Introduction

Electric valve actuators are essential components in industrial settings, responsible for opening and closing valves to control the flow of liquids or gases. Choosing the right electric actuator for your valves is crucial to ensure optimal performance and efficiency. There are three main types of actuators used to drive valves: electric ball valve actuators, quarter turn electric actuators, and multi-turn electric actuators.

Understanding the Function of Electric Valve Actuators

Electric valve actuators play a critical role in automating the operation of valves, eliminating the need for manual intervention. They are designed to provide precise control over the position and movement of the valve, allowing for seamless regulation of fluid flow within a system.

How to Choose the Right Electric Actuator for Your Valves

Selecting an electric actuator for your valves involves considering factors such as torque requirements, speed, control options, and environmental conditions. Understanding these key parameters will help you choose an actuator that is best suited for your specific application.

The 3 Main Types of Actuators for Driving Valves

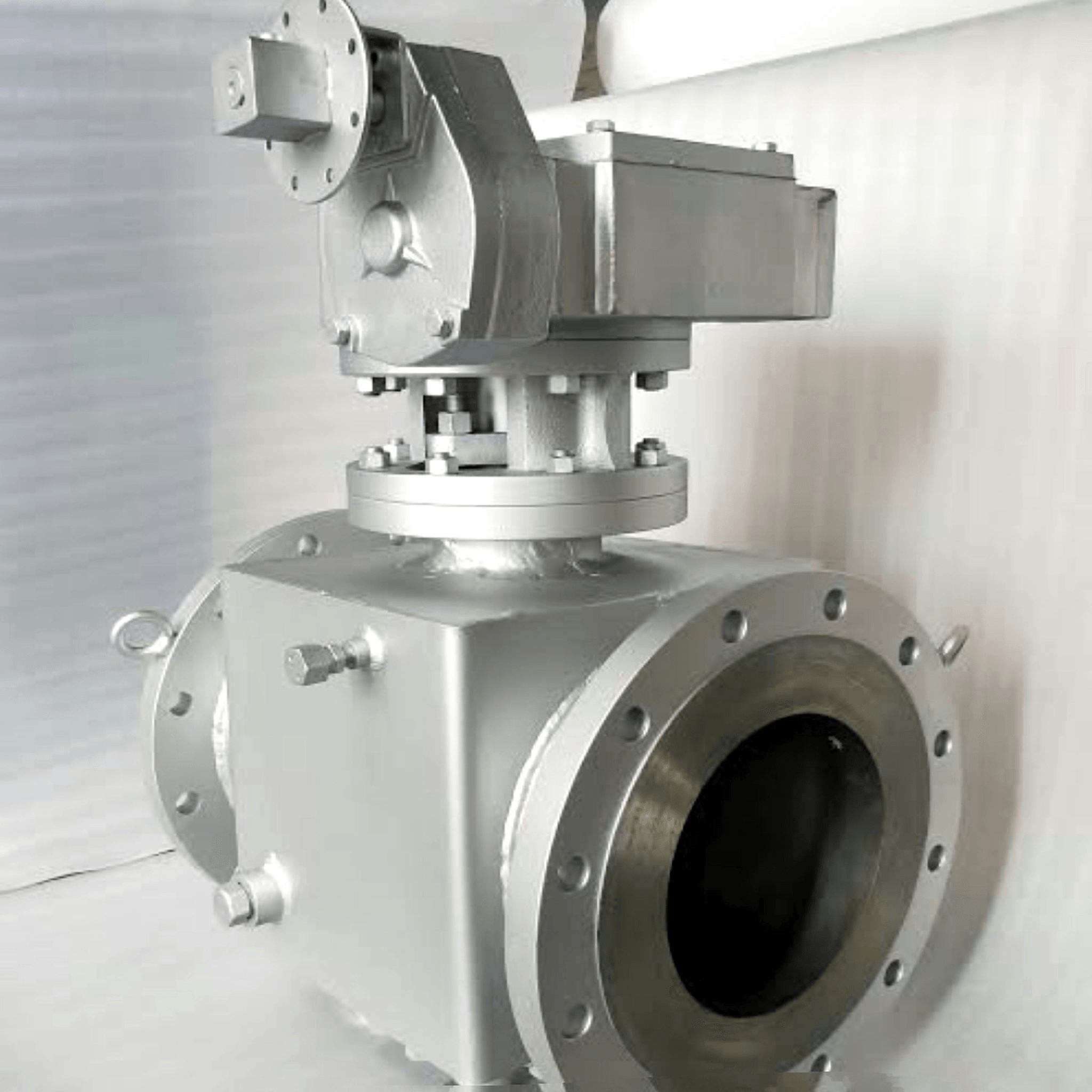

The three main types of actuators used to drive valves include electric ball valve actuators, which are ideal for on/off applications; quarter turn electric actuators, suitable for butterfly and ball valves; and multi-turn electric actuators, commonly used with gate and globe valves.

What Are Electric Valve Actuators?

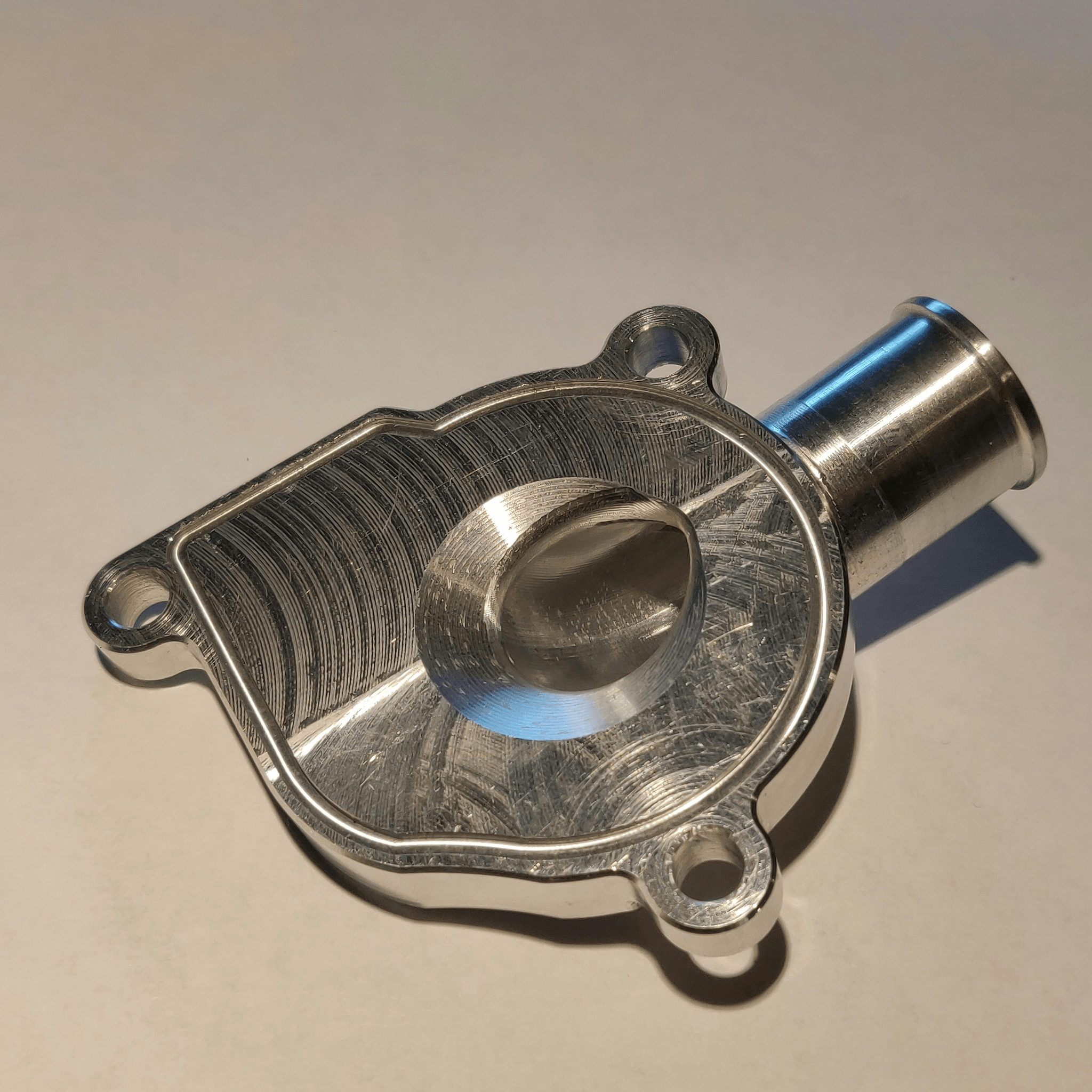

Electric valve actuators are devices used to control the opening and closing of valves in industrial settings. They provide the necessary force to move the valve to the desired position, allowing for precise control of fluid flow. This is achieved through the use of electric motors and gears, which convert electrical energy into mechanical motion.

Definition and Function of Electric Valve Actuators

The function of electric valve actuators is to automate the operation of valves, eliminating the need for manual intervention. They are essential in controlling the flow of various fluids such as water, oil, and gas in industrial processes. By using electric power, these actuators can achieve precise positioning and rapid response times, making them ideal for critical applications.

Electric valve actuators play a crucial role in ensuring the safety and efficiency of industrial processes. Their ability to automate valve operation reduces the risk of human error and allows for precise control over fluid flow. This is particularly important in industries where even minor deviations in flow rates can have significant consequences. Additionally, the durability of electric valve actuators ensures that they can withstand harsh operating conditions, making them a reliable choice for long-term use.

Importance of Reliable and Durable Actuators

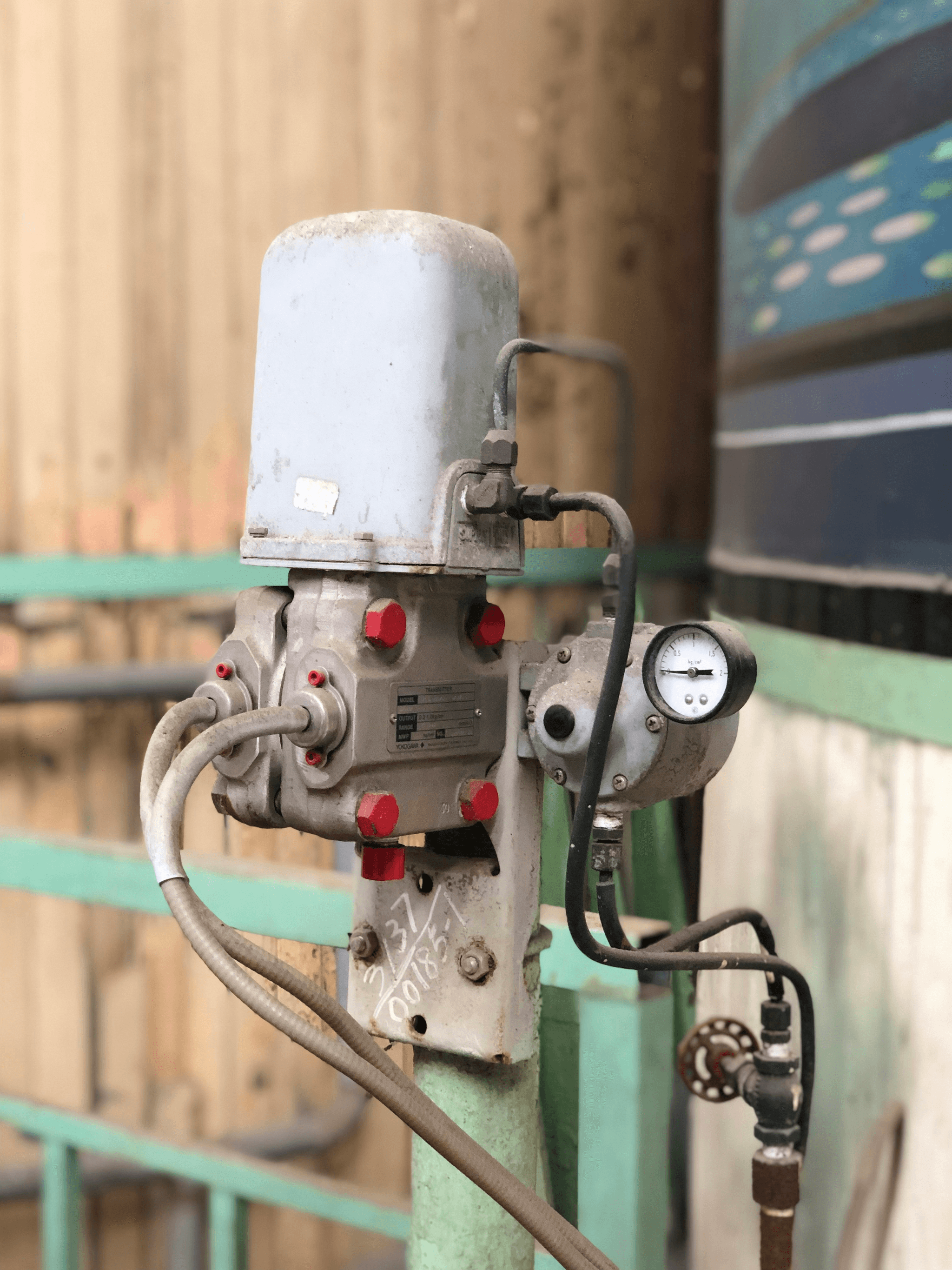

Reliability and durability are crucial when it comes to electric valve actuators. These devices often operate in harsh environments with extreme temperatures, high pressures, and corrosive substances. A reliable actuator ensures uninterrupted operation of critical processes, while durability guarantees a longer service life, reducing maintenance costs and downtime.

In addition to reliability and durability, electric valve actuators also need to be able to provide precise and accurate control over the flow of fluids and gases. This is essential for maintaining the efficiency and safety of industrial processes, as even small deviations in valve positioning can have significant consequences. Actuators with advanced control capabilities can ensure that operations run smoothly and according to specifications, minimizing the risk of errors or accidents.

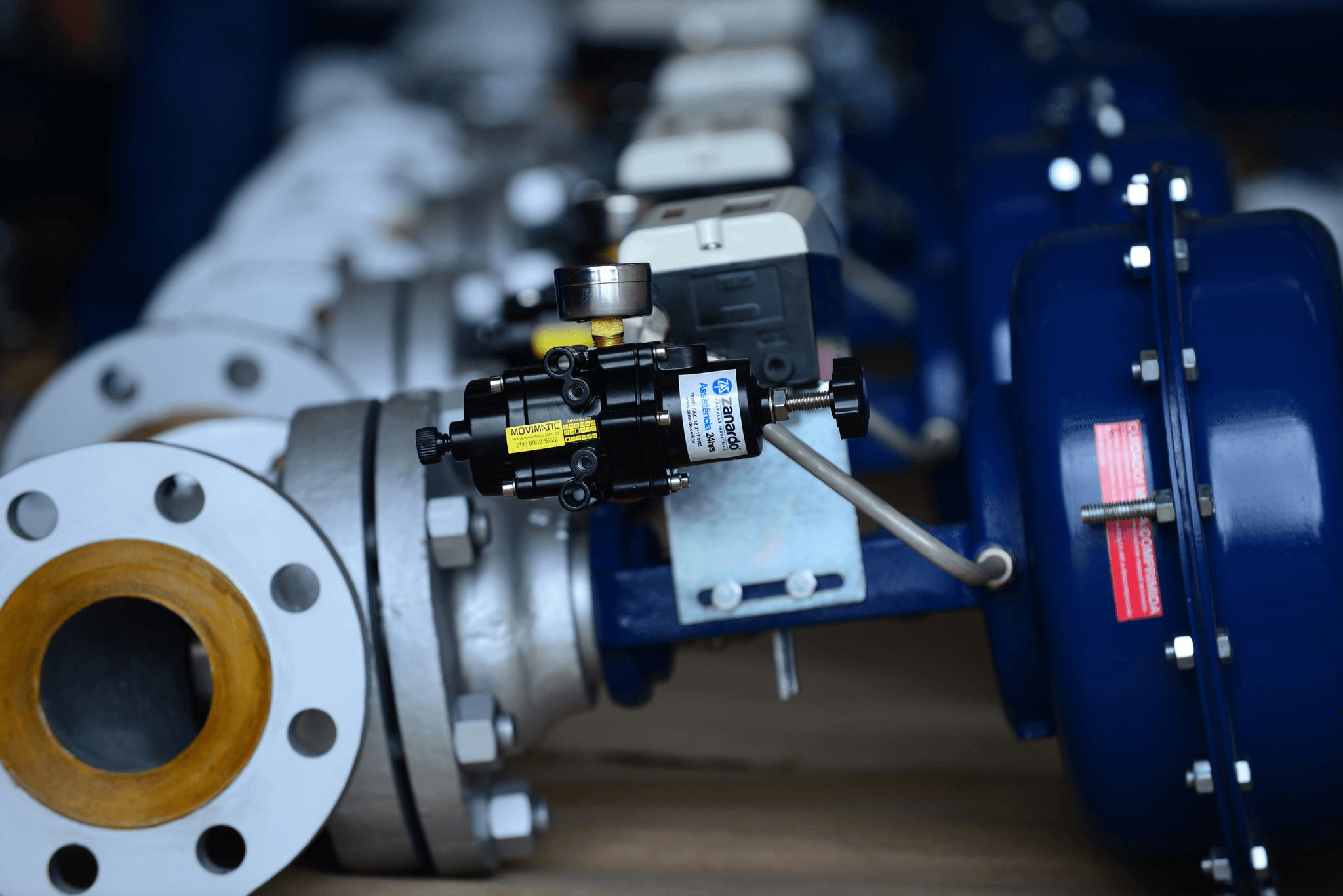

Common Applications in Industrial Settings

Electric valve actuators find widespread use in industries such as oil and gas, petrochemicals, water treatment plants, and power generation facilities. They are employed in a variety of applications including fluid control systems, pipelines, storage tanks, and process equipment where precise control over fluid flow is essential for operational efficiency.

Electric valve actuators are essential for maintaining the smooth operation of fluid control systems in industrial settings. These actuators play a vital role in ensuring the precise control of fluid flow in pipelines, storage tanks, and process equipment, which is crucial for operational efficiency. Without reliable electric valve actuators, industries such as oil and gas, petrochemicals, water treatment plants, and power generation facilities would struggle to maintain their production processes.

Remember that choosing the right electric actuator is crucial for ensuring optimal performance in industrial settings!

Choosing the Right Electric Actuator

When selecting an electric actuator for valves, there are several factors to consider. Firstly, you need to assess the torque requirements of your valves and ensure that the actuator can meet those demands. Additionally, you should take into account the environmental conditions and any specific industry standards that may apply to your application.

Factors to Consider When Selecting an Electric Actuator

Some key factors to consider include the type of valve being automated, the operating environment (such as temperature and humidity), and the required speed and precision of valve control. It's also important to think about maintenance requirements and the availability of spare parts for your chosen actuator.

When selecting an electric actuator, it's essential to consider the power supply available in your facility. Some electric actuators may require a specific voltage or electrical connection, so it's crucial to ensure compatibility with your existing infrastructure. Additionally, you'll want to think about the potential for future expansion or changes in your system, and whether the chosen actuator can accommodate these needs without significant modifications.

Comparison of Electric Ball Valve Actuator and Quarter Turn Electric Actuators

Electric ball valve actuators are known for their precise control over flow rates, making them ideal for applications where accuracy is crucial. In contrast, quarter turn electric actuators offer greater versatility by being compatible with a wider range of valves. This makes them a popular choice in industrial settings where different types of valves may be used within the same system. The ability to adapt to various valve types can save time and resources by allowing for standardized actuation across different processes.

Key Features to Look for in Electric Valve Actuators

When choosing an electric valve actuator, it's essential to look for features such as robust construction, reliable performance under varying conditions, and ease of installation and maintenance. Additionally, remote control capabilities, fail-safe options, and compatibility with existing control systems can make a significant difference in operational efficiency.

In addition to the essential features of robust construction and reliable performance, it's crucial to consider the power source for electric valve actuators. Opting for actuators with energy-efficient options can lead to cost savings and reduced environmental impact. Furthermore, the ability to integrate with smart technology and automation systems can streamline operations and improve overall efficiency, making it easier to monitor and control valve performance remotely.

By carefully considering these factors and comparing different types of electric actuators available on the market, you can make an informed decision that meets your specific needs while ensuring reliable performance in driving your valves.

Understanding the Operation of Electric Valve Actuators

How Electric Valve Actuators Work

Electric valve actuators are devices that are used to control the opening and closing of valves in various industrial applications. They work by converting electrical energy into mechanical motion, which is then used to drive the valve into the desired position. This allows for precise control over the flow of liquids or gases through the valve, making them essential components in many industrial processes.

Electric valve actuators also offer remote control capabilities, allowing operators to adjust valve positions from a distance. This is particularly useful in situations where valves are located in hard-to-reach or hazardous areas, as it eliminates the need for manual intervention. By enabling remote control, electric valve actuators improve safety and efficiency in industrial processes, making them a preferred choice for many applications.

Remote Control Capabilities of Electric Valve Actuators

One of the key advantages of electric valve actuators is their remote control capabilities. This means that operators can easily open or close valves from a distance, without having to manually adjust them. This not only improves efficiency but also enhances safety by allowing operators to operate valves from a safe distance, especially in hazardous environments.

Furthermore, electric valve actuators with remote control capabilities can also be integrated into automated systems, allowing for seamless operation without the need for constant human intervention. This can lead to significant cost savings and improved productivity, as the valves can be programmed to open or close at specific times or in response to certain conditions. Additionally, the ability to monitor and control valves remotely provides operators with real-time data and insights, enabling them to make informed decisions and adjustments as needed.

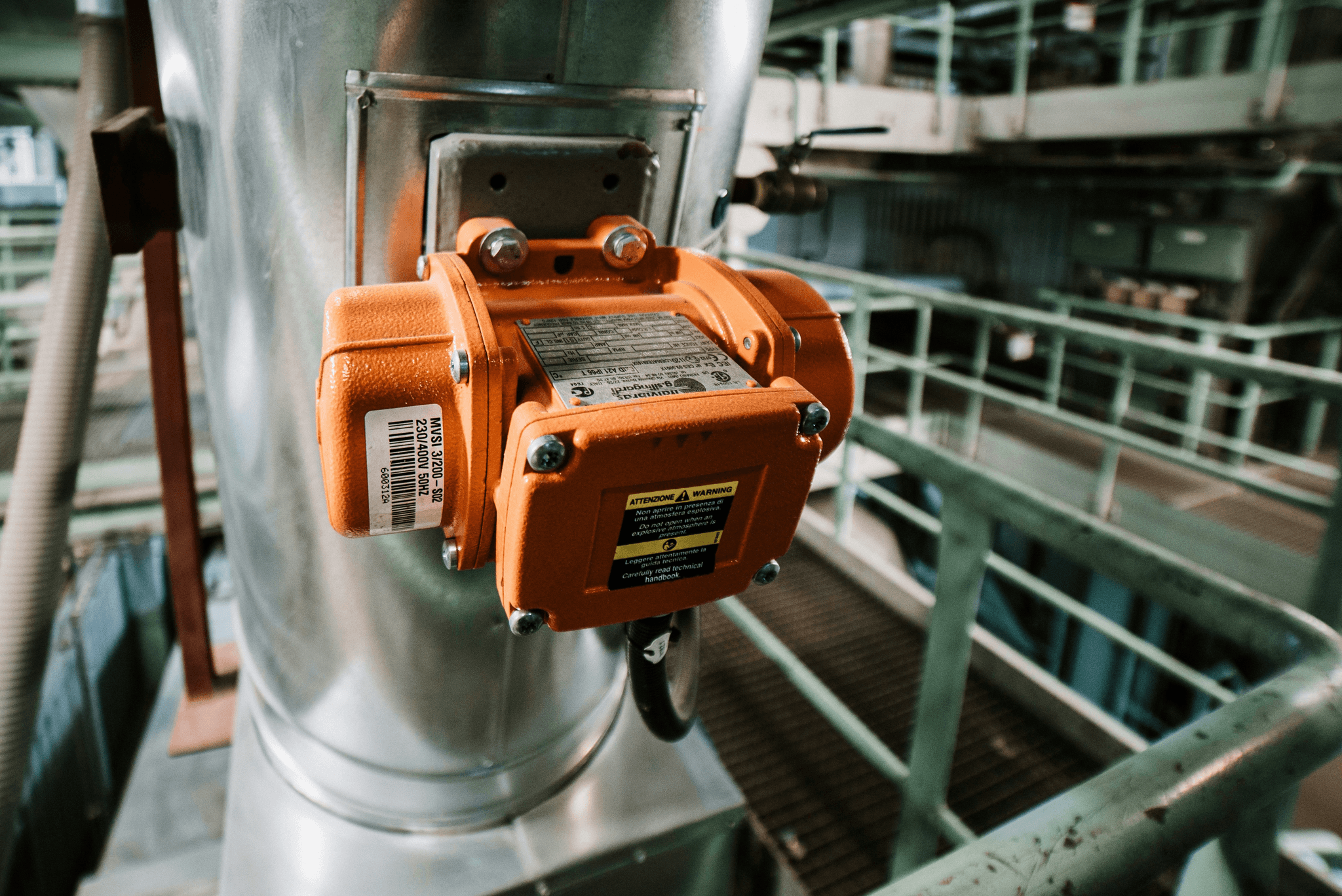

Benefits of Haisen's Part-Turn Valve Electric Actuator

Haisen's part-turn valve electric actuator offers a range of benefits for industrial applications. With its robust design and precision engineering, it provides reliable and efficient operation for driving valves in various settings. Its high torque output and compact size make it suitable for a wide range of valve types, making it a versatile choice for industrial automation needs.

Ensuring Durability and Reliability

Importance of Durability in Industrial Environments

When it comes to industrial environments, durability is key when choosing electric valve actuators. These settings often involve harsh conditions and heavy usage, so the actuators need to be able to withstand constant wear and tear. Investing in durable actuators ensures that your valves will continue to function reliably, minimizing downtime and maintenance costs.

Testing and Quality Assurance for Electric Valve Actuators

To ensure the durability and reliability of electric valve actuators, rigorous testing and quality assurance measures are essential. Actuators should undergo thorough testing to ensure they meet industry standards for performance and durability. Quality assurance processes help identify any potential issues before the actuators are put into use, guaranteeing their reliability in demanding industrial applications.

Investing in reliable electric valve actuators can lead to long-term benefits for industrial operations. By ensuring that the actuators undergo rigorous testing and quality assurance measures, companies can avoid costly downtime and maintenance issues. This proactive approach to quality control ultimately saves time and money in the long run, as reliable actuators are less likely to fail or require frequent repairs.

Long-Term Benefits of Investing in Reliable Actuators

Investing in reliable electric valve actuators brings long-term benefits to industrial operations. By choosing durable and well-tested actuators, you can minimize the risk of unexpected failures and costly downtime. Reliable actuators also contribute to overall operational efficiency, ensuring that valves function smoothly and consistently over an extended period. Additionally, these reliable actuators can enhance the safety of industrial processes by providing precise control over valve operation, reducing the likelihood of accidents or malfunctions. This not only protects personnel and equipment but also helps maintain a positive reputation for your business in terms of safety standards and compliance.

Conclusion

When it comes to choosing the right electric valve actuators, it's crucial to consider factors such as the type of valve, the required torque, and the environmental conditions in which the actuator will operate. The impact of reliable and durable actuators in industrial settings cannot be overstated, as they ensure smooth and efficient operation of valves, leading to increased productivity and safety. Key features to look for in electric valve actuators include robust construction, high torque output, and remote control capabilities.

Key Considerations for Choosing Electric Valve Actuators

When selecting electric valve actuators, it's important to understand their function and how they align with the specific needs of your valves. Consider factors such as torque requirements, operating environment, and control options to ensure that you choose an actuator that is well-suited for your application.

The Impact of Reliable and Durable Actuators in Industrial Settings

Reliable and durable electric valve actuators are essential in industrial settings where valves play a critical role in controlling fluid flow. These actuators ensure that valves operate smoothly and consistently, minimizing downtime and maintenance costs while maximizing operational efficiency. When selecting electric valve actuators, it's important to look for features such as robust construction, high torque output, and reliable performance in harsh environments. Actuators with these attributes can withstand the rigors of industrial operations, providing long-term reliability and reducing the need for frequent replacements or repairs.

Key Features to Look for in Electric Valve Actuators

When evaluating electric valve actuators, look for features such as robust construction materials, high torque output, and advanced control options. These features contribute to the overall reliability and performance of the actuator, making it a valuable asset in industrial applications.

Furthermore, it is essential to consider the environmental protection rating of electric valve actuators. Look for actuators with a high IP rating to ensure they can withstand harsh conditions, such as extreme temperatures and exposure to dust or water. This will help prolong the lifespan of the actuator and minimize maintenance requirements, ultimately saving time and resources for industrial operations.