Introduction

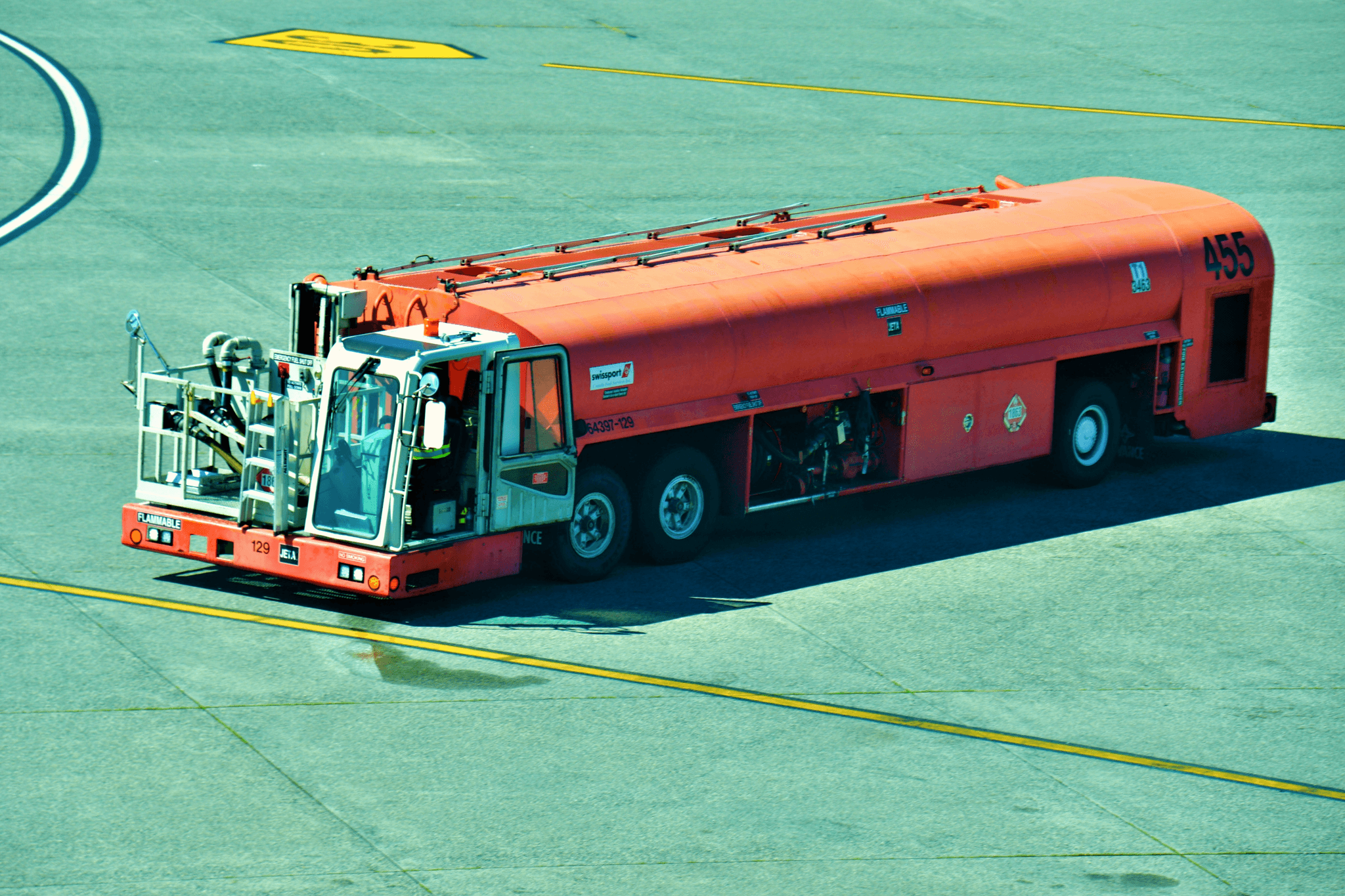

In the world of aviation, ensuring that your aircraft refuelers truck is in top-notch condition is not just a matter of convenience; it's a necessity. These trucks play a crucial role in maintaining the efficiency and safety of flight operations, making their maintenance paramount. With various components working together seamlessly, understanding what goes into keeping these vehicles operational can save time, money, and headaches down the line.

Importance of Aircraft Refuelers Truck Maintenance

Regular maintenance of aircraft refuelers trucks ensures optimal performance and reliability during critical operations. A well-maintained truck not only minimizes the risk of unexpected breakdowns but also enhances safety for ground crews and pilots alike. Neglecting maintenance can lead to costly repairs or even jeopardize flight schedules, emphasizing why every operator should prioritize upkeep.

Key Components of Refuelers Trucks

Aircraft refuelers trucks are complex machines equipped with several key components that work together to deliver fuel efficiently and safely. From the chassis to the piping system, pneumatic control system, hydraulic system, and electrical systems—each part plays a vital role in ensuring fuel is dispensed accurately at high flow rates. Understanding these specifications helps operators recognize what needs attention during routine checks.

Why Regular Maintenance Matters

Regular maintenance matters because it directly impacts both performance and longevity of your aircraft refueling truck. By adhering to a structured maintenance schedule, operators can prevent minor issues from escalating into major problems that could disrupt service or incur significant costs. Additionally, knowing how to maintain your aircraft fuel truck specifications helps ensure compliance with industry standards while maximizing operational efficiency.

Understanding Your Refueler Truck

When it comes to aircraft refuelers trucks, understanding the specific model you’re working with is crucial for effective maintenance and operation. Each truck has unique specifications and features that can significantly impact its performance. By familiarizing yourself with your Haisen Aircraft Pipeline Refueling Truck, you can ensure optimal functionality and safety during operations.

Overview of Haisen Aircraft Pipeline Refueling Truck

Haisen's Aircraft Pipeline Refueling Truck is engineered for high efficiency, equipped with a robust chassis, piping system, pneumatic control system, hydraulic system, and electrical system. This combination allows the truck to deliver effective refueling services tailored for various aircraft types at impressive flow rates. With the ability to filter out impurities such as dust and moisture during the fueling process, it ensures that only clean fuel reaches your aircraft.

The specifications of Haisen's aircraft refuelers truck include a significant fuel capacity that meets industry standards while maintaining an agile design for maneuverability on airfields. Additionally, this truck is designed to operate seamlessly in diverse environments, providing versatility that enhances its usability across different airport settings. Understanding these specifications helps in knowing what to expect from your equipment during operations.

Key Features of CF5060TJYGX Hydrant Dispenser

The CF5060TJYGX Hydrant Dispenser stands out among aircraft refueling trucks due to its low-altitude design—only 2 meters high—enabling more efficient underwing refueling services for a wide range of aircraft sizes. Its advanced filtration system ensures that fuel quality remains uncompromised by removing any contaminants before reaching the aircraft's tanks. Moreover, the dispenser’s precise flow rate measurement capabilities allow operators to monitor fuel delivery accurately.

When considering what makes this hydrant dispenser unique compared to other models in the market, it's essential to note its user-friendly interface and reliability under various operational pressures. The CF5060TJYGX is not just about speed; it's about ensuring safety and efficiency every time it’s deployed on the tarmac or runway. These key features make it an attractive option when searching for an aircraft refueling truck for sale.

Importance of Knowing Your Truck Model

Understanding your specific model of an aircraft refuelers truck is paramount not only for maintenance but also for maximizing operational efficiency. Each model may have different capacities regarding what is the volume of a fuel tanker truck or how quickly it can dispense fuel—questions critical in planning fueling operations at busy airports or military bases alike. Knowing these details also aids in troubleshooting issues that may arise during use.

Additionally, being well-versed in your truck's specifications allows operators to comply with safety regulations effectively while reducing downtime caused by unexpected repairs or inefficiencies during fueling operations. Regularly reviewing your vehicle’s manual will keep you informed about any updates regarding maintenance schedules or parts replacements needed over time as well as ensure you're aware of what is the flow rate of an aircraft fuel truck like yours specifically designed by Haisen. Ultimately, this knowledge empowers you to enhance both performance and longevity in managing your essential aviation resources.

Regular Inspection Checklist

Maintaining an aircraft refuelers truck is essential for ensuring its reliability and efficiency during operations. Regular inspections help identify potential issues before they escalate, ultimately prolonging the life of the vehicle and enhancing safety. This section outlines a thorough inspection checklist to keep your Aircraft Refueling Trucks in top shape.

Daily Pre-flight Checks

Before any flight operation, daily pre-flight checks are critical for an aircraft refuelers truck. These checks typically include inspecting fuel levels, verifying that safety equipment is functional, and ensuring there are no visible leaks or damage to the vehicle's structure. A quick glance at the hydraulic system and electrical components can save you from unexpected failures during refueling.

Moreover, it's important to check that all gauges are working correctly; this includes confirming what is the flow rate of aircraft fuel truck systems. If you notice any discrepancies or abnormalities in performance, addressing them immediately can prevent costly repairs down the line. Remember, a well-maintained Aircraft fuel truck ensures a safe and efficient operation when it matters most.

Weekly Fluid Level Inspections

Weekly fluid level inspections are another crucial aspect of maintaining your aircraft refuelers truck effectively. During these inspections, focus on checking engine oil levels, hydraulic fluids, and coolant systems to ensure optimal performance under varying conditions. Keeping these fluids at their recommended levels not only enhances efficiency but also helps avoid potential breakdowns.

Additionally, understanding the specifications of your Aircraft Refueling Truck will guide you on how frequently these fluids should be changed or topped off. For instance, knowing what is the volume of a fuel tanker truck can help you gauge how much fluid needs replenishing each week accurately. Consistent monitoring leads to smoother operations and extends your vehicle's lifespan significantly.

Monthly Comprehensive Inspections

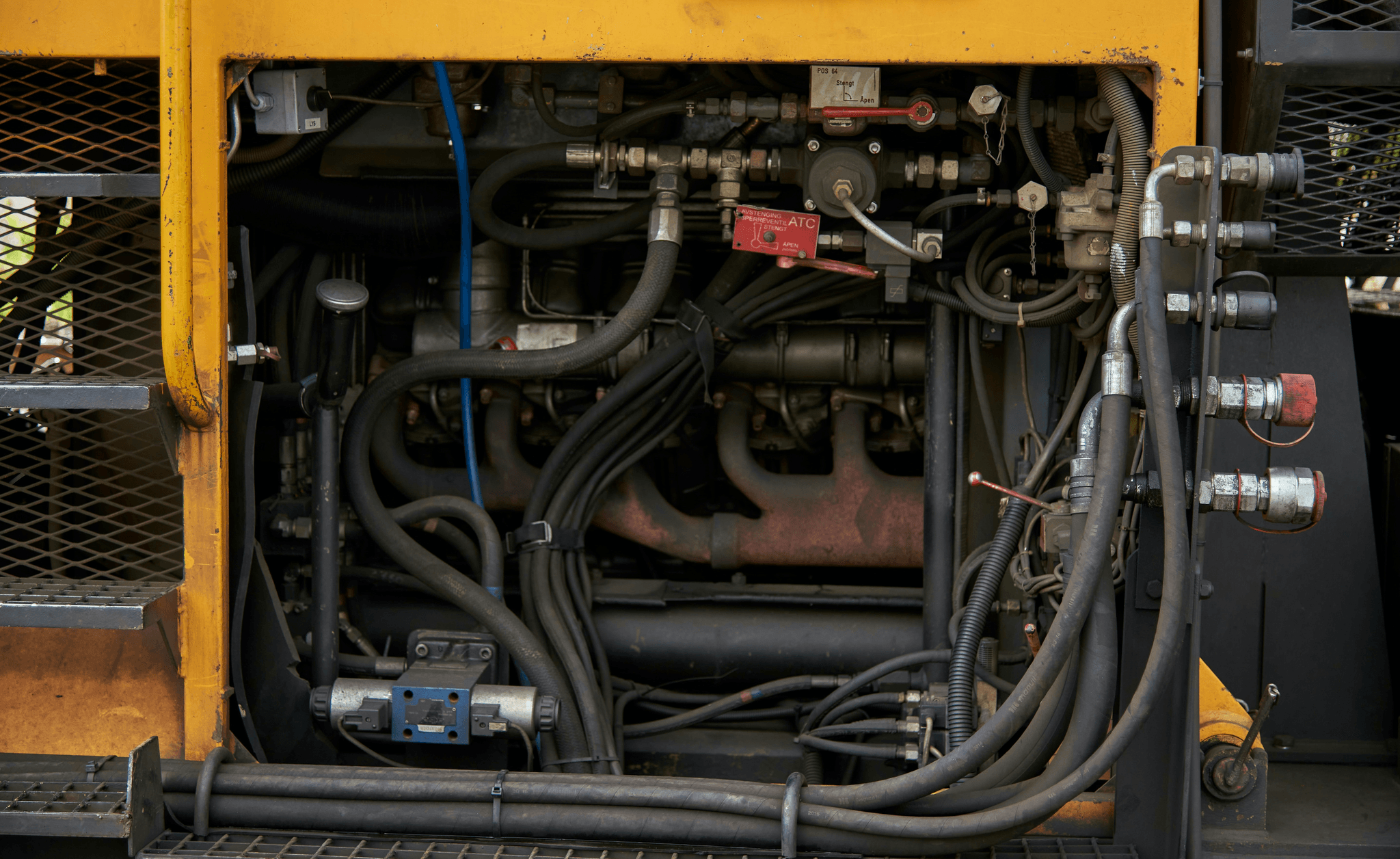

Monthly comprehensive inspections dive deeper into assessing all components of your aircraft refuelers truck beyond just fluid levels. This involves checking hoses for wear and tear, inspecting electrical connections for corrosion or loose fittings, and ensuring pneumatic control systems function properly without leaks or blockages. Each component plays a vital role in maintaining efficient service delivery during fueling operations.

Furthermore, take this opportunity to clean filters within the system; as impurities can cause significant operational issues if left unchecked over time—especially considering Haisen's emphasis on filtration during fueling processes! When looking at Aircraft fuel truck specifications like those from Haisen’s CF5060TJYGX Hydrant Dispenser model may provide insights into particular aspects needing attention during these monthly checks as well.

Fluid Maintenance for Optimal Performance

Maintaining fluid integrity is crucial for the optimal performance of aircraft refuelers trucks. Clean fuel and oil not only enhance the efficiency of the refueling process but also extend the lifespan of essential components. Regular fluid maintenance can prevent costly repairs and downtime, ensuring that your aircraft refuelers truck remains in top condition.

Importance of Clean Fuel and Oil

Clean fuel and oil are vital for the smooth operation of aircraft refueling trucks. Contaminated fuel can lead to clogs in the system, affecting flow rates and potentially damaging sensitive components within the truck. Regularly checking and replacing fuel filters will help maintain a high flow rate, which is critical when considering what is the flow rate of aircraft fuel truck during operations.

In addition to preventing clogs, clean oil lubricates moving parts effectively, reducing wear and tear on components such as pumps and engines. By ensuring that both oil and fuel are free from impurities, operators can significantly enhance their Aircraft Refueling Trucks' overall performance while minimizing maintenance costs in the long run.

How to Change Fuel Filters Properly

Changing fuel filters is a straightforward task that can have a significant impact on your aircraft refuelers truck's operational efficiency. First, ensure you have the right replacement filters according to your Aircraft fuel truck specifications before starting this process. When changing filters, always follow safety protocols to avoid spills or contamination.

To change a filter properly, start by relieving any pressure in the system; then remove the old filter carefully without spilling residual fuel. Install the new filter according to manufacturer instructions, making sure all connections are secure—this ensures optimal flow rates during subsequent operations.

Regularly scheduled filter changes will keep your refueler truck running smoothly while also preventing issues related to clogged lines or poor flow rates—critical factors when considering what is the volume of a fuel tanker truck during operations.

Checking Hydraulic Fluid Levels

Hydraulic systems play an essential role in operating various functions within an aircraft refuelers truck, including lifting mechanisms and pneumatic controls. Regular checks on hydraulic fluid levels should be part of your monthly comprehensive inspections; low levels can lead to inefficient operation or even system failure during critical moments.

To check hydraulic fluid levels effectively, locate the reservoir—usually marked clearly—and inspect it against recommended levels indicated on markings or dipsticks provided by manufacturers like Haisen. If levels are low, top off with compatible hydraulic fluid while being cautious not to introduce contaminants into the system.

Maintaining proper hydraulic fluid levels contributes significantly to ensuring that your Aircraft Refueling Trucks perform at their best under varying conditions—whether you're preparing for winter operations or dealing with summer heat checks for fluid maintenance.

Repairing Common Issues

Even the most reliable aircraft refuelers truck can encounter problems that need addressing to ensure optimal performance. Regular maintenance and prompt repairs are essential for keeping these critical vehicles operational. In this section, we’ll explore some common issues that may arise with your aircraft refuelers truck and how to address them effectively.

Addressing Electrical System Failures

Electrical system failures can be particularly troublesome for aircraft refueling trucks, as they often affect multiple components simultaneously. Issues such as faulty wiring, blown fuses, or malfunctioning sensors can lead to significant downtime if not addressed promptly. To tackle these problems, start by inspecting the electrical connections and wiring harnesses for any signs of wear or damage; ensuring a secure connection is key to maintaining functionality in your aircraft fuel truck.

Once you’ve identified potential electrical issues, it’s important to utilize diagnostic tools to pinpoint the exact source of the problem. For instance, checking voltage levels and continuity can help determine if a specific component is malfunctioning. If you're considering an upgrade or replacement part for your aircraft refueling truck, always refer to the manufacturer's specifications and guidelines for optimal compatibility.

Troubleshooting Pneumatic Control Problems

Pneumatic control systems play a crucial role in the operation of your aircraft refuelers truck, facilitating various functions such as valve operations and pressure regulation. When these systems fail or show signs of inefficiency, it can impact overall performance significantly. Begin troubleshooting by checking air supply lines for leaks or blockages; even a small leak can lead to major functionality issues in an aircraft fuel truck.

Next, inspect pneumatic components like valves and actuators for proper operation; ensure they’re free from debris that could hinder performance. If problems persist after thorough inspection and cleaning, consider consulting technical manuals specific to your model—like Haisen's Aircraft Pipeline Refueling Truck—for detailed troubleshooting steps tailored to your equipment’s specifications.

Recognizing Wear and Tear on Components

Regular inspections are vital for recognizing wear and tear on components before they become serious issues in your aircraft refuelers truck. Common areas of concern include hoses, seals, filters, and pumps—all essential elements that contribute to effective fueling operations. Pay particular attention during routine checks; if you notice any cracks in hoses or discoloration in seals, it’s time for replacements.

Understanding what normal wear looks like will help you differentiate between minor issues that need attention versus major problems requiring immediate action—after all, prevention is better than cure! Additionally, familiarizing yourself with the specifications of your Aircraft Refueling Trucks will aid you in identifying which parts may need more frequent monitoring based on their usage patterns.

In summary, addressing electrical system failures promptly while troubleshooting pneumatic control problems ensures smooth operations within your aircraft fuel truck fleet. Recognizing wear on components helps prolong their lifespan while maximizing safety through regular maintenance practices tailored specifically for each vehicle model.

Seasonal Maintenance Tips

Maintaining your aircraft refuelers truck is crucial year-round, but different seasons bring unique challenges. Seasonal maintenance ensures that your vehicle operates efficiently under varying weather conditions, which can impact performance and safety. By following specific tips for winter and summer, you can keep your aircraft refuelers truck in top shape.

Preparing for Winter Operations

As temperatures drop, it's essential to prepare your aircraft refuelers truck for winter operations. Start by checking the fuel system for any signs of water contamination; this can lead to freezing issues that affect flow rate and overall performance. Additionally, ensure that all electrical systems are functioning properly since cold weather can cause batteries to lose their charge more quickly.

Another critical aspect of winter readiness is inspecting the hydraulic system for leaks or damage caused by cold temperatures. When it comes to fluid maintenance, consider using low-temperature-rated oils and fuels specifically designed for colder climates. This will help maintain optimal flow rates and ensure efficient operation when you need it most.

Lastly, don't forget about tire pressure and tread depth; both can significantly affect traction on icy surfaces. A well-prepared aircraft refuelers truck not only enhances safety but also maximizes efficiency during the busy winter months when refueling services are in high demand.

Summer Heat Checks for Fluid Maintenance

When summer rolls around, the heat can take a toll on your aircraft fuel truck specifications if you're not careful. High temperatures can cause fluids to expand and potentially leak, so regular checks are crucial during this season. Make it a habit to inspect fluid levels weekly—especially hydraulic fluids—to prevent overheating issues that could compromise performance.

Additionally, you'll want to pay attention to the cooling systems within your aircraft refueling trucks; these systems are vital in maintaining optimal operating conditions during hot weather. An overheated engine could lead to catastrophic failures or reduced flow rates while dispensing fuel—definitely not something you want on a busy day at the tarmac!

Finally, consider adding heat-resistant materials or insulation where necessary to protect sensitive components from extreme temperatures. Keeping everything cool will not only enhance efficiency but also prolong the life of your equipment as you navigate through those sweltering summer days.

Importance of Climate-based Inspections

Climate-based inspections are essential when maintaining an aircraft refuelers truck because different environments present unique challenges that require tailored approaches. For instance, vehicles operating in humid climates may be more susceptible to corrosion due to moisture accumulation in various systems like piping and electrical components—leading ultimately to costly repairs down the line.

On the other hand, trucks used in arid regions face dust accumulation issues that could clog filters or impair flow rates over time if left unchecked. Regularly scheduled inspections based on local climate conditions help identify these problems early before they escalate into significant operational hurdles.

In summary, understanding how seasonal changes affect your aircraft fuel truck specifications allows you to implement proactive measures tailored specifically for each environment's demands. By staying vigilant with climate-based inspections throughout the year, you'll maximize safety while enhancing longevity—keeping those aircraft flying smoothly!

Conclusion

In conclusion, maintaining your aircraft refuelers truck is not just a task; it's a commitment to efficiency, safety, and longevity. Regular maintenance ensures that your equipment operates at optimal levels, ultimately affecting the quality of service you provide in aviation refueling. By understanding the key components and regularly inspecting them, you can keep your operations running smoothly.

Keeping Your Aircraft Refuelers Truck Efficient

Efficiency in aircraft refueling trucks is paramount for any operation that values time and reliability. Understanding specifications such as flow rates and tank volumes can significantly impact how quickly you can service an aircraft. For instance, knowing what is the flow rate of an aircraft fuel truck will help you plan your fueling operations more effectively, ensuring that every minute counts on the tarmac.

Maximizing Safety Through Regular Maintenance

Safety should always be at the forefront when it comes to operating aircraft refuelers trucks. Regular maintenance checks help identify potential issues before they escalate into serious problems that could jeopardize safety standards. Whether you're troubleshooting electrical system failures or checking hydraulic fluid levels, prioritizing maintenance can prevent accidents and ensure compliance with aviation regulations.

Enhancing Longevity of Your Refueler Truck

Investing time in regular upkeep not only maximizes safety but also enhances the longevity of your aircraft refuelers truck. A well-maintained vehicle will show fewer signs of wear and tear over time, saving you from costly repairs or replacements down the line. If you're considering purchasing an aircraft refueling truck for sale, remember: a history of proper maintenance is as crucial as its specifications.