Introduction

Refueling is a critical aspect of aviation operations, ensuring that aircraft can complete their journeys without interruption. The efficiency and reliability of aircraft refueling trucks play a pivotal role in this process, impacting everything from turnaround times to overall flight safety. Understanding the various types of refueling airplane trucks and their specific functions is essential for anyone involved in airport operations or aircraft management.

Understanding the Importance of Refueling

The importance of refueling cannot be overstated; it directly affects an aircraft's operational readiness and efficiency. Without timely and effective refueling, flights could face delays, increased operational costs, and even safety risks due to inadequate fuel levels. Knowing how much fuel does an airport fuel truck hold is vital for planning purposes, as it determines how quickly an aircraft can be serviced.

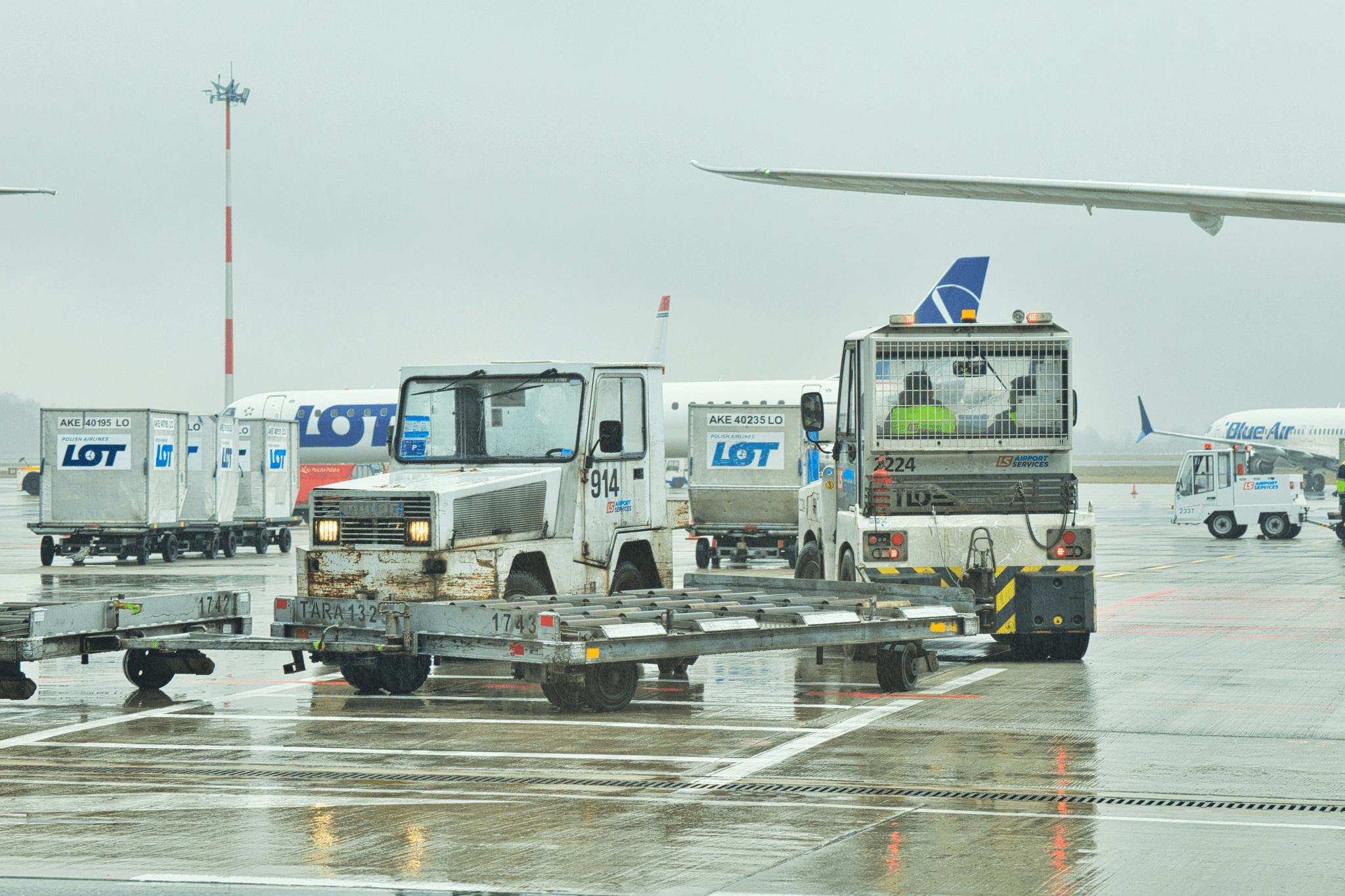

Types of Aircraft Refueling Trucks

Aircraft refueling trucks come in various designs tailored to meet the unique needs of different types of aircraft. From large tanker trucks capable of carrying significant amounts of fuel to specialized vehicles designed for specific tasks, understanding these options helps operators choose the right equipment for their fleet. When searching for an aircraft refueling truck for sale, it's crucial to consider not only capacity but also features like pump speed and filtration systems.

How Refueling Procedures Work

The procedure for refueling an aircraft involves several steps that must be executed with precision to ensure safety and efficiency. It typically includes connecting the fueling hose, monitoring flow rates, and adhering to strict safety protocols throughout the process. Familiarity with what is the capacity of a refueller can help ground crews manage their time effectively while minimizing risks during fueling operations.

Overview of Aircraft Refueling Trucks

Aircraft refueling trucks play a pivotal role in ensuring that airplanes are ready for takeoff with minimal downtime. These specialized vehicles are designed to transport and dispense fuel efficiently, catering to the needs of various aircraft types. Understanding the key features, popular models, and their significance in aircraft operations can help operators choose the right equipment for their needs.

Key Features and Specifications

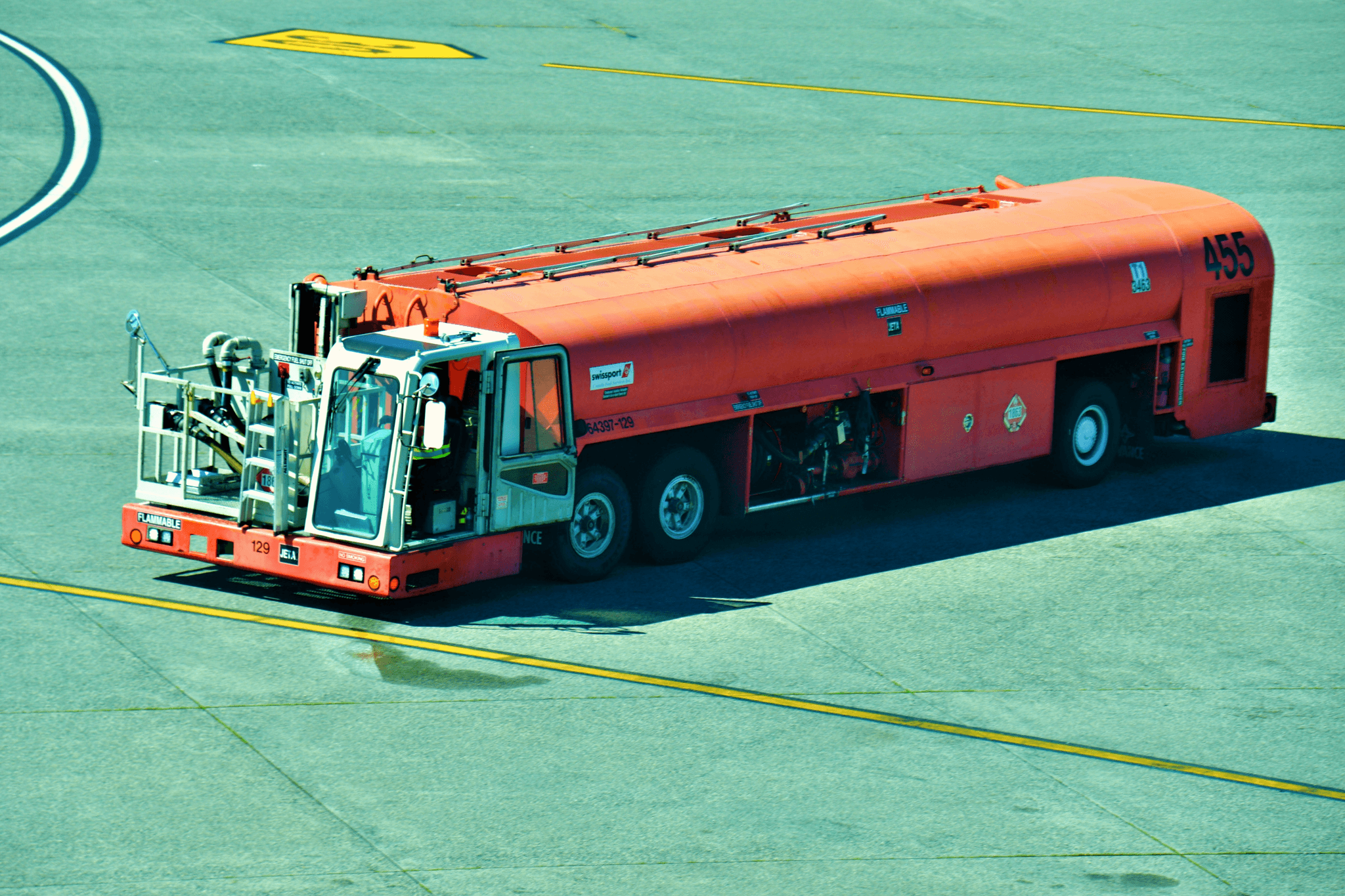

When looking at aircraft refueling trucks, several key features stand out that enhance their functionality. These trucks typically include large fuel tanks with capacities ranging from 1,000 to over 10,000 gallons—so how much fuel does an airport fuel truck hold? Additionally, they come equipped with advanced filtration systems to ensure clean fuel delivery and precise flow measurement devices for accuracy during refueling operations. The aircraft fuel truck specifications often include robust chassis designs capable of handling heavy loads while maintaining stability during operation.

Popular Models in the Market

In today’s market, various models of aircraft refueling trucks cater to different operational requirements. Some of the most notable options include Haisen's Aircraft Pipeline Refueling Truck and the CF5060TJYGX Aircraft Hydrant Dispenser. Each model brings unique advantages; for example, Haisen's design focuses on high flow rates and effective filtration processes while offering compatibility with a wide range of aircraft sizes—a crucial factor when considering an aircraft refueling truck for sale.

The Role of Refueling in Aircraft Operations

Refueling is not just about filling up tanks; it’s a critical component of aviation logistics that directly impacts flight schedules and operational efficiency. Understanding what is the procedure for refueling of an aircraft can help streamline operations at airports worldwide, ensuring safety and compliance with regulations. Furthermore, knowing what is the capacity of a refueller allows ground crews to optimize their fueling strategies based on flight demands and available resources.

Haisen Aircraft Pipeline Refueling Truck

Haisen's Aircraft Pipeline Refueling Truck represents a significant advancement in the realm of aircraft refueling technology. Designed for efficiency and versatility, it caters to the needs of various aircraft types, ensuring that every refueling operation is both swift and effective. With its robust construction and state-of-the-art systems, this refueling airplane truck is an indispensable asset for airports looking to optimize their operations.

Design and Functionality

The design of Haisen's Aircraft Pipeline Refueling Truck is both practical and innovative. It incorporates a chassis that supports a sophisticated piping system, alongside pneumatic, hydraulic, and electrical systems to facilitate seamless fuel transfer. The truck’s ability to deliver fuel at a high flow rate makes it particularly advantageous during peak operational hours when time is of the essence.

Additionally, this aircraft fuel truck features a low-profile design that allows for easier access to aircraft wings during refueling operations. This design consideration not only enhances safety but also improves efficiency by reducing the time spent maneuvering around different aircraft sizes. Ultimately, the combination of these elements ensures that operators can rely on this vehicle for consistent performance in various scenarios.

Advantages for Various Aircraft Types

One standout feature of Haisen's Aircraft Pipeline Refueling Truck is its adaptability across different aircraft types—ranging from small private planes to larger commercial jets. This versatility makes it an ideal choice for airports with diverse fleets or those that frequently host varying types of flights. The truck’s low altitude hydrant dispenser capability allows it to service most aircraft effectively without requiring extensive modifications or additional equipment.

Moreover, since many airports are concerned about how much fuel an airport fuel truck holds, Haisen has ensured that its trucks possess substantial capacity while maintaining maneuverability on the tarmac. This balance between capacity and agility means operators can maximize their refueling efficiency without compromising safety or accessibility during operations. In short, whether it's a regional jet or a large cargo plane, Haisen’s truck provides reliable support across the board.

Effective Filtration and Flow Measurement

Effective filtration is crucial in maintaining fuel quality during transfer processes; thus, Haisen's Aircraft Pipeline Refueling Truck excels in this area as well. The built-in filtration system removes impurities such as dust and moisture from the fuel before it reaches the aircraft tanks—ensuring optimal performance once airborne again. This attention to detail reflects broader industry concerns regarding what is often overlooked: clean fuel leads directly to enhanced engine efficiency.

In addition to filtration capabilities, precise flow measurement technology ensures accurate delivery rates throughout each refuel process—a vital aspect when considering what is the procedure for refueling an aircraft? Accurate measurements help avoid over-filling or under-filling issues that could lead to potential operational disruptions later on down the line. With these advanced features combined into one unit, operators can confidently manage their fueling tasks knowing they have reliable equipment at their disposal.

Analyzing CF5060TJYGX Aircraft Hydrant Dispenser

The CF5060TJYGX Aircraft Hydrant Dispenser is a standout in the realm of aircraft refueling technology. Its unique design caters specifically to low-altitude refueling, making it an ideal choice for various aircraft types. With its specialized features, this dispenser streamlines the process of refueling airplanes, ensuring efficiency and safety.

Unique Design for Low-Altitude Refueling

One of the most notable aspects of the CF5060TJYGX is its height; standing at just 2 meters, it qualifies as a low-altitude hydrant dispenser. This design allows for seamless underwing refueling services, accommodating a wide range of aircraft sizes without compromising accessibility or safety. The compact structure is particularly advantageous when maneuvering in tight spaces typically found at airport terminals.

Comparison with Standard Refueling Trucks

When comparing the CF5060TJYGX to standard refueling trucks, several key differences emerge that highlight its superiority in specific scenarios. Traditional aircraft fuel trucks often have larger profiles and may require more space to operate effectively, while this hydrant dispenser's low stature allows it to fit into tighter areas with ease. Additionally, standard refueling trucks may not be optimized for underwing access like the CF5060TJYGX, which enhances efficiency during aircraft fueling operations.

Efficiency in Underwing Refueling

The efficiency of the CF5060TJYGX in underwing refueling cannot be overstated; it provides quick and reliable service that minimizes downtime for aircraft on the tarmac. Its advanced filtration system ensures that impurities are removed from fuel before reaching the aircraft's tanks—critical when considering how much fuel does an airport fuel truck hold and how clean that fuel must be to maintain operational integrity. Moreover, understanding what is the capacity of a refueller like this can help operators make informed decisions regarding their fleet needs.

Capacity and Technical Specifications

When discussing aircraft refueling trucks, understanding their capacity and technical specifications is crucial for efficient operations. These vehicles are designed to hold substantial amounts of fuel to meet the demands of various aircraft types, ensuring that air travel remains uninterrupted. Knowing how much fuel these trucks can carry helps operators plan refueling schedules effectively.

How Much Fuel Does an Airport Fuel Truck Hold?

Airport fuel trucks come in various sizes, with capacities typically ranging from 1,500 to 10,000 gallons or more. The specific amount a refueling airplane truck can hold often depends on its design and intended use; larger commercial airports may require trucks with greater capacities for high-volume operations. This allows them to service multiple aircraft in a short period, reducing turnaround times significantly.

What is the Capacity of a Refueller?

The capacity of a refueller varies depending on the model and specifications but generally falls within similar ranges as airport fuel trucks. For instance, smaller models might hold around 2,500 gallons while larger ones can accommodate up to 12,000 gallons or beyond. Understanding what is the capacity of a refueller is essential for operators when planning logistics at busy airports where efficiency is key.

Essential Specifications for Operators

Operators looking into Aircraft Refueling Trucks should pay attention to several essential specifications that impact performance and safety. Key factors include pump flow rates, filtration systems, and materials used in construction which affect durability and maintenance needs. Additionally, features such as hose lengths and nozzle types play a significant role in determining how effectively these trucks can perform their duties during the critical procedure for refueling an aircraft.

Procedures for Refueling an Aircraft

Refueling an aircraft is a meticulous process that requires careful planning and execution to ensure safety and efficiency. Understanding the procedure for refueling of an aircraft is crucial for operators, as it involves various steps that must be followed precisely. This section will provide an overview of these procedures, highlight safety protocols, and address common challenges faced during the refueling process.

What is the Procedure for Refueling of an Aircraft?

The procedure for refueling of an aircraft typically begins with a thorough pre-refuel inspection of both the aircraft and the refueling airplane truck. Operators must ensure that all equipment is functioning correctly and that safety measures are in place before commencing fuel transfer. Once everything checks out, the next step involves connecting the fuel hose from the truck to the aircraft’s fueling port, followed by monitoring fuel flow until the desired quantity is reached.

After fueling is completed, operators must disconnect the hose carefully while ensuring no spillage occurs. The final step involves conducting a post-refuel inspection to confirm that all systems are intact and ready for flight operations. Understanding how much fuel does an airport fuel truck hold can help in planning these operations effectively; most trucks have capacities ranging from 5,000 to 12,000 gallons depending on their specifications.

Safety Protocols and Best Practices

Safety protocols during refueling are paramount due to the flammable nature of aviation fuels. Operators should always wear appropriate personal protective equipment (PPE) such as gloves and goggles when handling fuel hoses or connections from any aircraft refueling trucks. Additionally, it’s essential to maintain a safe distance between any potential ignition sources—like engines or electrical equipment—and ensure that fire extinguishers are readily accessible in case of emergencies.

Best practices also include establishing clear communication among ground crew members involved in the refueling operation. Utilizing hand signals or radios can help prevent misunderstandings that could lead to accidents during this critical phase. Regular training on safety measures should be conducted so that all personnel remain aware of potential hazards associated with handling fuels in various situations.

Common Challenges Faced During Refueling

Refueling operations can present several challenges that require quick thinking and adaptability from ground crew members using aircraft fuel trucks. One common issue includes dealing with adverse weather conditions such as rain or snow, which can hinder visibility and create slippery surfaces around fueling areas. To mitigate these risks, crews should always be prepared with proper gear and alternate plans if conditions worsen unexpectedly.

Another challenge arises from discrepancies between expected fuel quantity versus actual delivery amounts due to equipment malfunction or human error during transfer processes involving aircraft refueling trucks. Regular maintenance checks on both vehicles and hoses can help minimize such occurrences while ensuring accurate measurements throughout each operation phase—what is the capacity of a refueller? Knowing this information allows teams to avoid overfilling tanks inadvertently.

Finally, communication breakdowns among team members might lead to delays or unsafe situations during critical moments like fueling operations at busy airports where multiple flights may be scheduled closely together! Implementing effective communication strategies ensures everyone remains informed about ongoing tasks without confusion arising amidst high-pressure environments.

Conclusion

In the rapidly evolving aviation industry, the significance of efficient and reliable aircraft refueling cannot be overstated. As we look to the future, advancements in technology promise to enhance the capabilities of refueling airplane trucks, ensuring that they meet the growing demands of air travel. Innovations will likely focus on improved fuel efficiency, automation, and enhanced safety features that cater to various types of aircraft.

The Future of Aircraft Refueling Technology

The future of aircraft refueling technology is poised for exciting developments. With a push toward sustainability, we can expect an increase in electric and hybrid refueling airplane trucks that minimize environmental impact while maintaining high performance levels. Additionally, smart technologies that monitor fuel quality and automate the refueling process will become more prevalent, ensuring safety and efficiency during operations.

Essential Features to Look for in Trucks

When considering an aircraft refueling truck for sale, several essential features should be prioritized. First and foremost is the capacity; understanding how much fuel does an airport fuel truck hold can significantly influence operational efficiency. Other important specifications include effective filtration systems to maintain fuel quality, robust safety protocols integrated into the design, and compatibility with various aircraft types to maximize versatility.

Aircraft Refueling Trucks for Sale: Making the Right Choice

Choosing the right aircraft refueling truck involves careful consideration of various factors tailored to specific operational needs. Potential buyers should assess what is the capacity of a refueller they require based on their typical flight operations and traffic at their airport or facility. By evaluating options against essential specifications—like flow rate accuracy and maintenance requirements—operators can ensure they invest wisely in equipment that enhances their overall service delivery.