Introduction

When it comes to airport safety, runway friction testing plays a crucial role in ensuring smooth and secure operations. Over the years, the history of runway friction testing has evolved to meet the challenges of various weather conditions, particularly during winter operations.

Importance of Runway Friction Testing

The importance of runway friction testing lies in its ability to measure the friction between an aircraft's tires and the runway surface. This data is vital for pilots to make informed decisions during takeoff and landing, especially in adverse weather conditions.

History of Runway Friction Testing

The history of runway friction testing dates back to the early 20th century when engineers began developing methods to measure surface friction at airports. This led to the creation of various devices and machines that have since revolutionized how we assess runway conditions.

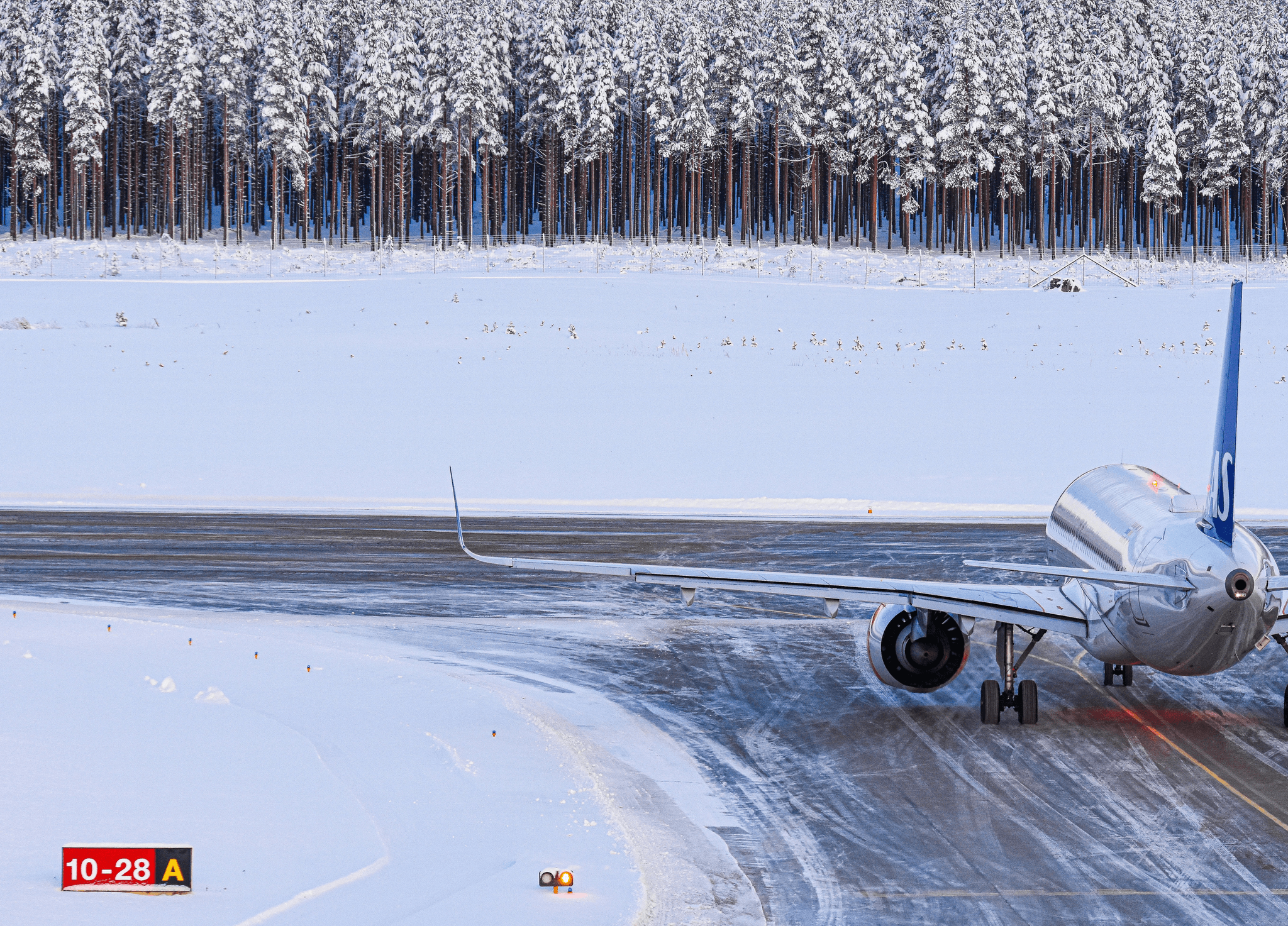

Challenges of Runway Friction Testing During Winter Operations

One of the biggest challenges in runway friction testing is maintaining accurate measurements during winter operations when snow, ice, and slush can significantly impact surface conditions. As a result, airports have had to adapt their testing methods and equipment to ensure safety during these challenging times.

What is Airport Runway Friction?

Airport runway friction refers to the resistance between the tires of an aircraft and the runway surface. This is a critical factor in ensuring safe takeoffs and landings, as it directly impacts the ability of an aircraft to stop or maneuver on the runway. The significance of maintaining optimal friction levels cannot be overstated, as it directly affects flight safety and operational efficiency.

Definition and Significance

Airport runway friction is defined as the force that resists the movement of an aircraft's tires on the runway surface. It is crucial for pilots to have accurate information about runway friction in order to make informed decisions during takeoff and landing. Insufficient friction can lead to skidding, hydroplaning, or difficulty in stopping, all of which pose serious safety risks for passengers and crew.

Factors affecting runway friction include the type and condition of the runway surface, as well as environmental factors such as weather and temperature. Runways with rough surfaces or standing water are likely to have lower friction, while rubber deposits from aircraft tires can also reduce friction over time. Pilots must take these factors into account when determining the appropriate speed and braking distance for takeoff and landing, in order to ensure a safe and smooth operation.

Factors Affecting Runway Friction

Several factors can affect runway friction, including rubber deposits from aircraft tires, surface contaminants such as water, snow, or ice, and variations in surface texture due to wear and tear. Other factors such as temperature fluctuations and maintenance practices also play a role in determining the level of friction available on airport runways.

In addition to the factors mentioned, weather conditions also have a significant impact on runway friction. For example, rain can create a layer of water on the runway surface, reducing friction and making it more slippery for aircraft during takeoff and landing. Similarly, snow and ice can further decrease friction, posing safety hazards for pilots. These weather-related factors require airports to implement effective de-icing and snow removal procedures to maintain optimal runway friction levels in adverse conditions.

Impact of Weather Conditions on Friction

Weather conditions have a significant impact on runway friction levels. For instance, rain can reduce friction by creating a layer of water between the tires and the pavement, while snow and ice can further decrease traction. It is essential for airports to monitor these conditions closely and conduct regular friction testing to ensure safe operations during inclement weather.

In addition to rain, fog and mist can also pose a significant challenge to runway friction. These weather conditions can create a thin layer of moisture on the pavement, reducing the effectiveness of braking and increasing the risk of skidding. Airport personnel must be vigilant in monitoring these conditions and taking appropriate measures to mitigate the impact on friction levels. This may include applying anti-skid materials or modifying landing and takeoff procedures to ensure the safety of aircraft operations.

How is Runway Friction Measured?

When it comes to measuring runway friction, various methods and techniques are employed to ensure accurate results. These include the use of friction sensors, which are essential for determining the level of friction between the runway surface and aircraft tires. These sensors provide crucial data that helps airport authorities make informed decisions regarding runway maintenance and safety measures.

Methods and Techniques

One common method for measuring runway friction is the use of a specialized device called a friction tester. This device is equipped with friction sensors that are used to assess the surface conditions of the runway by measuring the forces required to move a test wheel across it. Additionally, other techniques such as continuous friction measuring equipment (CFME) and dynamic friction testers are also utilized to gather comprehensive data on runway conditions.

Another method for assessing runway friction is the use of continuous friction measuring equipment (CFME). CFME continuously measures and records the friction coefficient of the runway surface as an aircraft travels along it, providing real-time data on the changing conditions. This allows airport personnel to monitor and respond to any changes in friction levels, ensuring the safety of aircraft operations. In addition, dynamic friction testers are also employed to measure runway conditions by simulating aircraft braking action and providing a more dynamic assessment of the surface. These techniques, combined with traditional friction testers, offer a comprehensive approach to evaluating and maintaining optimal runway conditions for safe landings and takeoffs.

Haisen's BHM01/02 Surface Friction Tester

Haisen's BHM01/02 Surface Friction Tester is a cutting-edge device designed specifically for assessing airport surface friction. Equipped with state-of-the-art friction sensor technology, this machine provides accurate and reliable measurements, enabling airport authorities to make informed decisions about runway maintenance and safety protocols. Its precision and efficiency set it apart from other conventional testing machines.

In addition to its advanced sensor technology, Haisen's BHM01/02 Surface Friction Tester offers a user-friendly interface and intuitive controls, making it easy for airport personnel to operate and interpret the results. This simplicity saves time and reduces the need for extensive training, allowing for quick implementation and use at airports worldwide. The machine's portability also sets it apart, as it can be easily transported between different runways for comprehensive testing without the need for additional equipment.

Comparison with Other Friction Testing Machines

In comparison with other friction testing machines, Haisen's BHM01/02 Surface Friction Tester stands out due to its advanced features and ability to provide real-time data on runway conditions. While traditional devices may offer basic measurements, Haisen's tester goes above and beyond by delivering comprehensive insights into the state of airport surfaces, making it an invaluable tool for ensuring safe operations.

Additionally, Haisen's Surface Friction Tester is designed to be user-friendly, allowing airport personnel to easily operate and interpret the data. This ease of use sets it apart from other testing machines that may require extensive training or specialized knowledge to operate effectively. By providing accessible and actionable information, Haisen's tester empowers airport staff to make informed decisions in real time, ultimately enhancing overall safety and efficiency.

Runway Friction Tester Devices

Overview of Friction Sensor Technology

Friction sensors are crucial components of runway friction testing devices, designed to measure the amount of force required to move an object across a surface. These sensors use various technologies such as piezoelectric, capacitive, and optical to accurately detect the friction between the aircraft tires and the runway surface.

Key Features of Friction Testing Equipment

The friction testing equipment used at airports is equipped with state-of-the-art features such as real-time data collection, automated reporting, and advanced calibration capabilities. These devices are designed to withstand harsh environmental conditions and provide accurate friction measurements for safe aircraft operations.

Advancements in Runway Friction Testing Technology

Recent advancements in runway friction testing technology have led to the development of more portable and user-friendly devices that can be easily operated by airport personnel. These advancements also include improved data analysis software that allows for better interpretation of friction test results.

Airport Surface Friction Tester

Airport surface friction testing plays a crucial role in ensuring the safety of aircraft operations. By measuring the friction between the runway surface and aircraft tires, it helps in determining the braking action available for landing and takeoff. This information is vital for pilots to make informed decisions during adverse weather conditions.

Role of Airport Surface Friction Testing

The primary role of airport surface friction testing is to assess the condition of the runway and provide accurate data on its friction levels. This allows airport authorities to take necessary measures to maintain safe operating conditions for aircraft. By regularly conducting friction tests, airports can ensure that runways meet required safety standards, especially during challenging weather conditions.

Runway Friction Coefficient Table

The runway friction coefficient table is a valuable reference tool that displays the measured friction values for different sections of the runway. It provides pilots with essential information on braking action and deceleration capabilities under various weather conditions. This table helps pilots make informed decisions when planning landings and takeoffs, contributing to safer operations at airports.

Importance of Accurate Friction Data for Safe Operations

Accurate friction data obtained from airport surface friction testing is crucial for maintaining safe operations at airports. It enables airport authorities to monitor runway conditions and take proactive measures to address any issues that may affect aircraft braking performance. By ensuring accurate friction data, airports can enhance overall safety standards and minimize potential risks during landing and takeoff procedures.

Ensuring Safe Winter Operations

During winter operations, utilizing friction test results is crucial for preparedness. By regularly measuring runway friction using advanced friction sensor technology, airports can accurately assess the condition of their runways and take necessary precautions to ensure safe landings and takeoffs in icy or snowy conditions.

Utilizing Friction Test Results for Winter Preparedness

Friction sensors play a key role in measuring runway friction, providing airports with real-time data on surface conditions. This data allows airport authorities to make informed decisions regarding snow removal, de-icing procedures, and runway maintenance during winter weather. By leveraging the information gathered from these sensors, airports can effectively prepare for adverse weather conditions and minimize potential hazards.

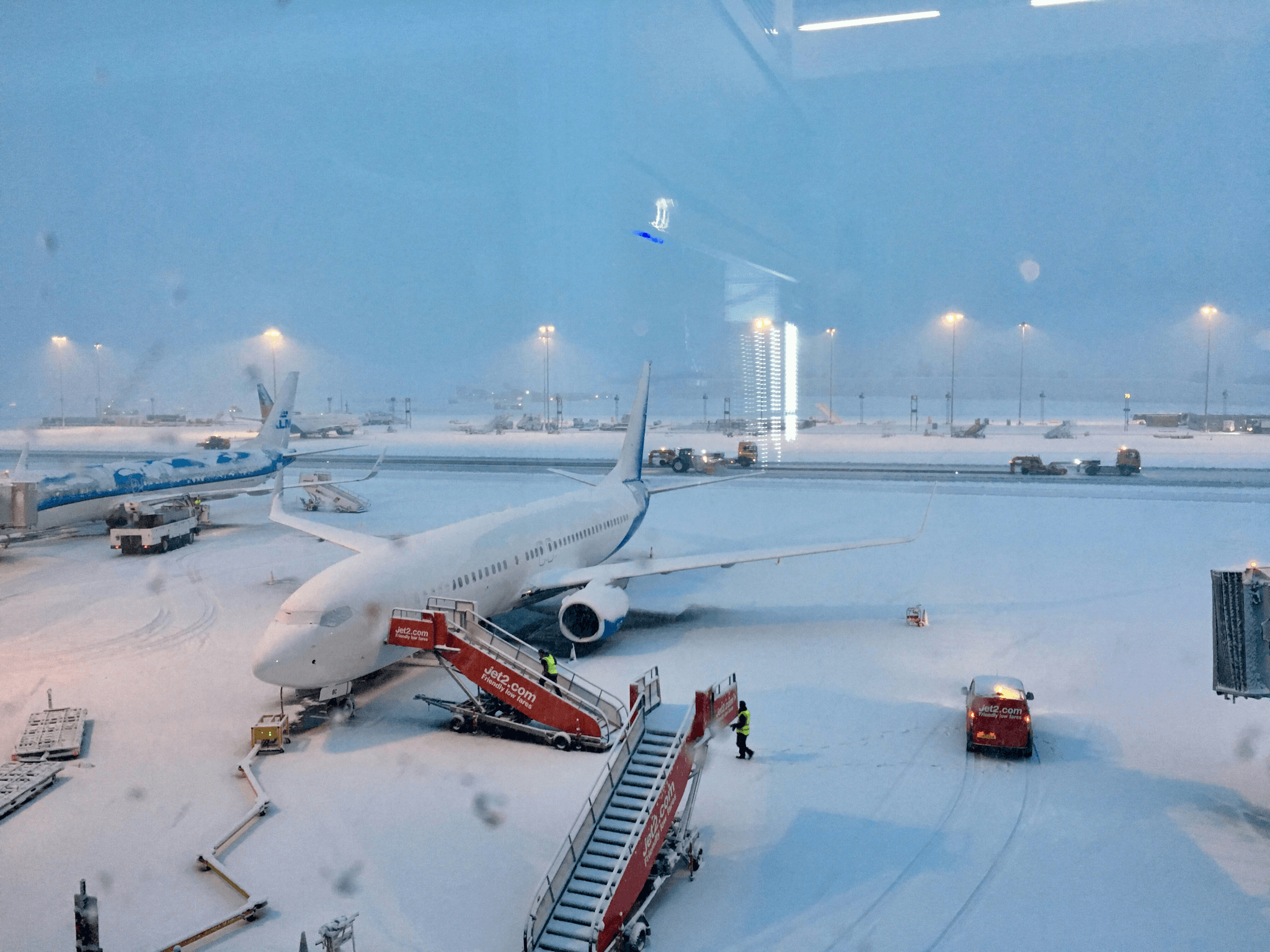

Impact of Friction Testing on Flight Delays

Accurate friction testing at airports significantly reduces the risk of flight delays caused by poor runway conditions during winter. With reliable data from friction testing machines, airlines can make informed decisions about flight schedules and anticipate potential delays due to inclement weather. This proactive approach helps minimize disruptions and ensures efficient operations even in challenging winter conditions.

Improving Passenger Safety During Winter Operations

The use of airport surface friction testers directly contributes to enhancing passenger safety during winter operations. By maintaining high standards of runway friction through regular testing and monitoring, airports can provide a safer environment for aircraft movements, reducing the likelihood of accidents or incidents caused by low traction on slippery surfaces.

Remember that accurate measurement is essential when it comes to ensuring safe airport operations during winter months!

Conclusion

Runway friction testing is crucial for ensuring safe airport operations, especially during winter. As technology continues to advance, the future of runway friction testing looks promising. Innovations in friction testing technology, such as the use of advanced friction sensors and sophisticated runway friction testers, are revolutionizing the way airports measure and monitor runway friction.

Future of Runway Friction Testing

The future of runway friction testing is bright, with advancements in technology leading to more accurate and efficient methods for measuring and monitoring airport surface friction. With the development of cutting-edge friction sensor technology, airports can look forward to improved safety standards and enhanced winter preparedness.

Innovations in Friction Testing Technology

Innovations in friction testing technology have paved the way for more sophisticated and reliable methods of measuring runway friction. The use of state-of-the-art runway friction testers equipped with advanced friction sensors allows airports to gather precise data on surface conditions, enabling them to make informed decisions about winter operations and ensure the safety of aircraft and passengers.

Ensuring Safe Airport Operations

By utilizing airport surface friction testers equipped with advanced friction sensor technology, airports can effectively measure and monitor runway friction, leading to safer airport operations year-round. Accurate data from a runway friction coefficient table enables airports to optimize their winter preparedness efforts, minimize flight delays, and enhance passenger safety during challenging weather conditions.