Introduction

When it comes to ensuring the safety of aircraft operations, friction testing plays a crucial role in analyzing runway conditions. Understanding the science behind friction testing and its impact on aviation safety is essential for airport authorities and airline operators alike. Utilizing high-performance friction testers like the BHM01/02 from Haisen can significantly enhance runway safety standards.

Understanding Friction Testing

Friction testing involves measuring the force required to move an object over a surface, which is crucial for determining the level of grip on airport runways. This process helps in assessing the potential risk of skidding or hydroplaning during aircraft landings and takeoffs, making it a vital aspect of aviation safety protocols.

Importance of Runway Analysis

Conducting thorough runway analysis through friction testing is essential for identifying any potential hazards that could compromise aircraft safety. By understanding the condition of runway surfaces, airport authorities can take proactive measures to maintain optimal friction levels and ensure safe operations for all flights.

Utilizing High-Performance Friction Tester

The use of high-performance friction testers such as Haisen's BHM01/02 is instrumental in accurately measuring and analyzing runway surface conditions. These advanced testing devices provide reliable data that enables airport authorities to make informed decisions regarding maintenance and safety protocols.

By incorporating advanced technology into friction testing equipment, airports can greatly improve their ability to maintain safe operating conditions for aircraft.

What is a Friction Tester?

A friction tester is a crucial tool used to measure the frictional force between an object and a surface. This device helps determine the coefficient of friction (COF), which is essential for assessing the safety of runway surfaces for aircraft operations.

Working Principle of Friction Tester

The working principle of a friction tester involves applying a controlled force to an object and measuring the resistance encountered when it moves across a surface. The BHM01/02 COF tester from Haisen utilizes advanced technology to accurately assess the friction levels on airport runways, ensuring optimal safety for aircraft landings and take-offs.

Accuracy and Reliability of BHM01/02

The BHM01/02 COF tester is renowned for its precision and reliability in providing accurate friction testing results. Its state-of-the-art design and advanced sensors make it a trusted tool for runway analysis, offering consistent and dependable data for assessing surface conditions.

Benefits of Accurate Friction Testing

Accurate friction testing with the BHM01/02 COF tester enables airports to maintain safe runway conditions by identifying areas with inadequate friction levels that may pose risks to aircraft operations. This proactive approach helps prevent potential accidents and enhances overall aviation safety standards.

Remember that accurate friction testing with high-quality equipment like the BHM01/02 COF tester is key in ensuring safe airport operations, as well as complying with regulatory requirements.

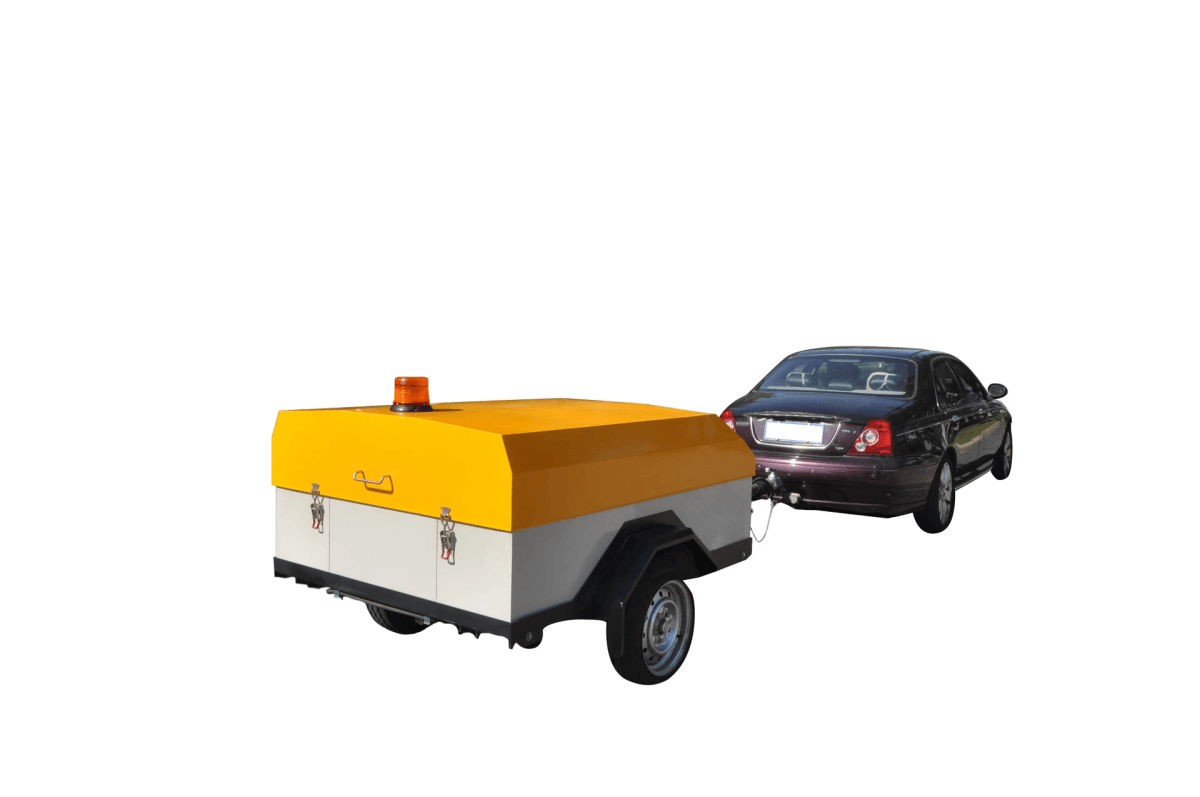

Runway Surface Friction Testing Equipment

Features of Haisen's BHM01/02

Haisen's BHM01/02 friction tester is equipped with advanced sensors and technology to accurately measure the frictional force on airport runways. Its user-friendly interface and portability make it a convenient tool for runway surface testing, providing real-time data for enhanced safety.

In addition, the Haisen's BHM01/02 friction tester is designed to be versatile for various surface types, ensuring accurate measurements regardless of the runway material. Whether it's concrete, asphalt, or even specialty surfaces, this tester can provide reliable data for all types of runways. This adaptability makes it an essential tool for airports with diverse runway compositions, allowing for comprehensive safety assessments across the entire airport.

Versatility for Various Surface Types

The BHM01/02 friction tester is designed to work effectively on various surface types, including asphalt, concrete, and even contaminated surfaces. This versatility ensures that airports can maintain optimal friction levels across all their runways, regardless of the materials used.

Furthermore, the BHM01/02 friction tester is equipped with advanced technology that allows it to adapt to changing surface conditions, such as wet or icy runways. This feature ensures that airports can accurately assess and address any potential hazards, ultimately enhancing safety for aircraft operations. By providing real-time data on friction levels, airport personnel can make informed decisions to minimize the risk of accidents and ensure smooth takeoffs and landings for all flights.

Enhancing Safety for Aircraft Operations

By utilizing the BHM01/02 friction tester, airports can proactively monitor and manage runway conditions, ultimately enhancing safety for aircraft operations. Accurate friction testing helps prevent skidding or hydroplaning incidents, reducing the risk of accidents during takeoff and landing.

In addition to preventing skidding and hydroplaning incidents, the BHM01/02 friction tester also allows airports to make informed decisions about runway maintenance and resurfacing. By regularly monitoring friction levels, airports can identify areas of the runway that may require attention, such as rubber buildup from landing gear or surface contaminants. This proactive approach to maintenance not only enhances safety for aircraft operations but also helps to extend the lifespan of the runway, saving airports time and money in the long run.

How do you Test for Frictional Force?

Measuring Coefficient of Friction (COF)

A friction tester, such as Haisen's BHM01/02, is the machine that measures friction by calculating the coefficient of friction (COF) between the runway surface and a test tire. This measurement helps determine the level of grip provided by the runway, crucial for safe aircraft operations.

Ensuring Optimal Runway Friction Levels

The use of a friction test is essential to ensure optimal runway friction levels. By regularly testing and monitoring COF, airport authorities can identify areas with low friction and take necessary measures to improve safety for aircraft landings and take-offs.

Impact on Aircraft Performance

The COF directly impacts aircraft performance during critical phases of flight. Low friction levels can lead to reduced braking efficiency and traction, potentially causing skidding or hydroplaning. Therefore, accurate friction testing is vital for maintaining safe operations at airports.

Airport / Runway Friction Testing

Airport and runway friction testing is a critical aspect of ensuring the safety of aircraft operations. Friction testers are utilized to measure the level of friction between the aircraft tires and the runway surface, providing essential data for pilots and airport authorities.

Regulatory Requirements for Friction Testing

Regulatory bodies such as the Federal Aviation Administration (FAA) and International Civil Aviation Organization (ICAO) mandate regular friction testing to maintain safe operating conditions for aircraft. These regulations ensure that airports adhere to strict standards in assessing and maintaining adequate levels of runway friction, preventing accidents and enhancing overall aviation safety.

Furthermore, these regulations also require airports to regularly monitor weather conditions and conduct friction tests after adverse weather events such as rain or snow. This proactive approach ensures that any changes in runway conditions are promptly identified and addressed, minimizing the risk of accidents due to reduced friction. By mandating these measures, regulatory bodies are actively promoting a culture of safety and accountability within the aviation industry.

Improving Runway Safety Standards

Friction testing plays a pivotal role in improving runway safety standards by providing accurate data on surface conditions. This information enables airports to take proactive measures in maintaining optimal friction levels, reducing the risk of skidding or hydroplaning during takeoff or landing. As a result, it significantly enhances the overall safety of aircraft operations.

Friction testing also allows airports to identify areas of the runway that may require maintenance or resurfacing, ultimately saving time and resources by addressing potential issues before they escalate. By regularly conducting friction tests, airports can ensure that their runways meet the necessary safety standards, providing peace of mind for both pilots and passengers. This proactive approach to runway maintenance not only enhances safety but also contributes to the overall efficiency of airport operations.

The Role of Friction Testers in Aviation Industry

Friction testers are indispensable tools in the aviation industry, contributing to the continuous improvement of safety standards at airports worldwide. By providing precise measurements of runway surface friction, these devices empower airport authorities to make informed decisions regarding maintenance and operational procedures, ultimately ensuring safe and efficient air travel.

Remember that accurate friction testing is crucial for maintaining safe operating conditions at airports and enhancing overall aviation safety. With regulatory requirements mandating regular testing, it's evident that friction testers play a vital role in ensuring optimal runway conditions for aircraft operations.

Haisen's Contribution to Aviation Safety

Innovations in Friction Testing Technology

Haisen has revolutionized the aviation industry with its cutting-edge innovations in friction testing technology. The company's friction testers, such as the BHM01/02, are equipped with advanced sensors and data analysis capabilities to provide accurate and reliable runway surface friction measurements. These innovations have significantly improved the safety and efficiency of aircraft operations.

Furthermore, Haisen's friction testing technology has also integrated AI-related ground support equipment (GSE) to further enhance the safety and efficiency of aircraft operations. By utilizing artificial intelligence, the GSE is able to analyze real-time data from the friction testers and provide immediate feedback to airport personnel. This proactive approach allows for prompt decision-making in addressing any potential runway surface issues, ultimately minimizing the risk of accidents and delays.

Supporting Safe Operations with AI-Related GSE

Haisen goes beyond traditional friction testing by incorporating artificial intelligence (AI) into its ground support equipment (GSE). By leveraging AI algorithms, Haisen's GSE can analyze friction test data in real-time, identify potential safety hazards, and provide proactive recommendations for runway maintenance. This integration of AI technology has elevated the standards for airport safety and operational excellence.

By implementing AI technology into its GSE, Haisen has revolutionized the way airports approach safety and maintenance. The real-time analysis of friction test data allows for immediate identification of potential hazards, enabling airports to take proactive measures to ensure safe operations. This proactive approach not only enhances safety but also minimizes downtime for maintenance, ultimately improving overall operational excellence.

Haisen's Commitment to Global Aviation Safety

As a leader in aviation safety solutions, Haisen is dedicated to upholding the highest standards of global aviation safety. The company collaborates with industry stakeholders, regulatory bodies, and airport authorities to continuously improve runway surface friction testing protocols and equipment. Haisen's unwavering commitment to enhancing aviation safety has earned the trust of airports and airlines worldwide.

Haisen's dedication to global aviation safety extends beyond just improving runway surface friction testing protocols and equipment. The company also invests in research and development to identify and address potential safety hazards in aviation operations. By staying at the forefront of technological advancements, Haisen is able to provide innovative solutions that contribute to the overall safety of air travel. This proactive approach demonstrates Haisen's commitment to not only meeting current safety standards but also anticipating and mitigating future risks.

Conclusion

Ensuring Aircraft Safety with Accurate Friction Testing

Friction testing is crucial for ensuring the safety of aircraft operations, and the use of a high-performance friction tester like Haisen's BHM01/02 is essential in achieving accurate results. By consistently testing for frictional force, airports can maintain optimal runway conditions and minimize the risk of accidents due to poor traction.

Haisen's BHM01/02: Advancing Runway Safety Standards

The BHM01/02 friction tester offers a reliable and accurate solution for measuring runway surface friction levels. Its advanced technology and versatility make it an indispensable tool for enhancing safety in aviation. With its ability to test various surface types, it has become a game-changer in advancing runway safety standards.

Future of Runway Analysis and Friction Testing

As aviation technology continues to evolve, the future of runway analysis and friction testing holds great promise. With innovations such as AI-related ground support equipment (GSE) from Haisen, we can expect even greater advancements in ensuring optimal runway conditions for safe aircraft operations.

By embracing cutting-edge technology and prioritizing accurate friction testing, the aviation industry can look forward to safer runways and improved aircraft performance in the years to come. Haisen's dedication to global aviation safety through innovative solutions will continue to play a pivotal role in shaping the future of runway analysis and friction testing.