Introduction

In the world of industrial automation, electric rotating actuators play a crucial role in providing precise and efficient control over various mechanical systems. These advanced devices are designed to convert electrical energy into rotational motion, offering a wide range of benefits and applications across different industries.

Understanding Electric Rotating Actuators

Electric rotating actuators are electromechanical devices that are used to control the rotation of a mechanical system, such as valves, dampers, and other components. These actuators offer precise and reliable operation, making them ideal for applications that require accurate positioning and control.

Electric rotating actuators are designed to be compact and lightweight, allowing for easy installation and integration into existing systems. Their low power consumption and high efficiency make them cost-effective and environmentally friendly options for automation. Additionally, these actuators can be easily programmed and controlled, providing flexibility in operation and reducing the need for manual adjustments.

Benefits of Electric Rotary Actuators

The benefits of electric rotary actuators are numerous, including high efficiency, low maintenance requirements, and the ability to provide consistent torque output. Additionally, these actuators offer enhanced flexibility in terms of speed and positioning control, making them suitable for a wide range of industrial applications.

Furthermore, electric rotary actuators are known for their precise and accurate positioning capabilities, allowing for seamless integration into automated systems. This level of precision is crucial in industries such as manufacturing and robotics, where consistent and reliable performance is essential. The ability to fine-tune the speed and positioning of these actuators also contributes to improved productivity and efficiency in various industrial processes.

Applications of Electric Rotating Actuators

Electric rotating actuators find extensive use in various industries such as petrochemicals, metallurgy, hydropower plants, municipal engineering, and shipbuilding. Their ability to provide precise control over valve and damper operations makes them indispensable in ensuring smooth and efficient industrial processes.

Electric rotating actuators are also widely used in the aerospace industry, where they play a crucial role in controlling the movement of aircraft components such as flaps, landing gear, and engine thrust reversers. Their ability to deliver precise and reliable motion control is essential for ensuring the safety and efficiency of air travel. Additionally, electric rotating actuators are favored for their compact size and lightweight design, making them ideal for use in the limited space and weight constraints of aircraft.

Superior Electric Rotating Actuators

When it comes to superior electric rotating actuators, Haisen's Part-Turn Valve Electric Actuator stands out for its precision and reliability. This innovative actuator is designed to provide seamless control in various industrial applications, making it a top choice for engineers and automation experts looking for high-performance solutions.

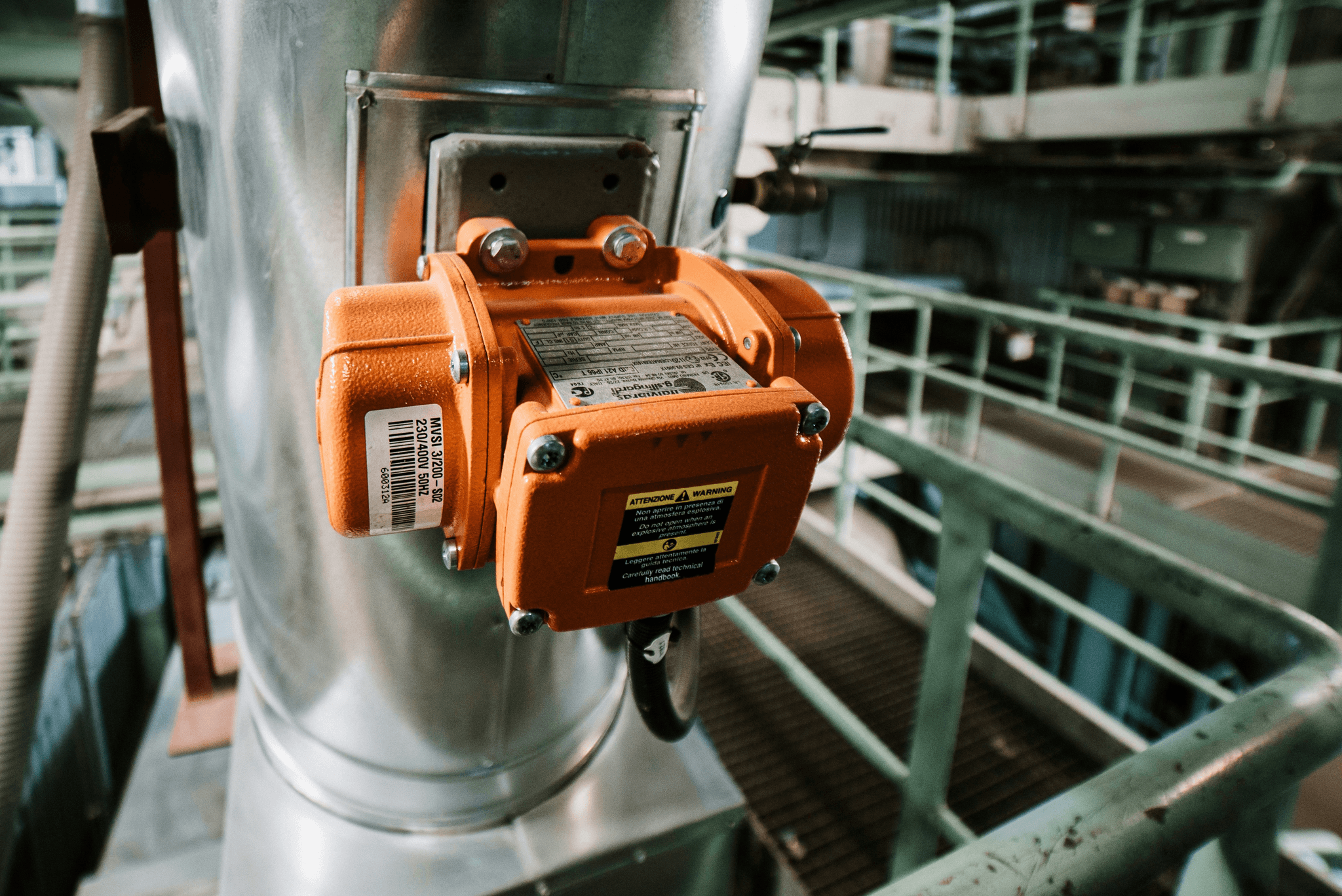

Haisen's Part-Turn Valve Electric Actuator

Haisen's Part-Turn Valve Electric Actuator is equipped with advanced technology that ensures smooth and accurate rotation, allowing for precise positioning of valves and other equipment. With its robust construction and efficient operation, this electric rotating actuator is ideal for demanding environments where reliability is crucial.

Furthermore, Haisen's Part-Turn Valve Electric Actuator is designed to withstand harsh conditions, making it suitable for use in industries such as oil and gas, petrochemical, and power generation. Its high torque capabilities ensure that it can effectively operate valves of varying sizes and weights, providing a versatile solution for a wide range of applications. This electric actuator also features built-in safety measures to prevent damage to the equipment or surrounding infrastructure.

High torque Electric Rotary Actuator

For applications that require a powerful performance, the high torque electric rotary actuator delivers exceptional strength and durability. Its high torque capabilities make it suitable for heavy-duty tasks, providing the necessary force to operate valves, dampers, and other mechanical components with ease.

In addition to its high torque capabilities, the electric rotary actuator also offers precise control and positioning, making it suitable for applications that require accuracy and reliability. Its robust construction and advanced technology ensure smooth operation and consistent performance, even in challenging environments. With a compact design and easy installation, this rotary actuator is a cost-effective solution for a wide range of industrial and commercial applications.

Versatility of 90 Degree Rotary Actuator

The 90 degree rotary actuator's versatility extends beyond just its angular movement capabilities. Its compact design and high torque output make it suitable for a wide range of industrial applications, from conveyor systems to robotic arms. This adaptability allows for seamless integration into existing machinery, minimizing downtime and maximizing productivity.

Efficiency and Performance

Advantages of Electric Rotary Actuator 90 degrees

Electric rotary actuators with a 90-degree rotation also offer the advantage of compact and lightweight design, making them easy to install and integrate into existing industrial systems. This not only saves space but also reduces the overall weight of the equipment, leading to more efficient operation and lower energy consumption. Additionally, their durable construction and minimal maintenance requirements contribute to cost savings and long-term reliability.

Impact of Electric Rotary Actuator in Industrial Use

The impact of electric rotary actuators in industrial use is undeniable, as they provide reliable and consistent performance in demanding environments. With their high torque capabilities and smooth operation, these actuators are essential for the efficient functioning of manufacturing facilities, power plants, and other industrial settings.

Electric rotary actuators also offer enhanced control and precision, allowing for more accurate positioning and movement of industrial equipment. This level of control is crucial in ensuring the safety of workers and the quality of production processes. Additionally, the 12v power supply requirement for these actuators makes them versatile and easily adaptable to a wide range of industrial applications, further enhancing their impact on industrial operations.

Enhanced Control with Rotary Actuator 12v

The use of a 12v electric rotary actuator offers enhanced control and flexibility in various applications. This low-voltage option allows for precise movement and positioning while consuming minimal power, making it an ideal choice for remote or battery-powered operations such as robotics, automotive systems, and agricultural machinery.

In addition to its low power consumption and precise movement capabilities, the 12v electric rotary actuator also offers a compact and lightweight design, making it easy to integrate into existing systems without adding unnecessary bulk or weight. This makes it an attractive option for applications where space is limited or weight restrictions are a concern, such as in aerospace and marine engineering. The versatility of the 12v electric rotary actuator allows for seamless integration with various control systems, offering engineers and designers the flexibility to create innovative solutions for a wide range of industries.

Industrial Applications

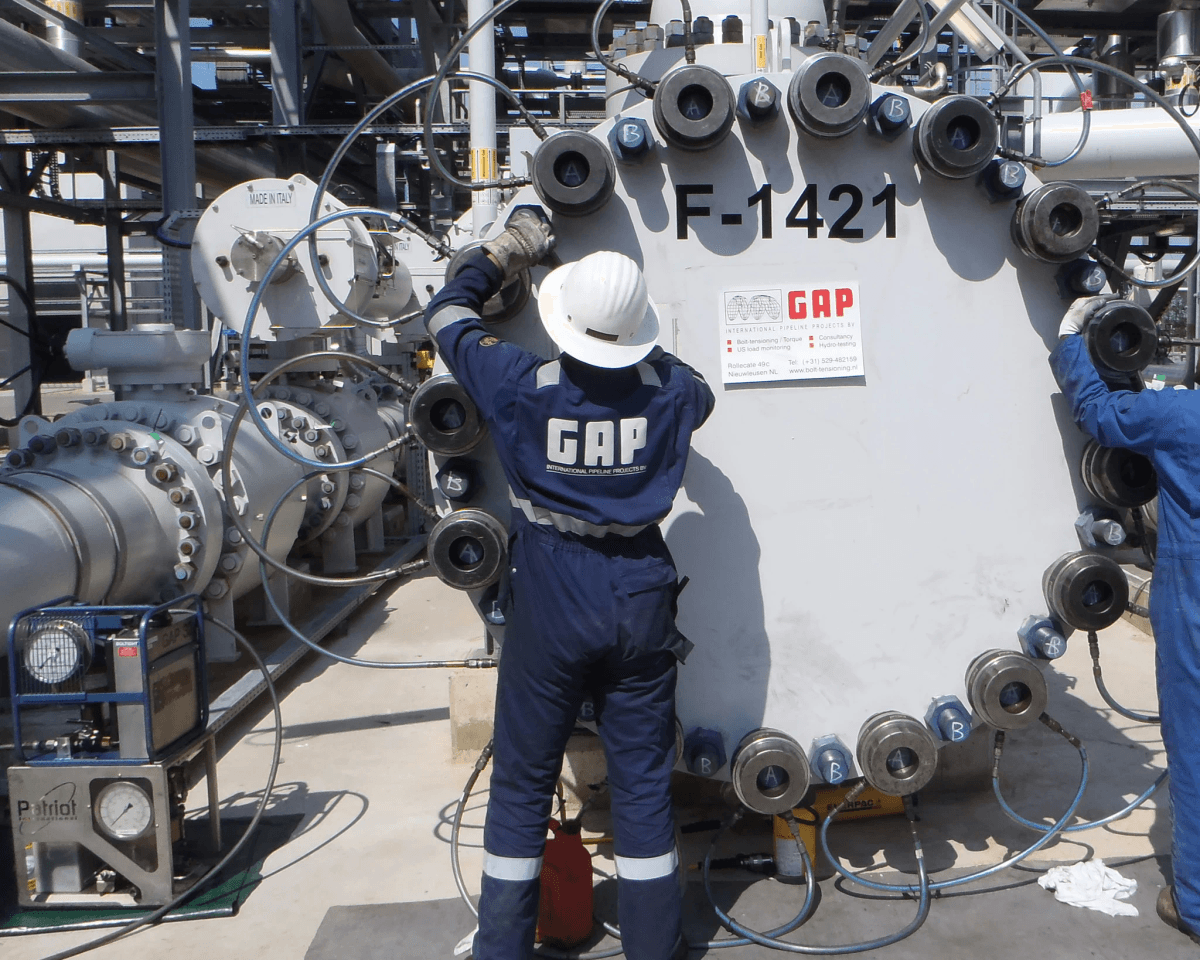

The use of electric rotating actuators has revolutionized the industrial landscape, offering efficient and precise control in various sectors. In the petrochemical industry, pneumatic rotary actuators are essential for valve automation, providing reliable performance in harsh environments. These actuators ensure seamless operation of valves, maintaining safety and productivity in petrochemical plants.

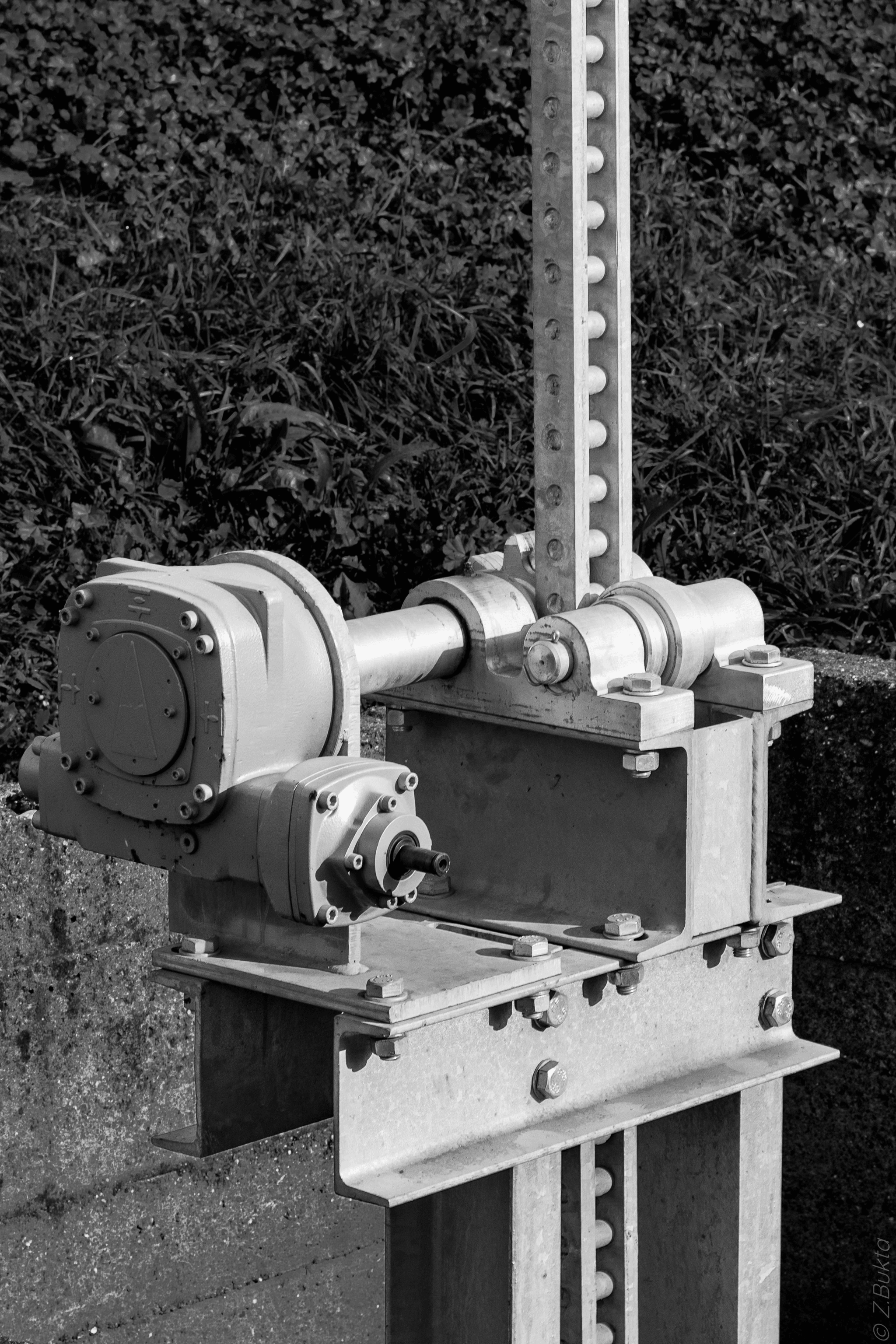

In metallurgy, the hollow rotary actuator plays a crucial role in the automation of heavy machinery and equipment. With its high torque capabilities, this actuator enables smooth and accurate movement, enhancing the efficiency of processes such as forging and casting. Its robust design withstands demanding conditions, making it an indispensable component in metallurgical operations.

Hydropower plants benefit from the use of electric rotary actuators to control the flow of water and manage turbine operations. The electric rotary actuator in hydropower plants offers precise positioning and torque control, optimizing energy generation while minimizing maintenance requirements. This advanced technology contributes to sustainable energy production and environmental preservation.

Remote Control Capabilities

In today's fast-paced industrial environment, remote operation of electric rotating actuators has become a game-changer. With the ability to control these actuators from a distance, operators can make adjustments without being physically present, saving time and increasing efficiency on the production floor.

Remote Operation of Electric Rotating Actuators

Remote operation of electric rotary actuators 90 degrees allows for seamless control and adjustment of valve positions, making it ideal for applications where accessibility is limited or hazardous. This feature ensures that operations can be managed safely and effectively from a distance, providing peace of mind to operators.

Haisen's Part-Turn Valve Electric Actuator in Shipbuilding

In shipbuilding, the use of Haisen's part-turn valve electric actuator has revolutionized the industry by offering precise and reliable control over critical systems. With remote capabilities, shipbuilders can now adjust valves and actuators from a central location, improving overall safety and operational efficiency during construction and maintenance.

Municipal Engineering Applications of Electric Rotary Actuators

Municipal engineering projects often require the use of electric rotary actuators to manage water treatment facilities, flood control systems, and other vital infrastructure. The remote control capabilities of these actuators enable swift response to changing conditions, ensuring that municipal operations run smoothly and effectively.

Market Trends and Future Outlook

Growing Demand for Electric Rotating Actuators

The market for electric rotating actuators is experiencing a surge in demand due to their efficiency and versatility in industrial automation. With the increasing focus on precision control and remote operation, industries are turning to electric rotary actuators 90 degrees and 12v rotary actuators for enhanced performance.

Future Development of Electric Rotary Actuator High Torque

As industries continue to demand higher torque capabilities, the future development of electric rotary actuators with high torque is inevitable. Manufacturers are investing in research and development to meet the growing need for powerful actuators that can handle heavy-duty applications across various sectors.

Innovations in Electric Rotating Actuators

Innovations in electric rotating actuators are paving the way for advanced features such as remote control capabilities, integrated sensors for feedback control, and improved durability. The integration of pneumatic rotary actuators and hollow rotary actuators with electric technology is also driving innovation in the industry.

Now that we've discussed the growing demand, future development, and innovations in electric rotating actuators, it's clear that these advanced technologies are reshaping industrial automation and setting new standards for efficiency and performance.

Conclusion

Electric rotating actuators have proven to be incredibly versatile in a wide range of industrial applications, offering precise control and efficient performance. The advancements in electric rotary actuator technology, such as the 90 Degree Rotary Actuator and Electric rotary actuator high torque, have revolutionized industrial automation, providing enhanced capabilities for various operations. The impact of electric rotating actuators in industrial automation is undeniable, as they continue to drive efficiency and productivity across different sectors.

The Versatility of Electric Rotating Actuators

The versatility of electric rotating actuators is unmatched, with the ability to adapt to different environments and applications. Whether it's the Pneumatic rotary actuator in the petrochemical industry or the Hollow Rotary Actuator in metallurgy, these actuators offer precise motion control and reliable performance. Their flexibility makes them an ideal choice for a wide range of industrial processes.

Advancements in Electric Rotary Actuator Technology

The continuous advancements in electric rotary actuator technology have led to the development of more powerful and efficient solutions. The introduction of the Rotary Actuator 12v has provided enhanced control capabilities, while the Electric rotary actuator high torque has expanded the scope of applications for these actuators. These advancements are driving innovation and pushing the boundaries of what is possible in industrial automation.

Impact of Electric Rotating Actuators in Industrial Automation

The impact of electric rotating actuators in industrial automation cannot be overstated. They have revolutionized processes across various industries, offering improved efficiency, precision, and reliability. As industries continue to embrace automation and digitalization, electric rotating actuators are playing a significant role in driving this transformation.