Introduction

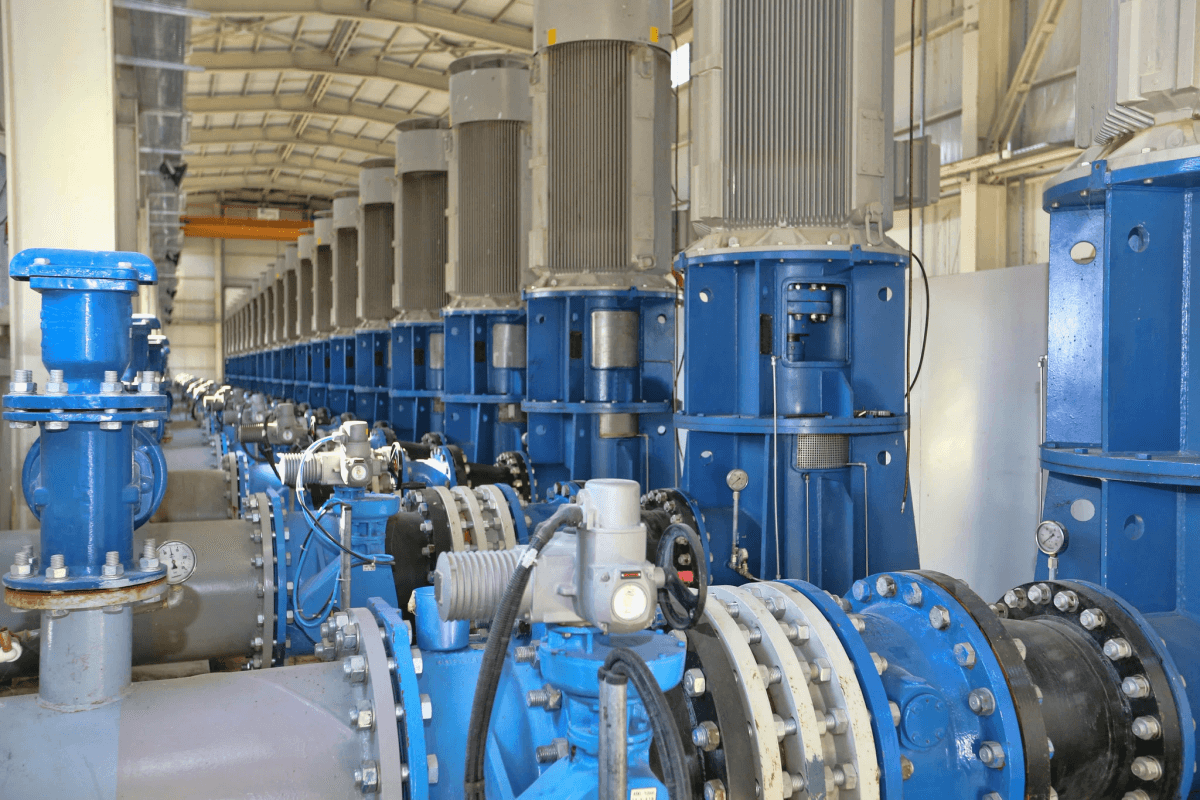

When it comes to efficient and precise valve control, electric rotating actuators are the go-to choice for many industries. These cutting-edge devices are designed to seamlessly automate the operation of various types of valves, providing unparalleled reliability and performance. Whether it's for regulating flow, pressure, or temperature, electric actuators offer a versatile solution that meets the demands of modern industrial processes.

Understanding Electric Rotating Actuators

Electric rotating actuators are specially designed to convert electrical energy into mechanical motion, allowing them to rotate valves in a controlled manner. This innovative technology eliminates the need for manual operation or pneumatic actuators, offering greater precision and flexibility in valve control.

Electric rotating actuators come with various control options, such as on/off control, modulating control, and digital communication protocols. This allows for seamless integration into existing automation systems and provides the flexibility to adapt to different operating conditions. With the ability to precisely adjust the valve position, electric actuators offer improved accuracy and repeatability, ensuring optimal process performance.

Key Features of Electric Actuators

One of the key features of electric actuators is their ability to provide consistent and accurate positioning of the valve, ensuring optimal flow regulation. With motorized actuator technology, users can enjoy customizable speed and torque settings to suit specific application requirements.

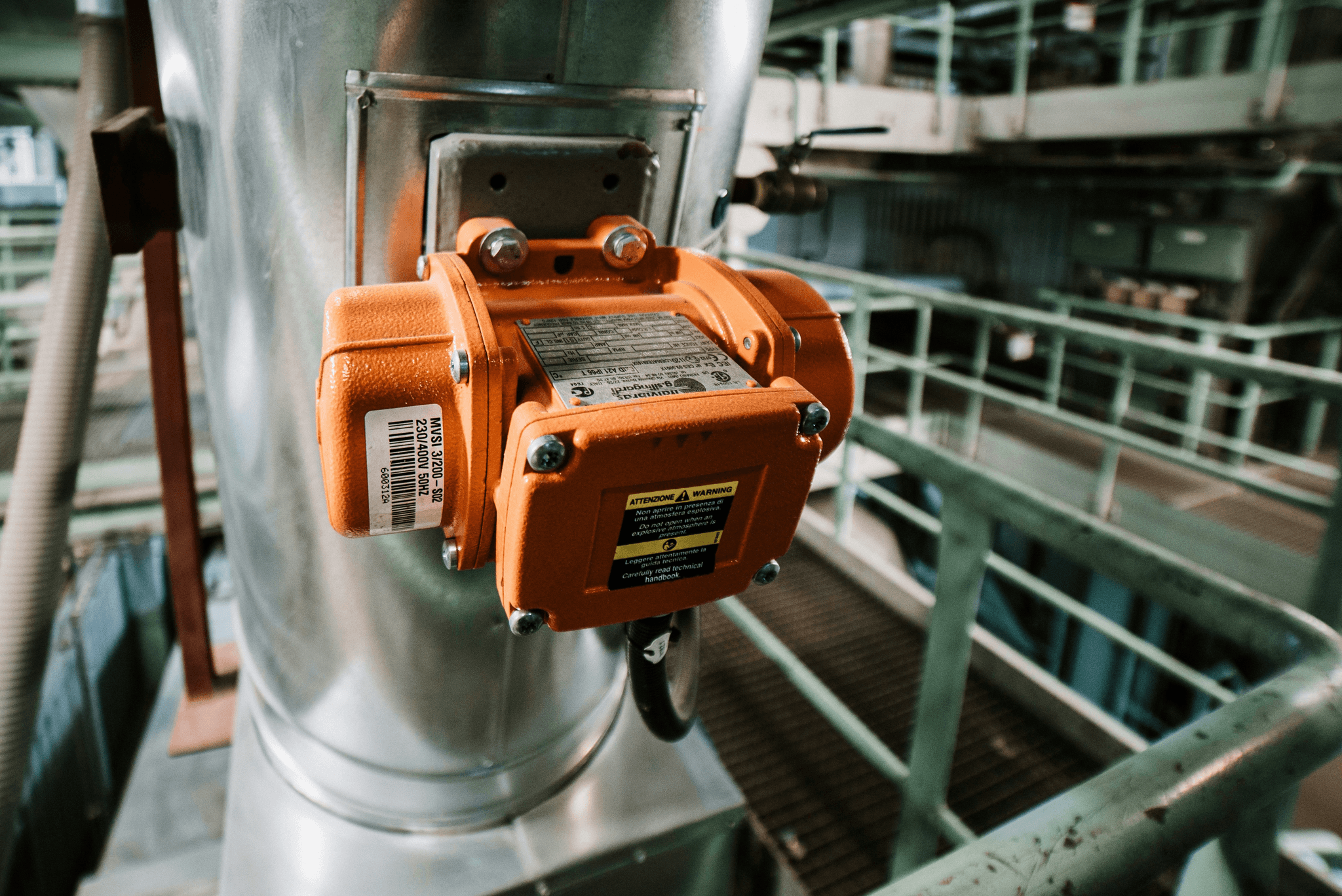

Common Applications of Electric Actuators

From industrial manufacturing plants to water treatment facilities, electric actuators are widely used in a variety of applications. Whether it's controlling flow rates in pipelines or automating process valves in chemical plants, these rotary actuators play a crucial role in optimizing operational efficiency and maintaining safety standards.

Electric actuators are also commonly used in the aerospace industry, where they are employed in aircraft control systems to adjust wing flaps, landing gear, and other critical components. The precise and reliable performance of electric actuators is essential for ensuring the safety and functionality of aircraft during flight and while on the ground. This demonstrates the versatility of electric actuators across different sectors and their ability to meet stringent operational requirements.

Types of Electric Rotating Actuators

Electric rotating actuators come in various types, each with unique features and advantages. Haisen's Part-Turn Valve Electric Actuator is known for its precision and reliability, making it ideal for applications that require accurate valve control. With a robust design and advanced technology, this electric actuator ensures smooth operation and long-term performance.

Key Advantages of QT Series Electric Actuator include its compact size, high torque output, and versatile mounting options. This makes it suitable for a wide range of industrial applications where space is limited but powerful performance is essential. The QT Series electric actuator offers superior control and efficiency, making it a popular choice among engineers and system integrators.

When comparing electric actuator options, it's important to consider factors such as torque output, speed, control options, and compatibility with different valve types. While some electric actuators are designed for specific applications or industries, others offer flexibility and adaptability to meet diverse needs. By carefully evaluating the available options, you can select the most suitable electric actuator for your specific requirements.

Benefits of Using Electric Actuators

Efficiency of Electric Actuators

Electric rotating actuators offer unmatched efficiency in valve control systems. With precise and rapid rotation capabilities, these actuators ensure quick and accurate adjustments to valve positions, resulting in optimal flow control and system performance. The seamless integration of electric actuator motors with valve mechanisms minimizes energy wastage and enhances overall operational efficiency. Additionally, the use of electric actuators reduces maintenance costs as they have fewer moving parts compared to traditional pneumatic or hydraulic systems. This translates to long-term cost savings for industries that rely on efficient valve control systems.

Cost-Effectiveness of Electric Actuators

When compared to traditional pneumatic actuators, electric actuators prove to be more cost-effective in the long run. Their low maintenance requirements and longer lifespan reduce operational costs significantly over time. Additionally, the precise control offered by electric actuator cylinders leads to minimized downtime and increased productivity, further contributing to cost savings for businesses.

Furthermore, electric actuators offer greater energy efficiency compared to pneumatic actuators, resulting in reduced electricity consumption and lower utility bills for businesses. This not only contributes to cost savings but also aligns with sustainability goals, making electric actuators a more environmentally friendly option. The long-term cost-effectiveness of electric actuators is further enhanced by their adaptability to automation systems, allowing for seamless integration with other smart technologies for improved operational efficiency.

Environmental Impact of Electric Actuators

The environmental impact of electric rotating actuators is undeniable, as they contribute to sustainability efforts in various industries. By eliminating the need for compressed air or hydraulic fluids, electric actuators reduce carbon emissions and minimize the use of non-renewable resources. This eco-friendly approach aligns with modern environmental regulations and demonstrates a commitment to reducing the carbon footprint associated with industrial operations.

Now you have a comprehensive understanding of the benefits provided by electric rotating actuators, including their efficiency, cost-effectiveness, and positive environmental impact on industrial operations. Let's explore how these advantages can be leveraged in choosing the right actuator for your specific needs and optimizing valve control systems for maximum performance and reliability.

Choosing the Right Electric Actuator

When selecting an electric rotating actuator for your valve control needs, there are several important factors to consider. Firstly, you'll want to assess the torque requirements of your application to ensure that the electric actuator motor can provide sufficient force for smooth and efficient operation. Additionally, it's crucial to take into account the speed and precision needed for your valve control system, as different electric actuators offer varying levels of speed and accuracy.

Factors to Consider When Selecting an Electric Actuator

Other key considerations include the environmental conditions in which the actuator will operate, such as temperature and humidity levels. It's also important to evaluate the power source available at your facility and whether it can support the specific requirements of the chosen electric actuator. By carefully assessing these factors, you can ensure that you select an electric actuator that meets all of your operational needs.

Other key considerations include the environmental conditions in which the actuator will operate, such as temperature and humidity levels. It's also important to evaluate the power source available at your facility and whether it can support the specific requirements of the chosen electric actuator. By carefully assessing these factors, you can ensure that you select an electric actuator that meets all of your operational needs.

Customization Options for Electric Actuators

Many manufacturers offer customization options for their electric actuators, allowing you to tailor the design and specifications to fit your unique requirements. From choosing specific materials for construction to selecting custom torque ratings and speed settings, having the ability to customize your electric actuator ensures that it will seamlessly integrate with your valve control system.

Furthermore, customization options for electric actuators also extend to the choice of control interfaces, such as digital or analog signals, and the inclusion of feedback devices for precise positioning. This level of customization ensures that your electric actuator will be compatible with different types of valves, including ball valves, butterfly valves, and globe valves. By tailoring the design and specifications to fit your specific valve control system, you can optimize performance and efficiency.

Ensuring Compatibility with Different Valve Types

Whether you're working with a butterfly valve, ball valve, or any other type of actuator valve, it's essential to confirm that your chosen electric actuator is compatible with these different valve types. This involves evaluating mounting options, interface connections, and any additional adaptors or accessories needed for proper integration.

Maintenance and Care for Electric Actuators

Best Practices for Maintaining Electric Actuators

To ensure the optimal performance of your electric rotating actuator, regular maintenance is crucial. This includes inspecting the actuator valve for any signs of wear and tear, checking the electrical connections, and lubricating moving parts to prevent friction. It's also important to keep the actuator motor clean and free from debris that could interfere with its operation.

Regular maintenance of your electric rotating actuator also involves checking the power supply and ensuring that it meets the necessary voltage requirements. Additionally, inspecting the control system for any signs of malfunction or damage is essential to prevent potential issues. It's important to create a maintenance schedule and adhere to it diligently to avoid unexpected breakdowns and costly repairs.

Troubleshooting Common Electric Actuator Issues

When encountering issues with your electric actuator cylinder, it's essential to troubleshoot the problem systematically. This may involve checking for faulty wiring, calibrating the actuator motor, or addressing any mechanical issues such as misalignment or excessive vibration. Understanding common troubleshooting techniques can help you quickly identify and resolve any issues that may arise.

After identifying the specific issue with your electric actuator cylinder, it's important to thoroughly inspect and test the components involved. This can include checking for any loose connections, damaged wiring, or worn-out parts that may be causing the problem. By conducting a comprehensive assessment of the actuator system, you can pinpoint the root cause of the issue and take appropriate measures to address it effectively.

Extending the Lifespan of Electric Actuators

By following a regular maintenance schedule and promptly addressing any issues that arise, you can significantly extend the lifespan of your electric actuators. Additionally, investing in high-quality components and ensuring proper installation can contribute to their longevity. Regularly monitoring the performance of your electric actuators and addressing any concerns promptly can help prevent premature wear and tear.

By implementing a preventive maintenance program, you can catch any potential issues before they become major problems, saving time and money in the long run. This proactive approach can also help to identify any areas for improvement in your electric actuators, allowing you to make necessary adjustments to optimize their performance. Regular maintenance can also help to ensure that your electric actuators are operating at their full potential, reducing the risk of unexpected breakdowns.

Conclusion

When it comes to selecting the best electric actuator for your needs, it's crucial to consider factors such as torque requirements, valve type, and environmental conditions. Embracing the future of actuator technology means staying updated with the latest innovations and advancements in the industry. By optimizing valve control with electric actuators, you can ensure precise and efficient operation for various applications.

Selecting the Best Electric Actuator for Your Needs

Choosing the right electric rotating actuator involves assessing your specific requirements, including torque output, speed, and control options. Whether you need an actuator valve for industrial or commercial use, considering factors such as compatibility with different valve types and customization options will help you make an informed decision.

After assessing your specific requirements for torque output, speed, and control options, it's important to consider the latest advancements in actuator technology. With the rapid pace of innovation in this field, staying up-to-date with the newest features and capabilities can give you a competitive edge. Look for electric rotating actuators that offer smart technology integration, such as IoT connectivity and predictive maintenance capabilities, to future-proof your investment and maximize efficiency.

Embracing the Future of Actuator Technology

As technology continues to advance, so do electric actuators. From improved efficiency and performance to enhanced connectivity and automation capabilities, staying ahead of the curve in actuator technology can provide numerous benefits for your operations. With the integration of advanced sensors and data analytics, electric actuators can now offer real-time monitoring and predictive maintenance, reducing downtime and improving overall reliability. Additionally, the use of smart actuators allows for remote operation and control, giving you the flexibility to manage your systems from anywhere, at any time. Embracing these advancements in actuator technology can streamline your operations and give you a competitive edge in today's fast-paced industrial landscape.

Optimizing Valve Control with Electric Actuators

By leveraging the power of electric actuators, you can optimize valve control in a wide range of applications. Whether it's a motorized actuator for precise positioning or a rotary actuator for 90-degree rotation, electric actuators offer versatility and reliability in managing fluid flow in various systems.

Electric actuators offer a level of precision and control that traditional pneumatic or hydraulic systems simply can't match. This is especially true in applications where variable speed, torque, and positioning are crucial. By utilizing electric actuators, you can ensure that your valve control system operates with the utmost accuracy and responsiveness, leading to improved overall performance and efficiency.