Introduction

In the realm of fire safety, foam system fire protection stands out as a highly effective solution for combating blazes that water alone simply can't handle. While traditional water fire systems have their merits, they often fall short in suppressing certain types of fires, particularly those fueled by flammable liquids and chemicals. This is where foam fire suppression systems come into play, offering a specialized approach tailored for industrial fire protection and other high-risk environments.

Understanding Foam System Fire Protection

Foam system fire protection utilizes specially formulated foam agents designed to smother flames and prevent re-ignition effectively. Unlike different types of fire suppression systems that primarily rely on water or dry chemicals, foam creates a blanket over the fuel source, cutting off oxygen and cooling the area simultaneously. This dual-action not only extinguishes fires more efficiently but also minimizes damage to surrounding equipment and structures.

Why Choose Foam Over Water?

Choosing foam over water can significantly enhance your firefighting capabilities, particularly in industrial settings where flammable materials are prevalent. Water can exacerbate certain fires—especially those involving oils or solvents—while a foam fire system is engineered to tackle these challenges head-on. With its ability to adapt to various scenarios, foam emerges as a superior choice among different fire suppression systems available today.

Applications of Foam Fire Solutions

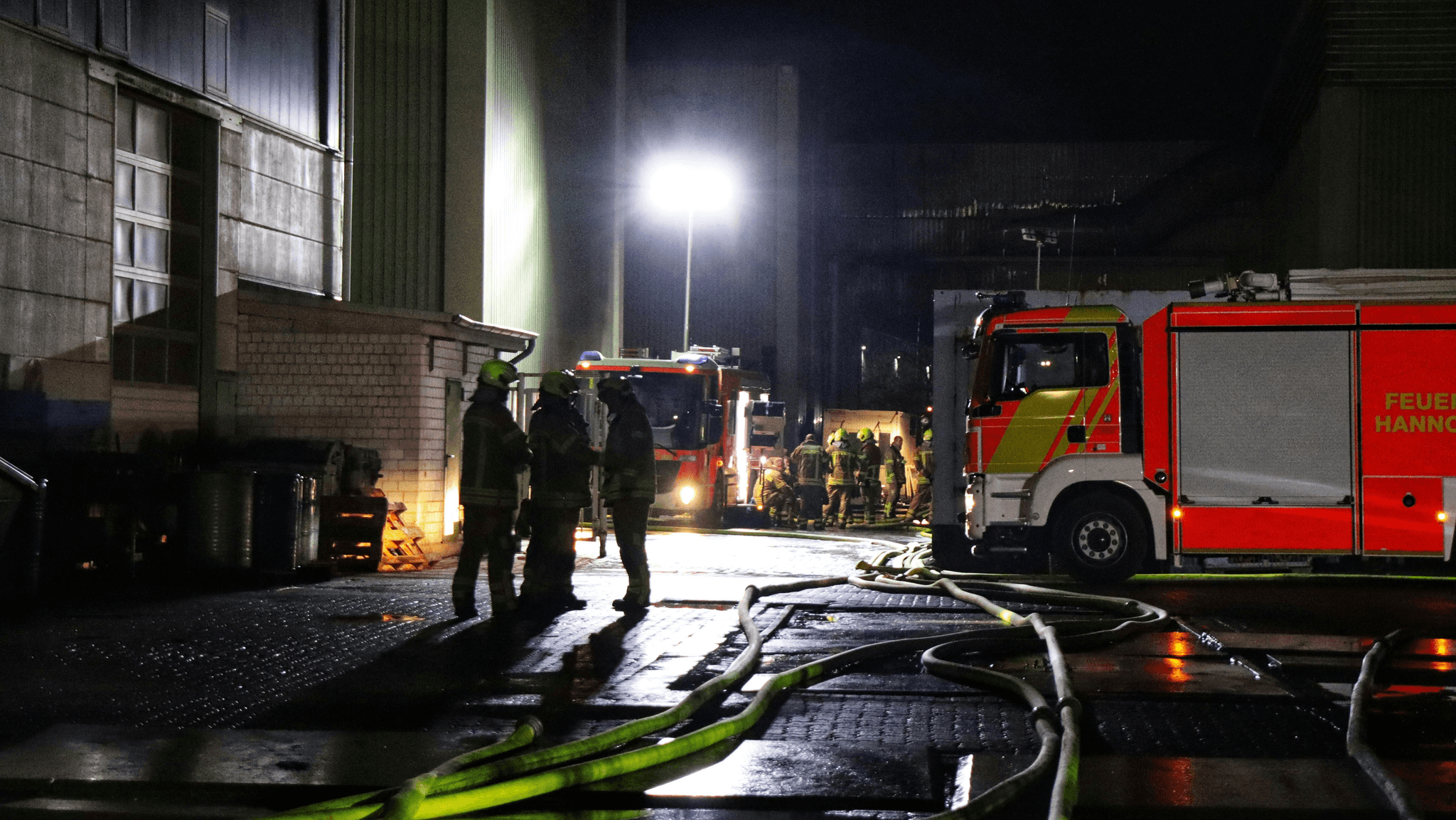

Foam solutions are versatile and find applications across various industries such as aviation, petrochemical, and manufacturing facilities where risks are heightened. From airport hangars needing specialized firefighting equipment to oil refineries requiring robust industrial fire protection measures, the use of foam has proven invaluable in real-world situations. As industries continue to evolve and face new challenges, implementing an effective foam system fire protection strategy becomes increasingly essential for safeguarding lives and assets.

Overview of Foam System Fire Protection

Types of Foam Agents

Foam agents are the heart and soul of any foam system fire protection strategy. The primary types include Class A foams for ordinary combustibles and Class B foams designed specifically for flammable liquids. Additionally, there are alcohol-resistant foams that provide enhanced protection against polar solvents—making them essential in industries dealing with hazardous materials.

Each type of foam agent has its unique formulation and purpose within a foam fire suppression system. For example, AFFF (Aqueous Film Forming Foam) is widely used for its rapid extinguishing capabilities on flammable liquid fires. Meanwhile, FFFP (Film Forming Fluoroprotein Foam) combines protein-based elements with fluorinated materials to tackle more challenging industrial fires effectively.

Advantages of Foam Fire Systems

The advantages of utilizing a foam system fire protection approach are numerous and compelling. First off, these systems can suppress fires more quickly than many traditional methods due to their ability to blanket flames with a thick layer of foam that cuts off oxygen supply. This rapid response is crucial for minimizing damage and ensuring safety in high-risk environments.

Moreover, unlike different types of fire suppression systems such as water-based solutions that may spread hazardous materials or create additional hazards like flooding or electrical risks, foam minimizes collateral damage while effectively controlling the blaze. Another significant advantage lies in its versatility; whether it’s an oil refinery or an aircraft hangar requiring specialized industrial fire protection measures, there’s a suitable foam solution available.

Lastly, using a foam fire suppression system can lead to reduced cleanup costs post-incident compared to water-based methods that often leave behind extensive damage from flooding or residue from chemicals used in other systems. In short, choosing foams not only enhances safety but also serves as a cost-effective strategy for managing potential disasters.

Common Myths Debunked

Despite their proven effectiveness, several myths about foam system fire protection persist—often leading to misunderstandings about their application and benefits. One common myth is that all foams are created equal; however, this couldn't be further from the truth! Different types of foam agents serve specific purposes based on the nature of the fuel involved in any given incident.

Another misconception is that using water alongside foams is sufficient for extinguishing all types of fires; unfortunately, this can sometimes exacerbate situations involving flammable liquids by spreading them further rather than containing them effectively through proper application techniques inherent in dedicated foam systems. It's essential to recognize that relying solely on water may not provide adequate industrial fire protection when dealing with volatile substances.

Key Components of Foam Fire Protection

Foam Proportioners Explained

Foam proportioners are critical devices that mix water and foam concentrate to create a fire-fighting solution tailored for different types of fire suppression systems. These proportioners ensure the correct ratio of foam to water, which is vital for maximizing the effectiveness of any foam fire suppression system. Whether it's a fixed or mobile setup, understanding how these devices function will help you appreciate their role in enhancing industrial fire protection.

There are various types of proportioners available on the market, including inline and balanced pressure models. Each type serves a specific purpose and is designed to meet different operational needs within a facility's overall safety framework. Choosing the right proportioner can significantly impact your facility’s response capability during an emergency.

Storage and Mixing Systems

Storage and mixing systems play a pivotal role in any effective foam system fire protection strategy by ensuring that foam concentrates are readily available when needed most. These systems typically include tanks for storing both water and foam concentrate, as well as mixing equipment designed to prepare the solution efficiently before deployment. Properly maintained storage solutions not only enhance safety but also ensure compliance with various regulations pertaining to industrial fire protection.

Moreover, selecting appropriate materials for your storage tanks is crucial; they must be resistant to corrosion and compatible with different types of fire suppression systems used in your facility. Regular inspections will help catch any issues before they escalate into costly repairs or safety hazards during an emergency situation. Ultimately, investing in robust storage and mixing systems contributes significantly to the overall reliability of your fire foam system.

Discharge Devices and Nozzles

Discharge devices and nozzles are where the magic happens; they deliver the mixed foamy solution onto a burning surface effectively fighting flames across various scenarios. Different types of discharge devices exist—such as monitors, handheld nozzles, or fixed installations—each tailored for specific applications within industrial environments or larger facilities dealing with heightened risks of flammable materials. The choice between these options should consider factors like reach, flow rate, and ease-of-use during emergencies.

Nozzles specifically come in varying designs that affect how foam spreads over surfaces; some create fine mists while others produce thicker blankets ideal for smothering flames quickly—a critical aspect when evaluating different fire suppression systems available today. Understanding how each nozzle performs under pressure allows you to optimize your response strategy based on unique facility requirements or potential hazards present on-site. With reliable discharge devices at hand, you'll be better equipped against unforeseen incidents requiring immediate action.

Haisen's Foam Fire Truck: A Game Changer

Features of Haisen’s Fire Truck

Haisen’s foam fire truck boasts an impressive array of features tailored for optimal performance in emergency situations. Equipped with a high-capacity foam tank and state-of-the-art mixing technology, it ensures that the right concentration of foam is delivered precisely when needed. Additionally, the vehicle's versatile discharge devices allow for rapid deployment across various terrains, making it a top choice among different fire suppression systems.

One standout feature is its automated proportioning system that adjusts the foam mixture based on the specific type of incident being addressed. This flexibility makes it suitable for a wide range of applications, from petrochemical facilities to large-scale manufacturing plants. Furthermore, the truck’s compact design enables easy maneuverability in tight spaces where traditional water fire systems might struggle.

Performance in Challenging Conditions

In challenging environments where conventional methods fall short, Haisen’s foam fire truck excels by using its specialized foam system fire protection capabilities. Whether battling blazes fueled by flammable liquids or navigating hazardous materials incidents, this vehicle proves that versatility and reliability go hand in hand. Its ability to perform under extreme conditions—such as high winds or low visibility—sets it apart from other options on the market.

Moreover, field tests have shown that Haisen's innovative technology provides faster knockdown times compared to standard water-based firefighting methods. The unique formulation of their foam enhances surface tension reduction and creates a protective blanket over flammable substances, effectively smothering flames before they can spread further. This level of performance is crucial for industrial sites where every second counts during an emergency response.

Real-World Applications and Success Stories

Haisen's foam fire truck has already made waves across various sectors with numerous real-world applications showcasing its effectiveness in industrial fire protection scenarios. For instance, at a major oil refinery facing regular risks from flammable materials, deploying this advanced vehicle resulted in significantly reduced response times and minimized damage during incidents involving large-scale fires.

Additionally, several municipalities have adopted Haisen trucks into their firefighting fleets after witnessing firsthand how these vehicles outperform traditional water fire systems during live training exercises and simulated emergencies. Success stories abound; one notable example involves a chemical plant where quick action using the foam suppression system prevented what could have been a catastrophic explosion.

In summary, Haisen's innovative approach to incorporating advanced features into their foam system offers unmatched performance under pressure while highlighting the importance of modernizing our strategies against fires within industrial settings.

Implementing Foam Fire Protection in Your Facility

Implementing a foam system fire protection strategy in your facility is not just about installing the latest technology; it’s about understanding your unique fire risks and needs. A well-designed foam fire suppression system can significantly enhance your industrial fire protection measures, ensuring that you’re prepared for any potential emergency. By evaluating different types of fire suppression systems, you can determine how foam solutions stack up against traditional water fire systems for your specific environment.

Assessing Fire Risks

The first step in implementing a foam system fire protection strategy is to conduct a thorough assessment of potential fire risks within your facility. This involves identifying areas where flammable materials are stored or processed, as these locations are prime candidates for a foam fire suppression system. By understanding the unique characteristics of your facility and the different types of fire suppression systems available, you can pinpoint where foam solutions will be most effective compared to conventional methods like water-based systems.

During this risk assessment phase, it’s crucial to consider not only the materials involved but also the layout of your space and access points for emergency services. This information will help determine how best to deploy a foam system that meets both safety standards and operational efficiency. Remember, an effective industrial fire protection plan isn’t just reactive; it should also incorporate preventive measures based on thorough risk analysis.

Designing a Custom Foam System

Once you've assessed the risks, the next step is designing a custom foam system tailored to your facility's specific needs. This involves selecting the right type of foam agent—whether it's AFFF (Aqueous Film Forming Foam), AR-AFFF (Alcohol-Resistant AFFF), or another option—based on the flammable substances present in your operations. The design process also includes determining appropriate storage and mixing systems to ensure that you have quick access to large quantities of firefighting foam when needed.

In addition to selecting agents and storage options, it's essential to choose discharge devices and nozzles that maximize coverage while minimizing waste during an actual incident. Consideration should also be given to integrating this new foam fire suppression system with existing safety protocols and equipment within your facility for seamless operation during emergencies. By investing time into custom design, you're setting up an effective defense against fires rather than relying solely on traditional water fire systems.

Training Staff for Effective Use

Even with state-of-the-art technology at hand, all those plans can go up in smoke if staff aren’t properly trained in using the new foam system effectively! Training should encompass everything from understanding how different types of fire suppression systems work—including their advantages over water-based solutions—to hands-on practice with equipment during drills or simulations. It’s important that employees feel confident using the equipment so they can act swiftly when every second counts.

Regular training sessions should be scheduled not only during initial implementation but as part of ongoing professional development within your organization—especially since regulations may evolve over time regarding industrial fire protection standards. Engaging staff through interactive training methods ensures they grasp essential concepts while fostering teamwork under pressure scenarios involving real-life applications of their skills with various firefighting tools like foams versus traditional methods.

Ultimately, empowering employees through comprehensive training creates a culture focused on safety—a critical element when implementing any form of emergency response plan including specialized solutions like a robust foam system for enhanced firefighting capabilities.

Regulatory Standards and Compliance

When it comes to foam system fire protection, understanding regulatory standards is essential for ensuring safety and compliance. Different types of fire suppression systems, including foam fire suppression systems, must adhere to established guidelines that dictate their design and implementation. This section will delve into the NFPA guidelines, local fire codes, and the importance of regular maintenance in maintaining an effective industrial fire protection strategy.

NFPA Guidelines on Foam Systems

The National Fire Protection Association (NFPA) provides critical guidelines for foam system fire protection through various codes and standards. These guidelines outline the necessary specifications for foam agents, application methods, and system designs to ensure optimal performance in emergency situations. Familiarity with these standards is crucial for anyone involved in the installation or management of a foam fire suppression system since non-compliance can lead to significant safety risks.

Furthermore, NFPA regulations help distinguish between different types of fire suppression systems by providing detailed requirements tailored to specific hazards. For example, certain industries may require specialized foam solutions that are compliant with NFPA 11 (Standard for Low-, Medium-, and High-Expansion Foam). Adhering to these guidelines not only enhances safety but also fortifies your facility’s credibility in industrial fire protection practices.

Understanding Local Fire Codes

While NFPA guidelines set a national standard for foam system fire protection, local fire codes play a pivotal role in determining how these regulations are applied within specific jurisdictions. Local authorities may have additional requirements based on regional risks or historical incidents that necessitate stricter measures than those outlined by the NFPA. Thus, it’s vital for facility managers to stay informed about their local codes regarding different types of fire suppression systems.

Engaging with local fire marshals or authorities having jurisdiction can provide valuable insight into compliance expectations specific to your area. This proactive approach ensures that your water fire system or any other type of industrial firefighting solution meets all necessary legal requirements while effectively mitigating potential hazards. Ignoring local codes could result in fines or even shutdowns during inspections—hardly an ideal scenario when lives are at stake!

Importance of Regular Maintenance

Regular maintenance is the unsung hero of any effective foam system fire protection strategy; after all, a well-maintained foam fire suppression system is like having a trusty sidekick ready at a moment's notice! Routine checks ensure that all components—such as proportioners and discharge devices—are functioning optimally so they can spring into action during emergencies without a hitch. Neglecting this aspect could mean facing dire consequences when you need your water-based firefighting solutions most.

Moreover, regular maintenance helps identify potential issues before they escalate into costly repairs or failures during critical moments. By adhering to scheduled inspections and maintenance protocols recommended by manufacturers and regulatory bodies alike, facilities can extend the lifespan of their different types of fire suppression systems while enhancing overall safety standards. Remember: an ounce of prevention is worth a pound of cure!

Conclusion

In wrapping up our exploration of foam system fire protection, it’s clear that the future is bright for foam fire suppression systems. As industries evolve and face new challenges, the demand for effective and efficient industrial fire protection solutions will only increase. Embracing advancements in technology and understanding the unique advantages of different types of fire suppression systems will be key to enhancing safety protocols.

The Future of Foam Fire Protection

Foam system fire protection is poised to lead the charge in modern firefighting tactics, especially as we witness an uptick in complex industrial environments. The development of more sophisticated foam agents promises improved performance against flammable liquids and hazardous materials, making a foam fire suppression system indispensable. As regulations tighten and safety standards rise, investing in advanced foam technology will ensure that facilities remain compliant while maximizing their safety measures.

Choosing the Right Solutions for Your Needs

When selecting from the myriad of different fire suppression systems available today, it’s crucial to assess your specific needs carefully. Each facility has its unique risks; thus, a tailored approach to choosing a foam fire system can make all the difference between effective protection and catastrophic failure. Consider factors such as facility size, potential hazards, and existing infrastructure when deciding on the best solution—whether it be a water fire system or a state-of-the-art foam application.

Ensuring Safety with Effective Systems

Implementing an effective foam system fire protection strategy requires more than just selecting equipment; ongoing training and maintenance are vital components too. Regular drills ensure that personnel are well-versed in using foam firefighting techniques effectively during emergencies while keeping systems up-to-date prevents costly failures down the line. Ultimately, prioritizing these elements within your industrial fire protection plan not only safeguards lives but also protects valuable assets from devastating losses.