Introduction

In the realm of industrial automation, understanding the nuances of linear actuators is crucial for optimizing performance and efficiency. These devices convert rotational motion into linear movement, making them indispensable in various applications. Among the different types available, heavy duty electric actuators stand out due to their robust capabilities and versatility.

Understanding Industrial Linear Actuators

Linear actuators are electromechanical devices designed to create motion in a straight line, as opposed to circular motion produced by rotary actuators. They play a vital role in automation systems across industries by providing precise positioning and control. The functionality of an electric actuator is rooted in its ability to transform electrical energy into mechanical energy, often using a linear motor or actuator motor for seamless operation.

Why Choose 12V Electric Actuators

When considering electric actuators, 12V models offer unique advantages that make them an attractive choice for many applications. Their compact size and lower voltage requirements allow for easier integration into existing systems without extensive modifications. Additionally, 12V heavy duty electric actuators are known for their reliability and energy efficiency, ensuring they can handle demanding tasks while minimizing energy consumption.

Applications of Heavy Duty Electric Actuators

Heavy duty electric actuators find their place in various industrial settings where strength and durability are paramount. From manufacturing lines to agricultural machinery, these motorized actuators provide the necessary force to automate processes effectively. Their adaptability means they can be utilized across multiple sectors including automotive assembly, robotics, and even aerospace applications—proving that they are indeed heavy hitters in the world of automation.

What is a Linear Actuator?

Linear actuators are essential components in various applications, converting rotational motion from motors into linear movement. They serve as the backbone of many automated systems, providing precise control over movement and positioning. Whether you're adjusting a valve or moving heavy machinery, understanding what a linear actuator is will help you appreciate its significance in industrial settings.

Definition and Functionality

A linear actuator is a device that creates motion in a straight line, as opposed to the circular motion produced by traditional motors. This functionality allows for the direct manipulation of loads along a specified path, making it ideal for tasks requiring accuracy and repeatability. In essence, these electromechanical linear actuators transform electrical energy into mechanical energy to perform work efficiently.

Types of Linear Actuators

There are several types of linear actuators available on the market today, each designed for specific applications and requirements. The most common types include electric actuators, pneumatic actuators, and hydraulic actuators; however, electric linear actuators have gained popularity due to their ease of use and maintenance. Heavy duty electric actuators are particularly noteworthy because they can handle substantial loads while maintaining precision and reliability.

Benefits of Electric Linear Actuators

Electric linear actuators offer numerous benefits that make them an attractive choice for various applications. For starters, they provide significant energy efficiency compared to their pneumatic or hydraulic counterparts—this translates into lower operational costs over time. Moreover, these motorized actuators are often equipped with advanced control systems that enhance speed and precision in movement while ensuring durability and reliability even under heavy-duty conditions.

Exploring Heavy Duty Electric Actuators

When it comes to heavy duty electric actuators, we're talking about the robust workhorses of the automation world. These linear actuators are designed to handle substantial loads and deliver reliable performance in demanding environments. Whether you need a motorized actuator for lifting, pushing, or pulling tasks, these electromechanical linear actuators are built to last and keep operations running smoothly.

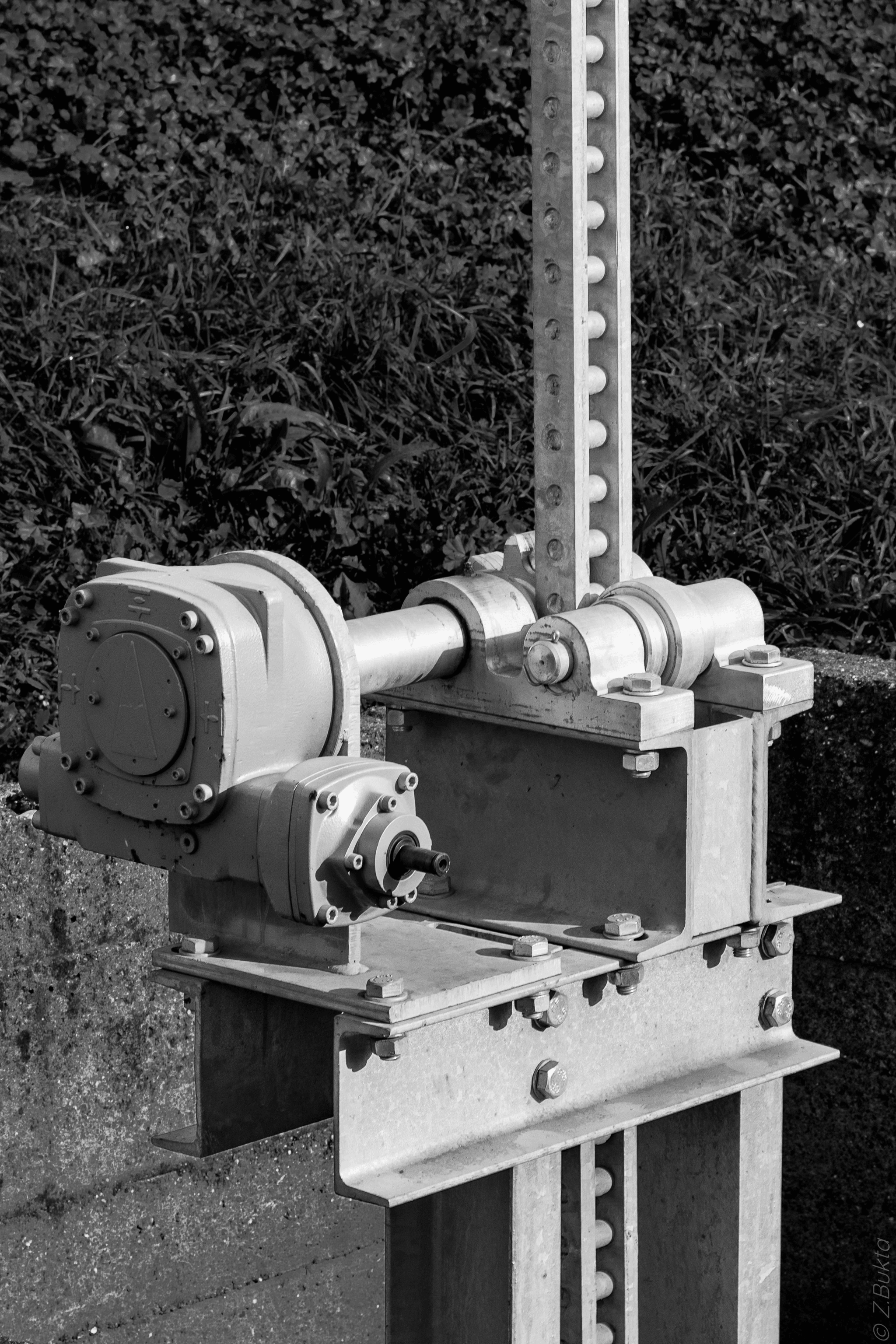

Characteristics of Heavy Duty Electric Actuators

Heavy duty electric actuators boast a range of characteristics that set them apart from standard models. First off, they typically feature a high load capacity, allowing them to manage significant weights without breaking a sweat. Additionally, their construction often includes durable materials and advanced sealing technologies that protect against dust and moisture—ideal for tough industrial settings where reliability is crucial.

Another defining trait is their precision in movement; these electric linear actuators can be finely tuned to achieve exact positioning with minimal backlash. This level of accuracy is vital in applications where even slight deviations can lead to inefficiencies or safety hazards. Moreover, many heavy duty electric actuators come equipped with advanced control systems that enhance their functionality, making them adaptable for various tasks.

Applications in Industrial Settings

The versatility of heavy duty electric actuators makes them indispensable across numerous industrial sectors. In manufacturing plants, these linear motors are often utilized for assembly lines where they automate processes such as material handling and product assembly efficiently. They also find use in robotics applications where precise movements are essential for tasks like welding or painting.

In the construction industry, heavy duty electric actuators play a critical role in powering equipment such as lifts and cranes that must perform under extreme conditions while carrying hefty loads. Furthermore, sectors like agriculture use motorized actuators for automated machinery that requires reliable movement over long durations—think irrigation systems or seed planting devices that need consistent performance day after day.

How They Enhance Efficiency

One of the standout benefits of using heavy duty electric actuators is their ability to enhance operational efficiency significantly. By automating repetitive tasks with precision and speed, businesses can reduce manual labor costs while increasing throughput—a win-win situation! Moreover, these electromechanical linear actuators often consume less energy compared to pneumatic or hydraulic systems, leading to lower operational costs over time.

Additionally, the reliability of electric actuator motors means less downtime due to maintenance issues; when machines run smoothly without frequent interruptions for repairs or adjustments, productivity soars! The integration of smart technology into many modern heavy duty electric actuators also allows for real-time monitoring and diagnostics—enabling proactive maintenance strategies rather than reactive ones.

In summary, investing in heavy duty electric actuators not only streamlines processes but also contributes significantly to overall productivity gains across various industries.

Key Features of Electric Linear Actuators

Electric linear actuators are transforming the way industries approach automation, offering a multitude of features that enhance their functionality and efficiency. Among these, speed and precision in movement stand out, along with durability and reliability that ensure long-lasting performance. Additionally, energy efficiency and cost-effectiveness make electric linear actuators a smart choice for businesses looking to optimize their operations.

Speed and Precision in Movement

When it comes to heavy duty electric actuators, speed is often a critical factor. These powerful devices can deliver rapid movements without sacrificing precision, making them ideal for applications requiring quick adjustments or responses. Whether you're utilizing a motorized actuator in manufacturing or an electromechanical linear actuator for robotics, the ability to achieve precise positioning consistently is invaluable.

Moreover, modern electric actuators are equipped with advanced control systems that enhance their responsiveness. This means you can expect not just fast movements but also accurate positioning down to the millimeter, which is essential for tasks such as automated assembly lines or intricate machinery operations. With the combination of speed and precision offered by electric linear actuators, businesses can significantly improve productivity while minimizing errors.

Durability and Reliability

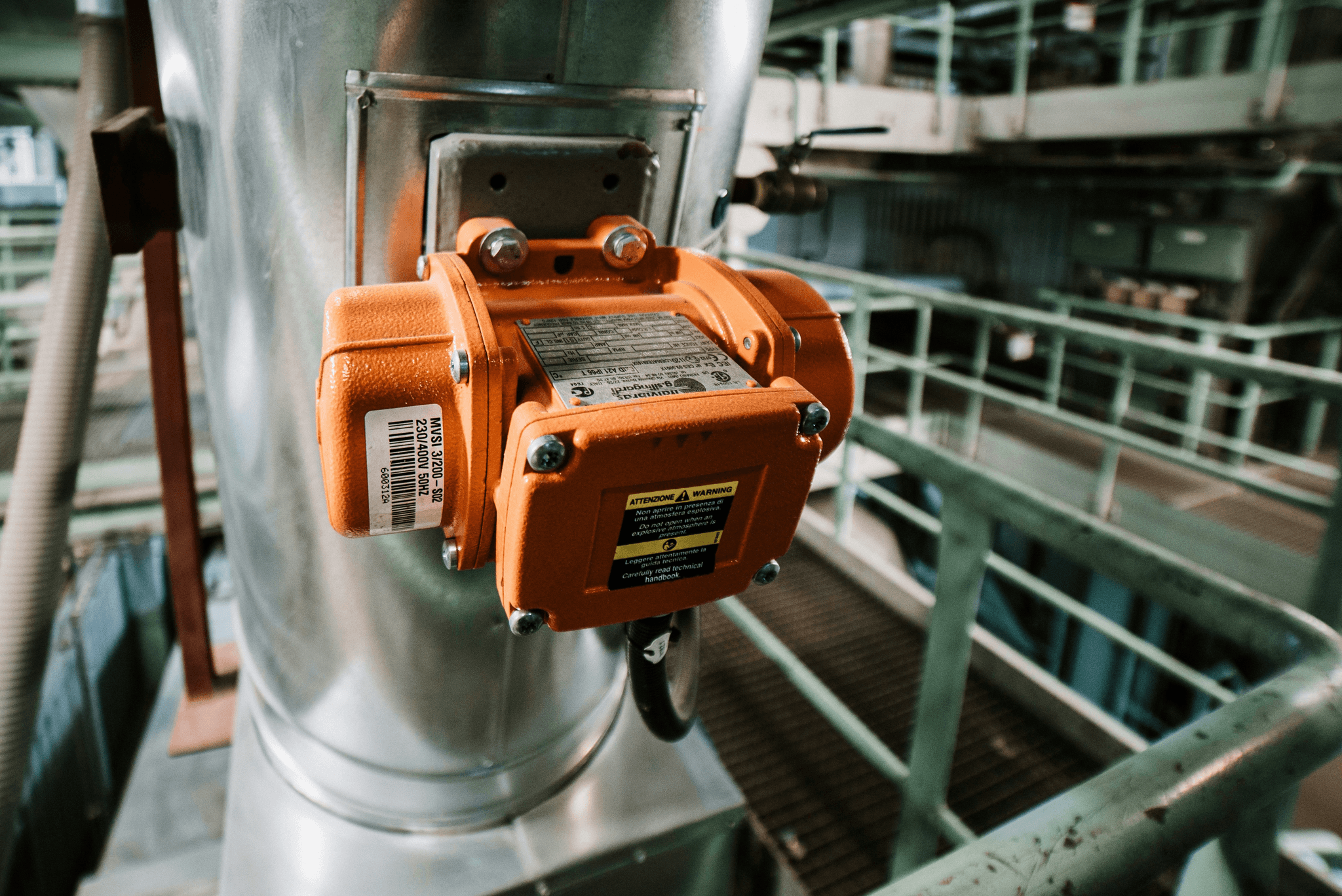

Durability is another hallmark feature of electric linear actuators that makes them stand out in industrial applications. Heavy duty electric actuators are designed to withstand harsh environments, including extreme temperatures, dust exposure, and moisture—conditions where traditional pneumatic or hydraulic systems might falter. This resilience ensures that your actuator motor will keep performing reliably over time without frequent maintenance interruptions.

Additionally, the robust construction of these electromechanical linear actuators means they can handle substantial loads without compromising performance. By investing in a reliable product like this, companies can avoid costly downtime due to equipment failure while ensuring consistent operation across various applications—from heavy machinery to automated processing systems.

Energy Efficiency and Cost-Effectiveness

In today’s economy, energy efficiency isn’t just a buzzword; it’s a necessity for sustainable operations. Electric linear actuators excel in this area by consuming less power compared to their hydraulic counterparts while delivering comparable performance levels. This translates into lower operational costs over time—an essential factor when considering the total cost of ownership for any actuator motor.

Furthermore, many modern heavy duty electric actuators come equipped with intelligent features that allow for optimized energy consumption based on actual load requirements during operation. This adaptability not only conserves energy but also reduces wear on components—extending the lifespan of your motorized actuator significantly. As industries increasingly prioritize sustainability alongside profitability, choosing an energy-efficient electromechanical linear actuator becomes an obvious choice.

Choosing the Right Actuator Motor

Choosing the right actuator motor is crucial for ensuring optimal performance in your applications. With various options available, selecting a heavy duty electric actuator or a more standard electric linear actuator can feel overwhelming. However, by understanding key factors and comparing brands, you can make an informed decision that meets your specific needs.

Factors to Consider When Buying

When purchasing an electric actuator, several factors come into play to ensure you select the best fit for your project. First and foremost, consider the required speed and precision of movement; different applications may necessitate varying levels of responsiveness from your linear motor or motorized actuator. Additionally, assess environmental conditions such as temperature and exposure to moisture; heavy duty electric actuators are designed to withstand harsh environments better than standard options.

Next, think about the size and weight of the load you'll be moving with your electromechanical linear actuator. It's essential to choose an actuator motor that can handle the intended load without compromising performance or safety. Lastly, consider power consumption and energy efficiency; opting for a well-designed electric linear actuator can yield long-term cost savings while minimizing energy waste.

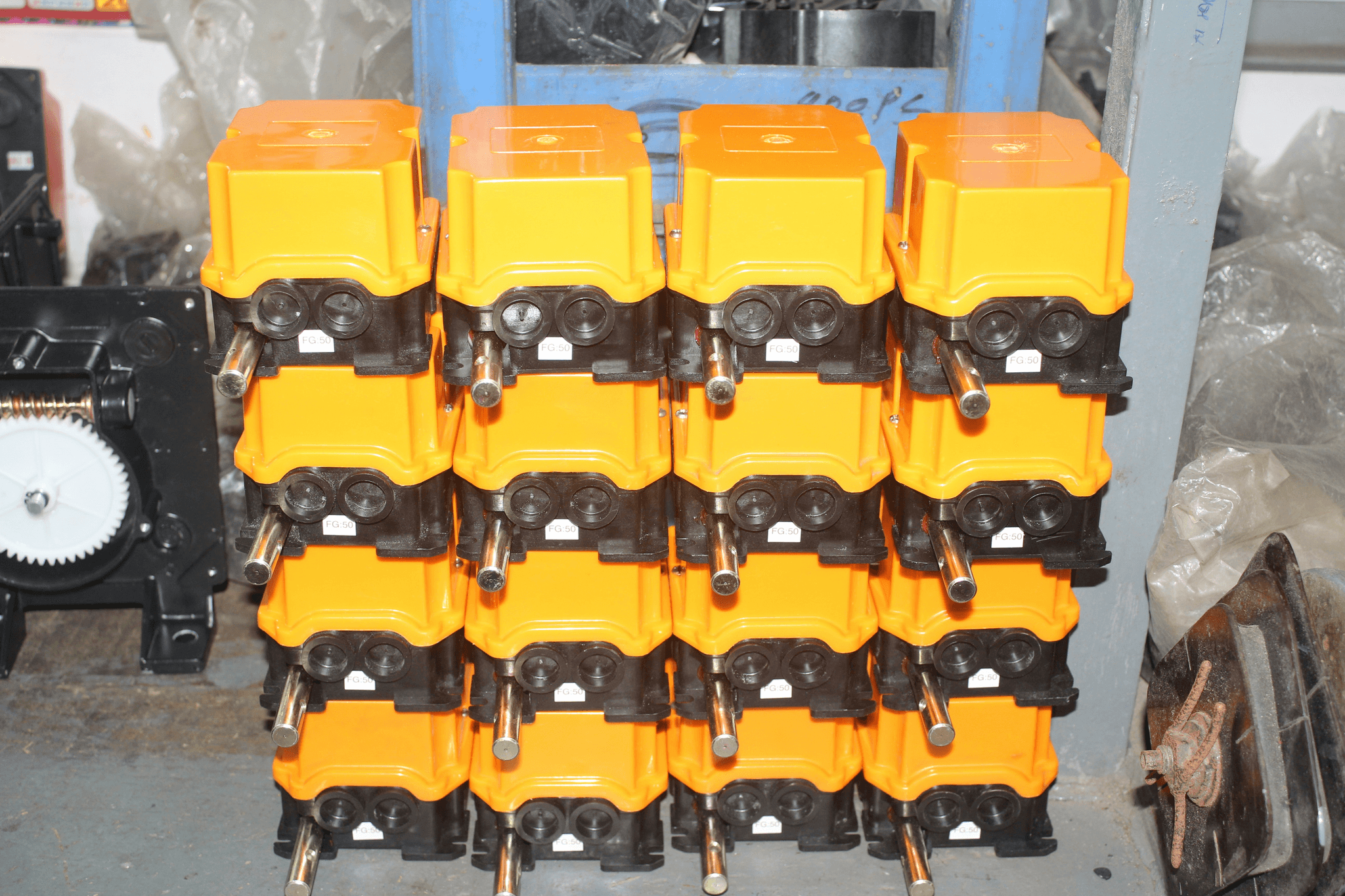

Comparing Leading Brands

With numerous manufacturers producing high-quality actuators, it's vital to compare leading brands before making a purchase decision. Some brands specialize in heavy duty electric actuators known for their robust construction and reliability under challenging conditions, while others may focus on compact models suitable for lighter applications. Researching customer reviews and industry ratings can provide valuable insights into which brands consistently deliver quality products.

Moreover, pay attention to warranty offerings and customer support services when comparing brands; a reliable manufacturer will stand behind their products with solid guarantees and accessible assistance should issues arise with your motorized actuator or electromechanical linear actuator. Ultimately, selecting a reputable brand ensures you're investing in an electric linear actuator that meets industry standards for durability and efficiency.

Understanding Load Requirements

Understanding load requirements is critical when choosing an appropriate linear actuator for any application. The first step is determining both static and dynamic loads—static loads refer to weight when stationary, while dynamic loads pertain to forces acting during movement. Accurate calculations help ensure you select a heavy duty electric actuator capable of handling these demands without risk of failure.

Additionally, consider factors like acceleration rates during operation; some applications require rapid movement that places additional stress on the chosen electromechanical linear actuator or other types of actuators like motorized ones designed for specific tasks. By fully grasping these load requirements upfront, you’ll avoid costly mistakes down the road—ensuring smooth operation from day one with your chosen electric actuator.

Spotlight on Haisen's Part-Turn Valve Electric Actuator

When it comes to heavy duty electric actuators, Haisen’s part-turn valve electric actuator stands out as an exemplary choice. This motorized actuator is specifically designed for applications requiring reliable and precise control of valve operations. With its robust construction and advanced electromechanical linear actuator technology, it’s engineered to meet the demands of various industrial settings.

Overview of Haisen’s Offering

Haisen offers a range of electric actuators that are tailored for part-turn applications, ensuring compatibility with numerous valve types. Their heavy duty electric actuator models are built to handle substantial loads while providing smooth and efficient operation. The combination of high torque output and compact design makes these linear motors ideal for space-constrained environments.

Benefits of Utilizing This Actuator

Utilizing Haisen's part-turn valve electric actuator brings several benefits to the table. First off, this electric linear actuator ensures exceptional precision in controlling valve positions, which is critical in maintaining process integrity. Additionally, the durability and reliability inherent in these actuators minimize downtime, ultimately enhancing overall operational efficiency in industrial applications.

Applications in Various Industries

The versatility of Haisen's heavy duty electric actuators allows them to be employed across multiple industries such as water treatment, oil and gas, and manufacturing. In water treatment facilities, for example, these actuators control flow rates with pinpoint accuracy while resisting harsh environmental conditions. Similarly, their application in the oil and gas sector facilitates safe and efficient management of critical processes that require dependable actuation solutions.

Conclusion

In wrapping up our exploration of electric actuators, it's clear that these devices have transformed the way we approach automation in various industries. The heavy duty electric actuator stands out for its robust performance, versatility, and reliability. With advancements in technology, the electric linear actuator has become an indispensable tool for enhancing efficiency across multiple applications.

Recap of Benefits of Electric Actuators

Electric actuators, particularly the heavy duty varieties, offer numerous benefits that make them a preferred choice over traditional mechanical systems. Their precision and control are unmatched, allowing for smooth operation and accurate positioning thanks to the advancements in linear motors and actuator motors. Moreover, their energy efficiency translates into cost savings over time—an appealing prospect for businesses looking to optimize their operations.

Selecting the Best Linear Actuator

When choosing the right linear actuator for your needs, several factors come into play: load capacity, speed requirements, and environmental conditions should all be considered. A thorough comparison of leading brands can also help ensure you select a reliable electromechanical linear actuator that meets your specific demands. Don't forget to assess your load requirements carefully; this will guide you toward selecting the most suitable motorized actuator that delivers optimal performance without compromising on durability.

Future Trends in Actuator Technology

As we look ahead, it's exciting to consider how actuator technology will evolve further—think smarter systems integrated with IoT capabilities! The future may see even more advanced heavy duty electric actuators that enhance automation with real-time data processing and adaptive control features. With ongoing innovations in materials and design efficiencies, electric linear actuators will undoubtedly continue to shape industrial landscapes for years to come.