Introduction

When it comes to ensuring the safety of aircraft, understanding runway friction testing is crucial. Runway friction plays a vital role in maintaining safe takeoffs and landings for airplanes. But what does RFT stand for? The Runway Friction Tester (RFT) is an essential tool used to measure and assess the friction levels of airport runways, ultimately contributing to safer aviation operations.

Understanding Runway Friction Testing

Runway friction testing refers to the process of measuring the level of grip or traction that a runway surface provides for aircraft tires during takeoff and landing. This testing is critical in determining the overall safety and usability of airport runways, as it directly impacts aircraft performance and control on the ground.

Importance of Runway Friction

The importance of runway friction cannot be overstated, as it directly affects the ability of aircraft to maneuver safely during critical phases of flight. Adequate runway friction is essential for preventing skidding, hydroplaning, and other hazardous conditions that can compromise aviation safety.

What Does RFT Stand For?

RFT stands for Runway Friction Tester, a specialized vehicle equipped with state-of-the-art technology designed to accurately measure and assess the friction levels on airport runways. By utilizing advanced testing equipment integrated into a one-ton truck, RFTs play a pivotal role in enhancing aviation safety through reliable and accurate runway friction testing.

The Significance of Runway Friction

Runway friction is crucial for safe aircraft operations, and it is measured using a runway friction tester (RFT) to determine the pavement's grip. This measurement is essential for ensuring safe take-offs and landings, especially in adverse weather conditions. The RFT plays a vital role in maintaining runway safety by accurately assessing the friction levels to prevent accidents and ensure smooth operations.

How is runway friction measured?

Runway friction is measured using specialized equipment that simulates the forces experienced by aircraft tires during take-off and landing. The RFT uses test tires with specific pressure levels to determine the pavement's grip, providing valuable data for airport authorities to make informed decisions about runway maintenance and safety measures.

In addition to measuring runway friction, airport authorities also utilize specialized equipment to monitor the condition of the pavement. This includes devices that can detect any irregularities or damage to the surface, such as cracks or potholes, which could affect the grip and safety of the runway. By regularly assessing the pavement's condition, airport authorities can proactively address any maintenance issues and ensure that the runway remains in optimal condition for aircraft operations.

Enhancing Runway Safety

Accurate measurement of runway friction helps enhance overall runway safety by identifying areas that require maintenance or improvement. By understanding the friction levels, airport authorities can take proactive measures to address potential hazards and ensure a secure environment for aircraft operations.

Runway Friction Tester (RFT) and its Role

The Runway Friction Tester (RFT) plays a crucial role in measuring pavement grip to maintain safe conditions for aircraft operations. Integrated into a one-ton truck, the RFT utilizes specialized test tires compliant with aviation standards to provide accurate data on runway friction levels. This information is invaluable for ensuring optimal safety standards at airports worldwide.

The technology behind the RFT is constantly evolving to meet the increasing demands of modern aviation. Advanced sensors and data collection systems are integrated into the RFT to provide real-time feedback on runway conditions. This allows airport authorities to make informed decisions about maintenance and de-icing procedures, ensuring that runways remain safe for takeoff and landing in all weather conditions. Additionally, the RFT can be equipped with cameras and other monitoring devices to further enhance its capabilities in assessing runway friction.

The Technology Behind RFT

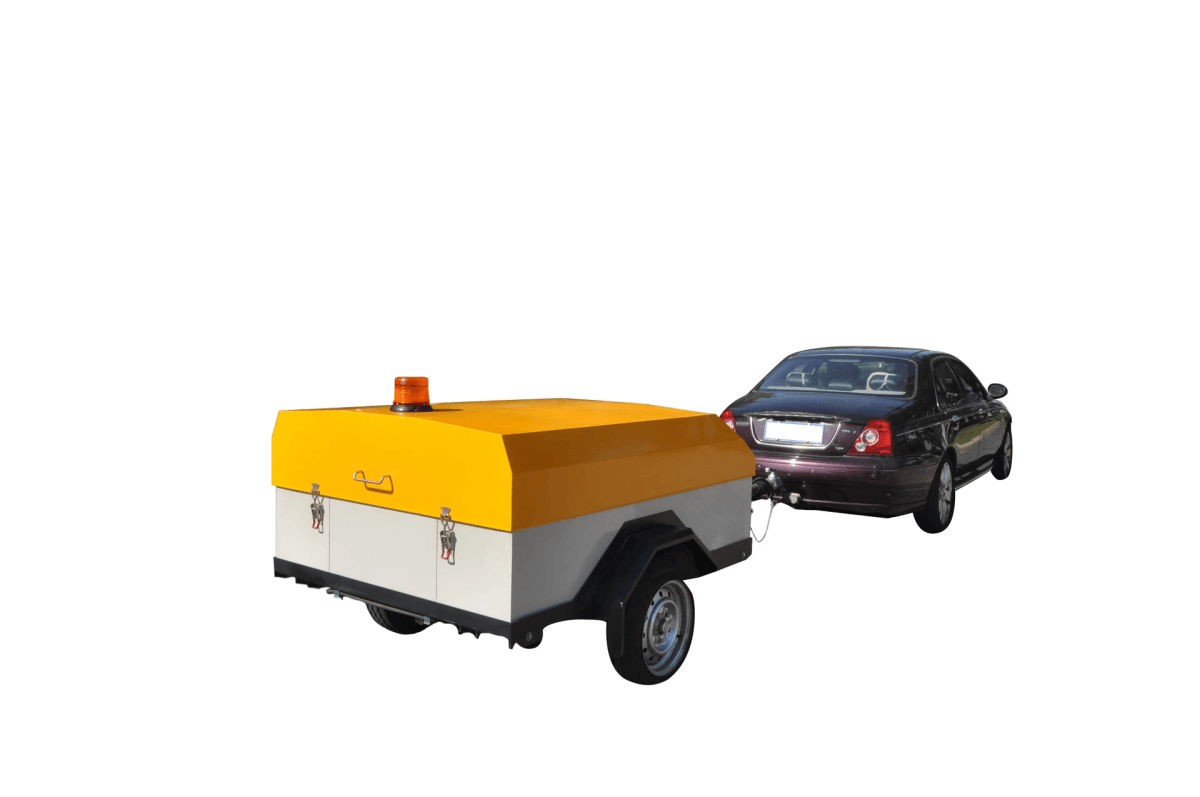

Runway Friction Tester Integrated into a one-ton truck

The Runway Friction Tester (RFT) is integrated into a one-ton truck, allowing for easy mobility and efficient testing of runway friction levels. This innovative design ensures that the RFT can be easily transported to different locations for comprehensive testing.

Haisen's BHM01/02 Surface Friction Tester

Haisen's BHM01/02 Surface Friction Tester is a state-of-the-art tool that maintains original vehicle systems for safety and performance. With a reinforced trunk for testing equipment, it offers reliability and precision in measuring runway friction levels.

Components and Calibration of RFT

The RFT is equipped with high-precision components and an industrial-grade laptop with a Chinese interface for reliable operation. It features an accurate external electronic calibration device, ensuring precise measurements of runway friction levels.

Benefits of RFT

When it comes to ensuring aircraft safety, the Runway Friction Tester (RFT) plays a crucial role in assessing the condition of airport runways. By accurately measuring the friction levels, RFT helps prevent potential accidents caused by poor runway conditions, ultimately safeguarding the lives of passengers and crew.

Ensuring Aircraft Safety

With its ability to provide real-time data on runway conditions, the RFT enables airports to take proactive measures in maintaining safe landing and takeoff surfaces for aircraft. By identifying areas with low friction, airports can promptly address potential hazards, reducing the risk of accidents due to poor runway conditions.

Reliable and Accurate Testing

The RFT utilizes advanced technology to deliver precise and reliable friction measurements on airport runways. This ensures that airports have access to accurate data for making informed decisions regarding runway maintenance and safety protocols, contributing to enhanced operational efficiency and overall safety.

Airport / Runway Friction Testing Products

In addition to the RFT itself, there are various products available for airport and runway friction testing that complement the capabilities of the tester. These products include specialized tires compliant with aviation regulations from CAAC, ICAO, and FAA, as well as water systems designed for conducting comprehensive tests over extended distances.

Operational Aspects of RFT

As the Runway Friction Tester (RFT) is integrated into a one-ton truck, it allows for efficient acceleration during testing. The vehicle's powerful engine and optimized design enable it to reach high speeds within a short distance, ensuring accurate and reliable friction measurements.

Acceleration of RFT vehicles

The RFT vehicles, such as the Ford Taurus 2.7T and Honda Acura, can accelerate to 96 km/h within just 200 meters. This rapid acceleration capability is essential for conducting precise friction tests on airport runways, contributing to enhanced safety for aircraft operations.

Furthermore, the advanced computer control systems in these RFT vehicles allow for precise data collection during acceleration tests. This data is crucial for evaluating runway conditions and determining the level of friction between the tires and the surface. By accurately measuring the coefficient of friction, airport authorities can make informed decisions about necessary maintenance and improvements to ensure optimal safety for aircraft operations.

Computer Control and Data Collection

Equipped with an industrial-grade laptop with a Chinese interface, the RFT allows for seamless computer control and data collection during friction testing. This advanced technology ensures that accurate measurements are obtained and recorded efficiently for analysis and reporting.

Test Tires and Water System

The RFT utilizes specialized tires compliant with CAAC, ICAO, and FAA standards, featuring 0.7MPa pressure for optimal performance during friction testing. Additionally, its water system includes a large tank capacity and components designed for tests covering extensive distances.

The specialized tires used by the RFT not only meet the standards set by CAAC, ICAO, and FAA but also offer exceptional durability and reliability. With a pressure of 0.7MPa, these tires are specifically designed to deliver optimal performance during friction testing, ensuring accurate and consistent results. Furthermore, the water system's large tank capacity and components tailored for tests covering extensive distances provide the necessary support for comprehensive and rigorous testing scenarios.

Cost and Implementation

As airports prioritize safety, the Runway Friction Tester (RFT) has become an essential tool for ensuring safe takeoffs and landings. The cost of a runway friction tester RFT can vary depending on the model and features, with prices ranging from $100,000 to $300,000. Despite the initial investment, the achievements of RFT in enhancing runway safety make it a worthwhile addition to airport operations.

Runway friction tester RFT price

The cost of a Runway Friction Tester (RFT) is a significant consideration for airports looking to enhance their safety measures. With prices ranging from $100,000 to $300,000 depending on the model and capabilities, airports must weigh the investment against the long-term benefits of improved runway safety.

The investment in a Runway Friction Tester may seem steep, but the long-term benefits are undeniable. By accurately measuring runway friction levels, airports can proactively address potential safety hazards and reduce the risk of accidents. This proactive approach not only enhances overall safety but also minimizes operational disruptions and potential liabilities, making the initial investment in an RFT a prudent decision for airports of all sizes.

Achievements of RFT

The achievements of Runway Friction Testers (RFTs) are evident in their widespread use at various airports worldwide. With over 200 units in operation at high-altitude locations and major international hubs, RFTs have proven their effectiveness in ensuring safe takeoffs and landings for aircraft.

Furthermore, RFTs offer cost-effective solutions for airports by providing accurate and real-time data on runway conditions. This allows airports to efficiently allocate resources for snow and ice removal, as well as pavement maintenance, ultimately saving time and money. With RFTs in place, airports can ensure that runways are safe for aircraft operations without overspending on unnecessary measures.

Cost-effective Solutions for Airports

Despite the initial investment required for acquiring a Runway Friction Tester (RFT), it ultimately provides a cost-effective solution for airports seeking to enhance their safety measures. By accurately measuring runway friction and identifying potential hazards, RFTs contribute to preventing accidents and minimizing operational disruptions.

Additionally, RFTs can help airports optimize their maintenance schedules by providing real-time data on runway conditions. This proactive approach allows airports to allocate resources more efficiently, reducing the need for costly emergency repairs and minimizing downtime. By investing in RFT technology, airports can save money in the long run while ensuring the safety and smooth operation of their facilities.

Conclusion

The importance of runway safety cannot be overstated, and the Runway Friction Tester (RFT) plays a crucial role in ensuring safe takeoffs and landings. With the future of runway friction testing relying on advanced technology and innovation, it's clear that RFT is here to stay. Implementing RFT for safer runways is not just a choice, but a necessity in today's aviation industry.

Runway Safety and RFT

Runway friction testing is constantly evolving to meet the demands of modern aviation. With advancements in technology, RFT systems are becoming more efficient and accurate, providing real-time data to airport authorities. This allows for proactive maintenance and decision-making, ensuring that runways are always in optimal condition for safe aircraft operations. As airports continue to expand and accommodate larger aircraft, the future of runway friction testing will involve adapting RFT technology to meet the changing needs of the industry.

Future of Runway Friction Testing

The future of runway friction testing is evolving with advancements in technology, such as the integration of RFT into one-ton trucks like Haisen's BHM01/02 Surface Friction Tester. As airports continue to prioritize safety measures, RFT will undoubtedly play a pivotal role in shaping the future of runway friction testing.

With the integration of RFT into surface friction testers like Haisen's BHM01/02, airports can now gather real-time data on runway conditions, allowing for immediate action to be taken in case of low friction levels. This proactive approach to maintenance and safety will result in reduced runway accidents and delays, ultimately improving overall airport efficiency. Additionally, the use of RFT will enable airports to optimize their snow and ice removal processes, ensuring that runways remain safe and operational during inclement weather.

Implementing RFT for Safer Runways

Implementing RFT for safer runways is not just about adhering to regulations; it's about safeguarding lives and assets. With airport authorities recognizing the value of reliable friction testing equipment like RFT, we can expect to see widespread adoption and implementation across airports globally. This shift towards prioritizing safety through advanced technology reflects a commitment to excellence in aviation operations. By investing in RFT, airports are demonstrating their dedication to providing a secure and efficient environment for both travelers and airline personnel.