Introduction

When it comes to ensuring the safety of airport runways, the use of a friction tester machine is paramount. These machines are designed to measure the frictional properties of runway surfaces, providing crucial data for safe aircraft landings and takeoffs. One notable example is Haisen's BHM01/02 Surface Friction Tester, a cutting-edge tool that has revolutionized runway safety testing.

What is a Friction Tester Machine?

A friction tester machine, also known as a runway friction tester (RFT), is an essential piece of equipment used to assess the frictional characteristics of airport runway surfaces. By measuring the level of grip or skid resistance, these machines play a critical role in ensuring safe aircraft operations on runways.

Importance of Runway Safety

The importance of maintaining optimal runway safety cannot be overstated. Runway surface conditions directly impact aircraft performance during landing and takeoff, making accurate friction testing equipment indispensable for ensuring safe and efficient air travel.

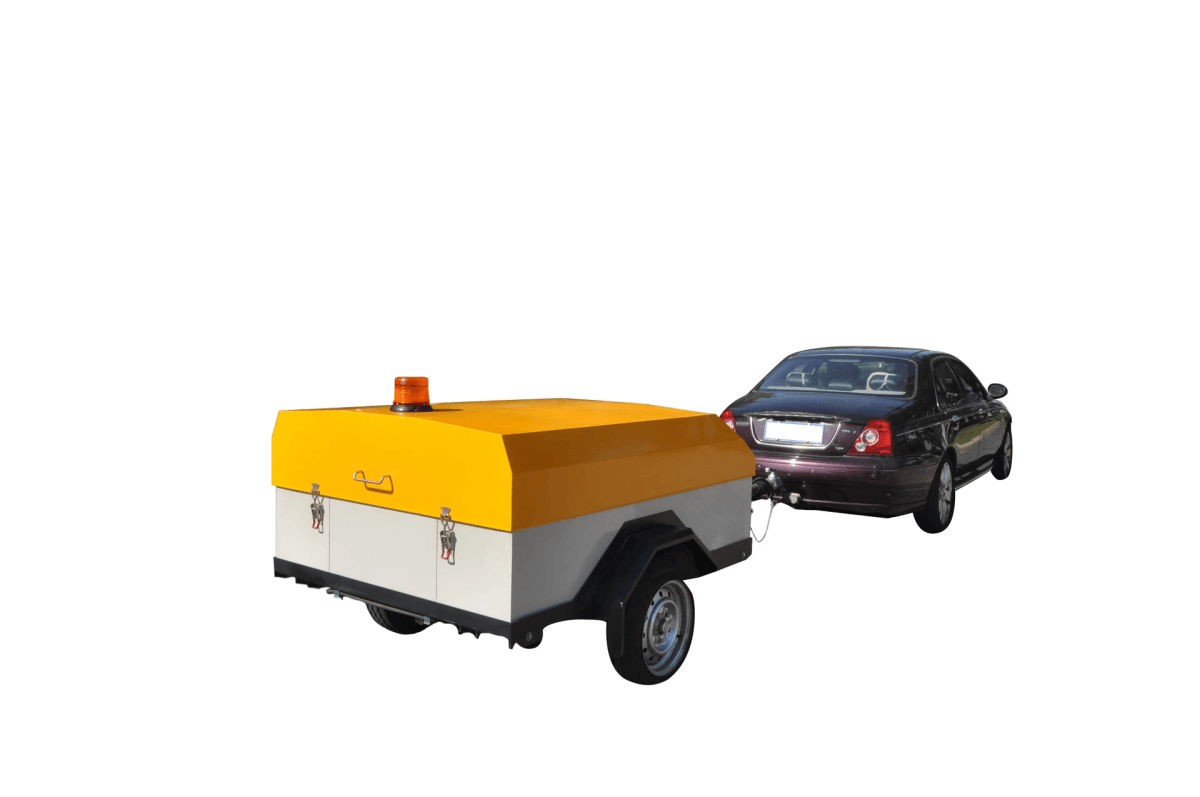

Haisen's BHM01/02 Surface Friction Tester Overview

Haisen's BHM01/02 Surface Friction Tester stands out as a leading solution for airport runway friction testing. With advanced features such as safety design, reliability, acceleration capabilities, and precise calibration processes, this cutting-edge machine has set new standards in runway safety technology.

Understanding Friction Tester Machine

When it comes to ensuring the safety of airport runways, the friction tester machine plays a crucial role. This equipment is designed to measure the frictional properties of runway surfaces, providing essential data for pilots and airport authorities to make informed decisions.

Definition and Function

The friction tester machine is a specialized device used to determine the frictional characteristics of airport runway surfaces. It measures the resistance between the tire and the pavement, helping to assess the skid resistance of the runway. This information is vital for ensuring safe takeoffs and landings, especially under adverse weather conditions.

The friction tester machine comes in various types, each designed to meet specific testing requirements. Some machines are portable and can be easily transported to different locations, while others are fixed and used for regular testing at a specific airport. The choice of equipment depends on the size of the airport, the frequency of testing, and the budget available for maintenance and operation.

Types of Friction Testing Equipment

There are various types of friction testing equipment available, including continuous friction measuring equipment (CFME), decelerometer systems, and portable friction testers. Each type has its own unique capabilities and features, catering to different operational requirements at airports.

In addition to the various types of friction testing equipment available, some systems are designed specifically for use in adverse weather conditions, such as ice or snow. These specialized friction testers are equipped with sensors and features that allow them to accurately measure runway conditions in challenging environments, providing crucial data for airport operations during inclement weather.

Key Features of Airport Runway Friction Testing Equipment

Airport runway friction testing equipment comes with key features such as precision measurement sensors, real-time data acquisition systems, and advanced calibration capabilities. These features enable accurate and reliable assessment of runway surface conditions, contributing to enhanced safety for aircraft operations.

Furthermore, the precision measurement sensors in airport runway friction testing equipment allow for the detection of even subtle changes in friction levels, providing valuable data for maintenance and operational decision-making. With real-time data acquisition systems, airport authorities can stay informed about runway conditions and take prompt action when necessary to ensure safe landings and take-offs. Additionally, the advanced calibration capabilities of this equipment help maintain accuracy over time, ensuring consistent and reliable performance in assessing runway friction.

The Role of Runway Friction Tester in Aviation Safety

Impact of Runway Surface Friction Testing Equipment on Aircraft Operations

The use of runway surface friction testing equipment, such as the Haisen's BHM01/02 Surface Friction Tester, has a profound impact on aircraft operations. By accurately measuring the friction coefficient of airport runways, pilots are able to make informed decisions about takeoff and landing procedures, ensuring the safety of passengers and crew.

The accurate measurement of the friction coefficient of airport runways is essential for pilots to make informed decisions about takeoff and landing procedures. With the use of runway surface friction testing equipment, such as the Haisen's BHM01/02 Surface Friction Tester, pilots can confidently assess runway conditions and adjust their approach accordingly. This not only ensures the safety of passengers and crew but also minimizes the risk of accidents due to poor runway conditions.

Importance of Airport / Runway Friction Testing Products for Safe Landings and Takeoffs

Airport runway friction testing equipment plays a crucial role in ensuring safe landings and takeoffs. The ability to assess the level of friction on a runway allows for proactive measures to be taken in order to prevent accidents caused by slippery surfaces. This highlights the importance of reliable and accurate friction testing products in maintaining aviation safety standards.

Additionally, runway friction testing equipment helps to identify areas of the runway that may require maintenance or resurfacing in order to improve overall safety. By regularly assessing the friction levels, airport authorities can prioritize and schedule necessary repairs to ensure that the runway remains in optimal condition for aircraft operations. This proactive approach can ultimately reduce the risk of accidents and enhance the overall efficiency of airport operations.

Runway Friction Tester Machine Price Considerations

When considering the purchase of a runway friction tester machine, it's important to factor in price considerations. While cost is certainly a consideration, it's essential to prioritize quality, reliability, and accuracy when investing in airport runway friction testing equipment. The Haisen's BHM01/02 Surface Friction Tester offers exceptional value with its advanced features and proven track record in enhancing aviation safety. In addition to its high-quality build and accurate results, the Haisen's BHM01/02 Surface Friction Tester also boasts user-friendly interface and easy maintenance, making it a cost-effective choice for airport operations.

Haisen's BHM01/02 Surface Friction Tester in Action

Safety Design and Performance of BHM01/02

Haisen's BHM01/02 friction tester machine maintains the original safety and performance systems of the vehicle, with a reinforced trunk to accommodate the testing equipment. This ensures that safety is not compromised during the testing process, providing peace of mind for operators and airport authorities.

Reliability and Precision Components Usage

The BHM01/02 utilizes high-precision components and an industrial-grade laptop with a Chinese interface for reliable operation. This guarantees accurate and consistent results, making it a trusted choice for airport runway friction testing equipment.

Acceleration Capabilities with Vehicles like Ford Taurus 2.7T and Honda Acura

Equipped with powerful vehicles like the Ford Taurus 2.7T and Honda Acura, the BHM01/02 can reach speeds of up to 96 km/h within just 200 meters. This impressive acceleration capability allows for efficient testing of runway surface friction under various conditions.

Calibration and Testing Process

When it comes to ensuring the accuracy of friction testing equipment, the external electronic calibration device used in Haisen's RFT is a game-changer. This device allows for precise calibration, ensuring that the friction tester machine provides accurate and reliable results for airport runway safety.

External Electronic Calibration Device

The external electronic calibration device used in Haisen's RFT is designed to provide an accurate and easy-to-use method for calibrating the equipment. This ensures that the friction tester machine delivers consistent and reliable results, crucial for maintaining safe runway conditions at airports around the world.

Furthermore, the external electronic calibration device is equipped with advanced technology to ensure precise measurements and adjustments. This level of accuracy is essential for meeting strict aviation regulations and standards, guaranteeing that the friction tester machine operates within the required parameters. By utilizing this state-of-the-art calibration device, airports can confidently maintain optimal runway conditions, ultimately enhancing safety for all aircraft operations.

Specialized Tires for Compliance with Aviation Regulations

To meet aviation regulations, Haisen's RFT is equipped with specialized tires that comply with CAAC, ICAO, and FAA standards. These tires are designed to withstand the pressures of testing while providing accurate readings essential for ensuring safe landings and takeoffs on airport runways.

Furthermore, Haisen's RFT undergoes computer-controlled testing using a Chinese Windows OS to ensure precision and accuracy in the measurement of tire performance. This advanced testing process allows for real-time monitoring and analysis of the tires' capabilities, providing valuable data for continuous improvement and innovation. By utilizing cutting-edge technology, Haisen's RFT sets a new standard for compliance with aviation regulations, guaranteeing optimal safety and efficiency for aircraft operations.

Computer-Controlled Testing with Chinese Windows OS

The computer-controlled testing system in Haisen's RFT utilizes a Chinese Windows OS laptop pre-programmed for continuous testing. This allows for efficient and precise data collection, contributing to the overall safety and reliability of airport runway friction testing equipment.

In addition to the efficient data collection, the Chinese Windows OS laptop also allows for easy integration with other testing equipment and software, streamlining the entire testing process. This seamless compatibility ensures that all components work together harmoniously, minimizing potential errors and maximizing testing accuracy. As a result, airport authorities can have full confidence in the reliability of the friction testing equipment, ultimately enhancing runway safety for all aircraft.

Water System and Endorsements

The Haisen's BHM01/02 Surface Friction Tester boasts an impressive 580L/620L tank capacity, allowing for extended testing periods without the need for frequent refills. This ensures that airport runway friction testing can be conducted efficiently and effectively, providing accurate results for enhanced safety measures.

With successful deployments at various airports and high-altitude locations, the Haisen's BHM01/02 has proven its reliability and effectiveness in diverse environmental conditions. Its versatility makes it a trusted choice for ensuring runway safety across different terrains and altitudes, making it a valuable asset for aviation authorities worldwide.

Endorsed by aviation authorities and with over 200 units in use at various airports, the Haisen's BHM01/02 Surface Friction Tester has garnered widespread recognition for its exceptional performance and contribution to runway safety. Its achievements in enhancing airport safety standards have solidified its position as a leading solution in the field of airport runway friction testing equipment.

Conclusion

The advancements in runway safety technology have been remarkable, with the introduction of highly reliable and precise friction testing equipment. By incorporating friction tester machines for safer air travel, airports can ensure that runways remain safe for aircraft operations. With reliable friction testing solutions like Haisen's BHM01/02 Surface Friction Tester, airports can maintain the highest standards of safety and performance.

Advancements in Runway Safety Technology

The evolution of runway safety technology has seen the development of advanced friction tester machines that provide accurate and reliable results. These innovative solutions have revolutionized how airports ensure the safety of their runways, leading to improved aviation safety standards worldwide.

The advancements in runway safety technology have also led to the development of automated friction tester machines, which can quickly and efficiently assess runway conditions without the need for manual intervention. These state-of-the-art devices not only provide accurate data but also reduce the time and resources required for regular safety inspections, allowing airports to maintain optimal runway conditions at all times. As a result, these innovations have significantly contributed to enhancing overall aviation safety and minimizing potential risks for air travelers.

Incorporating Friction Testing Equipment for Safer Air Travel

By integrating airport runway friction testers into their operations, airports can significantly enhance the safety of air travel. The use of cutting-edge runway surface friction testing equipment enables airports to proactively monitor and maintain optimal runway conditions, ensuring safe landings and takeoffs for all aircraft.

Keeping Runways Safe with Reliable Friction Testing Solutions

Reliable friction testing solutions like Haisen's BHM01/02 Surface Friction Tester play a crucial role in keeping runways safe for aircraft operations. With their high-precision components, specialized tires, and advanced water system capabilities, these friction tester machines provide airports with the tools they need to uphold the highest standards of safety.

Additionally, these friction testing solutions are designed to provide real-time data on runway conditions, allowing airport authorities to make informed decisions about maintenance and safety measures. This proactive approach helps prevent accidents and delays by ensuring that runways are always in optimal condition for takeoffs and landings. By investing in reliable friction testing solutions, airports can demonstrate their commitment to passenger safety and operational excellence.