Introduction

When it comes to ensuring the safety of aircraft landing and takeoff, accurate runway friction is of utmost importance. This is where the Haisen BHM01/02 Surface Friction Tester comes into play, providing reliable data for pilots and airport authorities to make informed decisions. Measuring friction in runway safety is crucial for maintaining safe operations and preventing accidents.

Importance of Accurate Runway Friction

Accurate friction measurement is essential for determining the level of grip on airport runways, especially during varying weather conditions. The coefficient of friction test equipment like the Haisen BHM01/02 ensures that pilots have the necessary information to execute safe landings and takeoffs, ultimately minimizing the risk of accidents. Additionally, having accurate runway friction data allows airport authorities to make informed decisions regarding runway maintenance and treatment, ensuring optimal conditions for aircraft operations. This not only enhances safety but also contributes to efficient airport operations, reducing delays and improving overall passenger experience.

Haisen BHM01/02 Surface Friction Tester Overview

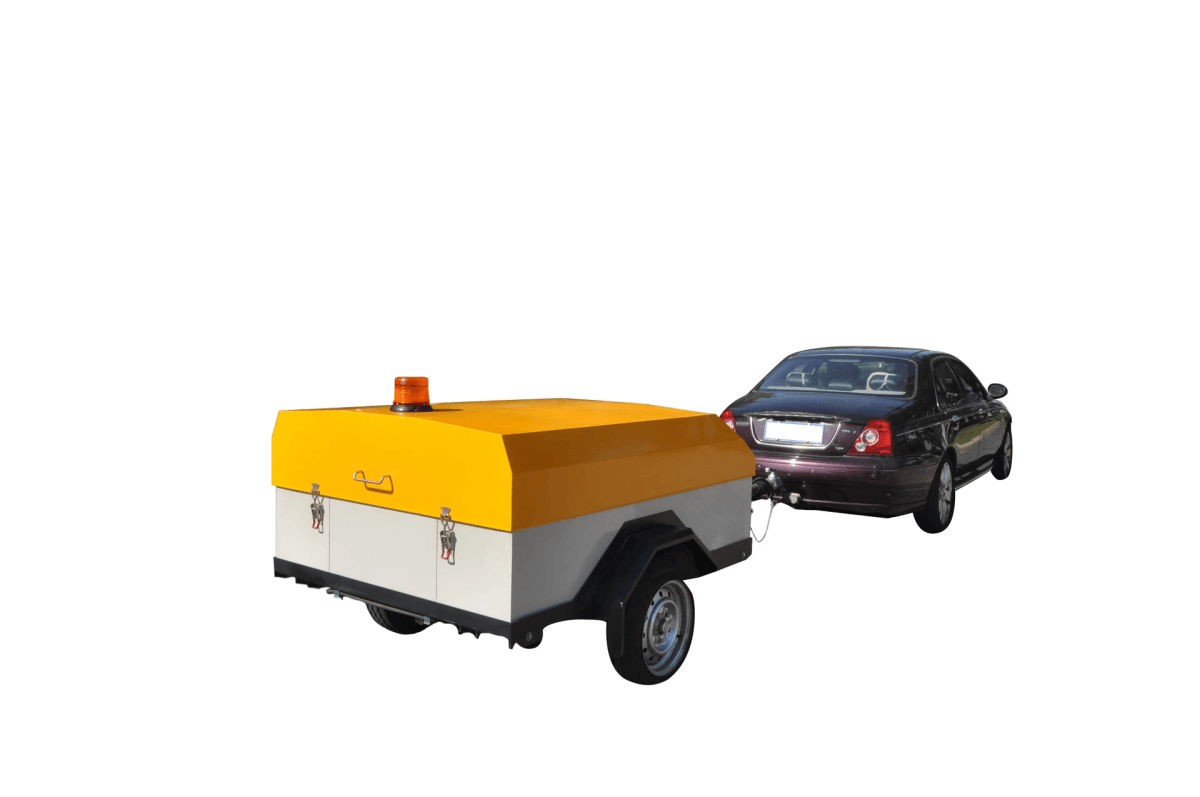

The Haisen BHM01/02 surface friction tester machine is designed with safety and reliability in mind. It maintains original vehicle systems for safety and performance, using high-precision components and an industrial-grade laptop with a Chinese interface for reliable operation. With specialized test tires compliant with aviation standards and a computer control system pre-programmed for continuous testing, it provides accurate and consistent results.

In addition to its reliable operation and accurate results, the Haisen BHM01/02 surface friction tester also offers ease of use and portability. Its compact design allows for easy transportation to different testing sites, making it convenient for runway safety inspections at various airports. This flexibility ensures that friction measurements can be taken promptly and efficiently, contributing to overall aviation safety.

Significance of Measuring Friction in Runway Safety

Measuring friction on runways also plays a crucial role in reducing the risk of runway excursions and overruns, which are significant contributors to aviation accidents. By accurately assessing the friction levels, airport authorities can take proactive measures to address any potential safety hazards, such as rubber build-up or standing water, before they pose a threat to aircraft operations. This proactive approach not only enhances overall safety but also minimizes disruptions to flight schedules, ultimately improving the passenger experience.

The Role of Measuring Friction in Runway Safety

Ensuring Safe Aircraft Landing and Takeoff

Accurate measurement of friction is crucial for ensuring safe aircraft landing and takeoff. The Haisen BHM01/02 surface friction tester machine plays a vital role in providing real-time data on runway conditions, allowing pilots to make informed decisions. This helps prevent accidents and ensures the safety of passengers and crew.

Impact of Weather Conditions on Runway Friction

Weather conditions such as rain, snow, or ice can significantly impact runway friction, making it essential to have reliable coefficient of friction test equipment. The Haisen friction testing machine is designed to withstand various weather conditions and provide accurate data for pilots to adjust their approach and takeoff speeds accordingly.

Importance of Accurate Friction Data for Pilots

Pilots rely on accurate friction data to determine the appropriate braking action and thrust settings during landing and takeoff. The Haisen RFT (Runway Friction Tester) provides pilots with real-time information on runway conditions, enabling them to make precise decisions that are crucial for the safety of the aircraft and its occupants.

Understanding the Haisen BHM01/02 Surface Friction Tester

Safety Design and Reliability Features

The Haisen BHM01/02 Surface Friction Tester is designed with safety as a top priority, maintaining original vehicle systems for safety and performance. The trunk is reinforced to accommodate the testing equipment, ensuring secure and reliable operation. With high-precision components and an industrial-grade laptop with a Chinese interface, the reliability of this friction tester machine is unmatched in the industry.

Furthermore, the Haisen BHM01/02 Surface Friction Tester boasts impressive acceleration and calibration capabilities, allowing for efficient and accurate testing of surface friction. The machine is equipped with advanced sensors and software that can quickly analyze and calibrate the data, providing precise results in a timely manner. This ensures that users can rely on the accuracy of the testing equipment for making informed decisions regarding safety and performance.

Acceleration and Calibration Capabilities

When it comes to acceleration and calibration, the Haisen friction testing machine does not disappoint. Vehicles like the Ford Taurus 2.7T and Honda Acura can reach speeds of 96 km/h within just 200 meters, showcasing impressive acceleration capabilities. In addition, the friction tester features an accurate and easy-to-use external electronic calibration device, ensuring precise measurements every time.

Specialized Test Tires and Computer Control System

The Haisen BHM01/02 Surface Friction Tester utilizes specialized tires that are compliant with CAAC, ICAO, and FAA standards, with a pressure of 0.7MPa to ensure accurate testing results. The computer control system operates with a Chinese Windows OS laptop that is pre-programmed for continuous testing, providing efficient and reliable data collection for coefficient of friction test equipment.

In addition to the specialized tires and computer control system, the Haisen BHM01/02 Surface Friction Tester is equipped with a high-resolution camera that captures real-time footage of the testing process. This allows for visual verification of the test results and provides an additional layer of data for analysis. The camera footage can be synchronized with the test data, offering a comprehensive view of surface conditions and tire performance.

Application and Benefits of Accurate Friction Measurement

The use of a friction tester machine like the Haisen BHM01/02 is instrumental in enhancing airport safety standards by providing accurate data on runway friction. This data allows airport authorities to take proactive measures to maintain safe landing and takeoff conditions for aircraft.

Enhancing Airport Safety Standards

By utilizing the Haisen BHM01/02 surface friction tester, airports can ensure that their runways meet the necessary safety standards. This helps in preventing accidents and ensuring the overall safety of flight operations. With reliable friction testing equipment, airports can prioritize maintenance efforts on areas with lower friction levels, ultimately reducing the risk of runway-related incidents.

Improving Flight Operations Efficiency

Accurate measurement of runway friction enables airlines to make informed decisions about flight operations. Pilots can have confidence in the runway conditions, leading to smoother landings and takeoffs. This not only enhances passenger comfort but also contributes to on-time performance and overall efficiency in flight operations.

Compliance with Aviation Regulatory Requirements

The use of a high-quality coefficient of friction test equipment like the Haisen BHM01/02 ensures that airports comply with aviation regulatory requirements. By regularly measuring and monitoring runway friction, airports can demonstrate their commitment to upholding safety standards set by organizations such as CAAC, ICAO, and FAA.

Qualitative Analysis of Friction Measurement Data

Accurate friction measurement data is crucial for real-time monitoring and analysis of runway conditions. The Haisen BHM01/02 Surface Friction Tester provides precise and reliable data, enabling airport authorities to make informed decisions regarding runway safety and maintenance. By continuously monitoring friction levels, potential hazards can be identified and addressed promptly.

Real-Time Monitoring and Analysis

The Haisen BHM01/02 allows for real-time monitoring and analysis of runway friction levels, ensuring that airport authorities have up-to-date information on surface conditions. This enables them to take proactive measures to address any issues that may compromise aircraft safety during landing and takeoff. With the ability to continuously monitor friction levels, the tester ensures that any changes in runway conditions are promptly detected.

Enhancing Runway Maintenance and Management

By providing accurate friction measurement data, the Haisen BHM01/02 Surface Friction Tester enhances runway maintenance and management practices. Airport authorities can use the data to identify areas of the runway that require attention, such as rubber buildup or surface contamination, allowing for targeted maintenance efforts. This proactive approach helps in preserving optimal surface friction levels for safe aircraft operations.

Improving Decision-Making for Runway Operations

The Haisen BHM01/02 Surface Friction Tester empowers airport authorities with valuable data for making informed decisions regarding runway operations. By having access to reliable friction measurement data, they can effectively plan for snow removal, de-icing procedures, or other weather-related interventions to maintain safe runway conditions. This leads to improved overall decision-making in ensuring safe aircraft operations.

Case Studies and Success Stories

Successful Implementation at Various Airports

The Haisen BHM01/02 Surface Friction Tester has seen successful implementation at various airports worldwide, including high-altitude locations. With over 200 units in use, it has proven to be a reliable and effective tool for measuring friction on airport runways, contributing to enhanced safety standards and operational efficiency.

Positive Impact on Runway Safety and Operations

The positive impact of the Haisen friction tester machine on runway safety and operations cannot be overstated. By providing accurate friction data, it has played a crucial role in ensuring safe aircraft landing and takeoff, especially in adverse weather conditions. This has significantly reduced the risk of runway-related incidents and accidents.

Testimonials from Airport Authorities and Aviation Professionals

Airport authorities and aviation professionals have lauded the Haisen BHM01/02 Surface Friction Tester for its precision, reliability, and user-friendly interface. Testimonials highlight its ability to improve decision-making for runway operations, enhance maintenance practices, and comply with stringent aviation regulatory requirements.

Conclusion

The Haisen BHM01/02 Surface Friction Tester offers numerous advantages for accurate runway friction measurement. Its safety design ensures the integrity of the vehicle's original systems, while its reliability is backed by high-precision components and an industrial-grade laptop. With impressive acceleration capabilities and specialized test tires, this friction testing machine guarantees precise and consistent results. As airports worldwide continue to prioritize safety, the future of accurate runway friction measurement lies in innovative solutions like the Haisen BHM01/02.

Advantages of Using Haisen BHM01/02 Surface Friction Tester

The Haisen BHM01/02 Surface Friction Tester stands out with its safety design, reliability features, and specialized test tires that comply with international standards. Its computer control system and water system further enhance its capabilities, making it a top choice for accurate friction measurement at airports around the world.

In addition to its safety design and reliability features, the Haisen BHM01/02 Surface Friction Tester also offers easy maintenance and user-friendly operation. This means that airport staff can quickly and efficiently conduct friction measurements without encountering technical difficulties or delays. The tester's intuitive interface and straightforward procedures make it a valuable asset for ensuring runway safety and efficiency.

Future of Accurate Runway Friction Measurement

As aviation technology continues to advance, the future of accurate runway friction measurement will rely on cutting-edge solutions like the Haisen BHM01/02 Surface Friction Tester. With its impressive track record and high-performance features, it is poised to set new standards in runway safety and operations.

Call to Action for Ensuring Safe Runway Operations

To ensure safe runway operations, airport authorities must prioritize the adoption of advanced friction testing equipment like the Haisen BHM01/02. By investing in reliable and precise tools for measuring friction, airports can significantly enhance their safety standards and contribute to a more efficient and secure aviation industry.

Investing in advanced friction testing equipment like the Haisen BHM01/02 also demonstrates a commitment to proactive maintenance and safety measures. By regularly monitoring and assessing runway friction, airports can identify potential hazards and address them before they become a safety issue. This proactive approach not only enhances safety standards but also minimizes the risk of accidents and disruptions, ultimately leading to more efficient operations.