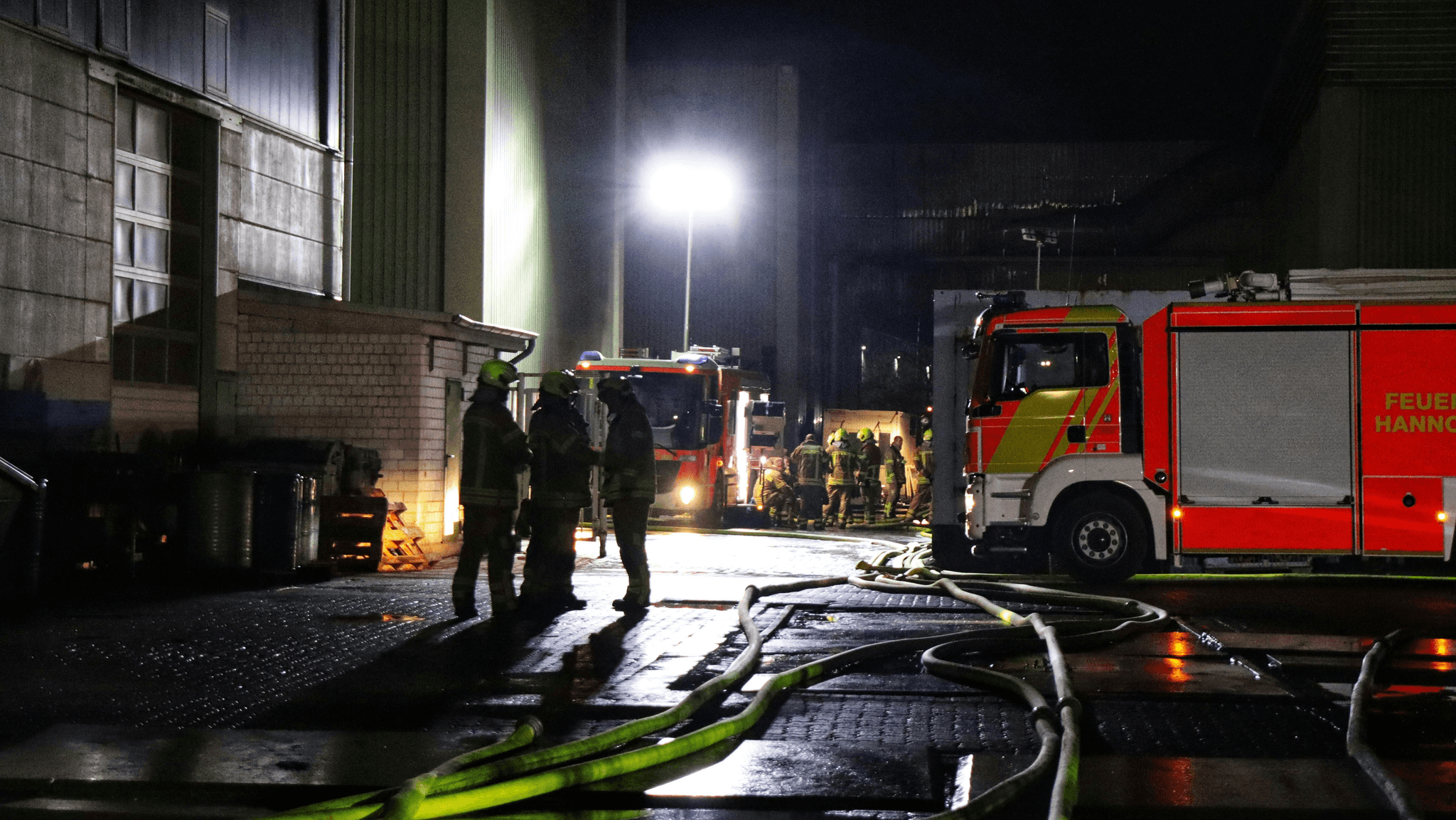

Introduction

Fire foam trucks are essential tools in modern firefighting, designed to tackle blazes that water alone simply can’t extinguish. Regular maintenance of these specialized vehicles is crucial, as it ensures they operate efficiently when every second counts. By understanding the importance of upkeep, firefighters can prevent common issues and maximize the effectiveness of their fire foam truck.

Importance of Regular Fire Foam Truck Maintenance

Maintaining a fire foam truck is not just about keeping it clean; it's about ensuring that the equipment is ready to perform under pressure. Regular maintenance helps identify potential problems before they become critical failures during an emergency response. Furthermore, a well-maintained fire foam truck enhances overall safety for both the crew and the community they serve.

Common Issues with Fire Foam Trucks

Despite their robust design, fire foam trucks can face several common issues that may hinder their performance. Problems such as pump malfunctions or clogged delivery systems can arise if routine checks are neglected. Understanding these issues allows firefighters to address them proactively, ensuring their fire foam truck remains reliable in high-stress situations.

Overview of Firefighting Foam Applications

Firefighting foam serves multiple purposes in combating various types of fires, making it an invaluable resource for firefighters worldwide. From suppressing flammable liquid fires to creating a protective barrier against heat, the versatility of firefighting foam cannot be overstated. Knowing what firefighting foam is used for and how different types of foam in fire fighting work enhances a firefighter's ability to respond effectively during emergencies.

Understanding Fire Foam Trucks

Fire foam trucks are specialized vehicles designed to combat fires using firefighting foam, which is a crucial element in modern fire suppression techniques. These trucks are equipped with advanced systems that mix water and foam concentrate, enabling firefighters to tackle various types of fires more effectively. Understanding what a fire foam truck is and how it operates can significantly enhance firefighting efforts and improve safety.

What is a Foam Fire Truck?

So, what is a foam fire truck? Essentially, it's a fire truck specifically designed to dispense firefighting foam in addition to water. This type of vehicle is particularly effective for fighting flammable liquid fires or hazardous material incidents where traditional water alone may not suffice. By utilizing specialized equipment, such as pumps and proportioning systems, these trucks ensure the right mix of foam concentrate and water to create an efficient firefighting solution.

Different Types of Foam in Fire Fighting

When discussing types of foam in fire fighting, it's essential to recognize the various formulations available for specific applications. There are primarily three categories: Class A foams for ordinary combustibles like wood and paper; Class B foams for flammable liquids such as gasoline; and film-forming foams that create a barrier between the fuel and air to prevent re-ignition. Each type has its unique properties tailored to combat different fire scenarios effectively.

Key Features of the Haisen's Foam Fire Truck

The Haisen's foam fire truck stands out due to its robust design and state-of-the-art technology tailored for optimal performance in emergency situations. Key features include an advanced foam proportioning system that delivers precise mixtures under varying conditions, ensuring effective use during critical moments. Additionally, it boasts a high-capacity tank specifically designed for storing firefighting foam, making it an invaluable asset during large-scale incidents where quick response times are vital.

Routine Maintenance Checklist

Maintaining a fire foam truck is crucial for ensuring optimal performance in emergencies. A well-maintained vehicle not only enhances firefighting capabilities but also ensures safety for the crew and the public. Below, we’ll break down the essential daily, monthly, and annual maintenance tasks that keep your foam fire truck in peak condition.

Daily Checks for Fire Foam Trucks

Every day, before heading out on calls, it’s vital to perform a series of checks on the fire foam truck. Start by inspecting the foam levels; knowing what firefighting foam is used for can help you gauge if you have enough to tackle potential fires effectively. Additionally, check all hoses and connections for leaks or wear—these components are essential when deploying types of foam in fire fighting scenarios.

Next, ensure that all gauges are functioning correctly; this includes pressure gauges and temperature indicators that could signal issues with your pump or overall system health. Don’t forget to inspect the battery and electrical systems as well; a dead battery can turn your fire truck into an expensive paperweight when every second counts! Lastly, confirm that all safety equipment is present and operational—this includes personal protective gear for firefighters who may be deployed from the truck.

Monthly Maintenance Tasks

While daily checks are crucial, monthly maintenance tasks take things a step further to ensure long-term reliability of your fire foam truck. During these monthly inspections, focus on cleaning and testing the foam proportioning systems; these systems play a critical role in mixing water with firefighting foam to create effective suppression agents during emergencies. Understanding how these systems work will help you identify potential issues before they become significant problems.

Additionally, check all fluid levels—this includes engine oil, coolant, and hydraulic fluids—as they directly affect performance during high-pressure situations. It’s also wise to inspect tires for wear and proper inflation; remember that a well-maintained vehicle is more maneuverable when responding to emergencies! Finally, schedule any necessary repairs or replacements identified during daily checks so you're never caught off guard when duty calls.

Annual Inspections and Overhauls

Annual inspections are where you really dive deep into maintaining your fire foam truck's integrity and functionality. This comprehensive review should include everything from pump performance tests to structural integrity assessments of the chassis and bodywork—after all, what is a fire truck called if it can't withstand tough conditions? Pay special attention to components like valves and seals within the firefighting system since these elements can wear out over time.

During this overhaul process, consider conducting flow tests on both water pumps and foam delivery systems; understanding how each component interacts will give insight into what firefighting foam is used for under different scenarios. Moreover, engaging with professionals who specialize in servicing these trucks can provide invaluable guidance on best practices specific to your model's needs while ensuring compliance with industry standards.

Importance of Firefighting Foam

Firefighting foam is a crucial tool in the arsenal of any fire foam truck, playing a vital role in modern firefighting strategies. Its unique properties allow it to smother flames and prevent reignition, making it especially effective for flammable liquid fires. Understanding what firefighting foam is used for can help firefighters optimize their response to various emergency situations.

What is Firefighting Foam Used For?

What is firefighting foam used for? The answer lies in its ability to create a barrier between the fire and the surrounding environment, effectively cutting off oxygen and cooling the flames. Firefighting foam is particularly beneficial for combating hazardous material fires, such as those involving oil or chemicals, where traditional water methods may prove ineffective or even dangerous.

Moreover, different types of foam in fire fighting are tailored to specific applications—whether it's Class A foam for ordinary combustibles or Class B foam designed for flammable liquids. This versatility makes firefighting foam an indispensable component of any fire truck called into action during emergencies. With proper application, firefighters can significantly reduce damage and enhance safety during operations.

Benefits of Effective Foam in Fire Suppression

The benefits of effective foam in fire suppression extend beyond mere extinguishment; they include faster response times and reduced collateral damage to property. When deployed correctly from a fire foam truck, firefighting foam can suppress flames more swiftly than water alone, allowing firefighters to control blazes before they spread uncontrollably. This not only saves lives but also minimizes economic losses associated with extensive property damage.

Additionally, effective foams help prevent re-ignition by forming a protective blanket over hot surfaces after the initial suppression effort has been completed. This feature allows firefighters to focus on rescue operations without worrying about flare-ups that could jeopardize their safety or that of civilians nearby. In essence, using quality firefighting foam enhances not just the effectiveness but also the efficiency of fire response efforts.

How Foam Affects Fire Truck Performance

Foam's impact on fire truck performance cannot be overstated; it influences both operational capabilities and overall effectiveness during emergency responses. A well-equipped fire foam truck integrates advanced systems designed specifically for delivering various types of foams seamlessly into its operations—this includes everything from pumps to proportioners that ensure accurate mixing ratios are maintained under pressure.

Furthermore, using appropriate types of foam in fire fighting directly affects how quickly and effectively a crew can respond to incidents involving hazardous materials or volatile substances. By optimizing these systems within a fire truck called into action, firefighters can maximize their chances of successfully extinguishing fires while minimizing risks associated with chemical reactions or environmental hazards.

When properly maintained and utilized according to best practices outlined earlier, your firefoam trucks become invaluable assets in ensuring community safety during emergencies—a testament to how critical effective firefighting foams are within this framework.

Addressing Common Maintenance Issues

Troubleshooting Pump Performance

The pump is the heart of any fire foam truck, and its performance directly impacts firefighting capabilities. If you notice irregularities such as low pressure or unusual noises coming from the pump, it’s time to investigate further. Start by checking fluid levels and filters; clogged filters can significantly hinder pump efficiency and may lead to costly repairs if not addressed promptly.

Another common issue with pumps in a fire foam truck is air leaks in the suction line. These leaks can cause cavitation, reducing the pump's ability to deliver water or firefighting foam effectively. Regularly inspect hoses and connections for signs of wear or damage—catching these issues early can save you from scrambling during an emergency.

Lastly, don’t forget about routine testing! Conduct regular operational tests on your fire foam truck’s pump under various conditions to ensure everything runs smoothly. This proactive approach helps identify potential problems before they escalate into major failures.

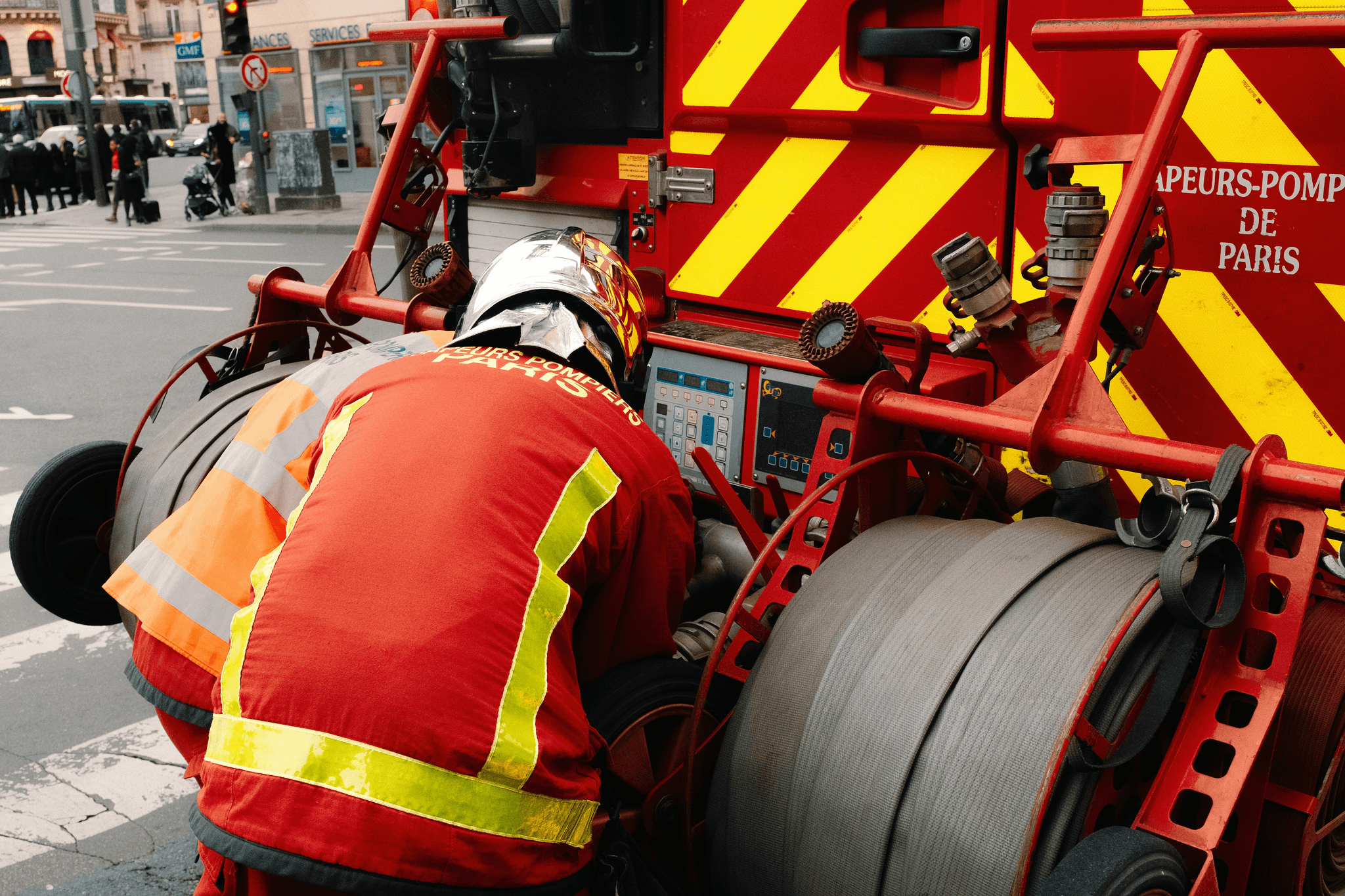

Inspecting Foam Proportioning Systems

What is a foam fire truck without an effective proportioning system? This system ensures that the right mix of water and firefighting foam is delivered during emergencies—too little or too much can compromise effectiveness. Begin your inspection by checking calibration settings; incorrect settings could lead to ineffective firefighting efforts when seconds count.

Next, look out for blockages in hoses or nozzles that could disrupt the flow of firefighting foam. A thorough cleaning routine will keep these components free from debris that might otherwise impair their function. Additionally, verify that all valves are operating correctly; malfunctioning valves can prevent proper mixing ratios essential for successful fire suppression.

Lastly, consider conducting periodic training sessions with your crew on how to operate the proportioning system effectively. Familiarity with this critical component ensures everyone knows how to react quickly during high-pressure situations—because when it comes down to it, knowing what firefighting foam is used for could save lives!

Maintaining the Foam Delivery System

A well-maintained foam delivery system is integral to a fire foam truck's overall functionality and effectiveness in extinguishing fires using different types of foam in fire fighting applications. Start by regularly inspecting all hoses and fittings for signs of wear or damage; even minor leaks can lead to significant losses in pressure over time.

Cleaning your delivery nozzles should also be part of your maintenance routine since buildup can affect spray patterns crucial for effective coverage during operations. Use appropriate cleaning solutions recommended by manufacturers—this helps prolong their lifespan while ensuring optimal performance when deployed at a scene.

Best Practices for Fire Foam Truck Care

Proper Usage to Extend Life Span

Understanding how to properly use a foam fire truck is essential for maximizing its lifespan. Operators should be trained in the specific functionalities of their fire foam truck, including how to deploy firefighting foam effectively. Misuse or overuse can lead to premature wear and tear on critical components, so always follow the manufacturer's guidelines.

Additionally, knowing what firefighting foam is used for can help ensure that you're using the right type of foam for each situation, thereby avoiding unnecessary strain on the system. Different types of foam in fire fighting serve unique purposes; using them correctly will enhance both safety and efficiency during operations. Remember, a well-used fire foam truck not only performs better but also lasts longer!

Cleaning and Storing Fire Foam Equipment

After every use, cleaning your fire foam equipment should be a top priority to prevent residue build-up and potential malfunctions later on. Residual firefighting foam can corrode components if left unchecked, leading to costly repairs down the line—nobody wants an unresponsive pump during an emergency! Rinse out hoses and nozzles thoroughly with fresh water after each deployment.

When to Seek Professional Help

Even with diligent maintenance practices, some issues may require professional expertise—this is where the pros come in! If you notice unusual noises from your pump or irregularities in how the firefighting foam is dispensed, don't hesitate to call in specialists who understand what a fire truck is called when it’s performing at its best: reliable! Early intervention can save you time and money by addressing problems before they escalate into major repairs.

Regular check-ups by qualified technicians are also beneficial; they can spot potential issues that might go unnoticed during routine inspections by less experienced personnel. Remember that maintaining a fire foam truck isn't just about DIY efforts—enlisting professional help ensures that every component functions optimally when lives are on the line. So don’t shy away from reaching out when needed!

Conclusion

In wrapping up our discussion on fire foam trucks, it’s clear that regular maintenance is essential for ensuring these vital vehicles operate at peak efficiency. A well-maintained fire foam truck not only extends its lifespan but also enhances its performance during emergencies. By adopting a proactive approach to maintenance, firefighters can ensure they are always ready to tackle any blaze with confidence.

Enhancing Fire Truck Efficiency Through Maintenance

One of the primary benefits of consistent maintenance for a fire foam truck is improved reliability when it matters most. Regular checks and servicing can prevent minor issues from escalating into major problems, which could hinder response times during critical situations. When firefighters know their equipment is in top shape, they can focus on what really matters—saving lives and protecting property.

The Role of Foam in Fire Safety

Firefighting foam plays a crucial role in modern fire suppression techniques, effectively smothering flames and preventing re-ignition. Understanding what firefighting foam is used for helps firefighters choose the right type of foam for various scenarios, whether it's a flammable liquid spill or structural fire. The different types of foam in fire fighting each have unique properties that enhance safety measures and improve overall firefighting strategies.

Staying Prepared with Your Fire Foam Truck

Ensuring that all components—from the pump performance to the delivery system—are functioning optimally will keep your team ready for action at all times. Remember, staying prepared with your fire foam truck isn't just about having the right tools; it's about fostering a culture of readiness and resilience within your firefighting team.