Introduction

Conducting a thorough runway friction test is crucial to ensuring the safety of aircraft operations. Surface friction testers, like Haisen's BHM01/02 grip tester, play a vital role in this process. The science behind runway friction testing involves measuring the resistance between the tire and the pavement to determine how much grip is available for landing and takeoff.

Importance of Runway Friction Testing

Runway friction testing equipment, such as the Sarsys friction tester or RFT calendar, allows airport authorities to assess the condition of their runways accurately. By regularly conducting surface friction tests, airports can ensure that their runways meet safety standards and provide adequate grip for aircraft tires. This enhances safety and minimizes potential risks associated with poor runway conditions.

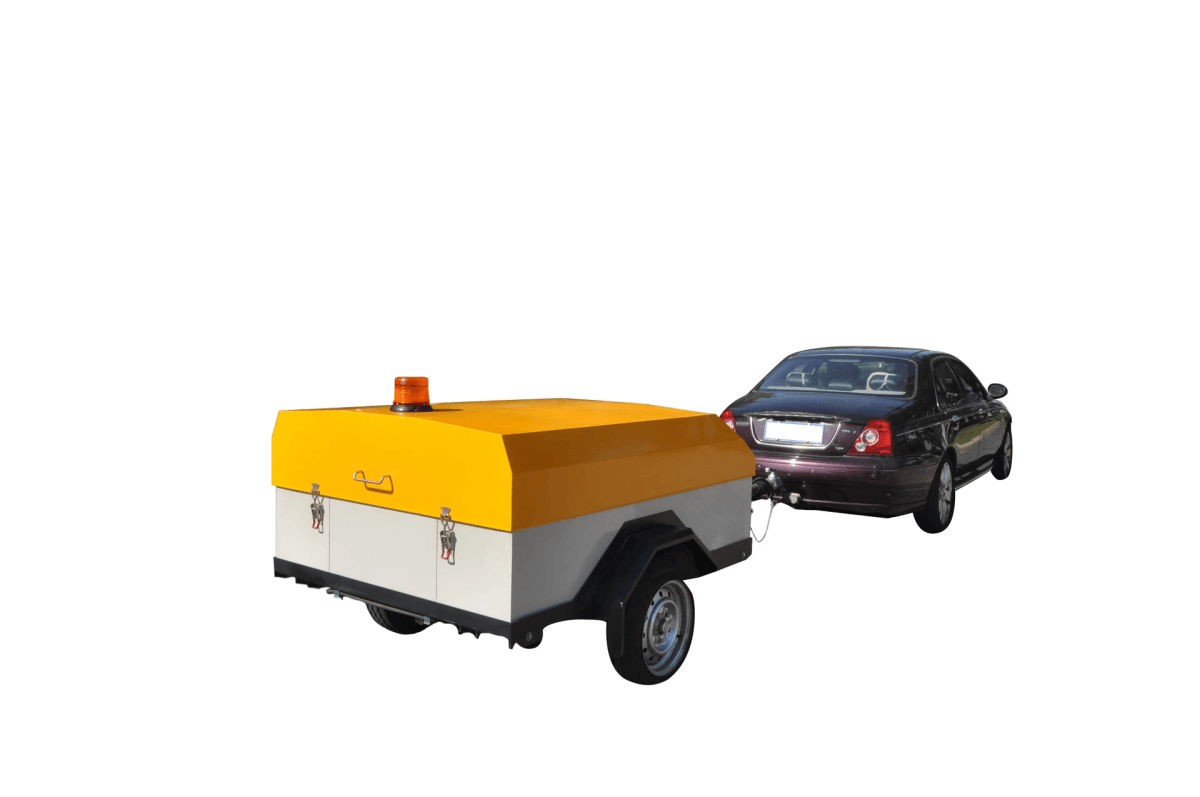

Haisen's BHM01/02 Surface Friction Tester

Haisen's BHM01/02 surface friction tester is a state-of-the-art device designed to provide accurate and reliable measurements of runway surface friction. With advanced technology and precision engineering, this friction tester offers a comprehensive solution for assessing runway conditions and ensuring optimal safety for aircraft operations.

The Science Behind Runway Friction Testing

Surface friction testers are essential tools for ensuring runway safety. These devices simulate tire-pavement interaction to measure the level of grip available. By evaluating key factors such as:

- Surface texture

- Contaminants

- Environmental conditions

These testers help airports accurately assess and maintain optimal runway conditions. Understanding and addressing these variables is crucial for preventing accidents and ensuring the safe operation of aircraft.

Regular friction testing is an indispensable component of comprehensive airport safety management.

Understanding Runway Friction

Runway friction testing is essential for ensuring safe aircraft operations, and surface friction testers play a crucial role in this process. These testers are specifically designed to measure the grip of the runway surface, providing valuable data for airport authorities and airline operators. Surface friction testers come in various models and designs, each equipped with advanced technology to accurately assess the friction levels on runways.

The Role of Surface Friction Testers

Surface friction testers, also known as grip testers or RFT calendars, are specialized tools used to evaluate runway surface friction. These devices are essential for assessing runway conditions and identifying potential safety hazards caused by low friction.

By conducting regular tests, airport authorities can:

- Proactively address runway grip issues.

- Ensure the safety of aircraft operations.

- Prevent accidents by identifying low-friction areas.

Surface friction testers are indispensable for maintaining safe and efficient airport operations. By providing accurate data, these tools help airport authorities make informed decisions and contribute to the overall safety of air travel.

Surface friction testers are vital equipment for ensuring runway safety. Their use is essential for preventing accidents and maintaining the smooth operation of airports.

Surface Friction Testing Equipment Overview

Surface friction testing equipment encompasses a range of devices, such as the Sarsys friction tester and Haisen's BHM01/02 surface friction tester. These advanced tools utilize cutting-edge technology to measure skid resistance and provide accurate data on runway conditions. With features like automated data collection and real-time analysis, these devices offer a comprehensive overview of the surface condition, enabling informed decision-making for airport maintenance and operation teams.

Key Factors Affecting Friction Test Results

Several factors can influence the results of a runway friction test. These include weather conditions, pavement material, tire pressure, and test speed. Understanding these key factors is crucial for obtaining reliable data from surface friction tests. Regular calibration and maintenance of surface friction testing equipment are essential to ensure accurate readings and consistent performance.

By utilizing advanced surface friction testing equipment such as the Haisen BHM01/02 or Sarsys friction tester, airport authorities can effectively monitor runway conditions to enhance safety measures for aircraft operations. The precision and reliability offered by these devices contribute significantly to improving overall airport safety standards.

Conducting Runway Friction Tests

Precision and reliability are crucial when conducting a friction test on the runway. To ensure accurate results, the surface friction tester must be operated with extreme care. It's essential to follow the RFT calendar for regular maintenance and calibration of the equipment.

Precision and Reliability in Friction Testing

The precision of a surface friction tester is essential for obtaining reliable data on runway conditions. Operators must adhere to strict protocols when conducting a friction test on the runway to minimize errors and ensure accuracy. The grip tester's sensitivity and responsiveness are significant in obtaining precise measurements.

The precision of a surface friction tester is crucial for ensuring aircraft safety during takeoff and landing. By following strict protocols and conducting regular calibration checks, operators can minimize errors and maintain the accuracy of friction testing results. Additionally, using advanced technology in grip testers can further enhance the precision and reliability of measurements, providing valuable data for airport authorities and airline operators.

Calibrating Friction Testers for Accurate Results

Calibrating friction testers is vital for obtaining accurate results during runway friction testing. Regular calibration ensures that the surface friction tester functions optimally and provides reliable data for decision-making purposes. Using state-of-the-art equipment such as the Sarsys friction tester can enhance the accuracy of calibration procedures.

Furthermore, regular calibration of friction testers helps identify potential issues or malfunctions early on, allowing for timely repairs and maintenance. This proactive approach can prevent costly downtime and ensure that friction testing can continue without interruption. By investing in the latest equipment and technology, airports and aviation authorities can demonstrate their commitment to safety and efficiency in runway operations.

Test Tires: Ensuring Compliance and Accuracy

Using compliant test tires is crucial in ensuring accuracy during runway friction testing. Test tires should meet specific standards to guarantee measurement consistency across different testing scenarios. Operators can maintain accuracy and compliance with industry regulations by utilizing reliable test tires.

It is important to note that the selection of test tires can significantly impact the accuracy of friction test results. The use of non-compliant or worn-out tires can lead to inconsistent measurements, compromising the safety and efficiency of runway operations. Therefore, operators should prioritize regularly inspecting and replacing test tires to ensure reliable and accurate testing outcomes.

Interpreting Friction Test Results

Friction test results provide crucial data on the condition of a runway surface, helping airport authorities make informed decisions to ensure safe aircraft operations. By analyzing the data from surface friction tests, airport personnel can identify areas that require maintenance or improvement to enhance runway safety and prevent potential accidents.

Using Data from Friction Tests

Surface friction test results offer valuable insights into a runway's level of grip and skid resistance, enabling airport authorities to assess the need for corrective measures. This data is essential for determining the effectiveness of runway maintenance activities and establishing appropriate friction coefficients for different sections of the airfield. By analyzing the friction test results, airport authorities can prioritize areas that require immediate attention, such as resurfacing or retexturing, to ensure aircraft safety during takeoff and landing. This data can also be used to compare the performance of different pavement materials and coatings, helping airports make informed decisions when planning future construction or renovation projects.

Real-world Applications of Friction Test Results

The real-world applications of friction test results are diverse, ranging from identifying areas prone to hydroplaning during wet conditions to evaluating the impact of rubber deposits on runway surfaces. Additionally, this data is instrumental in assessing the effectiveness of de-icing procedures and determining optimal braking distances for aircraft under varying weather conditions.

Making Informed Decisions Based on Friction Test Data

By leveraging friction test data, airport authorities can make informed decisions regarding runway maintenance schedules, surface treatments, and operational procedures. This enables them to prioritize resources effectively and implement targeted interventions to mitigate potential safety risks associated with inadequate surface friction.

Utilizing friction test data allows airport authorities to proactively address potential safety risks by identifying runway areas requiring maintenance or surface treatments. By analyzing the data, authorities can develop tailored operational procedures to maintain optimal friction levels, reducing the likelihood of accidents or incidents. This proactive approach enhances safety and optimizes resource allocation, ultimately leading to cost savings for the airport.

Advancements in Runway Friction Testing

With the increasing demand for accurate and reliable surface friction test data, Haisen's BHM01/02 Surface Friction Tester has emerged as a game-changer in the industry. This state-of-the-art friction tester has advanced sensors and technology to precisely measure runway surface conditions precisely, ensuring enhanced safety for aircraft operations. The grip tester also offers user-friendly features such as the RFT calendar, which allows for efficient scheduling and management of friction tests.

Haisen's BHM01/02 Surface Friction Tester Features

The Haisen BHM01/02 Surface Friction Tester has various innovative features to streamline runway friction testing processes. Its compatibility with Sarsys friction tester technology enables seamless integration and data sharing, maximizing efficiency and accuracy in friction testing. The runway friction testing equipment also has advanced calibration capabilities, ensuring consistent and reliable performance in various environmental conditions.

The Future of Surface Friction Testing Technology

The future of surface friction testing is bright, with potential for increased accuracy and efficiency. As technology advances, we can expect significant improvements in this critical area.

Specifically, we can anticipate:

- The development of more sophisticated surface friction testers.

- The integration of artificial intelligence and machine learning capabilities.

- Enhanced data analysis and predictive runway condition modeling.

These advancements will undoubtedly lead to a new era of runway safety management at airports worldwide.

By investing in research and development, we can harness technology's power to create a safer aviation industry for everyone.

Overcoming Challenges in Runway Friction Testing

Despite significant progress in runway friction testing technology, challenges such as varying weather conditions and environmental factors continue to hinder consistent test results. However, ongoing collaborations between industry experts and technological innovators are focused on developing solutions that address these challenges head-on. By leveraging cutting-edge materials science and engineering principles, we can anticipate breakthroughs that will mitigate the impact of external factors on friction test accuracy.

By embracing these advancements in surface friction testing technology, airports can proactively enhance safety measures by obtaining accurate data on runway conditions. Utilizing state-of-the-art grip testers like Haisen's BHM01/02 elevates airport operations and contributes significantly to the overall safety standards within the aviation industry.

Enhance Runway Safety with Accurate Friction Measurements

With the advancements in runway friction testing equipment, such as Haisen's BHM01/02 surface friction tester and the Sarsys friction tester, accurate and reliable friction test data has become more accessible. By enhancing runway safety with accurate friction measurements, airports can now make informed decisions based on this crucial data. The impact of reliable friction testers on airport operations cannot be overstated, as they play a vital role in ensuring the safety of aircraft and passengers. Utilizing surface friction test data for improved safety is not just a possibility - it's a necessity in today's aviation industry.

Using state-of-the-art runway friction testing equipment, such as grip testers and RFT calendars, has revolutionized how airports approach safety measures. With precise and reliable data from surface friction tests, airports can proactively address potential hazards on runways, ultimately enhancing overall safety for all aircraft operations.

The Impact of Reliable Friction Testers on Airport Operations

Reliable friction testers have significantly impacted airport operations by providing crucial data for informed decision-making. These indispensable tools have revolutionized airport operations, enhancing safety and efficiency.

Specifically, friction testers aid in:

- Optimizing maintenance schedules

- Determining safe landing conditions

- Improving overall airport performance

By accurately measuring runway friction, airports can proactively address potential hazards and ensure smooth aircraft operations, ultimately contributing to a safer aviation environment.

Utilizing Surface Friction Test Data for Improved Safety

By identifying areas with low surface friction through data analysis, airports can prioritize maintenance and improvement efforts to ensure the highest level of safety for aircraft operations. This targeted approach allows for more efficient allocation of resources, reducing unnecessary spending on areas that do not require immediate attention. Additionally, the ability to proactively address safety concerns can enhance the overall reputation of the airport and instill confidence in both airlines and passengers.