Introduction

In the bustling world of aviation, the plane refueling truck plays a pivotal role in ensuring that aircraft are ready for takeoff. These specialized vehicles are designed to transport and deliver fuel to planes, making them a crucial component of airport operations. Understanding how these trucks function and their significance in refueling operations helps highlight their importance in maintaining flight schedules and safety.

Understanding Plane Refueling Trucks

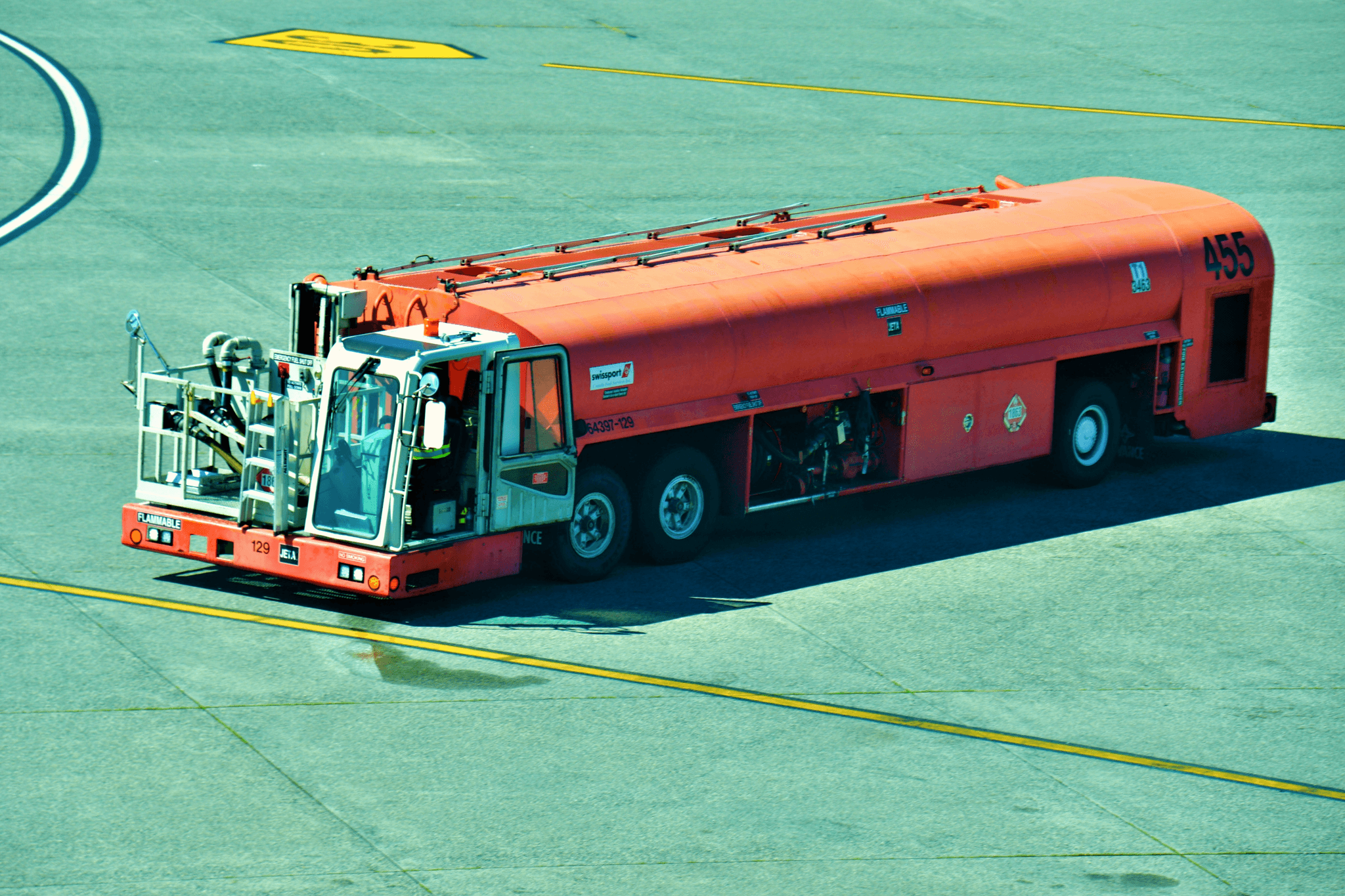

A plane refueling truck is not just any ordinary vehicle; it's a sophisticated piece of equipment engineered for one specific purpose—fueling aircraft efficiently and safely. These trucks come equipped with pumps, hoses, and tanks that can hold thousands of gallons of aviation fuel, making them essential for keeping planes operational. But what is the refueling plane called? While various terms exist, most refer to it simply as a “refueler” or “fuel truck,” emphasizing its critical role in aviation logistics.

Importance of Refueling in Aviation

Refueling is an essential process in aircraft operations, as it ensures that planes have enough fuel to complete their journeys safely. Do planes refuel every flight? The answer varies depending on the flight distance; short-haul flights may not require additional fuel at airports, while long-haul flights often do need top-ups before departure. The process of refuelling aircraft involves meticulous planning and execution to avoid delays while ensuring compliance with safety regulations.

Common Problems Faced with Refueling Trucks

Despite their importance, plane refueling trucks can encounter several common problems that hinder their operation. Frequent mechanical issues can arise from wear and tear or inadequate maintenance practices, leading to potential delays during busy airport hours. Additionally, understanding what are the trucks that pull airplanes is essential because these vehicles must be reliable under pressure; when they fail to perform optimally, it can disrupt entire flight schedules and create chaos on the tarmac.

The Anatomy of Plane Refueling Trucks

Understanding the anatomy of a plane refueling truck is essential for grasping how these vehicles support aviation operations. These trucks are engineered with precision to ensure safe and efficient fuel delivery to aircraft, which is critical for maintaining flight schedules. In this section, we will explore the key components that make up a refueling truck, how it integrates into aviation operations, and the role of Haisen's Aviation Automatic Weather Observation Station.

Key Components of a Refueling Truck

A typical plane refueling truck consists of several key components that work together seamlessly. First and foremost is the fuel tank, which stores aviation fuel in a safe manner; this tank can hold thousands of gallons depending on the size of the truck. Other critical components include pumps for transferring fuel at specific flow rates—often measured in gallons per minute—hoses for connecting to aircraft, filtration systems to ensure clean fuel delivery, and various gauges to monitor pressure and volume.

Moreover, these trucks often come equipped with safety features such as emergency shut-off valves and spill containment systems to mitigate risks associated with fuel spills. Understanding what is known as the refueling plane helps clarify that while some aircraft are designed specifically for mid-air refueling, ground-based trucks play an equally vital role in ensuring planes are ready for takeoff after landing. It's fascinating how these vehicles operate under strict regulations while being capable of delivering fuel efficiently.

How It Works in Aviation Operations

The process of refueling aircraft involves meticulous planning and execution to avoid any mishaps during fueling operations. When an aircraft lands, ground crew members assess its fuel needs based on flight requirements; this determines how much fuel the plane refueling truck will deliver before its next departure. The actual process includes connecting hoses from the truck's nozzle to designated ports on the aircraft—ensuring proper alignment—and then activating pumps that transfer fuel at controlled flow rates.

Once fueling begins, personnel monitor gauges closely to ensure that everything operates smoothly; they must also remain vigilant for any signs indicating potential issues or leaks during fueling. Do planes refuel every flight? Not always—depending on their range and mission requirements—but when they do require additional fuel, efficiency during this operation becomes paramount in maintaining tight schedules at busy airports.

The Role of Haisen's Aviation Automatic Weather Observation Station

Haisen's Aviation Automatic Weather Observation Station plays an indispensable role in ensuring safe fueling operations at airports by providing continuous real-time weather data crucial for decision-making processes during aviation activities. This station utilizes advanced sensors to measure temperature, wind speed and direction, visibility levels, cloud height, and atmospheric pressure—all factors that can affect both ground crew safety and operational efficiency during fueling.

For example, if strong winds or low visibility conditions arise while performing what is referred to as refueling in aircraft, it may necessitate delaying or modifying procedures until conditions improve. By integrating weather data into their operational protocols through Haisen's technology, airport staff can better anticipate challenges related not just to fueling but also overall flight safety—the ultimate goal being smooth transitions from one phase of air travel to another without compromising safety standards.

Frequent Mechanical Issues

Common Failure Points in Refueling Trucks

Refueling trucks are complex machines with multiple components that can fail over time. One of the most common failure points is the fuel pump, which is responsible for delivering fuel at a specific flow rate; if it malfunctions, it can disrupt the entire refueling process. Additionally, hoses and nozzles can develop leaks or become clogged due to contaminants in the fuel, leading to inefficiencies and safety hazards during operations.

Another frequent issue lies within the electronic systems that control various aspects of the plane refueling truck's functionality. These systems manage everything from flow rates to automated shut-off features; when they fail, it can result in overfilling or inadequate fueling of aircraft. Regular inspections and maintenance are essential to catch these issues before they escalate into bigger problems.

Maintenance Tips to Avoid Breakdowns

To keep your plane refueling truck in top shape, regular maintenance is non-negotiable. Establishing a routine check-up schedule that includes inspecting hoses for wear and tear, checking pump performance, and ensuring all electronic systems function correctly will go a long way toward preventing breakdowns. Additionally, keeping your fuel clean by regularly replacing filters will help avoid contamination—one of the leading causes of mechanical failures.

Operators should also be aware of seasonal changes that might affect equipment performance; for instance, colder temperatures can impact fluid viscosity within pumps and lines. Implementing preventive measures such as using appropriate anti-freeze products during winter months ensures smooth operation year-round. Lastly, training personnel on proper handling techniques will minimize human error—another significant factor contributing to mechanical issues.

Signs Your Plane Refueling Truck Needs Attention

Knowing when your plane refueling truck needs attention is key to avoiding costly repairs down the line. Some warning signs include unusual noises coming from pumps or engines during operation—these could indicate impending failure that needs immediate investigation. Additionally, if you notice inconsistent flow rates while fueling aircraft or see visible leaks around hoses or nozzles, it's time to take action.

Another red flag is excessive vibration during operation; this could mean something has come loose inside the mechanics of your truck or even an issue with its suspension system affecting stability while on-site at airports—especially critical when dealing with what are commonly referred to as the trucks that pull airplanes. Finally, keep an eye out for warning lights on control panels; these often signal underlying problems requiring prompt attention.

Fuel Quality Problems

Fuel quality is paramount in aviation, particularly when it comes to the operation of a plane refueling truck. Contaminated fuel can lead to significant operational issues, impacting not only the refueling process but also the performance of aircraft during flight. Understanding how fuel contamination occurs is essential for maintaining safety and efficiency in aviation.

How Fuel Contamination Occurs

Fuel contamination can arise from various sources, including water intrusion, microbial growth, and particulate matter entering the fuel system. For instance, if a plane refueling truck is not properly maintained or if its storage tanks are exposed to environmental elements, moisture can accumulate and mix with the fuel. Additionally, during the process of refueling aircraft, dirt or debris can inadvertently be introduced into the fuel lines, compromising its quality.

Effects of Poor Fuel Quality on Aircraft

The implications of poor fuel quality on aircraft are serious and multifaceted. Contaminated fuel can cause engine malfunctions or failures during flight—definitely not an ideal scenario for any pilot! Moreover, it can lead to increased maintenance costs and operational delays as technicians scramble to address issues that could have been avoided with proper fuel management practices.

Regulatory Standards for Aviation Fuel

To ensure safety in aviation operations, regulatory bodies have established stringent standards governing aviation fuel quality. These standards dictate acceptable levels of contaminants and require regular testing to guarantee compliance before fueling an aircraft. Adhering to these regulations not only protects the integrity of a plane refueling truck's operation but also ensures that every flight meets safety benchmarks—because nobody wants to find out mid-flight that their jet's had a bad hair day due to subpar fuel!

Operational Challenges

In the world of aviation, refueling is a critical operation that ensures aircraft are ready for takeoff. Refueling in aircraft involves transferring fuel from a plane refueling truck to the aircraft’s fuel tanks, ensuring that planes have sufficient fuel for their journeys. This process is not only about filling up; it requires precision, timing, and adherence to safety protocols to prevent any mishaps.

What is Refueling in Aircraft?

Refueling in aircraft refers to the process of replenishing an airplane's fuel supply before departure or during transit. It plays a vital role in aviation operations, as planes need specific amounts of fuel based on their flight plans and distances to be traveled. Understanding what is the refueling plane called? Typically, it’s referred to as a refueler or fuel truck, which transports aviation fuel directly to the aircraft.

Refueling must be executed efficiently, especially for commercial flights where time is money. Do planes refuel every flight? Not necessarily; some short-haul flights might not require full tanks if they can safely reach their destination without additional fuel. However, longer flights will always depend on proper refueling procedures to ensure safety and compliance with regulations.

The Process of Refueling Aircraft Explained

The process of refuelling aircraft begins with the arrival of a plane refueling truck at the designated parking area where an airplane awaits its fueling service. Once parked correctly, personnel connect hoses from the truck's tank directly into the aircraft's fueling ports while adhering strictly to safety protocols to avoid any hazardous situations. The flow rate of an aircraft fuel truck can vary but typically ranges from 300 to 1,200 gallons per minute depending on equipment and operational requirements.

During this process, ground crew must monitor both the quantity being transferred and any potential leaks or spills that could occur—safety first! After fueling is complete, checks are conducted before disconnecting hoses and ensuring all systems are secure for takeoff. This careful orchestration ensures that everything runs smoothly so that pilots can focus on flying rather than worrying about low fuel levels mid-air.

Training Requirements for Refueling Personnel

Training requirements for refueling personnel are stringent due to the high-stakes nature of aviation operations involving planes and flammable materials like jet fuel. Crew members must undergo comprehensive training programs covering everything from handling equipment safely to understanding emergency procedures related to spills or accidents during fueling operations. Knowledge about what are the trucks that pull airplanes also forms part of their training since familiarity with different types of refuelers enhances efficiency during operations.

Moreover, personnel learn about regulatory standards governing aviation fuels and how contamination can affect both equipment and flight safety—after all, poor-quality fuel can lead straight into disaster territory! Continuous education ensures that staff stays updated on best practices as technology evolves within aviation fueling systems—think Haisen's automatic weather observation station providing real-time data crucial for safe operations at airports.

Effective training not only minimizes risks but also contributes significantly towards maintaining optimal performance levels during each operation involving a plane refueling truck—ensuring smooth transitions from ground services right into seamless airborne experiences!

Environmental and Safety Concerns

In the aviation world, environmental and safety concerns are paramount, particularly when it comes to plane refueling trucks. Fuel spills can lead to catastrophic consequences, both environmentally and operationally. Understanding these risks is crucial for maintaining the integrity of airport operations and protecting our planet.

Risks Associated with Fuel Spills

Fuel spills during the refueling process can pose significant hazards. They not only threaten the immediate environment but also create fire risks that can jeopardize personnel and aircraft safety. Additionally, contaminated soil and water sources can lead to long-term ecological damage, making it essential to address these potential issues proactively.

Mitigation Strategies for Safe Refueling

To combat the risks associated with fuel spills, implementing robust mitigation strategies is vital. Regular training for personnel on safe refueling practices ensures that everyone understands what is involved in refueling in aircraft operations, including emergency response procedures. Furthermore, utilizing high-quality equipment in plane refueling trucks—like spill containment systems—can help minimize the impact of accidental spills.

What Are the Trucks That Pull Airplanes?

When we talk about What are the trucks that pull airplanes? we refer primarily to specialized ground support vehicles designed for towing aircraft on the ground. These trucks play a crucial role in airport operations by maneuvering planes from one location to another safely and efficiently before they take off or after they land. While their primary function isn't fuel delivery, understanding their operation alongside plane refueling trucks provides a comprehensive view of airport logistics.

Conclusion

In the world of aviation, understanding the intricacies of plane refueling trucks is paramount for ensuring safe and efficient operations. The maintenance of these vital vehicles not only prevents costly breakdowns but also guarantees that aircraft can be refueled without delays. By adhering to best practices in maintenance, embracing innovations in technology, and preparing for future developments, the aviation industry can enhance its refueling operations significantly.

Best Practices for Maintaining Refueling Trucks

To ensure that a plane refueling truck operates smoothly, regular inspections and preventive maintenance are essential. This includes checking fuel lines for leaks, ensuring proper filtration systems are in place to maintain fuel quality, and monitoring pumps to maintain optimal flow rates during aircraft fueling. Additionally, operators should be trained to recognize early signs of wear and tear; after all, ignoring minor issues can lead to major headaches down the line.

When it comes to refueling aircraft, what is the process? It starts with the careful preparation of the plane refueling truck before any aircraft approaches. By following a structured checklist and maintaining a clean environment around fueling areas, personnel can minimize risks associated with spills or contamination.

Innovations in Aviation Refueling Technology

The landscape of aviation refueling is evolving rapidly with technological advancements aimed at increasing efficiency and safety. For instance, automated systems are being developed that allow for real-time monitoring of fuel quality throughout the entire process—ensuring that only the best fuel reaches an aircraft's tanks. Moreover, innovations such as smart sensors integrated into plane refueling trucks help track flow rates more accurately; this answers questions like what is the flow rate of an aircraft fuel truck?

Furthermore, Haisen's Aviation Automatic Weather Observation Station plays a pivotal role by providing real-time weather data crucial for making informed decisions during fueling operations. With accurate weather conditions available at their fingertips, crews can optimize timing and procedures when dealing with various environmental challenges while fueling planes.

Future of Plane Refueling Operations

Looking ahead at future operations in aviation refueling reveals exciting possibilities driven by sustainability efforts and technological advancements. As airlines strive to reduce their carbon footprint, alternative fuels will likely become more prevalent in everyday use—prompting new protocols on how we handle these fuels within our plane refueling trucks.

Additionally, as air travel continues to grow globally—raising questions like do planes refuel every flight?—the demand for efficient fueling solutions will increase dramatically alongside it. The industry must adapt quickly by incorporating advanced training programs focused on new technologies while ensuring that personnel remain adept at handling both traditional fuels and emerging alternatives safely.