Introduction

Choosing the right aviation fuel truck is not just about convenience; it’s a critical decision that can significantly impact operational efficiency and safety in aviation. The right fuel truck ensures that aircraft are refueled quickly and accurately, minimizing downtime and enhancing overall productivity. With various types of aviation fuel trucks available, understanding your specific needs is paramount to making an informed choice.

The Importance of Choosing the Right Aviation Fuel Truck

Selecting the appropriate aviation fuel truck can streamline your refueling operations and reduce costs in the long run. An efficient jet and Avgas refueling truck can enhance flow rates, ensuring that aircraft are ready for takeoff without unnecessary delays. Moreover, the right equipment will comply with safety regulations, minimizing risks associated with fuel handling.

Understanding Aviation Fuel Types

Before diving into which aviation fuel truck to choose, it's essential to grasp the different types of aviation fuels available—specifically, what are 4 aviation fuels? Jet A, Jet A-1, Avgas 100LL, and Jet B are commonly used in various aircraft types. Each has unique properties that affect performance and compatibility with different engines.

Assessing Your Refueling Needs

Understanding your specific refueling requirements is crucial when selecting an aviation fuel truck. Factors such as fleet size, typical flight operations, and turnaround times all play a role in determining what type of equipment you need. Additionally, consider questions like “What is the flow rate of an aircraft fuel truck?” to ensure you meet operational demands efficiently.

Types of Aviation Fuel Trucks

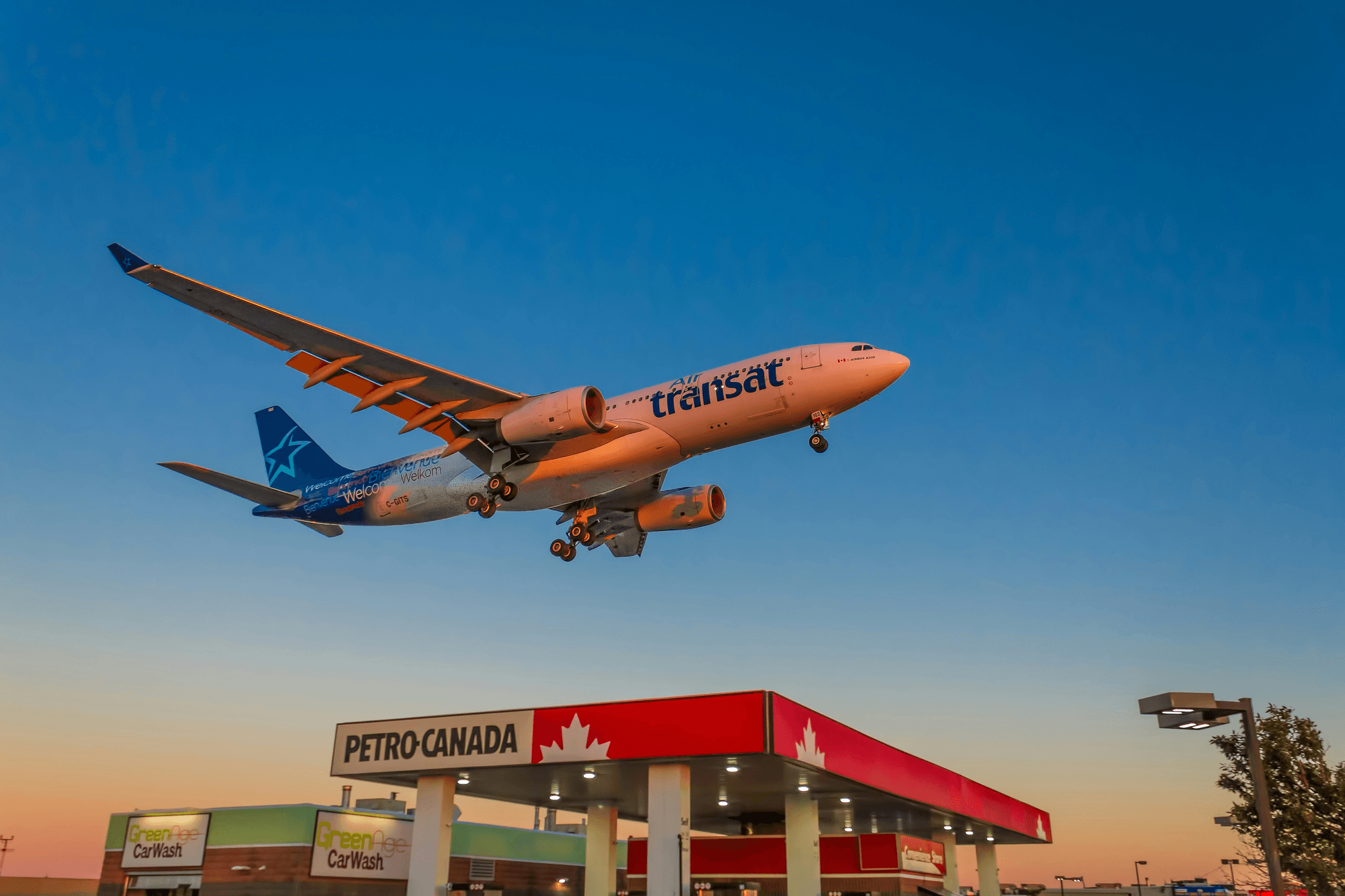

Jet and Avgas Refueling Trucks Overview

Jet and Avgas refueling trucks serve distinct purposes in the aviation industry, catering to various types of aircraft. Jet fuel trucks are typically larger and built for commercial jets that require a high volume of fuel quickly, while Avgas trucks cater to smaller general aviation aircraft that use 100LL (low lead) gasoline. Understanding what are 4 aviation fuels—Jet A, Jet B, AVGAS 100LL, and AVGAS 91/98—can help operators choose the right truck for their specific needs.

These refueling trucks come equipped with specialized pumps and hoses that ensure a safe transfer of fuel from the tank to the aircraft. They often have advanced filtration systems to maintain fuel quality during transfer processes. By using dedicated equipment designed for either Jet or Avgas fuels, operators can enhance safety protocols while minimizing contamination risks.

Key Features of Aviation Fuel Trucks

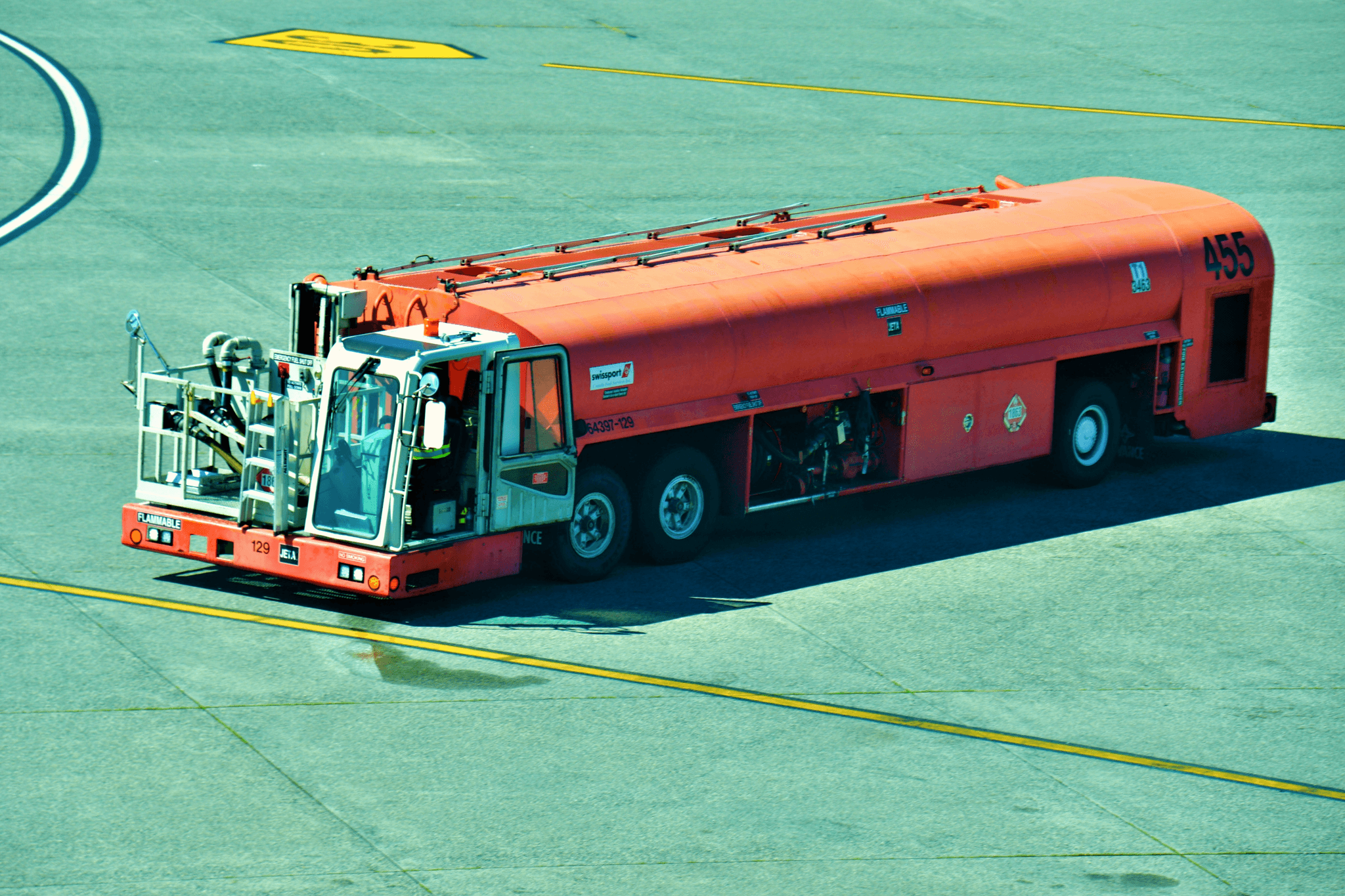

Aviation fuel trucks boast several key features that make them indispensable in airport operations. For starters, they typically include high-capacity tanks that allow for quick refueling without frequent stops at fueling stations—a vital consideration when assessing what is the flow rate of an aircraft fuel truck. Additionally, many modern tanks come equipped with digital monitoring systems that track fuel levels in real-time.

Safety features are paramount; these trucks often include emergency shut-off valves, grounding systems to prevent static discharge, and advanced filtration units that ensure only clean fuel enters the aircraft's system. Furthermore, user-friendly controls simplify operations for ground crew members who need to act swiftly during busy flight schedules. The combination of these features ensures efficient fueling processes while adhering to stringent safety standards.

Popular Manufacturers in the Market

The market is teeming with suppliers of aircraft refueler trucks who offer various models tailored to different operational requirements. Some popular manufacturers include Refueler Technologies Inc., TLD Group, and Garsite LLC—each providing innovative solutions designed specifically for aviation fueling needs. These companies focus on durability and functionality while ensuring compliance with international standards.

Additionally, some manufacturers specialize in custom-built options where clients can specify unique requirements based on their fleet size or type of operations—making it easier than ever to find an ideal match among available aviation fuel truck options. When choosing a supplier of aircraft refueler trucks, it's essential to consider not just price but also after-sales service and parts availability for long-term reliability.

Understanding Aviation Fuels

What Are 4 Aviation Fuels?

There are four primary types of aviation fuels that every operator should be aware of: Jet A, Jet A-1, Avgas 100LL, and Avgas 100. Jet A is a kerosene-type fuel commonly used in commercial jet engines, while Jet A-1 has a lower freezing point suitable for international flights. On the other hand, Avgas 100LL (low lead) is specifically formulated for piston-engine aircraft, providing optimal performance at high altitudes. Each type plays a vital role in ensuring that aircraft perform efficiently during operations while being compatible with various aviation fuel trucks designed for specific fueling needs.

Differences Between Aviation Fuel and Diesel

One key question often arises: what is the difference between aviation fuel and diesel? While both are derived from crude oil, their chemical compositions differ significantly; aviation fuels have a lower density and higher energy content than diesel. This distinction means that using diesel in an aircraft would be catastrophic, as it could lead to engine failure due to improper combustion characteristics. Additionally, specialized aviation fuel trucks are equipped to handle these differences safely during refueling operations.

Fuel Tankering in Aviation Explained

What is fuel tankering in aviation? Fuel tankering refers to the practice of carrying extra fuel on board an aircraft beyond what is necessary for a flight's direct route—essentially filling up at one location before flying to another with potentially higher refueling costs. This practice can save money when flying into airports where fuel prices are inflated or when weather conditions may require diversions that increase overall flight time and consumption. Understanding this concept can also help operators make informed decisions regarding their choice of suppliers of aircraft refueler trucks capable of accommodating larger quantities while maintaining safety standards.

Flow Rates and Efficiency

What Is the Flow Rate of Aircraft Fuel Truck?

The flow rate of an aircraft fuel truck refers to the volume of fuel that can be dispensed per unit of time, typically measured in liters per minute or gallons per minute. For instance, a standard Jet and Avgas refueling truck may have a flow rate ranging from 300 to 1,200 liters per minute, depending on its design and purpose. This measurement is vital for planning refueling operations as it affects how long a refueling process will take, which can be critical during busy flight schedules.

Importance of Flow Rate in Operations

Flow rate plays a significant role in aviation operations because it directly influences the efficiency and effectiveness of refueling processes. When airlines understand what is the flow rate of aircraft fuel truck they are using, they can better manage their operational timelines and ensure that planes are back in the air as swiftly as possible. Additionally, having a high-performing aviation fuel truck with optimal flow rates minimizes waiting times for pilots and crew members while enhancing overall airport throughput.

Optimizing Fuel Efficiency with the Right Truck

To optimize fuel efficiency with an aviation fuel truck, it's essential to select equipment designed for specific operational needs while also considering factors like maintenance costs and reliability from suppliers of aircraft refueler trucks. Investing in modern technology that offers advanced monitoring systems not only improves accuracy but also helps in maintaining optimal flow rates during refueling operations. Furthermore, understanding what is the difference between aviation fuel and diesel allows operators to make informed decisions about their fueling strategies—ensuring they choose the right type of equipment tailored for Jet or Avgas fuels.

Sourcing the Best Equipment

Suppliers of Aircraft Refueler Trucks

Finding reliable suppliers of aircraft refueler trucks is essential for maintaining a smooth operation. Many manufacturers specialize in producing high-quality aviation fuel trucks designed to meet industry standards and regulations. Some well-known suppliers include companies that focus on both new and used inventory, allowing you to weigh your options based on budget and operational needs.

When evaluating suppliers, consider their reputation in the industry, customer reviews, and after-sales support services. A good supplier will not only provide you with a robust aviation fuel truck but also offer maintenance services to keep your equipment running efficiently over time. It’s also wise to inquire about warranties or guarantees that can protect your investment long-term.

Evaluating Equipment Quality and Reliability

Quality should never be compromised when it comes to selecting an aviation fuel truck; after all, this equipment plays a pivotal role in fueling aircraft safely and efficiently. Look for features that enhance reliability such as corrosion-resistant materials, advanced filtration systems, and state-of-the-art monitoring technology. These elements are particularly important when considering what is the flow rate of aircraft fuel truck during operations.

Conducting thorough inspections before purchasing can save you from future headaches; check for compliance with safety standards as well as operational efficiency metrics like flow rates or tankering capabilities. Additionally, understanding what is fuel tankering in aviation can help you evaluate how well a particular truck meets your unique refueling demands—especially if you're working with multiple aircraft types or different fuel specifications.

Considerations for New vs. Used Trucks

Deciding between new versus used aviation fuel trucks involves weighing several factors that could impact your operations significantly. New trucks often come equipped with the latest technology advancements—like those found in Haisen's RVR measurement equipment—ensuring optimal performance right out of the gate. On the other hand, used trucks may offer significant cost savings but require careful evaluation regarding their condition and remaining lifespan.

When considering what is the difference between aviation fuel and diesel vehicles during this decision-making process, remember that each type has its own set of maintenance requirements which could affect long-term costs associated with ownership or leasing arrangements. Always factor in additional expenses such as insurance, maintenance contracts, or potential retrofitting needed for older models to meet current safety standards.

In conclusion, sourcing an aviation fuel truck requires careful consideration of various factors including supplier reliability, equipment quality, and whether to invest in new or used models—all while keeping an eye on evolving technologies shaping this critical aspect of air travel logistics.

Innovations in Aviation Fuel Technology

In the fast-paced world of aviation, staying ahead means embracing cutting-edge innovations in fuel technology. The aviation fuel truck has evolved significantly, integrating advanced systems that enhance efficiency and safety during refueling operations. This section will explore Haisen's RVR measurement equipment, advancements in fuel monitoring systems, and the emerging trends shaping the future of aviation fueling solutions.

Role of Haisen's RVR Measurement Equipment

Haisen's BHP01 Transmission RVR Measurement Equipment plays a pivotal role in ensuring safe airport operations by providing accurate visibility measurements. Utilizing a laser with the most sensitive wavelength to human eyes, it measures transmission attenuation in the atmosphere to determine how far pilots can see runway signs and lights. This technology not only enhances safety but also aids in optimizing refueling schedules for Jet and Avgas refueling trucks by ensuring operations can proceed smoothly under varying visibility conditions.

The ability to measure visual range accurately is critical for effective refueling operations as it directly impacts decision-making for aircraft movements on the ground. By integrating this system into aviation fuel trucks, operators can improve their situational awareness, ensuring that they are not just fueling aircraft but doing so with an acute understanding of environmental conditions. This innovation exemplifies how modern technology is being harnessed to elevate safety standards across aviation operations.

Advancements in Fuel Monitoring Systems

Fuel monitoring systems have undergone significant advancements, transforming how operators manage their aviation fuel truck fleets. These systems offer real-time data on fuel levels, flow rates, and consumption patterns—essential metrics that help answer questions like What is the flow rate of an aircraft fuel truck? With precise tracking capabilities, these technologies minimize waste and ensure that every drop counts during refueling.

Moreover, modern monitoring solutions often integrate with existing fleet management software to provide comprehensive insights into operational efficiency. By analyzing data trends over time, operators can make informed decisions about maintenance schedules or even when to consider sourcing from different suppliers of aircraft refueler trucks based on performance metrics. Ultimately, these advancements not only streamline operations but also contribute to cost savings and enhanced accountability within fueling processes.

Future Trends in Aviation Fueling Solutions

As we look towards the future of aviation fueling solutions, several trends are poised to reshape industry standards fundamentally. One prominent trend is the increasing use of sustainable fuels alongside traditional options; understanding What are 4 aviation fuels? will become essential knowledge for operators as they adapt their strategies accordingly. The shift towards greener alternatives reflects a growing commitment within the industry to reduce carbon footprints while maintaining high operational standards.

Additionally, automation is set to play a more significant role in fueling processes—think automated dispensing systems that enhance efficiency while reducing human error risks during critical operations like fuel tankering in aviation. As these technologies continue evolving, we can expect suppliers of aircraft refueler trucks to offer more integrated solutions that combine both automation and advanced analytics for smarter decision-making at every stage of operation.

In conclusion, embracing innovations such as Haisen's RVR measurement equipment and advanced monitoring systems will be crucial for those involved with aviation fueling logistics moving forward—especially as sustainability becomes a central theme across all sectors within this dynamic field.

Conclusion

In the ever-evolving world of aviation, making informed decisions about aviation fuel trucks is crucial for operational success. The right choice can enhance safety, efficiency, and overall performance in refueling operations. By understanding the various types of aviation fuels available and their specific applications, you can ensure your fleet is equipped to meet diverse needs.

Making an Informed Decision on Fuel Trucks

Choosing an aviation fuel truck requires careful consideration of multiple factors, including the type of fuel—whether Jet or Avgas—and the specific requirements of your operations. Understanding what are 4 aviation fuels can help you select a truck that meets your needs effectively. Additionally, assessing suppliers of aircraft refueler trucks will provide insights into quality and reliability, ensuring you make a sound investment.

Key Factors for Successful Aviation Operations

Successful aviation operations hinge on several key factors: equipment quality, flow rates, and adherence to safety protocols. Knowing what is the flow rate of aircraft fuel truck helps optimize refueling times and enhances operational efficiency. Furthermore, understanding what is fuel tankering in aviation allows operators to manage fuel logistics better while ensuring compliance with safety standards.

Enhancing Safety and Efficiency in Refueling

Safety and efficiency should always be at the forefront when it comes to refueling aircraft with an aviation fuel truck. Implementing advanced technologies like Haisen's BHP01 Transmission RVR Measurement Equipment can significantly improve visibility during low-light conditions at airports. This system not only enhances safety but also ensures that operators are well-equipped to handle various types of fuels while maintaining compliance with industry regulations.