Introduction

In the world of industrial automation, electric actuator valves have emerged as essential components for controlling fluid flow with precision and efficiency. These devices simplify operations by automating the movement of valves, allowing for remote operation and reducing manual labor. Understanding what an electric valve actuator is and its functionality can significantly enhance operational efficiency across various industries.

Understanding Quarter Turn Electric Actuators

Quarter turn electric actuators are specialized devices designed to control valves that require a 90° rotation, such as butterfly, ball, and plug valves. What is an electric valve actuator? Simply put, it converts electrical energy into mechanical motion to open or close a valve in a controlled manner. The function of the electric actuator is crucial in ensuring that processes run smoothly without the need for constant human intervention.

Key Features of QT Series Actuators

Haisen's QT series part-turn valve electric actuator stands out in the market with its innovative design tailored for various industrial applications. This product offers features such as local and remote operation capabilities, making it versatile for different setups. The difference between an actuator and a motorized valve lies in their control mechanisms; while both serve to regulate flow, actuators provide automated movement that enhances efficiency compared to traditional motorized solutions.

Applications of Electric Actuator Valves

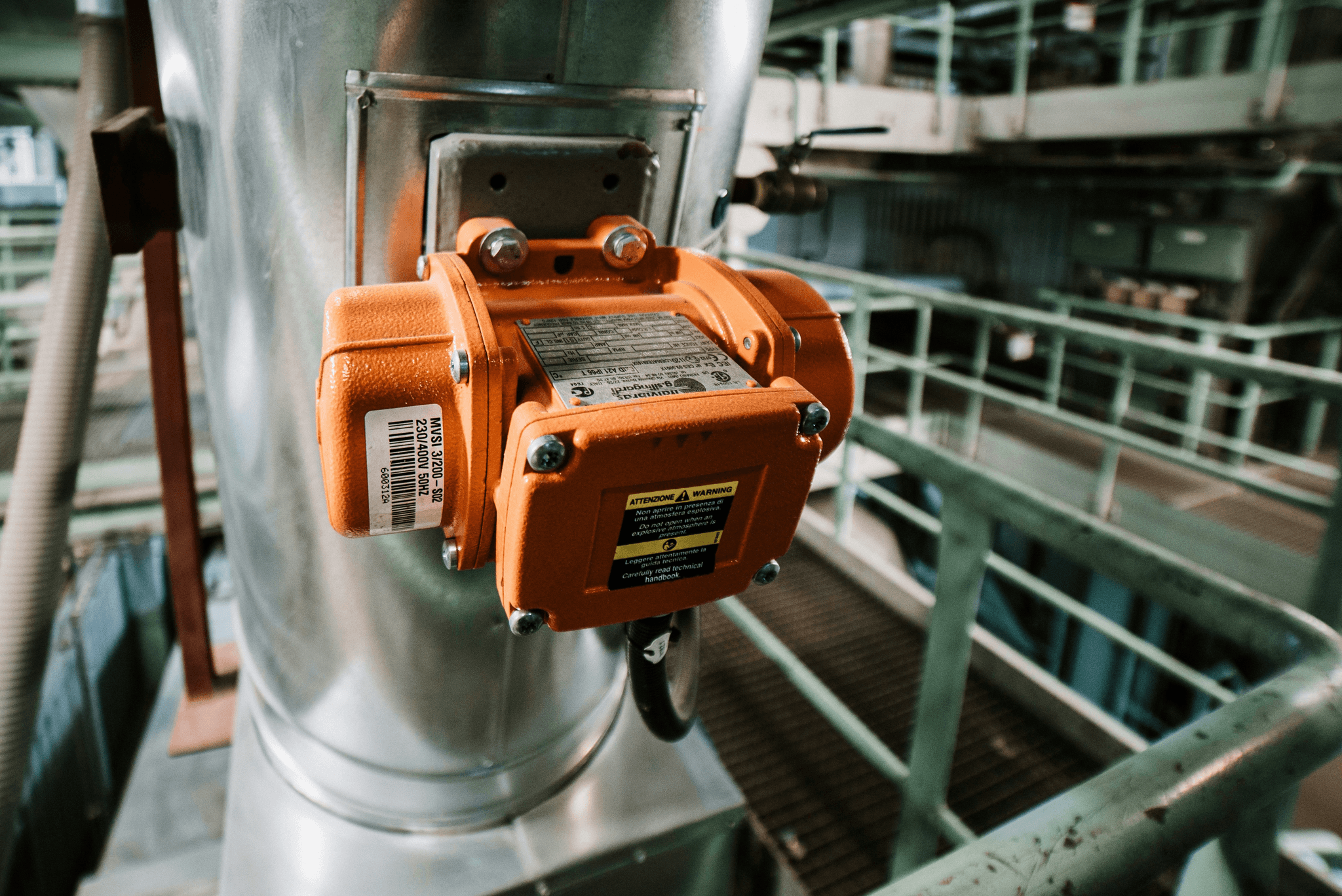

Electric actuator valves find their purpose across numerous sectors including petrochemicals, shipbuilding, and power generation. In these industries, they play a vital role in managing fluid dynamics safely and efficiently—ensuring optimal performance under varying conditions. As industries evolve towards automation, understanding how these devices integrate into existing systems becomes increasingly important for maintaining competitive advantages.

What is a Quarter Turn Electric Actuator?

Quarter turn electric actuators are specialized devices designed to automate the opening and closing of valves with a 90° rotation. These electric actuator valves serve as essential components in various industrial applications, providing precise control over fluid flow. Understanding their definition and functionality is crucial for anyone involved in process automation.

Definition and Functionality

So, what is an electric valve actuator? At its core, it’s an electromechanical device that converts electrical energy into mechanical motion to operate a valve. The function of electric actuators is to facilitate quick and efficient valve operations, eliminating the need for manual intervention while enhancing safety and reliability in processes.

The primary purpose of the valve actuator is to manage fluid flow within pipelines effectively. It achieves this by rotating the valve stem, which either opens or closes the valve depending on the desired flow rate. This functionality makes them indispensable in industries where precise control over fluid dynamics is critical.

How It Works with Valves

When discussing how it works with valves, it's important to note that quarter turn electric actuators are typically paired with butterfly valves, ball valves, or plug valves—all of which require only a 90° movement for operation. The actuator receives commands from a control system (either locally or remotely) that dictate when to open or close the valve based on process requirements.

The mechanism inside an electric actuator consists of various components such as gears and motors that convert electrical signals into rotational motion. This seamless integration allows for quick response times and consistent performance across multiple cycles without wear typical of manual operations.

Understanding what is the difference between an actuator and a motorized valve can also clarify their roles in industrial settings; while motorized valves include built-in actuation mechanisms, traditional actuators like those found in Haisen's QT series are separate units providing enhanced flexibility for installation and maintenance.

Advantages Over Manual Options

One significant advantage of using electric industrial actuators over manual options lies in their ability to operate remotely without requiring physical presence at the site of installation. This capability not only saves time but also reduces labor costs associated with manual operation—especially valuable in hazardous environments where human presence may be risky.

Additionally, what is the function of an electric actuator? Beyond just opening and closing valves, these devices provide precise control over flow rates through programmable settings that can adapt to varying operational conditions. This level of automation leads to increased efficiency, reduced downtime during maintenance activities, and improved overall system reliability.

In summary, choosing quarter turn electric actuators offers numerous benefits compared to manual alternatives: enhanced safety features due to remote operation capabilities, precise control over fluid dynamics through advanced programming options, and increased operational efficiency across various industries—from petrochemical applications to shipbuilding projects.

Unpacking the QT Series from Haisen

When it comes to electric actuator valves, Haisen's QT series stands out as a remarkable innovation in the field of automation. This product line is designed to meet the diverse needs of various industries, providing reliable solutions for controlling valves with precision and efficiency. With a focus on performance and adaptability, Haisen has positioned itself as a leader in the electric actuator market.

Overview of Haisen's Product Line

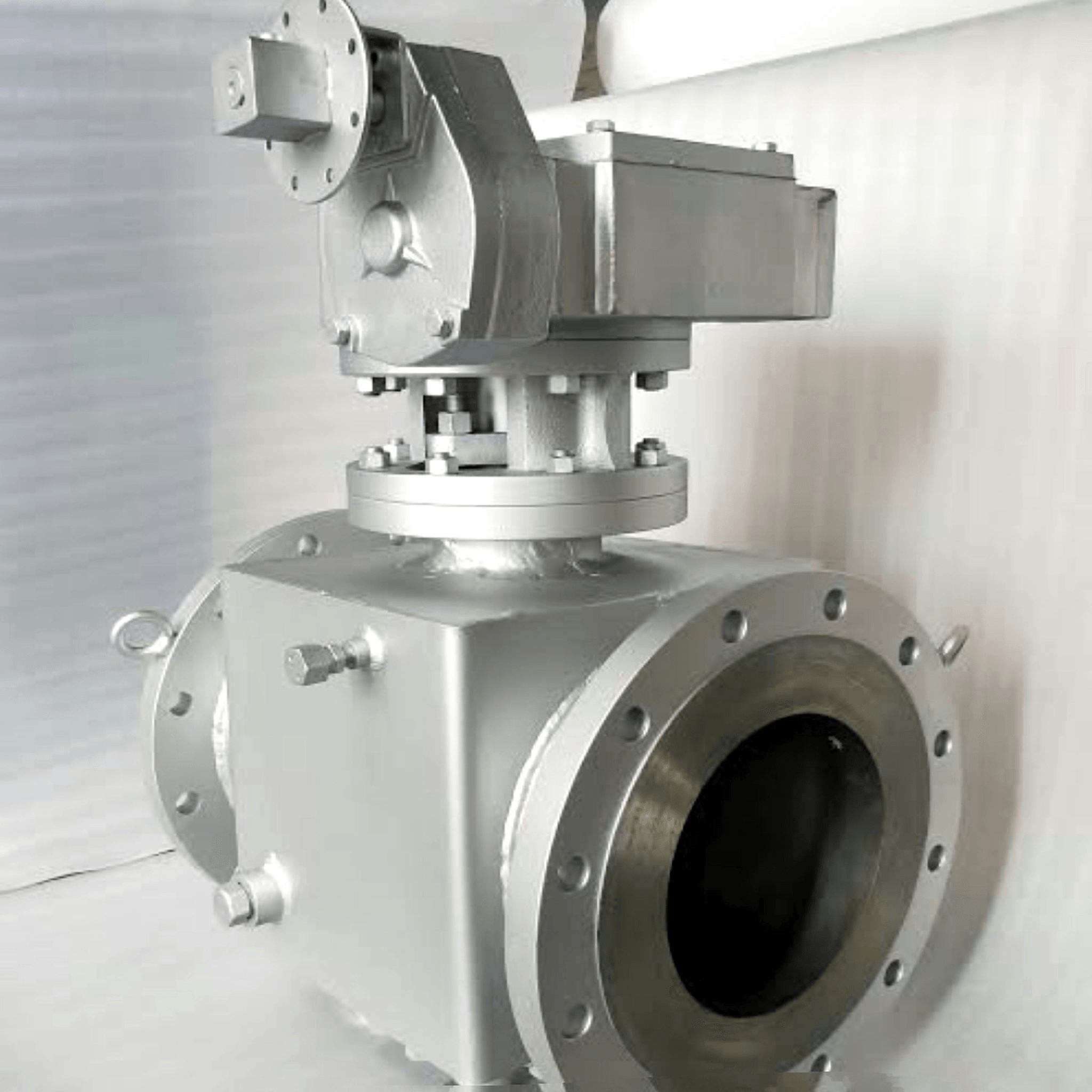

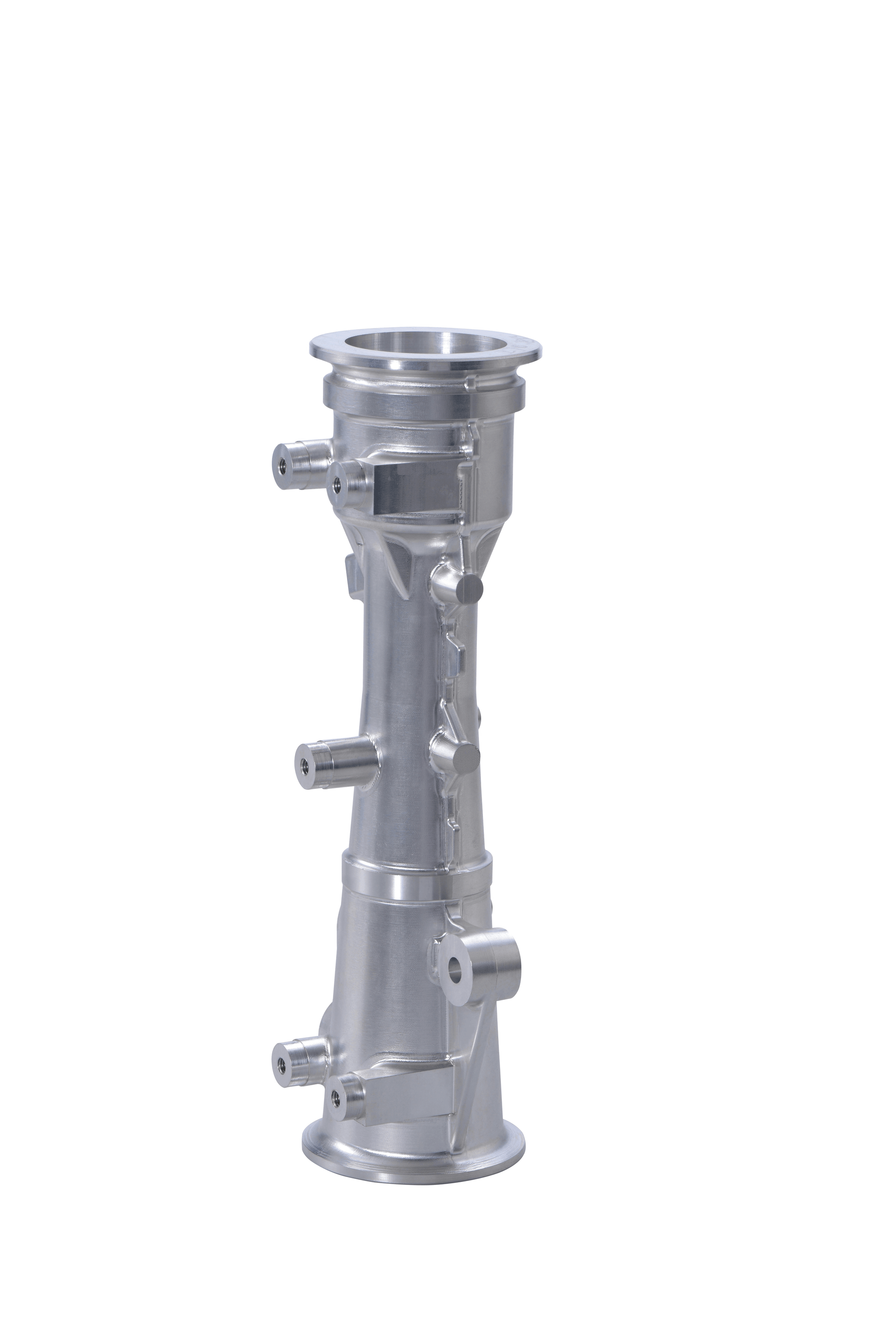

Haisen offers a comprehensive range of electric industrial actuators that cater to different applications and operational requirements. The QT series part-turn valve electric actuator is specifically engineered for controlling butterfly valves, ball valves, and plug valves with a 90° rotation. By combining advanced technology with user-friendly features, these actuators ensure seamless integration into existing systems while enhancing overall operational efficiency.

Haisen's product line also includes various models tailored to specific industry needs, making it easier for customers to find the perfect fit for their operations. Whether you are looking for an actuator that operates locally or one that can be controlled remotely, Haisen has you covered. The versatility of these electric valve actuators allows them to be employed across multiple sectors such as petrochemical, metallurgy, shipbuilding, and more.

Unique Features of QT Series

What sets the QT series apart from other electric actuator valves on the market? For starters, this innovative product boasts exceptional durability and reliability under demanding conditions. Built with high-quality materials and advanced engineering techniques, these actuators are designed to withstand harsh environments while delivering consistent performance.

Another unique feature is their ease of installation and maintenance; users can quickly set up their electric valve actuators without extensive training or specialized tools. Additionally, Haisen's QT series integrates smart technology that allows users to monitor performance metrics in real-time—an invaluable asset when considering what is the function of an electric actuator? This capability not only enhances operational oversight but also facilitates proactive maintenance strategies.

Moreover, the QT series incorporates safety features that protect both equipment and personnel during operation. This attention to detail ensures that users can rely on their actuators to perform optimally while minimizing risks associated with valve control systems.

Comparisons with Competitors

When comparing Haisen's QT series to competitors in the market, it's clear that this product line offers superior value in terms of functionality and adaptability. While many brands provide basic motorized valve options, few match the versatility found within the QT series' design—making it an excellent choice for those asking what is the difference between an actuator and a motorized valve?

Competitors often lack advanced monitoring capabilities or robust construction suited for heavy-duty applications; however, Haisen’s commitment to quality ensures its products excel even under challenging conditions. Additionally, while some alternatives may require complex setup processes or frequent maintenance checks—what is the purpose of the valve actuator?—the QT series simplifies these tasks significantly.

In summary, when evaluating options in electric industrial actuators available today, Haisen's QT series emerges as a top contender due to its unique features combined with exceptional reliability across various industries including thermal power and hydropower sectors.

Applications Across Industries

Electric actuator valves have rapidly become essential components in various industrial sectors, thanks to their efficiency and reliability. Understanding how these devices operate and their specific applications can provide invaluable insights into their importance across different fields. This section will delve into the diverse applications of electric actuator valves, highlighting their significance in petrochemical industries, shipbuilding, and thermal and hydropower sectors.

Use in Petrochemical Industries

In the petrochemical industry, electric actuator valves play a crucial role in managing the flow of fluids through pipelines and processing units. These electric valve actuators are designed to withstand harsh environments while providing precise control over valve operations. The primary function of an electric actuator is to automate valve movements, ensuring efficient processes that meet safety and regulatory standards.

The advantages of using an electric actuator over manual options become evident in high-demand settings like petrochemical plants, where quick response times are essential. Electric actuators can be integrated into automated systems, allowing for remote monitoring and control—what is an electric valve actuator? It's your go-to solution for achieving seamless operations without compromising safety or efficiency. With Haisen's QT series specifically designed for such applications, users benefit from reliable performance even under extreme conditions.

Moreover, the purpose of the valve actuator extends beyond mere automation; it enhances overall system reliability by minimizing human error during operation. By employing Electric Industrial Actuators like those from Haisen, companies can optimize their workflows while ensuring compliance with environmental regulations—a win-win situation for both operational efficiency and sustainability.

Relevance in Shipbuilding

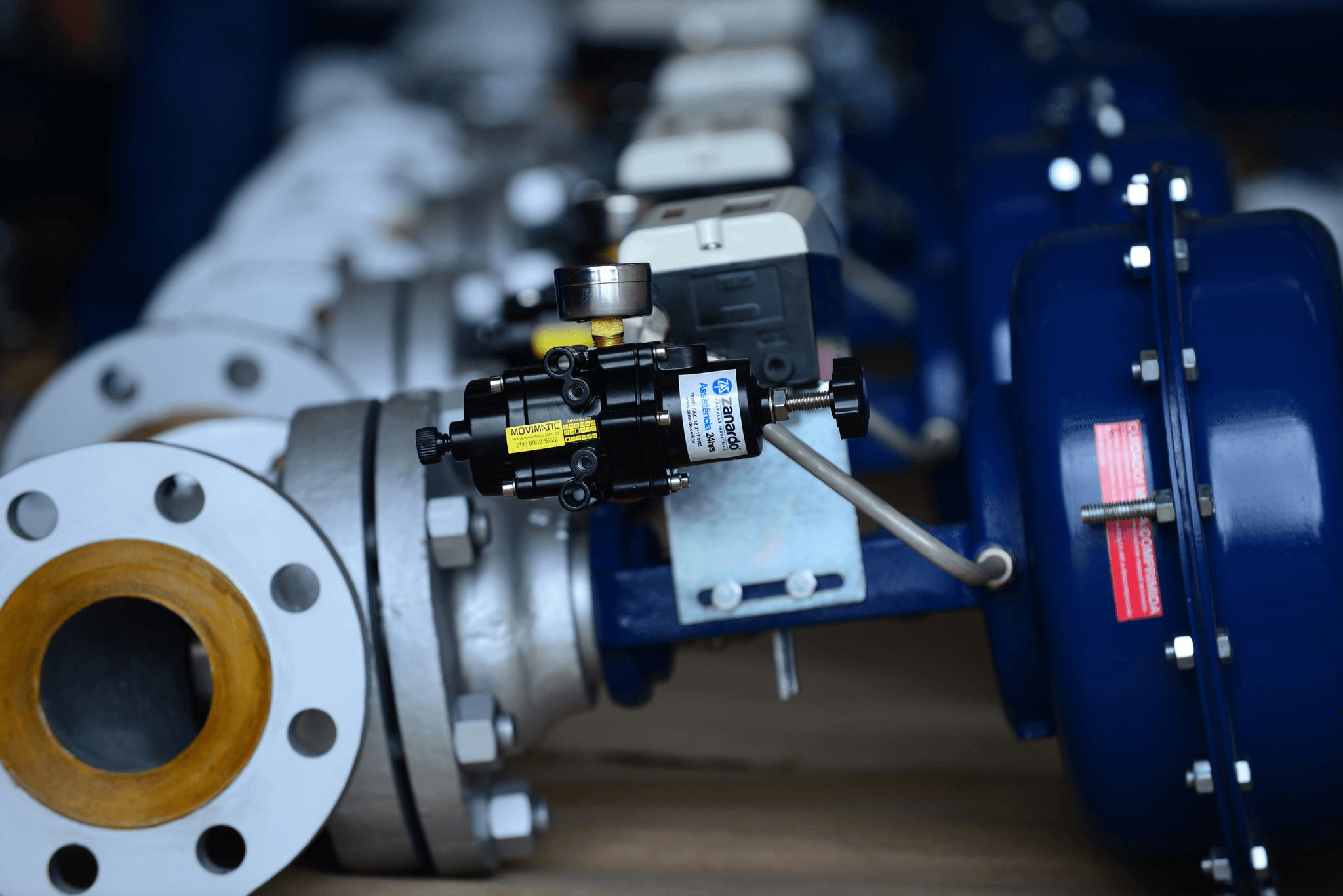

The shipbuilding industry also greatly benefits from the use of electric actuator valves due to their ability to manage various fluids onboard vessels efficiently. In this sector, it's vital that systems operate flawlessly under varying pressures and conditions—this is where understanding what is the function of an electric actuator comes into play. These devices ensure that critical systems such as ballast water management or fuel transfer work seamlessly.

Electric actuators offer significant advantages over traditional motorized valves by providing precise control with minimal maintenance requirements. Unlike manual options that can be labor-intensive and prone to errors during operation, these automated solutions improve safety on ships by reducing human intervention when controlling vital systems. So what's the difference between an actuator and a motorized valve? The former automates movement while the latter refers more broadly to any device controlling fluid flow.

Haisen’s QT series part-turn valve electric actuators are perfect for shipbuilding applications due to their robust design tailored for marine environments. Their ability to handle butterfly valves or ball valves with ease ensures reliable performance throughout a vessel's lifecycle—keeping everything shipshape!

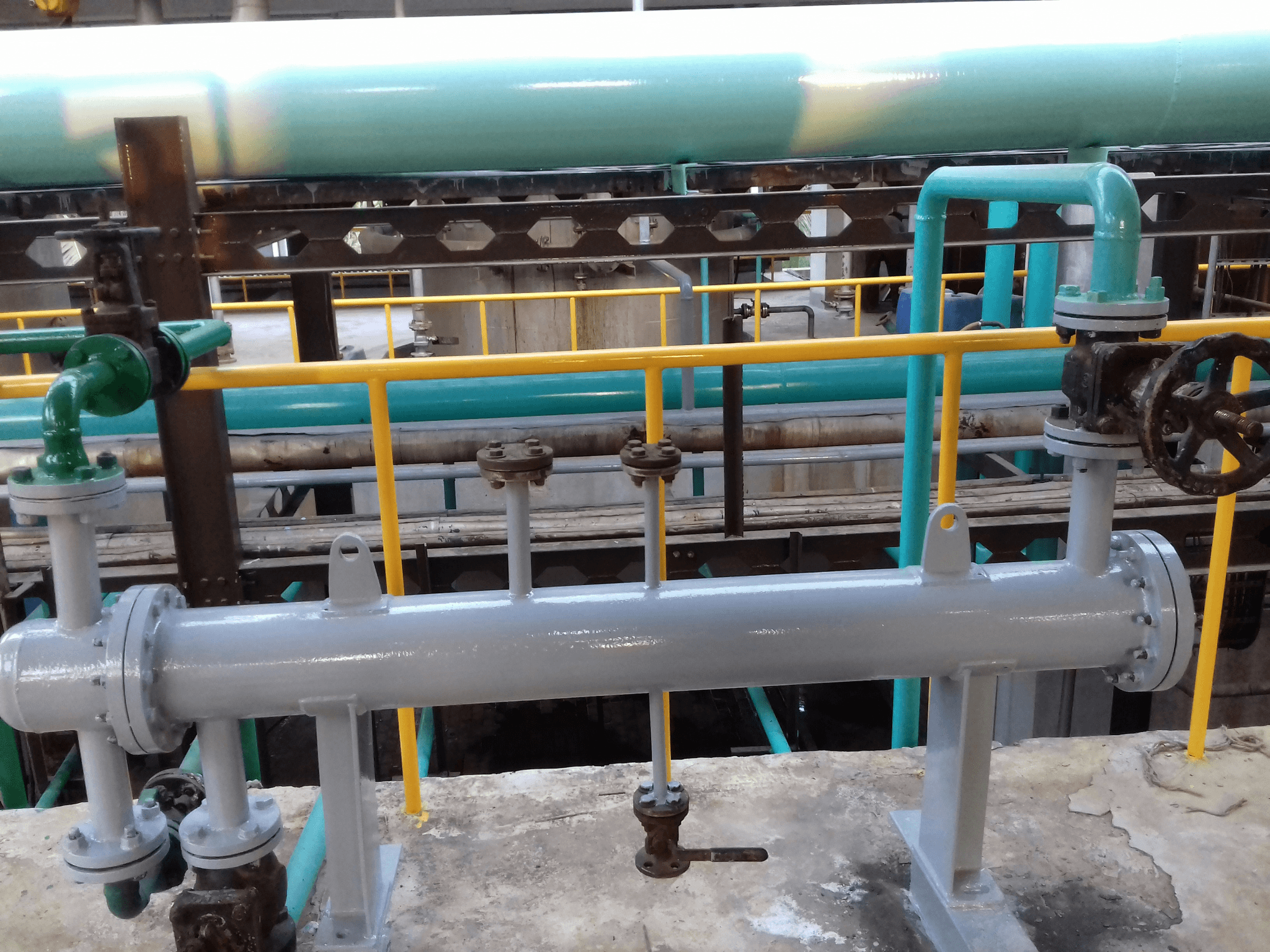

Role in Thermal and Hydropower Sectors

In thermal power plants and hydropower facilities, efficient fluid management is essential for optimizing energy production processes—enter electric actuator valves! These devices help regulate water flow through turbines or cooling systems with precision that manual options simply can't match. Understanding what is an electric valve actuator allows operators to appreciate its role in enhancing energy efficiency while maintaining system integrity.

The purpose of the valve actuator here involves more than just opening or closing; it ensures that operations run smoothly under varying load conditions typical in power generation environments. This capability significantly reduces downtime caused by mechanical failures often associated with traditional actuation methods—a clear advantage when considering what is the function of an electric actuator?

As industries evolve towards greater automation, Electric Industrial Actuators like those from Haisen will continue leading innovations within thermal power generation processes as well as hydropower facilities worldwide—keeping pace with growing energy demands sustainably.

Installation and Maintenance Tips

Installing and maintaining your electric actuator valve is crucial for ensuring optimal performance and longevity. Proper setup not only enhances functionality but also minimizes the risk of operational issues down the line. Here, we’ll guide you through the steps for installation, routine maintenance practices, and troubleshooting common problems.

Setting Up Your Electric Actuator Valve

When setting up your electric actuator valve, begin by ensuring that all necessary tools are at hand, including wrenches, screwdrivers, and safety equipment. Start by securely mounting the electric actuator onto the valve according to manufacturer specifications; this ensures a snug fit and proper alignment. After connection, it’s essential to connect the power supply while adhering to electrical safety standards to avoid any mishaps during operation.

The next step involves configuring the control settings as per your requirements; this is where understanding What is an electric valve actuator? comes into play—it's designed to automate valve operations effectively. Ensure that you test both local and remote control capabilities if applicable; this will help verify that everything functions as intended right from the start. Lastly, double-check all connections before powering on your system to prevent any electrical issues.

Routine Maintenance Practices

Routine maintenance of your electric actuator valve is vital for its efficient operation over time. Regularly inspect components such as seals, gears, and wiring for signs of wear or damage; this proactive approach can save you from costly repairs later on. Lubricating moving parts according to manufacturer guidelines will also help maintain smooth operation while extending the lifespan of your device.

Understanding What is the function of an electric actuator? helps in recognizing when maintenance is needed—these devices convert electrical energy into mechanical motion which can wear down components over time. Additionally, keeping a logbook of maintenance activities helps track performance trends and identify potential issues early on. Regularly testing functionality ensures that you catch any deviations before they become major problems.

Troubleshooting Common Issues

Even with diligent care, you may encounter some common issues with your electric actuator valve that require troubleshooting. If you notice erratic movements or failure to operate altogether, first check for power supply disruptions or loose connections; these are often culprits behind malfunctioning systems. Understanding What is the difference between an actuator and a motorized valve? can also provide insight—actuators are typically responsible for movement while motorized valves may include integrated controls that could affect performance.

Another frequent issue involves improper calibration which may lead to inaccurate positioning of valves; recalibrating based on manufacturer instructions usually resolves this problem swiftly. If you experience overheating or unusual noises during operation, it’s advisable to stop using the device immediately until a thorough inspection has been conducted—safety should always come first! Remember that knowing What is the purpose of the valve actuator? gives clarity on how critical these devices are in maintaining system integrity across various applications.

Future Trends in Electric Actuators

The landscape of electric actuators, especially electric actuator valves, is rapidly evolving as industries seek more efficient and reliable solutions. With advancements in technology and an increasing push towards automation, the future holds exciting possibilities for electric industrial actuators. Let's explore some of these trends that are set to shape the industry.

Innovations on the Horizon

Innovations in electric actuator valves are paving the way for enhanced performance and functionality. One notable development is the integration of smart technology into what is an electric valve actuator? These smart actuators can communicate with other devices, allowing for real-time monitoring and control, which vastly improves operational efficiency. Furthermore, advancements in materials and design are making these devices more compact and energy-efficient while maintaining their robustness.

As we look ahead, it's clear that the function of electric actuators will expand beyond simple valve control to encompass more complex tasks such as predictive maintenance and automated adjustments based on system feedback. This evolution will not only streamline operations but also significantly reduce downtime across various sectors. The difference between an actuator and a motorized valve will blur as both technologies converge to offer unparalleled versatility.

Impact of Automation in Industries

The impact of automation on industries utilizing electric industrial actuators cannot be overstated. As companies strive for greater efficiency, automation plays a critical role in optimizing processes—especially when considering what is the purpose of the valve actuator? By automating valve operations through advanced electric actuator valves, organizations can minimize human error while maximizing productivity.

Moreover, automated systems allow for remote monitoring and control capabilities that were previously unattainable with manual options. This shift not only enhances safety by reducing human intervention but also leads to significant cost savings over time as operational efficiencies improve. The trend toward automation indicates a growing reliance on technologies that can adapt quickly to changing demands while ensuring consistent performance.

Evolving Standards and Regulations

As technology progresses, so too do the standards governing its use within various industries—particularly concerning safety and environmental regulations surrounding electric actuator valves. Organizations must stay abreast of evolving standards to ensure compliance while leveraging innovations effectively; this includes understanding what is an electric valve actuator?

Regulatory bodies are increasingly focusing on sustainability metrics as well; therefore, manufacturers must prioritize eco-friendly designs without compromising functionality or safety features. As a result, we can expect new guidelines regarding energy consumption levels from these devices alongside stricter testing protocols to guarantee reliability under varying conditions—defining what is the function of an electric actuator within modern frameworks.

In conclusion, keeping pace with these trends will be crucial for businesses seeking competitive advantages through improved efficiency and reliability in their operations involving electrical industrial actuators.

Conclusion

In summary, the selection of the right actuator is crucial for ensuring optimal performance in various industrial applications. The electric actuator valve serves as a pivotal component in automation, providing efficiency and reliability that manual options simply cannot match. Understanding the nuances of electric actuators, particularly Haisen's QT series, can significantly enhance operational workflows.

The Importance of Choosing the Right Actuator

Choosing the right electric actuator valve is essential for achieving desired operational outcomes in any industrial setting. An effective actuator not only streamlines processes but also minimizes downtime and maintenance costs. When evaluating options, it’s vital to understand what is an electric valve actuator? This knowledge helps in selecting an actuator that aligns with specific needs and applications.

Key Takeaways on QT Series Features

Haisen's QT series part-turn valve electric actuator stands out due to its innovative design tailored for a variety of valves including butterfly valves, ball valves, and plug valves with a 90° rotation. Its ability to operate both locally and remotely makes it versatile across multiple industries like petrochemical and shipbuilding. Additionally, understanding what is the function of an electric actuator within these systems can further highlight its advantages over traditional methods.

Enhancing Efficiency with Electric Actuator Valves

Electric Industrial Actuators are revolutionizing how industries manage fluid control through enhanced precision and speed. By exploring what is the difference between an actuator and a motorized valve, one can appreciate how electric actuators provide superior control mechanisms essential for modern operations. Ultimately, knowing what is the purpose of the valve actuator allows organizations to leverage technology effectively to boost productivity while reducing energy consumption.