Introduction

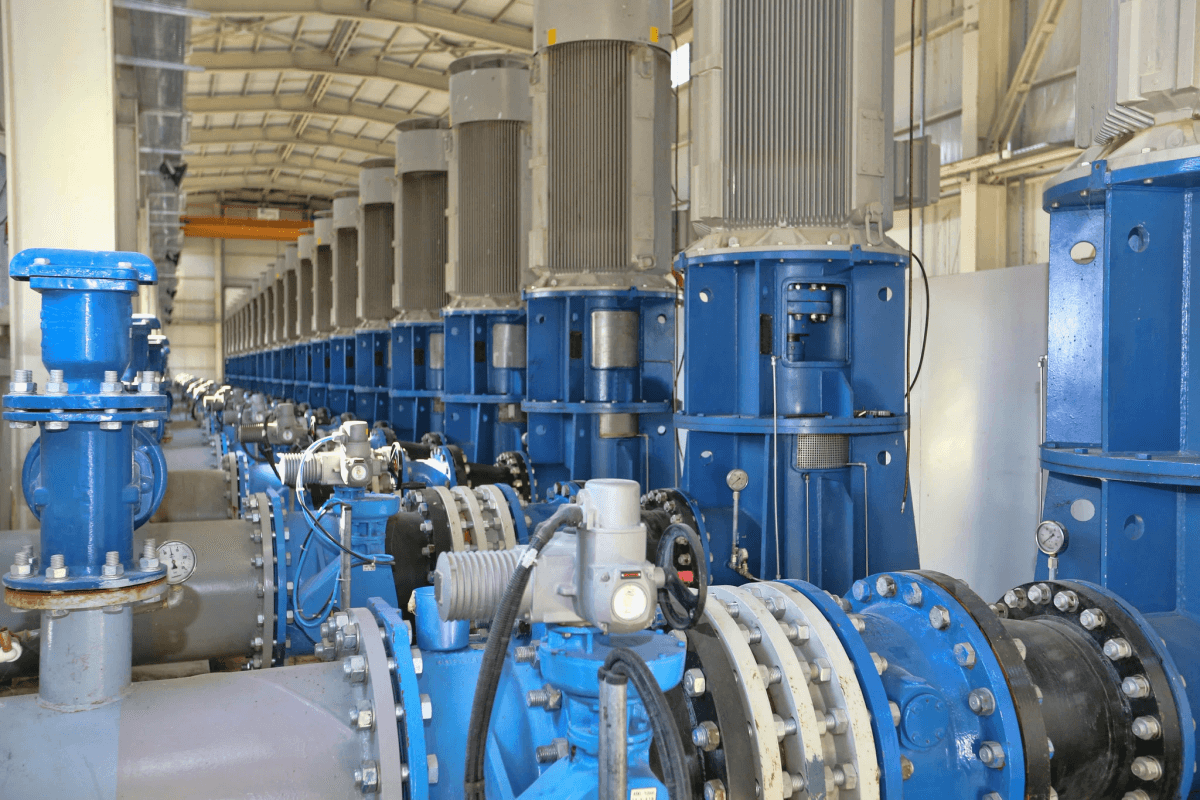

Electric valve actuators play a crucial role in controlling the flow of fluids in various industrial applications. These motorized devices are designed to automate the operation of valves, ensuring precision and efficiency in the process. It's essential to understand the different types of electric valve actuators and choose the right one for specific applications. One such innovative product is Haisen's Part-Turn Valve Electric Actuator, which offers advanced control capabilities for various valve types.

Understanding Electric Valve Actuators

Electric valve actuators are devices that use electric power to open and close valves, eliminating the need for manual operation. They are commonly used in industries such as petrochemicals, metallurgy, and power generation to regulate the flow of liquids and gases. These actuators provide precise control over valve positioning, making them indispensable in various industrial processes.

Importance of Choosing the Right Actuator

When selecting electric actuators for industrial valves, several key factors must be considered to ensure optimal performance and reliability.

- Torque Requirements: Determine the precise torque needed to operate the valve effectively. Underestimating torque can lead to incomplete valve actuation while overestimating can result in unnecessary energy consumption.

- Speed Control: Consider whether precise speed control is necessary for the application. Some actuators offer adjustable speed settings, allowing for fine-tuning valve operation.

- Environmental Considerations: Evaluate the operating environment, including temperature extremes, humidity, and corrosive substances. Select an actuator with suitable protection ratings to withstand harsh conditions.

- Duty Cycle: Assess the valve's expected duty cycle, which refers to the percentage of time it will be in operation. Choose an actuator with a duty cycle rating that aligns with your application's demands.

- Feedback and Monitoring: Determine if feedback and monitoring capabilities are required. Some actuators provide feedback signals such as position or current, enabling real-time monitoring and troubleshooting.

By carefully considering these factors and selecting the appropriate electric actuator, you can optimize valve performance, enhance operational efficiency, and minimize downtime in your industrial processes.

Exploring Haisen's Part-Turn Valve Electric Actuator

Haisen's QT series part-turn valve electric actuator is a cutting-edge product offering independent part-turn control for butterfly, ball, and plug valves with a 90° rotation. This versatile device can be operated locally or remotely, making it suitable for various industrial applications. With its advanced features and robust design, Haisen's electric actuator is designed to meet the stringent demands of modern industrial operations.

Types of Electric Valve Actuators

Two main types of electric valve actuators are to consider: quarter-turn and multi-turn actuators. Quarter-turn actuators are designed to control valves requiring a 90-degree rotation for fully open or fully closed positions, such as butterfly and ball valves. On the other hand, multi-turn actuators are suitable for valves that need multiple rotations to open or close, like gate valves and globe valves.

Quarter-Turn vs. Multi-Turn Actuators

Like Haisen's QT series part-turn valve electric actuators, quarter-turn actuators are ideal for applications where quick and efficient operation is essential. These actuators offer precise control over the valve position and can be operated locally or remotely, making them versatile for various industrial settings. On the other hand, multi-turn actuators are better suited for valves that require a more gradual opening or closing process, providing the necessary torque for smooth operation.

In addition, quarter-turn actuators are often preferred for on/off applications, where the valve must be fully open or closed. This makes them suitable for processes that require a simple start/stop functionality, such as in emergency shut-off systems or basic flow control. On the other hand, multi-turn actuators are more commonly used for modulating applications, where the valve needs to be adjusted to different positions to regulate the flow of a substance. This makes them essential for processes that demand precise control over the rate of flow or pressure within a system.

On/Off vs. Modulating Actuators

Another important consideration when choosing an electric valve actuator is whether you need an on-off or modulating actuator. On-off actuators are designed for simple open-and-close operations, making them suitable for basic applications where full flow control is not necessary. In contrast, modulating actuators provide continuous and precise control over the valve position, allowing for adjustable flow rates and pressure regulation.

On/off actuators are ideal for simple on/off control of water or air flow in industrial processes, HVAC systems, or basic irrigation systems. These actuators are cost-effective and easy to install, making them popular for many basic control applications. However, a modulating actuator would be the better choice if your application requires precise flow control, such as in chemical processing or pharmaceutical manufacturing. Modulating actuators allow for adjustable flow rates and pressure regulation, providing the level of control necessary for these types of processes.

Choosing the Right Actuator for Your Application

Selecting the right electric valve actuator depends on factors such as the type of valve being controlled, torque requirements, speed and control preferences, environmental conditions, and integration with existing control systems. It's essential to assess your specific application carefully to determine which type of actuator will deliver optimal performance and reliability.

When considering the type of valve being controlled, it's important to evaluate whether it is a linear or rotary valve, as this will impact the type of actuator required. A linear actuator that provides straight-line motion is essential for linear valves, such as globe or gate valves. On the other hand, rotary valves, like ball or butterfly valves, will require a rotary actuator that delivers rotational movement. Understanding the specific valve type is crucial in selecting the right actuator to ensure compatibility and efficient operation.

Now that we've explored the different types of electric valve actuators available on the market let's examine the factors that should be considered when making this crucial decision.

Factors to Consider

When selecting an electric valve actuator, it's crucial to consider the torque requirements for your specific application. Different valves require different levels of force to operate, so understanding the torque needed will ensure that the actuator can effectively control the valve's movement.

Torque Requirements

The torque requirements for an electric valve actuator are determined by the size and type of valve being operated. For example, larger valves, such as butterfly valves, may require higher torque than smaller ball valves. It's important to accurately assess the torque needed to ensure that the actuator can provide sufficient force for smooth and reliable operation.

Speed and Control

In addition to torque, speed, and control are essential factors when choosing an electric valve actuator. The speed at which a valve needs to open or close and the level of precision required in its positioning will determine the type of actuator that best suits your needs.

Environmental Considerations

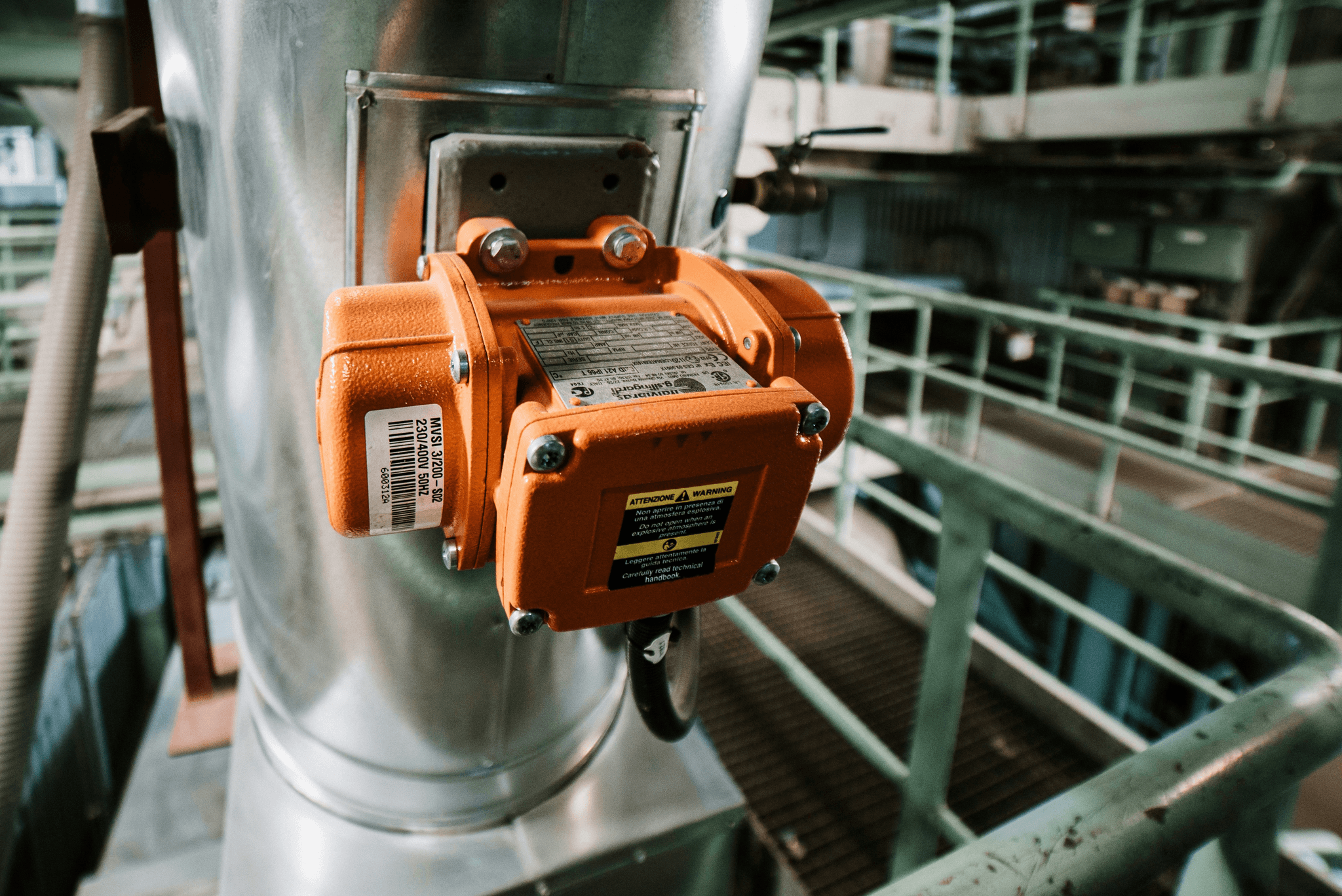

Environmental factors such as temperature, humidity, and exposure to corrosive substances can impact the performance and longevity of electric valve actuators. To ensure optimal functionality and durability, it's important to select an actuator designed to withstand your facility's specific environmental conditions.

Selecting the Right Actuator Valve

When selecting the right actuator valve, compatibility with the valve type is crucial. Different valves require specific types of electric actuators to ensure seamless operation. For example, Haisen's Part-Turn Valve Electric Actuator is designed to control butterfly, ball, and plug valves with a 90° rotation, making it suitable for a wide range of industrial applications.

Compatibility with Valve Type

It's essential to match the electric valve actuator with the specific type of valve it controls. The QT series part-turn valve electric actuator from Haisen is tailored for use with different valves requiring a 90° rotation for optimal functionality. This compatibility ensures seamless integration and smooth operation, reducing the risk of malfunctions or breakdowns. Whether it's a butterfly, ball, or plug valve, the QT series is designed to provide reliable performance across various applications.

Integration with Control Systems

Another critical factor in selecting the right actuator valve is its integration with control systems. The electric actuator should seamlessly integrate with existing control systems to ensure smooth operation and efficient control over valve functions.

Long-Term Reliability

Long-term reliability is paramount when choosing an actuator valve. The selected electric valve actuator should be durable and reliable, capable of enduring continuous operation in industrial settings without compromising performance or safety. In addition to durability, it is important to consider the actuator valve's maintenance requirements. Regular maintenance and servicing can significantly extend the valve's lifespan, reducing downtime and ensuring consistent performance over time. Furthermore, investing in a high-quality actuator valve from a reputable manufacturer can provide peace of mind and confidence in its long-term reliability.

When selecting an actuator valve, carefully consider compatibility with valve type, integration with control systems, and long-term reliability to ensure optimal performance and longevity in your industrial operations.

Advantages of Electric Valve Actuators

Efficiency and Precision

Electric valve actuators offer unparalleled efficiency and precision in controlling the flow of fluids through valves. With their motorized operation, they can precisely regulate the opening and closing of valves, ensuring accurate flow control and optimal performance in various industrial applications. This precision minimizes the risk of leaks or pressure fluctuations, improving safety and reliability in fluid handling systems. Additionally, the efficiency of electric valve actuators reduces energy consumption, making them a cost-effective choice for businesses looking to streamline their operations and reduce overhead costs.

Remote Operation Capabilities

One key advantage of electric valve actuators is their remote operation capabilities. This feature allows operators to control the actuator valves from a distance, enhancing convenience and safety in industrial settings. For example, Haisen's Part-Turn Valve Electric Actuator can be remotely controlled to ensure seamless operation without the need for manual intervention.

Furthermore, electric valve actuators' remote operation capabilities also contribute to long-term cost-effectiveness. By allowing operators to control the valves from a distance, these actuators minimize the need for manual intervention, reducing labor costs and increasing operational efficiency. Additionally, remote operation can help prevent accidents and equipment damage, saving on maintenance and repair expenses.

Cost-Effectiveness in the Long Run

Electric valve actuators are known for their long-term cost-effectiveness. While they may require a higher initial investment compared to traditional manual actuators, their efficient operation and minimal maintenance requirements result in significant cost savings over time. This makes them a practical choice for industries looking to optimize their operational expenses.

Furthermore, electric valve actuators offer precise control and automation, leading to improved operational efficiency. This allows for better regulation of flow rates and pressure, reducing the risk of overuse or resource wastage. As a result, industries can achieve higher productivity and cost-effectiveness in their processes, ultimately contributing to their bottom line.

Now that we've explored the advantages of electric valve actuators let's explore installation and maintenance tips to ensure optimal performance in industrial applications.

Installation and Maintenance Tips

When installing an electric valve actuator, it's crucial to ensure that it is securely mounted to the valve and that all electrical connections are properly made. Proper actuator alignment with the valve is also essential to ensure smooth operation. Additionally, it's important to follow the manufacturer's guidelines for wiring and setup to avoid any potential issues.

Proper Installation Procedures

Electric valve actuators are essential components in many industrial and commercial applications. Proper installation and maintenance are crucial to ensure their reliable and efficient operation.

Steps for Proper Installation and Maintenance:

- Align the actuator with the valve stem: Carefully position the actuator to align correctly with the valve stem. For specific alignment requirements, refer to the manufacturer's instructions.

- Securely fasten the mounting hardware: Use the provided mounting hardware to attach the actuator to the valve body. Ensure that all bolts and screws are tightened according to the manufacturer's specifications.

- Connect the electrical wiring: Carefully connect the electrical wiring to the actuator, following the wiring diagram provided in the manufacturer's manual. Ensure that all connections are secure and properly insulated.

- Test the actuator: After completing the installation, test the actuator to verify its functionality. Operate the actuator manually and observe its movement.

- Establish a regular maintenance schedule: Inspect the actuator and valve for any signs of wear, damage, or leaks. Lubricate moving parts as needed and replace any worn components.

By following these steps for proper installation and maintenance, you can help ensure your electric valve actuator's long-term reliability and performance. If you encounter any problems or have questions, consult the manufacturer's instructions or contact a qualified technician.

Routine Maintenance Practices

Regular maintenance of electric valve actuators ensures their long-term performance and reliability. This includes periodic inspection of all moving parts, lubricating gears, and bearings as needed, and checking for any signs of wear or damage. It's also important to regularly test the actuator's functionality to identify potential issues before they escalate.

After conducting routine maintenance on electric valve actuators, it's important to document all inspections and repairs for future reference. This record-keeping can help track the actuators' performance over time and identify any recurring issues that may need further attention. Additionally, maintaining a detailed maintenance log can be beneficial for compliance with industry regulations and standards and for warranty purposes.

Troubleshooting Common Issues

Electric valve actuators are essential components in industrial processes, but they can encounter various issues that disrupt operations.

- Power Supply Problems: Ensure the actuator receives the correct voltage and current. Check for loose connections, damaged wiring, or faulty power sources.

- Mechanical Failures: Inspect the actuator for signs of wear, corrosion, or physical damage. Also, check the gearbox, motor, and other moving parts for abnormalities.

- Control Signal Issues: Verify that the control signal is being sent correctly and received by the actuator. Test the signal voltage and frequency using a multimeter.

By systematically addressing these common issues, you can effectively troubleshoot and resolve problems with your electric valve actuators, ensuring optimal performance and reliability in your industrial processes.

Make the Right Choice for Your Operation

When selecting the right electric valve actuator for your operation, factors such as torque requirements, speed and control, and environmental considerations must be considered. By understanding your specific needs and the features of different actuators, you can make an informed decision that will ensure optimal performance and efficiency for your system.

Ensuring Smooth Operation with the Right Actuator

Choosing the appropriate actuator valve electric is essential for ensuring smooth operation of your valves and actuators. For example, Haisen's Part-Turn Valve Electric Actuator offers precise control over butterfly, ball, and plug valves with its 90° rotation capability. This level of control allows for seamless integration into various industrial applications, providing reliable performance and peace of mind.

Maximizing Efficiency with Electric Valve Actuators

Electric valve actuators offer numerous advantages, such as efficiency, precision, remote operation capabilities, and long-term cost-effectiveness. By leveraging these benefits, you can maximize the efficiency of your operations while reducing maintenance costs in the long run. Electric valve actuators can significantly enhance overall system performance with proper installation and routine maintenance practices.