Introduction

In the world of automation and control systems, the quarter turn electric actuator stands out as a pivotal component. These devices are designed to efficiently operate valves and dampers with a simple rotation of 90 degrees, making them essential in various industrial applications. Understanding how these actuators work, their distinctions from other types like multi-turn actuators, and their specific advantages is crucial for optimizing operational efficiency.

Understanding the Quarter Turn Electric Actuator

A quarter turn electric actuator is an electromechanical device that converts electrical energy into rotational motion to control valves or similar equipment. This mechanism allows for precise control over the opening and closing of valves, which is vital in processes where flow regulation is necessary. By using electric power, these actuators eliminate the need for manual operation, increasing both safety and efficiency in industrial settings.

Applications of Quarter Turn Electric Actuators

Quarter turn electric actuators are widely used across various industries such as water treatment, oil and gas, HVAC systems, and food processing. Their ability to provide reliable and quick valve operation makes them ideal for applications requiring rapid response times or where automation is essential. From controlling flow rates in pipelines to managing air dampers in climate control systems, these actuators prove indispensable.

Importance of Choosing the Right Actuator

Selecting the right actuator can significantly impact system performance and longevity; therefore, understanding what is a quarter-turn actuator? becomes crucial for engineers and operators alike. Factors such as torque requirements, environmental conditions, and compatibility with existing systems must be considered when making this choice. Additionally, distinguishing between different types—like what is the difference between quarter-turn and multi-turn actuators?—can help ensure optimal functionality tailored to specific operational needs.

What is a Quarter Turn Electric Actuator?

Definition and Functionality

A quarter turn electric actuator is an electromechanical device that converts electrical energy into rotational motion, specifically designed for applications requiring a 90-degree movement. This functionality allows the actuator to open or close valves efficiently, making it integral to fluid control systems. Essentially, these actuators streamline operations by automating tasks that would otherwise require manual intervention.

Key Components and Design Features

The design of a quarter turn electric actuator typically includes several key components: an electric motor, gear system, housing, and feedback mechanism. The electric motor drives the gear system to achieve the required torque for moving valves or dampers smoothly and reliably. Additionally, many models come equipped with built-in sensors that provide real-time feedback on position and performance—essential for ensuring optimal operation in demanding environments.

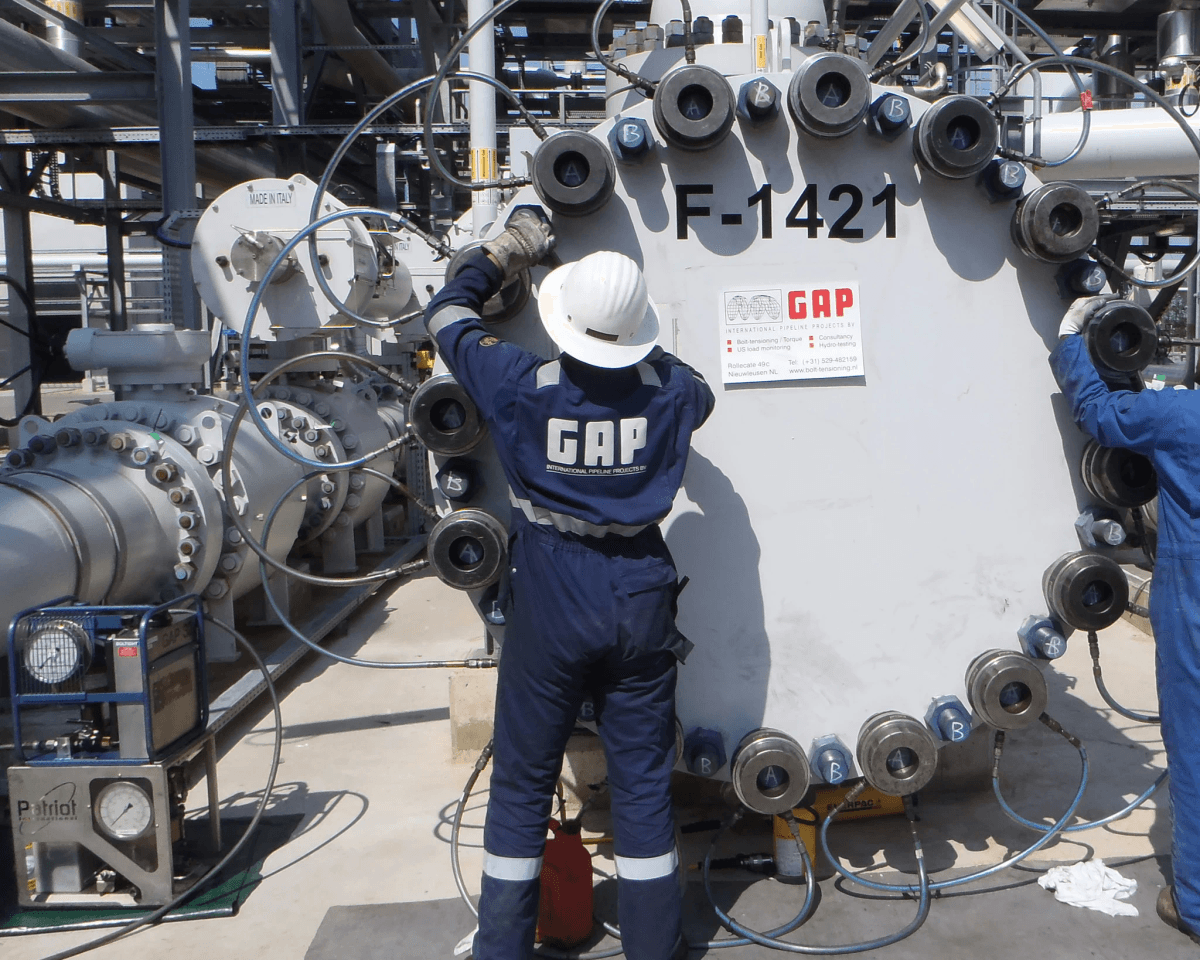

Applications in Various Industries

Quarter turn electric actuators find applications across numerous industries including oil and gas, water treatment, HVAC systems, and food processing. In oil and gas operations, they help manage pipeline flow efficiently while ensuring safety standards are met. Similarly, in HVAC systems, these actuators regulate airflow through dampers—demonstrating their versatility as essential tools in both industrial settings and everyday infrastructure projects.

What is the Difference Between Quarter-Turn and Multi-Turn Actuators?

Operational Differences Explained

The operational differences between quarter-turn and multi-turn actuators are primarily based on their movement capabilities. A quarter turn electric actuator completes its motion in a single 90-degree rotation, which allows it to swiftly engage or disengage valves like ball or butterfly types. On the other hand, multi-turn actuators can rotate several times—often up to several hundred degrees—making them suitable for applications that require gradual adjustments in position and flow.

Understanding these operational distinctions is essential when asking yourself, What is the difference between quarter-turn and multi-turn actuators? Essentially, if you need quick on/off control without precision modulation, then a quarter turn electric actuator is your best bet. Conversely, if you require fine-tuned adjustments over an extended range of motion, then a multi-turn actuator would be more appropriate.

Use Cases for Each Type

Use cases vary significantly between these two types of actuators due to their distinct functionalities. Quarter turn electric actuators are commonly found in industries such as water treatment plants and HVAC systems where rapid valve operation is required. They excel at controlling flow quickly and efficiently with minimal downtime.

Multi-turn actuators find their niche in applications like gate valves or globe valves that demand precise control over fluid dynamics. Industries such as oil and gas often utilize these devices where gradual adjustments can prevent pressure spikes or ensure optimal flow rates. Thus, understanding What are the three types of actuators? helps clarify that both quarter turn and multi-turn options serve specific purposes tailored to various operational needs.

Advantages of Quarter Turn Actuators

The advantages of using quarter turn electric actuators are numerous and compelling when compared to their multi-turn counterparts. Firstly, they offer faster response times due to their simple rotational motion; this efficiency translates into improved overall system performance in applications requiring immediate action. Additionally, they typically have a simpler design with fewer moving parts than multi-turn models—resulting in lower maintenance requirements and costs.

Moreover, when considering how does the electric actuator work? The integration of electrical controls allows for enhanced automation capabilities that further streamline operations across various sectors—from manufacturing to energy management systems. Ultimately, choosing a quarter turn electric actuator means investing in reliability while enjoying swift operation without sacrificing control quality.

What are the Three Types of Actuators?

When it comes to actuators, there are three main types that dominate the landscape: electric, hydraulic, and pneumatic actuators. Each type serves a distinct purpose and operates on different principles, making them suitable for various applications in industries ranging from manufacturing to aerospace. Understanding these actuator types is crucial for selecting the right solution for your specific needs.

Overview of Electric, Hydraulic, and Pneumatic Actuators

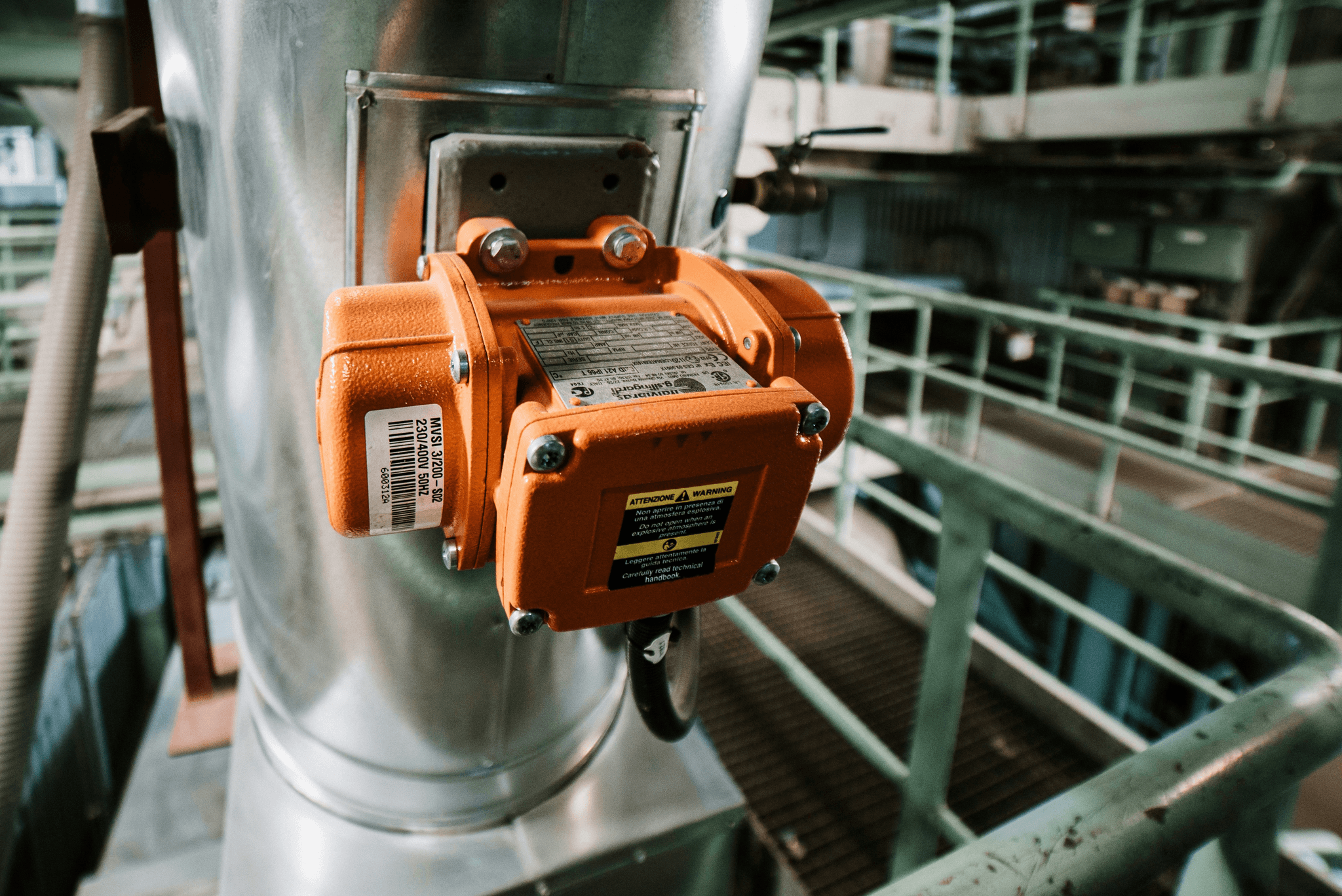

Electric actuators use electrical energy to create motion and are often favored for their precision and ease of integration with control systems. Hydraulic actuators harness fluid pressure to generate force, making them ideal for heavy-duty applications where significant power is required. Pneumatic actuators operate using compressed air, providing quick movements and responsiveness in environments where speed is essential.

Features of Each Type

The quarter turn electric actuator stands out due to its ability to provide accurate positioning with minimal maintenance needs compared to hydraulic or pneumatic options. Electric actuators typically offer built-in feedback systems that enhance control capabilities, allowing users to monitor performance in real-time. On the other hand, hydraulic actuators excel in high-force applications but require more maintenance due to fluid management challenges; meanwhile, pneumatic actuators are lightweight and can rapidly cycle but may lack the precision offered by their electric counterparts.

Suitability for Different Applications

Choosing between these three types of actuators largely depends on the specific requirements of your application. For instance, if you need a quarter turn electric actuator for precise valve control in chemical processing or water treatment plants, an electric actuator would be a perfect fit due to its accuracy and reliability. Conversely, if you’re dealing with heavy machinery that demands high torque output without concern for speed or precision—like in construction or mining—hydraulic actuators might be your go-to choice; while pneumatic options shine in assembly lines where quick actuation is paramount.

How Does the Electric Actuator Work?

Electric actuators, particularly quarter turn electric actuators, operate using a straightforward yet effective mechanism that converts electrical energy into mechanical motion. This transformation allows them to efficiently control the opening and closing of valves and dampers in various industrial applications. Understanding how electric actuators work is crucial for selecting the right actuator for specific tasks.

Mechanism of Action

At the heart of a quarter turn electric actuator is a motor that drives a gear system, enabling it to rotate 90 degrees to perform its function. This simple yet powerful mechanism allows for precise control over valve positioning, making it ideal for applications requiring quick response times. The actuator's design ensures smooth operation while minimizing wear and tear, which enhances its longevity and reliability.

The motor receives signals from an external controller or sensor, which dictates when and how much to move based on system requirements. This efficiency is what differentiates What is a quarter-turn actuator? from other types; it provides both speed and accuracy in operation. Notably, this mechanism supports various configurations depending on specific application needs, allowing users to customize their setups.

Electrical Control and Feedback Systems

Modern quarter turn electric actuators are equipped with advanced electrical control systems that facilitate seamless integration into automated processes. These systems often include feedback mechanisms like position sensors that provide real-time data about the actuator's status back to the controller. This feature not only enhances operational efficiency but also increases safety by ensuring that any deviations from expected performance can be promptly addressed.

The electrical control systems can be programmed or adjusted based on user preferences or operational requirements, making them versatile tools in any setting where How does the electric actuator work? is a key consideration. Additionally, these systems can communicate with other devices within an industrial network, allowing for centralized monitoring and control of multiple actuators simultaneously.

Benefits Over Manual Operation

When comparing quarter turn electric actuators with manual operations, several advantages become evident that make them stand out in various applications. Firstly, they significantly reduce labor costs since they require minimal human intervention once installed—no more strenuous cranking or turning! Secondly, their precision means less risk of human error during operation; you get consistent results every time without breaking a sweat.

Moreover, electric valve actuators offer enhanced safety features such as overload protection and emergency shut-off capabilities that manual operations simply cannot match. These benefits make them increasingly popular across industries looking to optimize performance while minimizing risks associated with manual handling—truly an upgrade worth considering!

Spotlight on Haisen's Part-Turn Valve Electric Actuator

When it comes to choosing a quarter turn electric actuator, Haisen's Part-Turn Valve Electric Actuator stands out for its remarkable features and cutting-edge technology. This actuator is designed to optimize performance while ensuring reliability across various applications. With its user-friendly interface and advanced capabilities, it redefines what one might expect from an electric valve actuator.

Innovative Features and Technology

Haisen’s Part-Turn Valve Electric Actuator boasts several innovative features that enhance its functionality. For starters, it incorporates a robust feedback system that allows for precise control over valve positioning, making it easier to understand what is going on within the system—essentially answering the question: What is a quarter-turn actuator? This actuator also utilizes smart technology for diagnostics and troubleshooting, allowing operators to identify issues before they escalate.

Moreover, this electric actuator is equipped with adjustable torque settings, which provide flexibility in various operational scenarios. The use of durable materials ensures longevity, while its compact design allows for easy installation in tight spaces. All these elements contribute to making Haisen’s offering a top choice among those exploring the differences between quarter-turn and multi-turn actuators.

Versatility in Industrial Applications

One of the standout qualities of Haisen's Part-Turn Valve Electric Actuator is its versatility across different industrial applications. Whether it's in water treatment plants or chemical processing facilities, this quarter turn electric actuator can adapt seamlessly to diverse environments. Its ability to handle various media types further emphasizes why industries are increasingly turning towards electric valve actuators over traditional options.

In addition to handling standard tasks like opening and closing valves, this actuator can also be integrated into automated systems for enhanced efficiency. This makes it an ideal solution for industries looking to streamline operations without sacrificing safety or reliability. It exemplifies how understanding what are the three types of actuators? can lead you directly to innovative products tailored for specific needs.

Installation and Operating Benefits

Installing Haisen’s Part-Turn Valve Electric Actuator is a breeze thanks to its intuitive design and clear instructions provided by the manufacturer. Unlike manual systems that require significant effort for operation—prompting many users to ask how does the electric actuator work?—this device simplifies processes through automation and remote control capabilities.

Operating this electric valve actuator not only reduces labor costs but also minimizes human error associated with manual controls, enhancing overall process efficiency significantly. Additionally, maintenance has been made easier due to built-in diagnostic features that alert users about potential issues before they become problematic. Clearly, choosing Haisen's product means opting for convenience without compromising on quality or performance.

Conclusion

In summary, quarter turn electric actuators are essential components in modern industrial automation, providing precision and efficiency across various applications. Understanding what a quarter-turn actuator is and how it operates can significantly enhance your decision-making process when selecting an actuator for specific tasks. With the right knowledge about the differences between quarter-turn and multi-turn actuators, as well as the three types of actuators available, you can make informed choices that lead to optimal performance.

Key Takeaways on Quarter Turn Electric Actuators

Quarter turn electric actuators are designed to perform a full rotation of 90 degrees, making them ideal for controlling valves and dampers in many settings. Their operational simplicity and effectiveness set them apart from other types such as multi-turn actuators, which require more complex mechanisms for greater rotational movement. Ultimately, understanding how does the electric actuator work will help you appreciate its benefits over manual systems—providing not just efficiency but also reliability in demanding environments.

Choosing the Right Actuator for Your Needs

When selecting an actuator, consider factors like application requirements, environmental conditions, and your budget. Each type has its unique strengths; for instance, if you need rapid response times and precise control of flow rates in piping systems, a quarter turn electric actuator might be your best bet. Make sure to evaluate what is the difference between quarter-turn and multi-turn actuators so you can choose wisely based on your specific application needs.

Future Trends in Electric Valve Actuators

The future of electric valve actuators looks promising with advancements in smart technology integration and IoT capabilities that enhance their functionality even further. Innovations aim to improve energy efficiency while providing real-time monitoring capabilities—making it easier than ever to manage operations remotely. As industries continue to evolve towards automation solutions, understanding what are the three types of actuators will be crucial in adapting to changing technologies while ensuring optimal performance.