Introduction

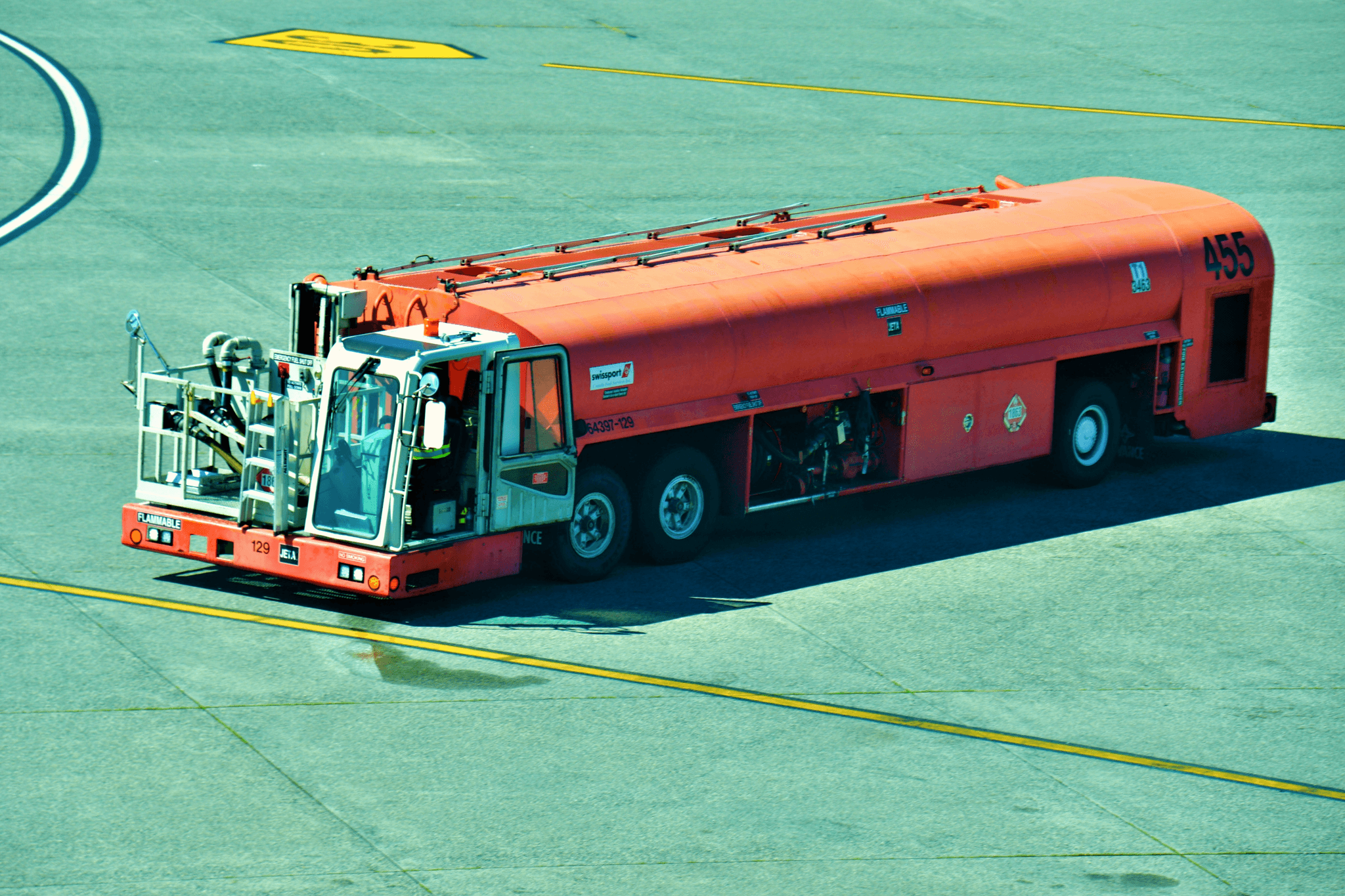

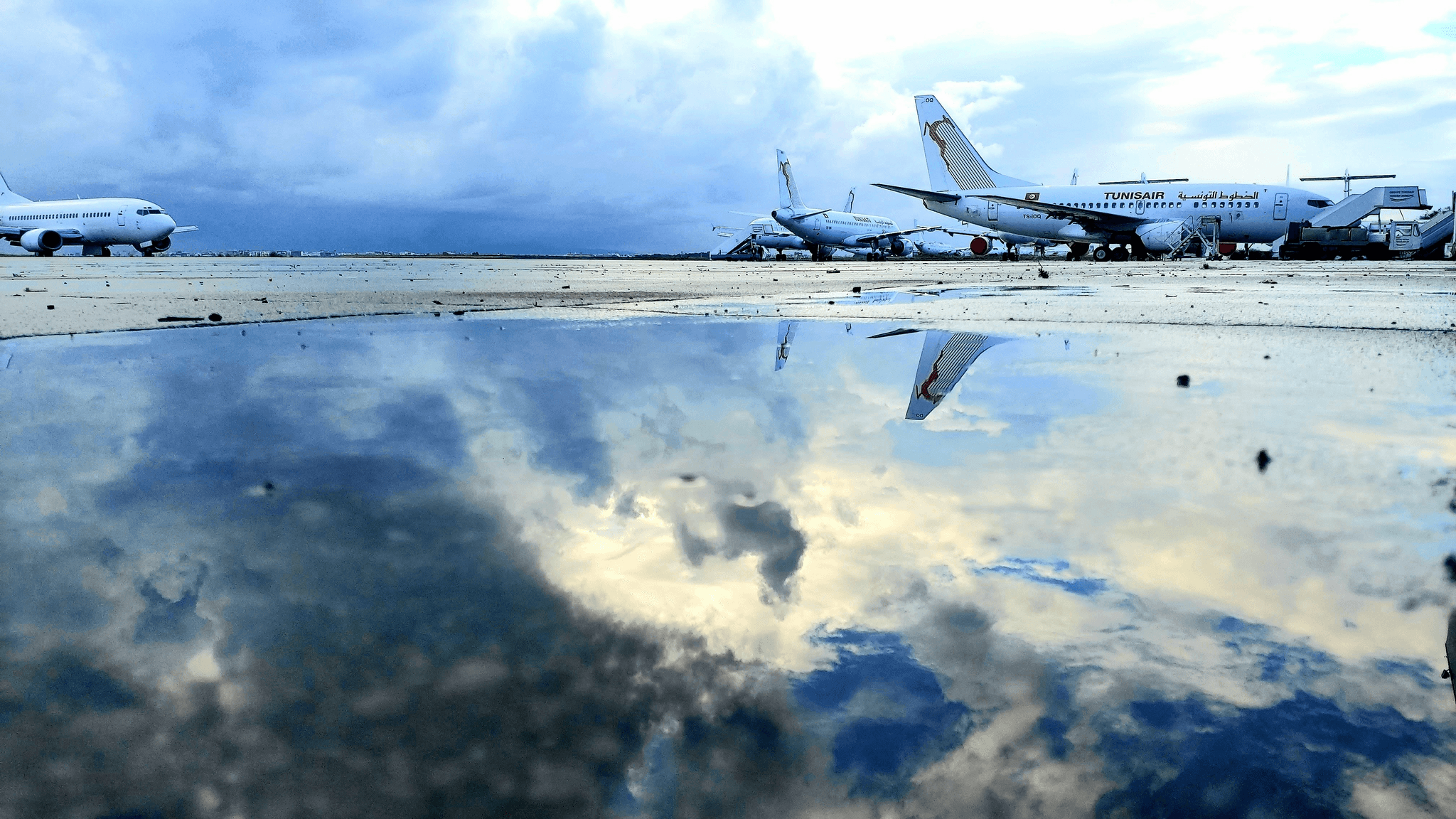

In the world of aviation, airplane fuel trucks play a crucial role in ensuring that aircraft are ready for takeoff. These specialized vehicles are designed to transport and deliver aviation fuel safely and efficiently, making them a vital component of airport operations. Understanding the various types of aircraft refueling trucks available can help airport managers make informed decisions about their fleet.

Understanding Airplane Fuel Trucks

Airplane fuel trucks come in various shapes and sizes, each tailored to meet specific refueling needs. Whether it's a large tanker capable of holding significant amounts of fuel or a smaller dispenser designed for quick service, knowing the differences is essential. For instance, many wonder how much fuel does an airport fuel truck hold? The answer varies widely depending on the model and purpose but typically ranges from several thousand to tens of thousands of liters.

Importance of Choosing the Right Truck

Choosing the right airplane fuel truck is not just about capacity; it also impacts operational efficiency and safety. Selecting an appropriate truck ensures that fueling operations run smoothly without unnecessary delays or complications. Additionally, understanding what type of fuel do airplanes use is vital for ensuring compatibility between the truck and aircraft.

Overview of Refueling Process

The refueling process involves several steps that require coordination between ground staff and pilots to ensure safety at all times. Initially, the airplane fuel truck connects to the aircraft's fueling system through a series of hoses and couplings designed for secure connections. As part of this process, many operators often ask how many fuel trucks to fill a 747? This question highlights the importance of having enough resources on hand to support large aircraft during busy periods at airports.

Types of Airplane Fuel Trucks

Differences Between Aviation Fuel Trucks

Aviation fuel trucks come in various configurations, designed to meet distinct requirements based on the type of aircraft they service. For instance, some trucks are tailored for commercial airlines like Boeing 747s, while others are optimized for smaller general aviation planes. This differentiation is vital because it directly impacts how much fuel does an airport fuel truck hold? Larger models can accommodate thousands of gallons, making them suitable for major airports with heavy traffic.

Additionally, the design and features vary significantly among aviation fuel trucks. Some may have advanced filtration systems to ensure that only clean fuel reaches the aircraft, while others might be equipped with high-flow pumps for faster refueling times. The choice between these options often depends on operational demands and budget considerations.

Features of Aircraft Refueling Trucks

Aircraft refueling trucks boast a range of features that enhance their efficiency and reliability during operations. One critical aspect is their ability to maintain compatibility with various types of fuels used in aviation—such as Jet A or Avgas—ensuring they meet industry standards and regulations regarding what type of fuel do airplanes use? This versatility allows airports to adapt quickly to different aircraft refueling needs.

Moreover, modern airplane fuel trucks often include state-of-the-art technology such as automated monitoring systems that track flow rates and detect contaminants in real-time. These features not only streamline the refueling process but also enhance safety by minimizing human error during operations. In addition to this, robust construction ensures durability under various weather conditions and airport environments.

Specialized Trucks for Different Flights

Specialized airplane fuel trucks cater specifically to unique flight operations or particular types of aircraft, enhancing efficiency across diverse scenarios. For example, Haisen's Aircraft Pipeline Refueling Truck is engineered for high flow rates while effectively filtering out impurities from the fuel during dispensing—ideal for large commercial jets needing quick turnaround times at busy airports.

On the other hand, low-altitude hydrant dispensers like the CF5060TJYGX are designed specifically for underwing refueling services on a range of aircraft sizes without requiring extensive infrastructure changes at an airport facility. Such specialized equipment ensures that every type of flight can be serviced promptly and safely—a crucial factor when considering logistics like how many fuel trucks to fill a 747?

In summary, understanding these distinctions among airplane fuel trucks allows airport operators to make informed decisions about their fleet composition based on operational needs and cost-effectiveness.

Key Specifications to Consider

When selecting an airplane fuel truck, understanding key specifications is crucial for operational efficiency and compatibility with aircraft. These specifications not only influence the performance of aviation fuel trucks but also determine how well they meet the needs of various airports. In this section, we will explore three essential aspects: capacity, flow rate, and compatibility with aircraft fuel requirements.

Capacity: How Much Fuel Does an Airport Truck Hold?

The capacity of an airport fuel truck is a critical factor that directly impacts refueling operations. Most aviation fuel trucks can hold anywhere from 1,000 to 10,000 gallons of fuel, depending on their design and intended use. To put it into perspective, if you're wondering how many fuel trucks to fill a 747, you would typically need several trucks since a Boeing 747 can hold around 48,000 gallons of jet fuel at maximum capacity.

Having a sufficient capacity not only ensures that you have enough fuel on hand for larger aircraft but also minimizes downtime during refueling operations. If your airport frequently services large planes like the 747 or other wide-body jets, investing in larger-capacity airplane fuel trucks could be beneficial for maintaining efficiency. Ultimately, understanding how much fuel does an airport truck hold will help you make informed decisions about your fleet size and operational capabilities.

Flow Rate: Ensuring Efficient Refueling

Flow rate is another vital specification to consider when selecting Aircraft Refueling Trucks. This metric indicates how quickly the truck can transfer fuel to an aircraft during refueling operations—typically measured in gallons per minute (GPM). A higher flow rate means faster service; for instance, some advanced models like Haisen's Aircraft Pipeline Refueling Truck can achieve impressive flow rates while ensuring that filtration systems effectively remove impurities.

Efficient refueling is particularly important during peak travel times when minimizing turnaround time is essential for airlines and airports alike. If you're working with multiple flights or busy schedules, understanding the flow rate will help you assess whether your chosen airplane fuel truck meets operational demands effectively. In summary, ensuring efficient refueling through optimal flow rates contributes significantly to overall airport productivity.

Compatibility with Aircraft: What Type of Fuel Do Airplanes Use?

Compatibility with aircraft is paramount when selecting aviation fuel trucks because different types of airplanes require specific fuels for optimal performance. Most commercial jets utilize Jet A or Jet A-1 kerosene-based fuels; thus it's crucial that your airplane fuel truck accommodates these types effectively. Knowing what type of fuel do airplanes use will guide you in choosing refueling equipment designed specifically for those needs.

Moreover, specialized features such as filtration systems are essential in maintaining the quality of the delivered jet fuels while preventing contamination during transfer processes—especially important when dealing with sensitive high-performance engines found in modern aircrafts. Additionally, some newer models like Haisen's low-altitude hydrant dispenser are designed to cater to various sizes and types of aircraft efficiently without compromising on safety or effectiveness.

In conclusion, recognizing compatibility requirements alongside other specifications such as capacity and flow rate will ensure that your aviation fueling operations run smoothly while meeting industry standards.

Understanding Fuel Delivery Systems

Piping Systems in Fuel Trucks

The piping system within an airplane fuel truck is designed to transport aviation fuel from the tank to the aircraft with minimal loss and maximum safety. These systems can vary in complexity depending on the model of Aviation Fuel Trucks, but they generally include a series of hoses, valves, and pumps that work together seamlessly. Knowing how much fuel does an airport fuel truck hold can help determine how many trips are needed to fill larger aircraft like a Boeing 747.

Significance of Filtration in Refueling

Filtration plays a vital role in maintaining the quality of aviation fuel during refueling operations. Contaminants such as dust, water, or other impurities can severely affect an aircraft's performance if introduced into its system. Therefore, effective filtration methods ensure that only clean fuel reaches the aircraft; this is particularly important when considering what type of fuel do airplanes use and ensuring it meets stringent quality standards.

Haisen's Innovative Refueling Technology

Haisen's Aircraft Pipeline Refueling Truck stands out due to its sophisticated design that integrates multiple systems for optimal performance. The vehicle not only boasts a high flow rate but also features advanced filtration mechanisms that remove impurities during refueling operations—making it ideal for various types of aircrafts at different altitudes. Compared to models like the CF5060TJYGX Aircraft Hydrant Dispenser, Haisen’s solution offers a low-altitude hydrant dispenser option that enhances underwing refueling services effectively across a wide range of sizes.

Comparing Popular Fuel Truck Models

When it comes to airplane fuel trucks, selecting the right model can significantly enhance operational efficiency and safety. In this section, we will explore two prominent models: Haisen's Aircraft Pipeline Refueling Truck and the CF5060TJYGX Aircraft Hydrant Dispenser. Understanding their features will help you make an informed decision about which aviation fuel truck best suits your needs.

Haisen Aircraft Pipeline Refueling Truck Overview

Haisen's Aircraft Pipeline Refueling Truck is a robust piece of machinery designed for effective refueling services across various types of aircraft. This truck consists of essential components such as a chassis, piping system, pneumatic control system, hydraulic system, and electrical system. With its high flow rate capabilities, this airplane fuel truck can efficiently deliver fuel while ensuring that impurities like dust and moisture are filtered out during the process.

One standout feature of Haisen’s model is its ability to accurately measure flow rates during refueling operations. This precision ensures that operators know exactly how much fuel they are delivering to each aircraft, addressing the critical question: how much fuel does an airport fuel truck hold? Additionally, its versatility allows it to service a wide range of aircraft sizes effectively.

Benefits of CF5060TJYGX Aircraft Hydrant Dispenser

The CF5060TJYGX Aircraft Hydrant Dispenser offers unique advantages that make it a popular choice among aviation professionals. One notable benefit is its low-altitude design; standing at only 2 meters high, it excels in underwing refueling services for most aircraft types. This feature provides easier access for ground crews while maintaining efficiency in delivering aviation fuels.

Moreover, this hydrant dispenser is equipped with advanced filtration systems that ensure clean fuel delivery—an essential requirement given the sensitive nature of what type of fuel do airplanes use? The CF5060TJYGX also boasts impressive flow rates similar to larger models but in a more compact form factor. These characteristics make it particularly appealing for airports with limited space or specific operational constraints.

Choosing Between High and Low-Altitude Dispensers

Deciding between high and low-altitude dispensers can significantly impact your airport's refueling strategy. High-altitude dispensers may offer broader reach and higher capacity but can be cumbersome when servicing smaller aircraft or tight spaces on the tarmac. Conversely, low-altitude dispensers like the CF5060TJYGX provide agility without compromising flow rates or filtration quality.

When evaluating how many fuel trucks to fill a 747 or any large aircraft, it's crucial to consider both capacity and accessibility offered by these models. In many cases, combining both high and low-altitude options may yield optimal results tailored to your specific fleet requirements while maximizing efficiency within your airport operations.

Logistics and Cost Considerations

When it comes to managing an airport's refueling operations, logistics and cost are paramount. The acquisition of an airplane fuel truck is not just about the initial purchase price; it involves a comprehensive budget that considers operational efficiency, maintenance, and potential return on investment. Understanding these financial elements can help airports make informed decisions that enhance their refueling capabilities while staying within budget.

Budgeting for Fuel Truck Acquisition

Budgeting for the acquisition of an airplane fuel truck requires a thorough analysis of various factors, including the type of aircraft serviced and the volume of fuel needed. Prices for Aircraft Refueling Trucks can vary significantly based on features, capacity, and technology. For instance, Haisen’s Aircraft Pipeline Refueling Truck offers advanced systems that may come at a premium but provide long-term savings through efficient operations.

When determining how much to allocate for purchasing an aviation fuel truck, it's essential to consider not only the upfront costs but also financing options if necessary. Many airports opt for leasing arrangements to spread out expenses over time while maintaining access to cutting-edge refueling technology. Ultimately, a well-thought-out budget will ensure that airports are equipped with reliable equipment without breaking the bank.

Maintenance Costs of Aviation Fuel Trucks

Maintenance costs are another critical aspect to consider when evaluating airplane fuel trucks. Regular upkeep is necessary to ensure optimal performance and longevity; this includes everything from routine inspections to replacing worn parts in systems such as piping or filtration components. Skimping on maintenance can lead to costly repairs down the line or even downtime during peak operational hours.

The maintenance regime will depend largely on the type of aviation fuel truck in use; some models may require more frequent servicing than others due to their complexity or usage patterns. For example, Haisen trucks are designed with durability in mind but still need periodic checks on their hydraulic systems and filtration units to maintain high flow rates during refueling operations. Understanding these costs upfront allows airport managers to better forecast annual budgets and avoid unexpected financial strain.

How Many Fuel Trucks to Fill a 747?

Now let's tackle one burning question: How many fuel trucks does it take to fill a 747? Given that a Boeing 747 can hold approximately 48,000 gallons (or around 182,000 liters) of jet fuel depending on its model configuration, careful calculations must be made based on the capacity of each airplane fuel truck used in operations.

Most aviation fuel trucks have capacities ranging from 5,000 gallons up to 12,000 gallons per trip; thus an airport might need anywhere from four to ten trips with these vehicles just for one full tanking session of a 747! This makes it crucial for airports operating large aircraft like this one not only have enough trucks but also ensure they are strategically deployed during peak times—after all, nobody likes waiting around when they could be soaring through the skies!

Conclusion

In summary, selecting the right airplane fuel truck is crucial for efficient airport operations. Understanding the various types of Aviation Fuel Trucks, their specifications, and how they fit into your refueling strategy can make all the difference. From capacity to flow rate and compatibility with aircraft fuel types, each element plays a significant role in ensuring that your refueling process runs smoothly.

Recap of Key Features to Evaluate

When evaluating Aircraft Refueling Trucks, consider key features such as capacity—how much fuel an airport fuel truck holds—and flow rate for efficient refueling. Additionally, ensure compatibility with the specific type of fuel do airplanes use, which can vary depending on the aircraft model. Don’t forget about innovative technologies like Haisen's Aircraft Pipeline Refueling Truck that streamline the entire process and enhance safety through advanced filtration systems.

Final Thoughts on Fuel Truck Selection

Choosing between different models of aviation fuel trucks requires careful consideration of your operational needs and budget constraints. For instance, if you frequently service larger aircraft like a Boeing 747, you might wonder how many fuel trucks to fill a 747 effectively without delays. Ultimately, investing in a reliable and high-capacity airplane fuel truck will pay dividends in efficiency and performance for your airport operations.

Moving Forward with Your Refueling Strategy

As you move forward with your refueling strategy, keep an eye on market trends and technological advancements in aviation fuel trucks. The right investment will not only improve your current operations but also prepare you for future demands in air travel logistics. With the right equipment at hand—like Haisen's low-altitude hydrant dispenser—you'll be well-equipped to handle any refueling scenario efficiently.