Introduction

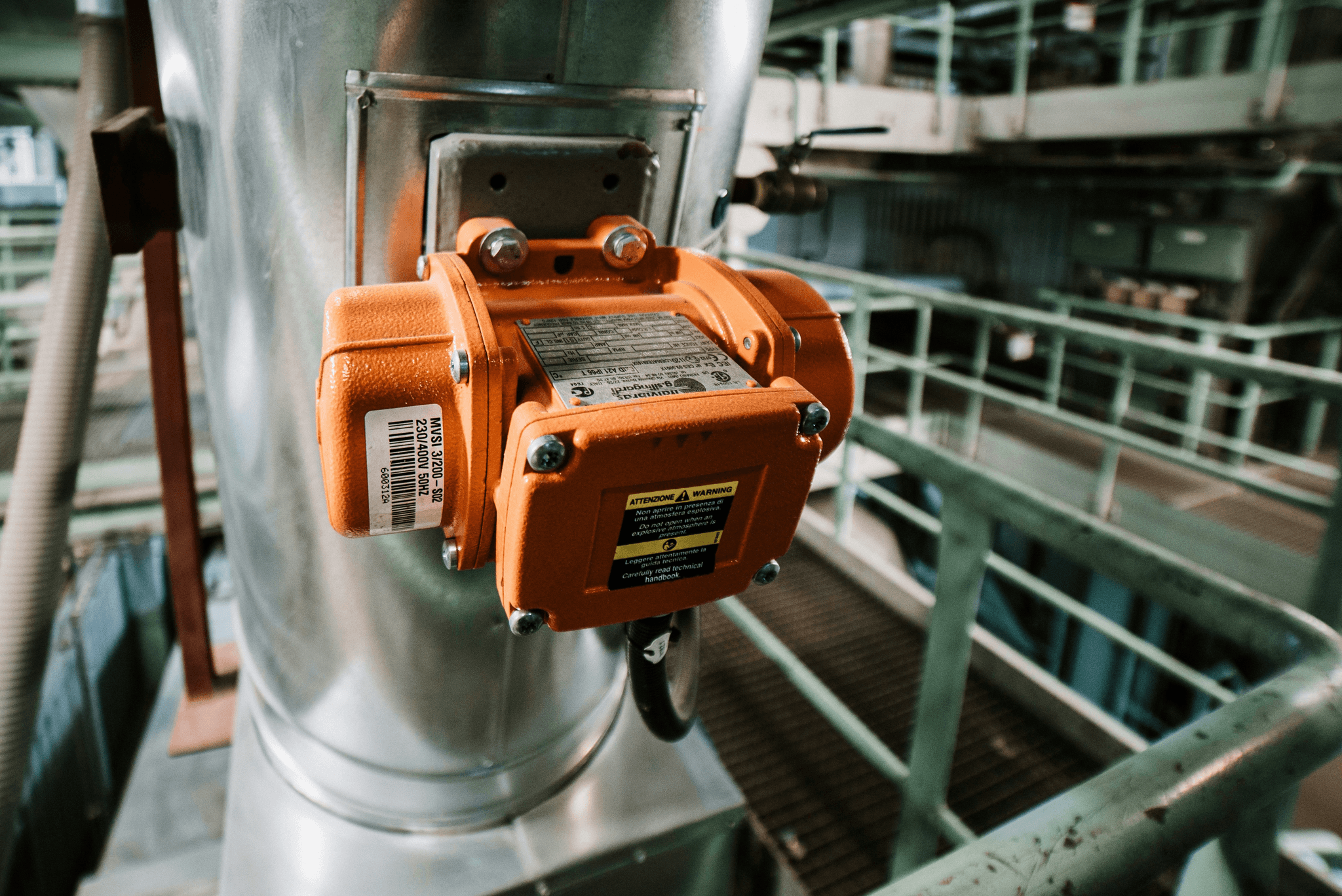

Industrial electric actuators play a crucial role in efficiently operating various industrial processes. These motorized devices are essential for controlling valves and ensuring seamless operations in industrial settings.

Understanding Industrial Electric Actuators

Industrial electric actuators are devices used to control the opening and closing of valves in industrial applications. They provide precise and reliable movement, allowing for accurate flow and pressure regulation within pipelines.

Industrial electric actuators play a crucial role in ensuring the efficient operation of industrial processes. By providing precise and reliable movement, these devices enable accurate flow and pressure regulation within pipelines, leading to improved productivity and reduced downtime. Their ability to control the opening and closing of valves with precision contributes to the overall smooth functioning of various industrial applications.

Importance of Efficient Operations

Efficient operations are vital for maximizing productivity and minimizing downtime in industrial facilities. Actuators are key in achieving this efficiency by providing precise control over valve operation, leading to smooth and optimized processes. By allowing for accurate and responsive control, actuators help to reduce the risk of errors and malfunctions, ultimately improving overall operational reliability. This level of precision also contributes to cost savings by optimizing energy usage and reducing waste, making actuators an essential component for any industrial facility looking to streamline its operations.

The Role of Actuators in Industrial Settings

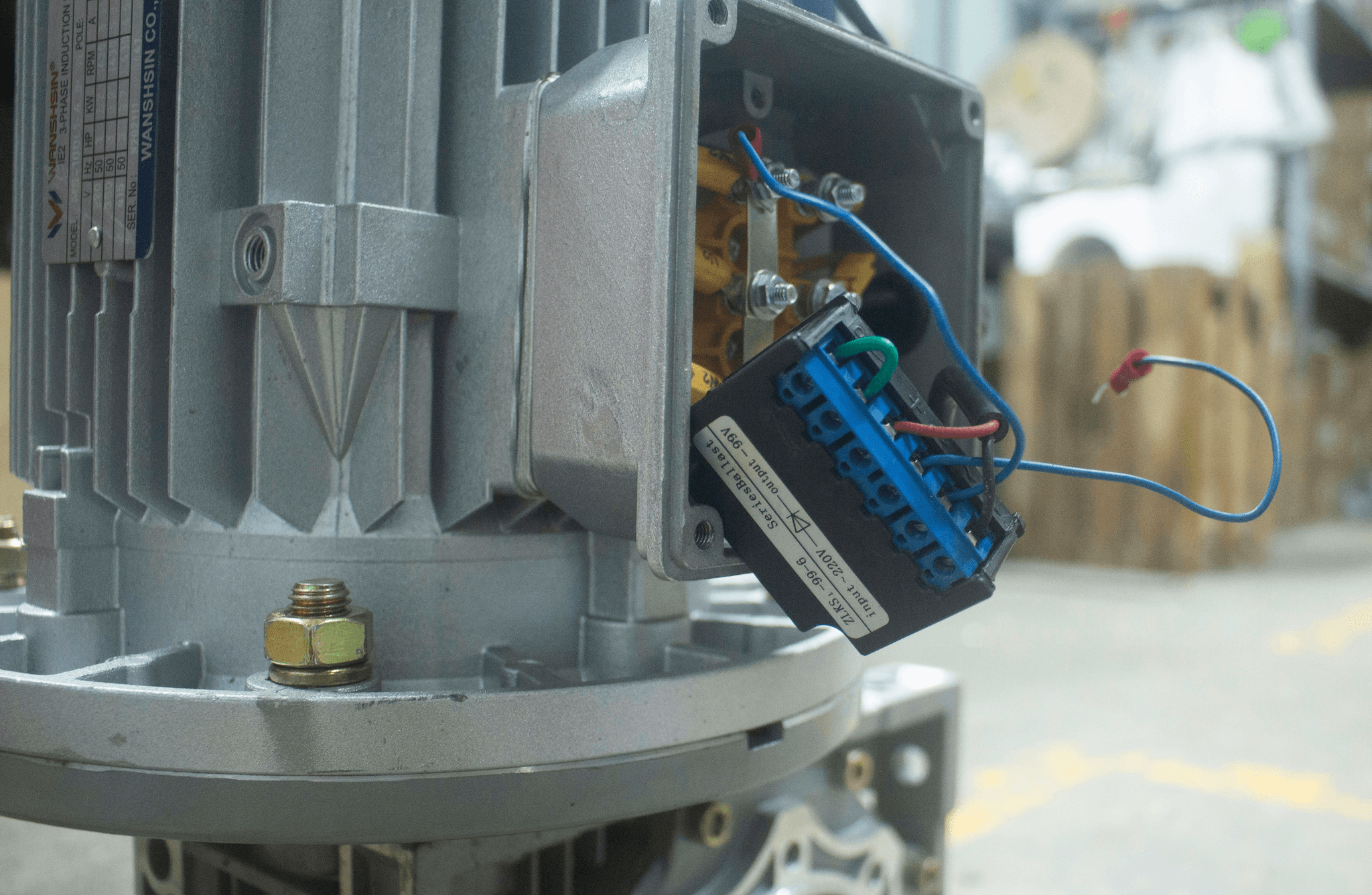

In industrial settings, valves and actuators are critical components for controlling the flow of substances. Like Haisen's Part-Turn Valve Electric Actuator, electric valve actuators provide advanced control options for precise and efficient operation.

Benefits of Electric Valve Actuators:

- Precision and Accuracy: Electric valve actuators offer high-precision control, ensuring accurate flow rates and pressure levels.

- Advanced Control Options: Features like torque control and position feedback allow fine-tuning to meet specific industrial needs.

- Versatility: Suitable for various applications, from water treatment to oil refining.

- Reliability: Ensures consistent and reliable operation across various industries.

Electric valve actuators are essential tools for modern industrial processes. They offer precision, versatility, and reliability. By incorporating these actuators into your operations, you can optimize efficiency and ensure seamless fluid flow control.

The Versatility of Industrial Electric Actuators

Industrial electric actuators are highly versatile and can control various types of valves in industrial settings, providing efficient and precise operation. These actuators can handle different types of valves, including butterfly valves, ball valves, and plug valves, making them essential components in industrial automation systems.

Controlling Butterfly Valves

Industrial electric actuators are crucial in ensuring smooth and accurate operation when controlling butterfly valves. Using a motorized actuator, the valve can be easily opened or closed precisely, allowing for efficient flow control in pipelines. This level of control is essential for industries such as petrochemical and municipal engineering, where precise valve operation is vital.

Furthermore, industrial electric actuators offer the advantage of remote operation, allowing control of the butterfly valve from a centralized location. This feature is particularly beneficial in large-scale industrial facilities where multiple valves must be managed simultaneously. With the ability to monitor and adjust valve positions remotely, operators can optimize flow control and respond quickly to changes in demand or system conditions.

Operating Ball Valves

Electric valve actuators are also well-suited for operating ball valves in industrial applications. With their ability to provide consistent torque and reliable performance, these actuators ensure seamless operation of ball valves for regulating flow in pipelines. This capability is particularly valuable in hydropower and thermal power industries, where precise flow control is critical.

Electric valve actuators are also ideal for managing plug valves in industrial settings. These actuators offer precise control and reliable performance, ensuring seamless operation of plug valves for controlling flow in pipelines. This capability is particularly valuable in industries such as oil and gas, where accurate flow regulation is essential for efficient and safe operations.

Managing Plug Valves

Plug valves are commonly used in various industrial processes, and electric actuators efficiently manage their operation. A high-quality electric actuator such as Haisen's Part-Turn Valve Electric Actuator can precisely control plug valves for optimal performance in industries such as metallurgy and shipbuilding.

Electric actuators offer several advantages over manual plug valve operation. With an electric actuator, the valve can be opened and closed remotely, reducing the need for manual labor and improving safety in hazardous environments. Additionally, electric actuators provide precise control over the valve's position, allowing for more accurate regulation of flow rates and pressure levels. This level of control is essential in industries such as oil and gas, where precise management of plug valves is crucial for maintaining operational efficiency.

Benefits of Using Haisen's Part-Turn Valve Electric Actuator

Enhanced Control Options

The Haisen QT series part-turn valve electric actuator offers enhanced control options, allowing for precise and efficient management of industrial valves. Its advanced technology provides accurate positioning and control over valve operations, ensuring optimal performance in industrial settings.

Furthermore, the Haisen QT series electric actuator offers remote operation capabilities, allowing for convenient and efficient control of industrial valves from a distance. This feature enables operators to manage valve operations without needing physical presence, enhancing flexibility and convenience in industrial settings. With the ability to remotely monitor and adjust valve positions, this electric actuator ensures seamless and reliable performance.

Remote Operation Capabilities

This electric actuator valve has remote operation capabilities, enabling operators to control valve functions from a distance. This feature enhances convenience and safety in industrial operations, allowing for seamless valve management without the need for direct physical access.

Furthermore, this electric actuator valve's remote operation capabilities allow for real-time monitoring and adjustments, increasing efficiency and productivity in industrial settings. Operators can easily troubleshoot issues and make necessary changes without physically being present at the valve site. This level of control and flexibility can lead to cost savings and reduced downtime, making it an invaluable asset across various industries.

Wide Application in Various Industries

The Haisen part-turn valve electric actuator is a versatile and reliable solution for various industrial applications.

- Wide Applicability: Suitable for various industries, including petrochemicals, metallurgy, shipbuilding, light industry, food processing, papermaking, construction, municipal engineering, and thermal and hydropower plants.

- Durability and Reliability: Designed for continuous and heavy-duty operation in harsh industrial environments.

- Robust Construction: Ensures long-term efficiency and effectiveness, making it a top choice for companies seeking reliable automation solutions.

With its versatility, durability, and reliability, the Haisen part-turn valve electric actuator is an excellent choice for industries seeking efficient and dependable automation solutions.

Efficiency and Cost-Effectiveness of Electric Actuators

Electric actuators are crucial in ensuring streamlined operations in various industrial settings. By automating the process of opening and closing valves, these actuators eliminate the need for manual labor, resulting in increased efficiency and productivity. With the ability to precisely control butterfly, ball, and plug valves, electric actuators offer a cost-effective solution for managing valve operations.

Streamlined Operations

Industrial electric actuators provide a seamless control of valve operations, allowing for precise adjustments and quick response times. Motorized actuators allow valve settings to be easily adjusted to meet specific operational requirements, ensuring smooth and efficient processes within industrial facilities.

Furthermore, industrial electric actuators contribute to streamlined operations by reducing the need for manual adjustments and maintenance. This saves time and labor costs and minimizes the risk of human error, ensuring consistent and reliable valve performance. The seamless integration of electric actuators into industrial processes promotes a more efficient and productive workflow, ultimately leading to increased operational efficiency.

Reduced Maintenance Costs

By automating valve operations with electric actuator valves, companies can significantly reduce maintenance costs associated with manual valve operation. The precise control offered by electric actuators minimizes wear and tear on valves, extending their lifespan and reducing the need for frequent repairs or replacements. This saves money on replacement parts and labor and reduces downtime for maintenance, allowing production to continue uninterrupted. The reduced need for manual intervention also lowers the risk of human error, further contributing to cost savings and operational efficiency.

Energy Efficiency in Industrial Settings

Electric valve actuators are essential components in modern industrial settings, crucial in enhancing efficiency and sustainability. By enabling precise control over fluid and gas flow, these actuators reduce energy consumption and minimize environmental impact.

Here are some key benefits of using electric valve actuators:

- Improved Energy Efficiency: Precise control over fluid and gas flow optimizes energy usage, leading to significant cost savings.

- Reduced Environmental Impact: Electric valve actuators contribute to a more sustainable industrial landscape by minimizing energy consumption and emissions.

- Enhanced Operational Efficiency: Streamlined operations and reduced maintenance requirements increase productivity and overall efficiency.

- Remote Monitoring and Control: Advanced features enable remote monitoring and control, improving operational flexibility and responsiveness.

- Long-Term Cost Savings: While initial investments may be higher, the long-term benefits, such as energy savings, reduced maintenance, and improved efficiency, often outweigh the upfront costs.

Electric valve actuators offer a valuable solution for companies seeking to enhance their operational processes, reduce costs, and contribute to a more sustainable future. By adopting these innovative technologies, industries can optimize their performance while minimizing their environmental footprint.

Ensuring Reliability with High-Quality Electric Actuators

Reliability is key in industrial operations, and high-quality electric actuators play a crucial role in ensuring dependable performance. Haisen's Part-Turn Valve Electric Actuator, such as the QT series, is designed to provide consistent and reliable control of various valves and actuators in industrial settings. With its precision engineering and robust construction, this electric actuator delivers dependable performance even in the most demanding applications.

Furthermore, long-term durability is a hallmark of Haisen's electric valve actuators. These motorized actuators are built to withstand the rigors of industrial environments, offering longevity and resilience that contribute to uninterrupted operations. Their durable construction ensures that they can withstand harsh conditions and continue to perform reliably over an extended period.

Safety and security are paramount in industrial operations, and Haisen's electric actuators are designed with these considerations in mind. With advanced safety features and secure operation mechanisms, these actuators provide operators and maintenance personnel peace of mind. Integrating safety protocols ensures that the operation of valves with electric actuators is efficient and safe for personnel and surrounding equipment.

The Value of High-Quality Actuators

Industrial electric actuators play a crucial role in enhancing the efficiency and reliability of operations in various industrial settings. They can control valve operations, which makes them essential for ensuring the smooth and precise functioning of industrial processes.

Elevating Industrial Operations with Electric Actuators

The use of industrial electric actuators has revolutionized the way valve operations are managed in industrial settings. By providing precise control over actuator valves, these devices have elevated industrial processes' overall efficiency and productivity, leading to improved output and reduced downtime.

The value of high-quality electric actuators cannot be overstated. These devices provide precise control over valve operations and offer durability and reliability. They ensure that industrial processes run smoothly without the need for frequent maintenance or replacement, resulting in business cost savings and a more sustainable approach to industrial operations.

Investing in high-quality electric actuators like Haisen's Part-Turn Valve Electric Actuator ensures seamless and reliable valve operations. These motorized actuators offer enhanced control options and remote operation capabilities, making them invaluable assets for industries that rely on efficient valve management. Furthermore, high-quality actuators can significantly reduce maintenance costs by minimizing wear and tear on valves, leading to longer equipment lifespan and decreased downtime for repairs. These advanced actuators are also designed to provide precise positioning and torque control, allowing for more accurate and efficient flow regulation within industrial processes.

Embracing Efficiency in Industrial Settings

In today's competitive industrial landscape, efficiency is key to success. Electric valve actuators provide a cost-effective solution for streamlining operations, reducing maintenance costs, and promoting energy efficiency in industrial settings. Embracing these advanced technologies is essential for staying ahead in the industry.

By embracing the versatility, efficiency, and reliability offered by high-quality electric actuators, industries can elevate their operational standards and stay ahead of the competition. These advanced devices are indispensable assets for driving progress and success in modern industrial settings.