement in Overall Operational Safety and Reliability

By utilizing rotary electric actuators, industrial operations can experience a significant improvement in overall safety and reliability. These actuators are equipped with advanced safety features such as overload protection and fail-safe mechanisms, ensuring that valve operations are carried out with utmost precision and without compromising the safety of personnel or equipment.

Common Problems with Actuators and Solutions

Addressing Potential Issues in Actuator Performance

One common problem with rotary electric actuators is the occurrence of mechanical wear and tear over time, leading to decreased performance and efficiency. This can result in issues such as reduced torque output and slower valve operation. To address this, regular maintenance and lubrication of the actuator components are essential to ensure optimal performance and longevity.

Troubleshooting Tips for Actuator Malfunctions

In some cases, actuators may experience electrical malfunctions due to issues such as wiring problems or sensor failures. When encountering such malfunctions, it is crucial to conduct a thorough inspection of the electrical connections and sensors to identify any potential issues. Additionally, performing diagnostic tests using specialized equipment can help pinpoint the root cause of the malfunction and facilitate timely repairs.

Best Practices for Maintaining Optimal Actuator Functionality

To maintain optimal functionality of rotary electric actuators, implementing best practices such as regular inspection, cleaning, and calibration are paramount. This includes checking for any signs of corrosion or damage, ensuring proper alignment of components, and calibrating the actuator settings as needed. By adhering to these best practices, operators can mitigate potential issues and prolong the lifespan of their rotary electric actuators.

The Most Efficient Type of Actuator

When comparing different types of actuators, it becomes evident that the rotary electric actuator stands out due to its versatility and precision in controlling rotational movements. Unlike other actuators, such as pneumatic or hydraulic ones, the rotary electric actuator offers a wider range of applications and can be easily integrated into various industrial systems.

Comparing Different Types of Actuators

While pneumatic and hydraulic actuators have their advantages in certain applications, they often lack the precision and control offered by rotary electric actuators. Additionally, these traditional actuators may require more maintenance and are less adaptable to different environments compared to their electrical counterpart. Rotary electric actuators also offer a wider range of motion and can be easily integrated with modern control systems, allowing for seamless automation and improved efficiency in various industrial processes. Furthermore, the ability to accurately adjust speed and torque makes rotary electric actuators ideal for applications where precise positioning and movement are essential, giving them a clear edge over pneumatic and hydraulic alternatives.

Highlighting the Superiority of Rotary Electric Actuators

One key advantage of rotary electric actuators is their ability to provide precise and consistent rotational power, making them ideal for applications that require accurate positioning and control. Their compact design also allows for easy installation and integration into existing systems, reducing downtime and maintenance costs.

In addition, rotary electric actuators are highly versatile and can be used in a wide range of industries, including manufacturing, automotive, aerospace, and robotics. Their ability to deliver precise and consistent rotational power makes them suitable for tasks such as valve control, conveyor belt positioning, and robotic arm movement. This versatility allows for seamless integration into various applications, providing a reliable solution for complex automation needs.

Applications and Industries Where Rotary Electric Actuators Excel

Rotary electric actuators are commonly used in industries such as oil and gas, water treatment, power generation, and manufacturing due to their ability to efficiently control valves, dampers, and other rotating equipment. Their reliability and adaptability make them a preferred choice for critical operations where precision is paramount.

Conclusion

In conclusion, the use of rotary electric actuators has revolutionized industrial automation, providing efficient and precise control over valve manipulation. Embracing innovations in actuator technology is crucial for enhancing operational efficiency and ensuring seamless industrial processes. By leveraging the power of rotary electric actuators, industries can optimize their operations and stay ahead in the competitive market.

Leveraging the Power of Rotary Electric Actuators

Rotary electric actuators offer unmatched power and precision, making them indispensable in various industrial applications. With their ability to provide seamless rotational movement, these actuators play a pivotal role in ensuring optimal performance and reliability in valve automation systems.

Rotary electric actuators are continuously evolving to meet the ever-changing demands of industrial automation. The latest innovations in actuator technology have led to the development of more compact and lightweight designs, allowing for easier installation and integration into existing systems. Additionally, advancements in materials and construction have enhanced the durability and longevity of these actuators, minimizing maintenance requirements and downtime for increased productivity.

Embracing Innovations in Actuator Technology

As industries continue to evolve, embracing innovations in actuator technology is essential for staying competitive. The advancements in rotary electric actuators have paved the way for enhanced efficiency, control, and adaptability, enabling businesses to meet the demands of modern industrial processes.

The integration of rotary electric actuators has also led to a reduction in maintenance costs, as these innovative technologies are designed for longevity and durability. Additionally, the precision and accuracy of rotary electric actuators have improved the overall quality of industrial processes, leading to higher customer satisfaction and loyalty. By embracing these advancements, industries can position themselves as leaders in their respective fields, attracting new business opportunities and partnerships.

Enhancing Industrial Operations with Rotary Electric Actuators

By utilizing rotary electric actuators, industries can also benefit from improved environmental sustainability. These actuators can help reduce energy consumption and emissions by optimizing the efficiency of valve systems. This not only aligns with corporate social responsibility goals but also contributes to a greener, more sustainable industrial landscape. Additionally, the precise control offered by these actuators minimizes the risk of leaks or spills, further enhancing environmental protection efforts.