Introduction

In the world of aviation, the airplane fueling tank is a crucial component that ensures aircraft operate efficiently and safely. Understanding how these tanks function is essential for anyone involved in aviation, from pilots to ground crew. The Aircraft Fuel Tank System plays a vital role in determining an aircraft's range and performance, making it imperative to explore its intricacies.

Understanding the Airplane Fueling Tank

So, what exactly is an aeroplane fuel tank called? It’s simply referred to as an airplane fueling tank, but its design and functionality are anything but simple. These tanks are engineered to hold vast amounts of fuel while also accommodating various pressures and temperatures encountered during flight. This complexity highlights the importance of understanding these systems for effective aviation operations.

Importance of an Efficient Fueling System

An efficient fueling system is paramount for ensuring that aircraft can take off on time and reach their destinations without unnecessary delays or complications. With multiple types of aircraft fuel tanks available, each designed for specific operational needs, knowing which system works best can save time and resources. Moreover, a well-functioning fueling system directly impacts flight safety; after all, no one wants to be grounded due to fuel issues!

The Science Behind Aircraft Fuel Tanks

The science behind aircraft fuel tanks involves intricate engineering principles that ensure safety and reliability at high altitudes. Various factors influence how big the fuel tank on an airplane needs to be—such as weight limits and desired range—while still maintaining optimal performance levels during flight. Additionally, understanding how long a plane can fly on one tank of fuel helps operators plan routes effectively and manage their fleets efficiently.

Overview of Aircraft Fuel Tank Systems

Types of Aircraft Fuel Tanks

What is an aeroplane fuel tank called? Generally, they are referred to as aircraft fuel tanks, and there are three primary types: fixed tanks, integral tanks, and bladder tanks. Fixed fuel tanks are commonly found in commercial aircraft and are built into the structure of the plane itself. Integral fuel tanks are often utilized in military jets for added aerodynamic efficiency, while bladder fuel tanks serve general aviation by providing flexibility and ease of maintenance.

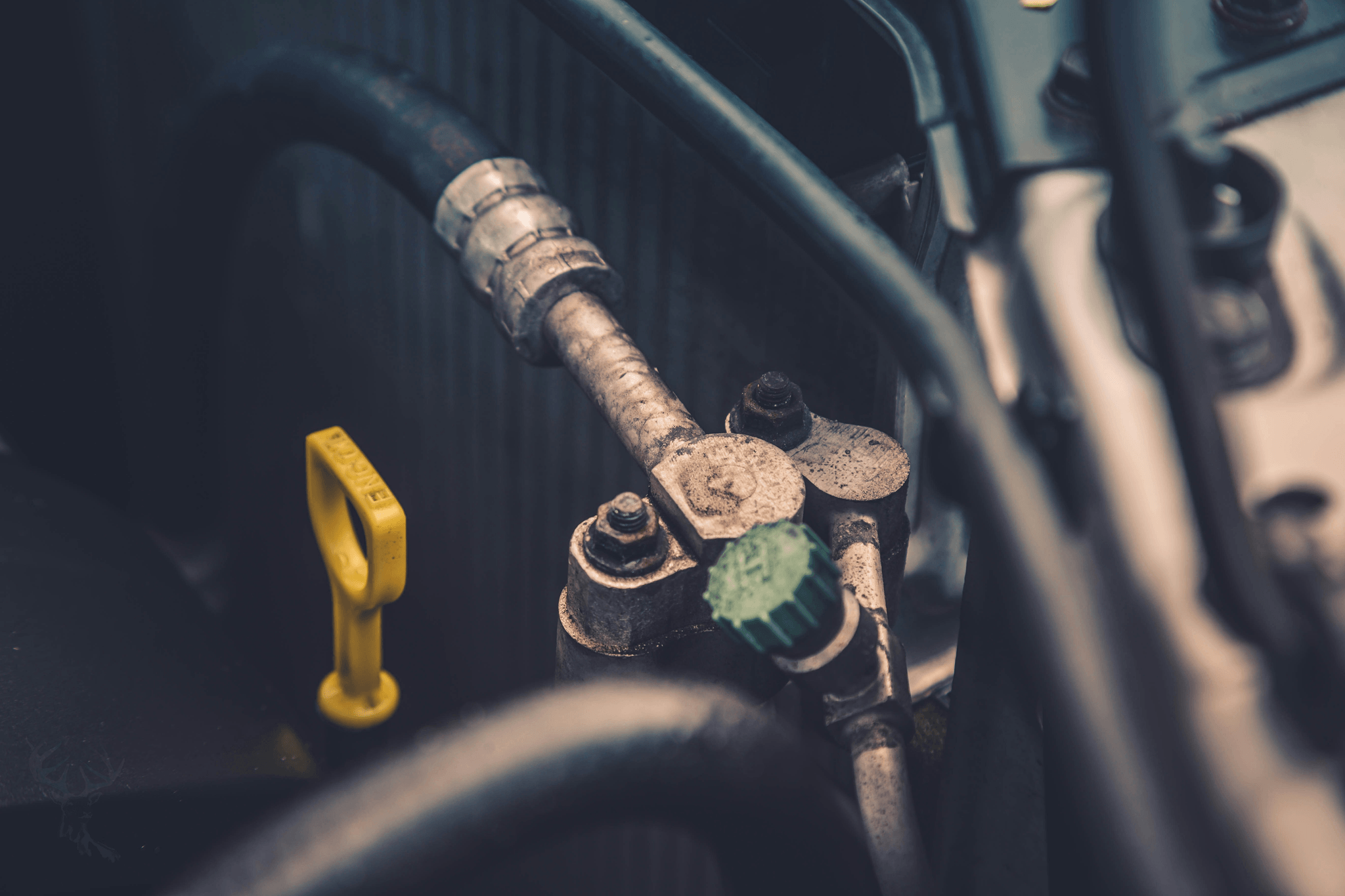

Components of Airplane Fueling Tanks

The components of airplane fueling tanks work together seamlessly to ensure optimal performance and safety during operations. Key elements include pumps for transferring fuel, valves for controlling flow rates, filtration systems for removing impurities, and sensors that monitor levels and pressure within the tank. Each component plays a vital role in maintaining the integrity of the aircraft fuel tank system—ensuring that airplanes can operate effectively without compromising safety.

Functionality and Design Considerations

When designing an airplane fueling tank, engineers must consider various factors that influence its functionality. For instance, high flow rate capabilities are essential for quick refueling operations at airports; this is where equipment like Haisen's Aircraft Pipeline Refueling Truck shines with its efficient pumping systems. Additionally, considerations such as weight distribution within the aircraft body impact overall flight performance—meaning every aspect from size to material choice matters when creating an efficient aircraft fuel tank system.

Key Features of an Efficient Airplane Fueling Tank

An efficient airplane fueling tank is vital for the overall performance and safety of any aircraft. The design and functionality of the Aircraft Fuel Tank System directly impact fuel delivery, operational efficiency, and maintenance costs. Understanding these key features ensures that both operators and manufacturers prioritize quality in their fueling systems.

High Flow Rate Capabilities

One of the most crucial features of an airplane fueling tank is its high flow rate capabilities. A high flow rate allows for faster refueling times, which is essential for commercial airlines looking to minimize turnaround time between flights. Aircraft Fuel Tank Systems designed with this feature can significantly enhance airport efficiency, ensuring that planes are ready to take off sooner rather than later.

A well-optimized fuel tank can deliver fuel at rates that meet or exceed industry standards, accommodating various aircraft sizes and types. This capability not only streamlines operations but also contributes to reduced labor costs during refueling processes. Ultimately, high flow rates in airplane fueling tanks lead to improved overall productivity in aviation operations.

Filtration and Impurity Removal

The quality of fuel delivered to an aircraft is paramount for safe operation; thus, effective filtration and impurity removal are critical features of any airplane fueling tank. Contaminated fuel can lead to engine failures or reduced performance, making filtration systems indispensable within the Aircraft Fuel Tank System. These systems utilize advanced filtration technology to remove impurities such as dust, moisture, and other particulates before they reach the aircraft's fuel system.

Haisen's Aircraft Pipeline Refueling Truck exemplifies this principle by incorporating a sophisticated filtration system that ensures clean fuel delivery at a high flow rate. During refueling operations, impurities are effectively filtered out while maintaining optimal pressure levels throughout the process. This attention to detail in impurity removal safeguards against potential hazards associated with contaminated fuel.

Accurate Flow Rate Measurement

Accurate flow rate measurement is another essential feature that enhances the efficiency of an airplane fueling tank. Precise measurement tools ensure that each aircraft receives the correct amount of fuel during refueling operations—crucial information for flight planning and operational safety. An accurate understanding of how much fuel has been added allows pilots and ground crews to calculate weight distribution effectively and ensure compliance with performance specifications.

Incorporating advanced technologies such as digital flow meters into the Aircraft Fuel Tank System provides real-time data on fuel quantities being dispensed. This level of accuracy not only minimizes waste but also helps maintain transparency during refueling transactions—an important aspect when adhering to regulatory standards in aviation fueling equipment management. With accurate measurements in place, operators can confidently determine how long a plane can fly on one tank of fuel based on established consumption rates.

Different Types of Aircraft Fuel Tanks

When it comes to airplane fueling tanks, understanding the various types is crucial for both efficiency and safety in aviation. The Aircraft Fuel Tank System is designed to cater to different aircraft needs based on their operational requirements. Let's dive into the three primary types of aircraft fuel tanks: fixed fuel tanks, integral fuel tanks, and bladder fuel tanks.

Fixed Fuel Tanks in Commercial Aircraft

Fixed fuel tanks are commonly found in commercial aircraft, serving as the primary storage for aviation fuel. These tanks are usually integrated into the wings or fuselage, designed to optimize space while maintaining structural integrity. The size of these airplane fueling tanks can vary significantly depending on the aircraft model; for instance, larger jets like the Boeing 747 can hold over 50,000 liters of fuel.

One major advantage of fixed fuel tanks is that they provide a stable center of gravity during flight, which is essential for aerodynamics and performance. As a result, commercial airlines benefit from these designs as they enhance range and endurance—how long can a plane fly on one tank of fuel? That often depends on the specific aircraft’s efficiency and payload capacity. Overall, fixed fuel tanks play a vital role in ensuring that commercial flights operate smoothly and safely.

Integral Fuel Tanks in Military Jets

Integral fuel tanks are specifically designed for military jets and serve a dual purpose: storing fuel while contributing to the structural integrity of the aircraft. These airplane fueling tanks are typically built into the wings or fuselage itself, allowing military designs to maximize space without adding extra weight through external storage solutions. This integration helps improve stealth capabilities by reducing drag and enhancing aerodynamic performance.

What sets integral tank systems apart is their ability to accommodate rapid refueling processes during missions without compromising speed or agility. Additionally, military jets often require flexibility in their operations; thus, integral designs allow them to carry varying amounts of fuel based on mission profiles—what are the three types of aircraft fuel tanks? Integral ones certainly make their mark!

Bladder Fuel Tanks for General Aviation

Bladder fuel tanks offer yet another innovative approach within airplane fueling systems tailored specifically for general aviation needs. These flexible bags made from durable materials provide a lightweight solution that can be installed within an airframe or in cargo areas where traditional rigid tank systems may not fit well. Bladder tank systems are particularly advantageous because they can expand and contract with changes in altitude and pressure.

The adaptability offered by bladder fuels means smaller private planes can still achieve impressive range capabilities despite having relatively compact sizes—how big is the fuel tank on an airplane? With bladder systems generally ranging from 100 to 500 liters depending on design choices, general aviation pilots appreciate this versatility when planning flights across varying distances.

In summary, understanding these different types of airplane fueling tanks helps clarify how each system meets specific operational needs within aviation—from commercial giants soaring across continents to nimble military jets executing tactical maneuvers or general aviation planes flying weekend getaways.

Size and Capacity of Airplane Fueling Tanks

When discussing the size and capacity of airplane fueling tanks, it’s essential to understand that these tanks are designed to meet the specific needs of different aircraft types. The capacity can vary significantly based on the aircraft's intended use, ranging from small general aviation planes to large commercial airliners. Knowing how big the fuel tank on an airplane is crucial for understanding its operational range and efficiency.

How Big is the Fuel Tank on an Airplane?

The size of an airplane fueling tank can vary widely depending on the aircraft model and its purpose. For instance, a typical commercial jet like a Boeing 737 has a fuel capacity of around 26,000 liters (approximately 6,900 gallons), while larger models like the Boeing 777 can hold over 180,000 liters (about 47,000 gallons). This variation raises an interesting question: What is an aeroplane fuel tank called? It's commonly referred to as just that—an aeroplane fuel tank or simply fuel tank, but in technical terms, it falls under the broader category of Aircraft Fuel Tank Systems.

Factors Influencing Tank Size

Several factors influence how big an airplane fueling tank needs to be. Firstly, the type of mission plays a key role; for example, military jets often require integral fuel tanks designed for stealth and performance rather than sheer volume. Additionally, considerations such as weight restrictions and aerodynamics impact design; larger tanks may affect flight characteristics negatively if not managed properly. Furthermore, advancements in Aviation Fueling Equipment have allowed engineers to optimize designs without compromising performance or safety.

Range and Endurance on a Full Tank

How long can a plane fly on one tank of fuel? This question depends heavily on both the size of the fueling tank and the efficiency of the aircraft's engines. Generally speaking, commercial jets can achieve flight durations ranging from several hours up to over fifteen hours with full tanks; this capability is crucial for long-haul flights connecting distant cities across continents. The relationship between range and endurance highlights why understanding airplane fueling tanks is vital—not just for operational planning but also for enhancing overall flight efficiency.

Equipment Essential for Aviation Fueling

In the world of aviation, having the right equipment for fueling is crucial to maintaining the efficiency and safety of aircraft operations. The airplane fueling tank system relies heavily on specialized machinery designed to deliver fuel quickly and safely. Understanding the different types of aviation fueling equipment can help streamline operations and ensure that aircraft are ready for takeoff without unnecessary delays.

Overview of Haisen Aircraft Pipeline Refueling Truck

The Haisen Aircraft Pipeline Refueling Truck is a remarkable piece of equipment in the aviation fueling landscape. This truck consists of a robust chassis, an efficient piping system, and sophisticated pneumatic, hydraulic, and electrical systems that work together seamlessly. It provides effective refueling services at high flow rates while ensuring that impurities such as dust and moisture are filtered out before they enter the airplane fueling tank.

Equipped with advanced filtration technology, this refueling truck guarantees that only clean fuel reaches the aircraft's fuel tanks. The accurate flow rate measurement further enhances its reliability during operations, making it an essential component of any Aircraft Fuel Tank System. With its capabilities, it supports various types of aircraft efficiently, catering to both commercial and military needs.

Comparison with CF5060TJYGX Aircraft Hydrant Dispenser

When comparing the Haisen Aircraft Pipeline Refueling Truck with the CF5060TJYGX Aircraft Hydrant Dispenser, several key differences emerge that highlight their unique functionalities. The CF5060TJYGX is notably a low-altitude hydrant dispenser at just 2 meters high, making it especially effective for underwing refueling services on various aircraft sizes. While both systems excel in delivering fuel efficiently, their design caters to different operational needs within aviation.

The Haisen truck's ability to provide high flow rates makes it ideal for larger commercial jets or military aircraft requiring rapid refueling processes. In contrast, the CF5060TJYGX excels in situations where space constraints might hinder traditional refueling methods but still require precision and speed in delivering fuel into airplane fueling tanks. Understanding these distinctions helps operators choose appropriate equipment based on specific requirements.

Importance of Proper Aviation Fueling Equipment

Proper aviation fueling equipment is paramount for ensuring not only efficiency but also safety during aircraft operations. An effective airplane fueling tank system relies on well-designed machinery like those offered by Haisen or CF5060TJYGX to minimize downtime between flights while maximizing operational readiness. Without reliable Aviation Fueling Equipment, airlines can face significant delays that impact schedules and customer satisfaction.

Moreover, using subpar or outdated equipment can lead to contamination issues within fuel tanks—an outcome no airline wants when considering how critical clean fuel is for safe flight operations. By investing in advanced technologies such as those found in modern refueling trucks and dispensers, aviation companies can enhance their overall service quality while adhering to strict safety regulations across all types of aircraft fuel tanks.

Conclusion

In the ever-evolving world of aviation, understanding the airplane fueling tank and its efficiency is paramount for safe and economical flight operations. An efficient Aircraft Fuel Tank System not only ensures that aircraft can be refueled quickly but also maximizes range and operational capabilities. By focusing on the intricacies of these systems, we can enhance overall aviation performance.

Ensuring Efficiency in Aircraft Fuel Systems

Ensuring efficiency in aircraft fuel systems is crucial for minimizing downtime and maximizing flight time. Properly designed airplane fueling tanks allow for rapid refueling while maintaining safety standards, which is essential in today's fast-paced travel environment. With advancements in technology, airlines can optimize their operations by selecting the right type of fuel tank based on their specific needs.

The Role of Technology in Fueling

Technology plays a pivotal role in modern aviation fueling practices, transforming how we approach airplane fueling tanks. Innovations such as Haisen's Aircraft Pipeline Refueling Truck provide high flow rates and effective filtration to ensure clean fuel reaches the aircraft without unnecessary delays. With precise measurement capabilities, these systems enhance accuracy during refueling, which ultimately contributes to improved operational efficiency.

Future Trends in Airplane Fueling Tanks

Looking ahead, future trends in airplane fueling tanks will likely focus on sustainability and improved design efficiencies. As airlines seek to reduce their carbon footprint, alternative fuels may become more prevalent alongside traditional jet fuels, requiring adaptable Aircraft Fuel Tank Systems. Additionally, advancements in materials science could lead to lighter and more durable tank designs that further enhance fuel capacity while ensuring safety—ultimately allowing planes to fly longer distances on a single tank of fuel.