Introduction

In the world of industrial applications, understanding the butterfly valve actuator is essential for optimizing processes and ensuring efficiency. These devices play a crucial role in controlling fluid flow, making them indispensable in various sectors such as petrochemical, food processing, and municipal engineering. But what exactly is a butterfly valve actuator? This introduction sets the stage for exploring its definition, functionality, and importance in modern industry.

Understanding the Butterfly Valve Actuator

A butterfly valve actuator serves as the driving force behind the operation of a butterfly valve, allowing it to open or close based on system requirements. Essentially, it converts electrical or pneumatic energy into mechanical motion that rotates the valve disc to regulate flow. Delving deeper into what is an actuator in a valve reveals that these components are vital for automation and remote control capabilities in complex systems.

Importance in Industrial Applications

The significance of butterfly valve actuators cannot be overstated; they are integral to maintaining operational efficiency across many industries. By providing precise control over fluid dynamics, these actuators help prevent leaks and ensure safety standards are met. Moreover, understanding what is the purpose of the butterfly valve helps highlight how these actuators contribute to overall system reliability.

Overview of Different Actuator Types

When discussing actuators in general, it's important to recognize that they come in various types—electric, pneumatic, and hydraulic—each with its own set of advantages and applications. Electric actuators offer precise control with minimal maintenance needs; pneumatic actuators excel in speed; while hydraulic options provide immense power for heavy-duty applications. As we explore each type further along this guide, you'll discover how selecting the right actuator can enhance your operations significantly.

What is a Butterfly Valve Actuator?

Butterfly valve actuators play a crucial role in the operation of butterfly valves, which are widely used in various industrial applications. Understanding what a butterfly valve actuator is can enhance your knowledge of fluid control systems and their efficiency. This section will delve into the definition, mechanism, key components, and real-world applications of butterfly valve actuators.

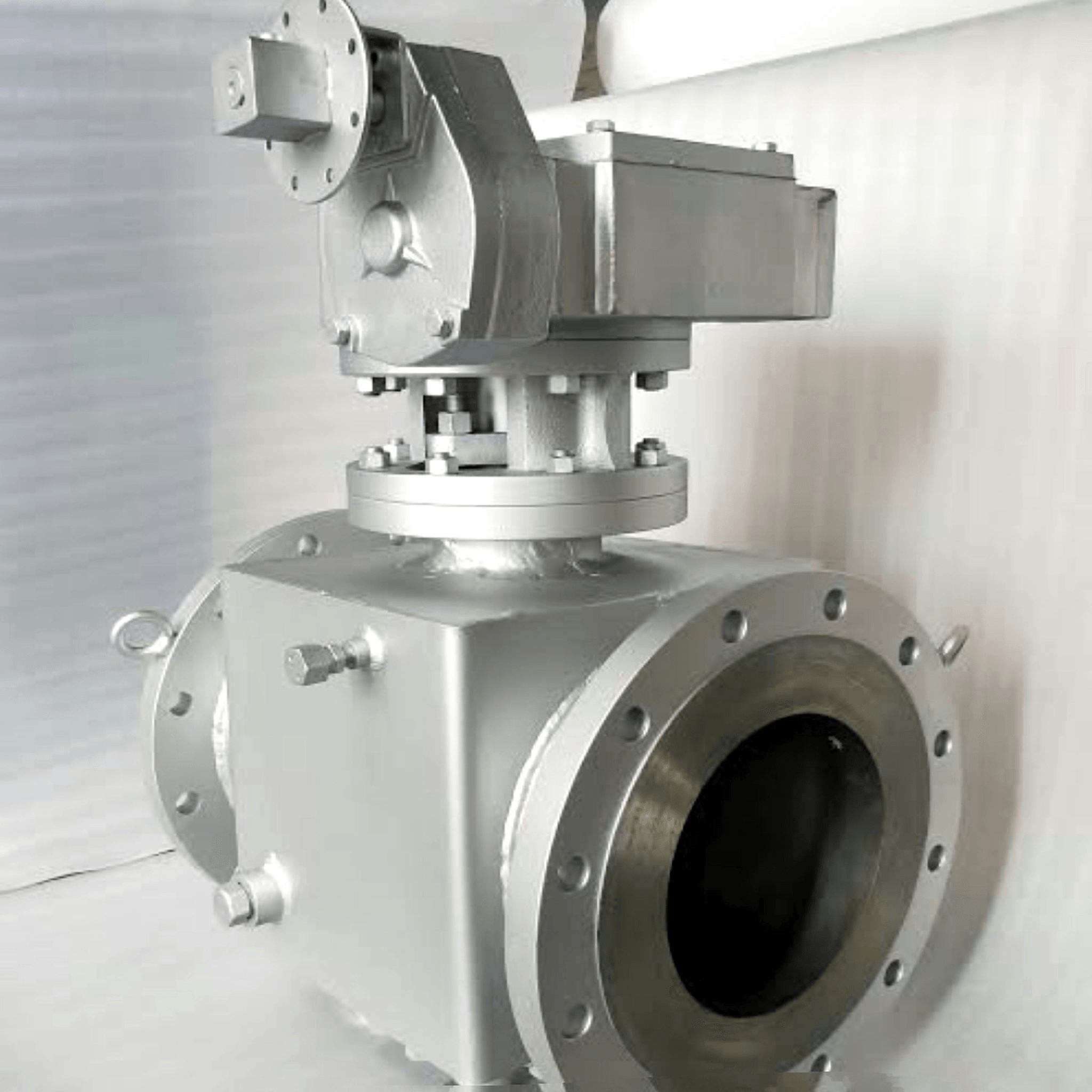

Definition and Mechanism

What is a butterfly valve actuator? Simply put, it is a device that controls the opening and closing of a butterfly valve. The mechanism typically consists of a disc that rotates around an axis, allowing for precise flow control within pipelines. When the actuator receives a signal—whether pneumatic, electric, or hydraulic—it moves the disc to either allow or restrict fluid flow.

The beauty of this system lies in its simplicity and effectiveness; when fully opened, the disc presents minimal resistance to flow, making it an efficient choice for many industrial processes. Additionally, understanding what is an actuator in a valve context helps clarify how these devices contribute to overall system performance by providing reliable movement based on operational requirements.

Key Components Explained

A butterfly valve actuator comprises several key components that work together seamlessly to ensure smooth operation. The main parts include the actuator body, which houses the motor or pneumatic components; the drive shaft connected to the disc of the valve; and various sensors that provide feedback on position and performance. Each component plays an integral role in ensuring that what is the purpose of the butterfly valve—controlling fluid flow—is achieved efficiently.

Moreover, these actuators may also feature limit switches for safety measures and manual overrides for emergencies or maintenance situations. Understanding these elements can help users select suitable products based on their specific needs while ensuring optimal functionality from their butterfly valve actuators.

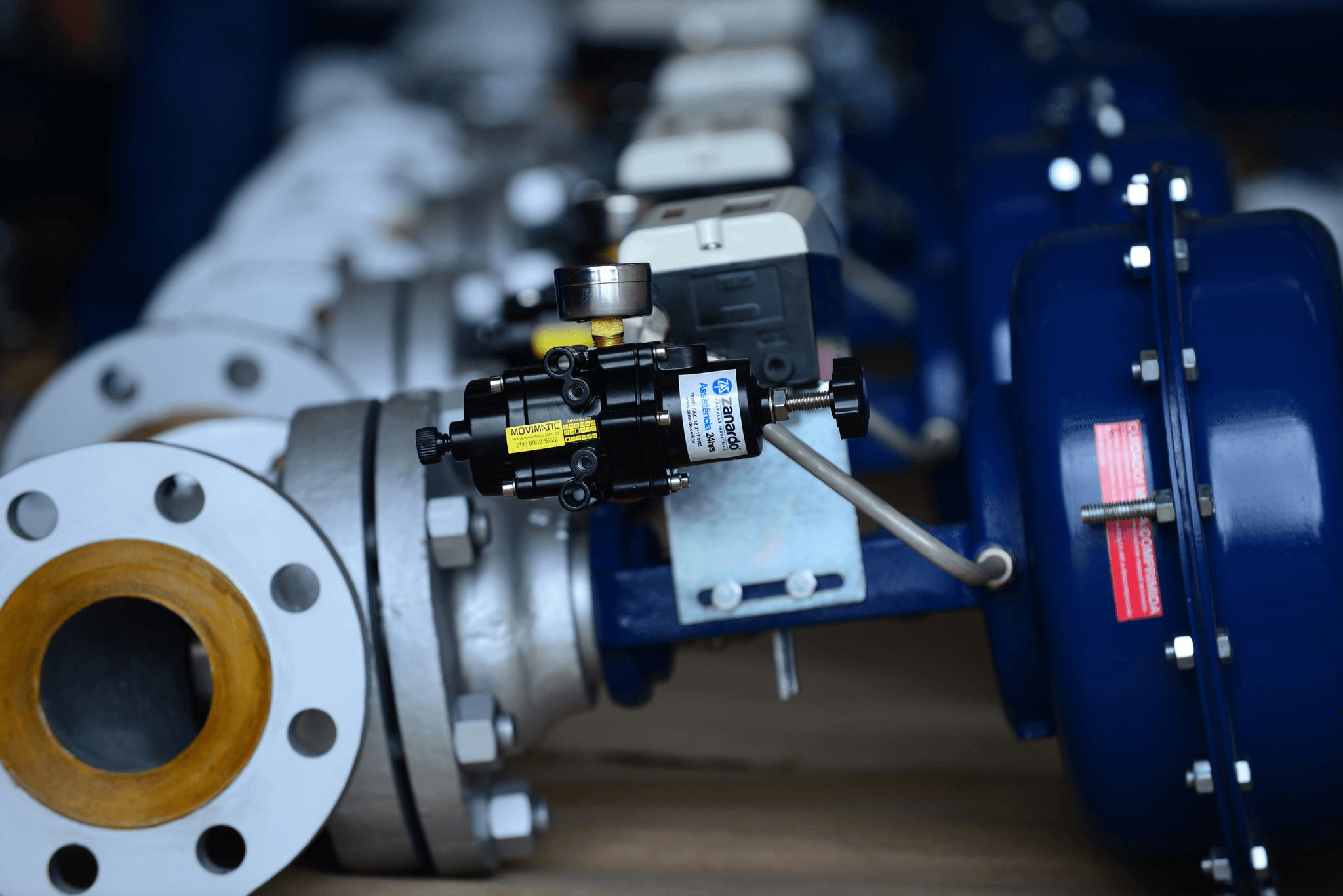

Real-World Applications

Butterfly valve actuators find their way into numerous industries due to their versatility and efficiency in controlling fluid flows. Applications range from petrochemical plants where large volumes of liquids need regulation to municipal water treatment facilities where precise flow control ensures safe drinking water supply. Additionally, sectors like food processing utilize these actuators for hygienic handling of liquids without contamination risks.

In thermal power plants or hydropower systems, motorized butterfly valves equipped with reliable actuators manage steam or water flows critical for energy generation processes effectively. By understanding real-world applications of butterfly valve actuators across industries, stakeholders can appreciate their importance in maintaining operational efficiency while adhering to safety standards.

What is an Actuator in a Valve?

An actuator is a critical component in valve systems, responsible for controlling the opening and closing of valves, including butterfly valves. Essentially, it converts energy into mechanical motion to manipulate the valve's position, thereby regulating fluid flow within a system. Understanding what an actuator is in a valve context is essential for optimizing performance and ensuring operational efficiency.

Role of Actuators in Valve Functionality

The primary role of actuators in valve functionality is to provide precise control over the flow of fluids through various pipelines. For instance, a butterfly valve actuator enables quick adjustments, allowing operators to manage flow rates effectively while minimizing pressure drops. By automating these processes, actuators enhance safety and reliability across numerous industrial applications.

Furthermore, actuators play a vital role in remote operations where manual control isn't feasible or safe. They help facilitate seamless integration with control systems that monitor and adjust parameters based on real-time data. This ability to automate processes not only improves efficiency but also reduces the risk of human error.

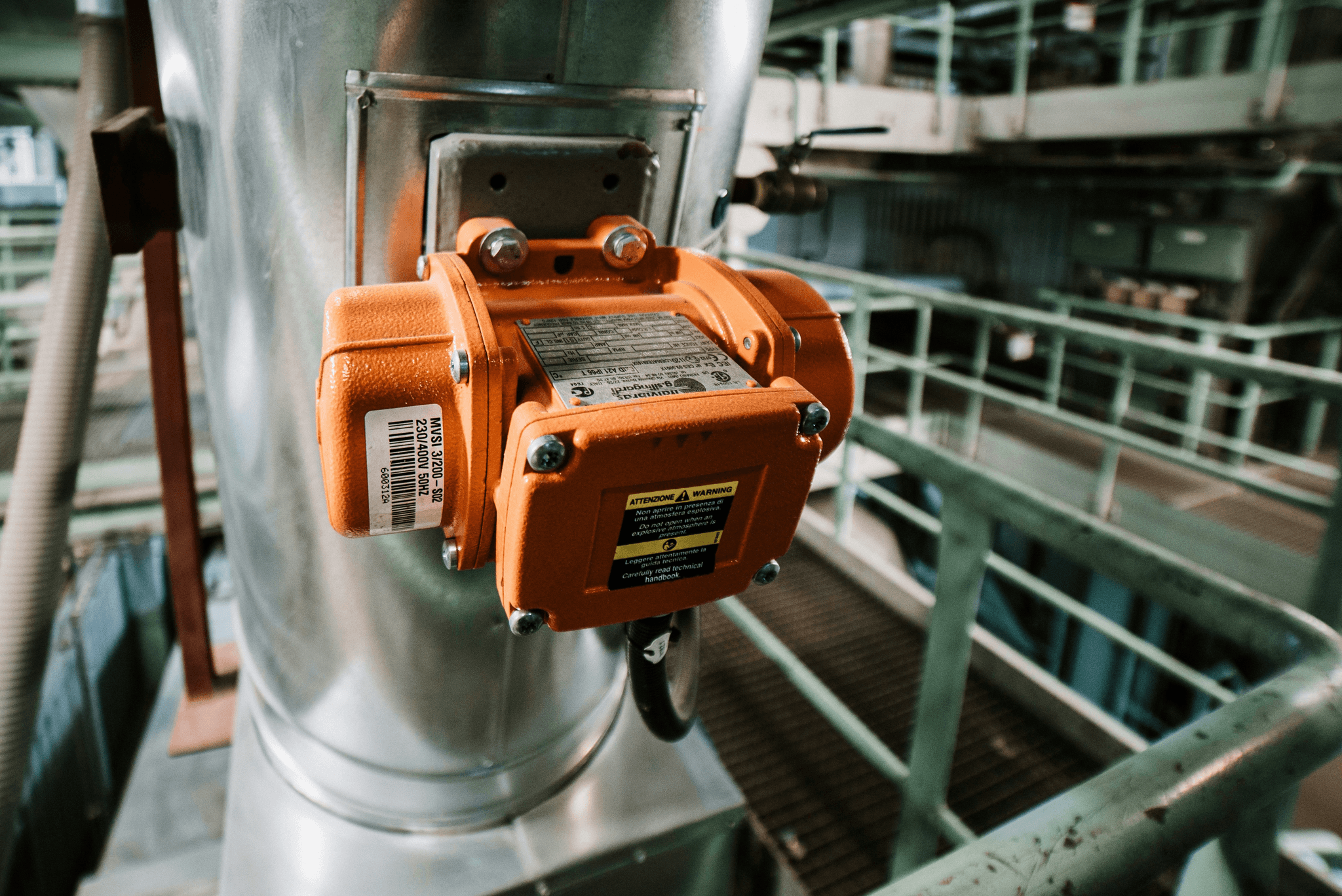

Types of Actuators: Electric, Pneumatic, and Hydraulic

When discussing what is a butterfly valve actuator specifically, it's important to note that there are three main types: electric, pneumatic, and hydraulic actuators. Electric actuators use electrical energy to create motion; they are known for their precision and ease of integration with electronic control systems. On the other hand, pneumatic actuators rely on compressed air to operate quickly and effectively but may require additional infrastructure for air supply.

Hydraulic actuators utilize pressurized fluid to generate movement; they are ideal for high-force applications but can be more complex due to fluid management requirements. Each type has its own advantages depending on the specific needs of your application—whether it's speed, power output or environmental considerations. Understanding these distinctions helps you choose the right actuator for your needs when dealing with butterfly valves or any other type.

Selecting the Right Actuator for Your Needs

Selecting the right actuator involves assessing several factors such as torque requirements, response time, installation space constraints, and environmental conditions where it will operate. For example, if you're looking at what is an actuator in a valve like a butterfly valve actuator used in harsh environments (like petrochemical plants), you might favor hydraulic options due to their robustness against extreme conditions.

Moreover, compatibility with existing systems plays a crucial role; ensure that your chosen actuator can integrate seamlessly with your current setup without requiring extensive modifications or additional components. When making this choice consider future scalability as well—will this solution still meet your needs as operations expand? Ultimately making informed decisions about which actuator aligns best with your operational goals will lead to improved efficiency and reduced downtime.

What is the Purpose of the Butterfly Valve?

Butterfly valves serve a crucial role in controlling fluid flow within various industrial systems. Understanding their purpose involves recognizing how they manage and regulate flow with minimal pressure drop, making them efficient solutions for many applications. The butterfly valve actuator enhances this functionality, ensuring precise control over the valve's position and flow rate.

Understanding Flow Control with Butterfly Valves

At its core, the butterfly valve operates by using a rotating disc to regulate flow through a pipe. When the disc is turned parallel to the flow, it allows maximum passage; conversely, when turned perpendicular, it blocks flow entirely. This simple yet effective mechanism is further enhanced by the butterfly valve actuator, which automates movement and ensures rapid response times in fluid control systems.

The ability to maintain consistent flow rates while minimizing energy loss is vital in industries like water treatment and chemical processing. By utilizing a butterfly valve actuator, operators can achieve greater efficiency and accuracy in managing these processes. Ultimately, understanding what is the function of motorized butterfly valves reveals their indispensable role in modern industrial applications.

Advantages Over Other Valve Types

Butterfly valves offer several advantages compared to other types of valves such as gate or globe valves. One significant benefit is their compact design, which allows for easier installation and less space consumption within piping systems. Additionally, they provide excellent sealing capabilities while maintaining low pressure drops across the valve.

The speed at which a butterfly valve can open or close also makes it preferable for applications requiring quick adjustments to flow rates or shut-off capabilities. With the integration of a butterfly valve actuator, these advantages are amplified through automation and remote control options that enhance operational efficiency even further. Thus, understanding what is an actuator in a valve becomes essential for optimizing system performance.

Use Cases in Different Industries

Butterfly valves are widely utilized across various industries due to their versatility and reliability in fluid control applications. In petrochemical plants, they manage high-flow liquids efficiently while ensuring safety protocols are met during operations. Similarly, water treatment facilities rely on these valves for effective regulation of water distribution processes.

In addition to petrochemical and water treatment sectors, industries such as food processing and pharmaceuticals benefit from using butterfly valves due to their ability to handle sanitary requirements effectively without compromising hygiene standards. The role of a butterfly valve actuator becomes crucial here as well—ensuring that each operation adheres strictly to industry regulations while maintaining optimal performance levels across diverse environments.

As we look towards future trends in actuation technology, it's clear that advancements will continue enhancing how we utilize tools like Haisen's QT series part-turn electric actuators alongside butterfly valves—making them even more integral to industrial processes worldwide.

Functionality of Motorized Butterfly Valves

Motorized butterfly valves are a crucial component in modern industrial applications, allowing for efficient flow control and automation. Understanding how motorized actuation works is essential to grasping the full potential of a butterfly valve actuator. By integrating motorized systems, industries can enhance their operational effectiveness while ensuring precise control over fluid dynamics.

How Motorized Actuation Works

Motorized actuation in butterfly valves involves the use of electric motors or actuators to rotate the valve disc, thereby controlling flow. This mechanism allows for quick and accurate adjustments to the valve position, which is vital when managing varying flow rates and pressure conditions. Essentially, what is an actuator in a valve? It serves as the driving force that transforms electrical signals into mechanical movement, facilitating seamless operation.

Benefits of Using Motorized Systems

The benefits of using motorized systems with butterfly valve actuators are manifold. Firstly, they provide enhanced precision in flow control compared to manual systems, reducing human error and improving overall efficiency. Additionally, what is the purpose of the butterfly valve? When paired with a motorized actuator, it optimizes performance by enabling remote operation and real-time monitoring—features that are invaluable in complex industrial settings.

Maintenance Tips for Motorized Butterfly Valves

To ensure longevity and optimal performance from your motorized butterfly valves, regular maintenance is key. Start by inspecting the actuator for any signs of wear or damage; this includes checking electrical connections and mechanical components regularly. Furthermore, understanding what is the function of a motorized butterfly valve extends beyond installation; routine lubrication and cleaning can prevent malfunctions and extend service life.

Exploring Haisen's Part-Turn Valve Electric Actuator

In the realm of butterfly valve actuators, Haisen’s QT series part-turn valve electric actuator stands out for its innovative design and functionality. This actuator is engineered to provide reliable performance in controlling various types of valves, including butterfly and ball valves. Understanding what a butterfly valve actuator can do is essential for industries looking to enhance their operational efficiency.

Features of the QT Series Actuator

Haisen's QT series actuator boasts several impressive features that make it a top choice for industrial applications. First and foremost, it offers precise control with a 90° rotation capability, making it ideal for both butterfly valves and ball valves. Additionally, this actuator supports local and remote operation, providing flexibility in how you manage your flow control systems.

Another noteworthy feature is its robust construction designed to withstand challenging environments commonly found in sectors such as petrochemical and metallurgy. The device also incorporates advanced technology that ensures energy efficiency while maintaining high-performance levels. When considering what is an actuator in a valve context, the QT series exemplifies how modern engineering meets practical needs.

Applications in Butterfly and Ball Valves

The versatility of Haisen's QT series part-turn valve electric actuator makes it suitable for various applications across multiple industries. In particular, its ability to control butterfly valves allows for effective flow regulation in processes such as water treatment and chemical processing. Moreover, its compatibility with ball valves adds another layer of functionality that many industrial setups require.

In sectors like shipbuilding and food production, where precision is paramount, this actuator helps maintain optimal conditions by ensuring smooth operation of the valves involved. By understanding what is the purpose of the butterfly valve within these contexts—such as controlling fluid dynamics—the role of Haisen’s actuator becomes even clearer. It not only enhances process efficiency but also contributes to safety standards across diverse applications.

Why Choose Haisen for Your Actuation Needs

Choosing Haisen means investing in quality, reliability, and innovation tailored specifically for your actuation needs. With their QT series part-turn valve electric actuator leading the charge in technology advancements, you can trust that your operations will benefit from superior performance over time. What is the function of motorized butterfly valves? It’s about achieving seamless automation without compromising on safety or effectiveness—qualities that Haisen embodies.

Furthermore, Haisen has established itself as a reputable brand within industries like thermal power and hydropower due to its commitment to customer satisfaction and product excellence. Their actuators are designed not just to meet current demands but also adapt to future trends in actuation technology—a crucial factor when selecting equipment for long-term projects. Ultimately, opting for Haisen means equipping yourself with cutting-edge solutions that enhance productivity while ensuring peace of mind.

Conclusion

In summary, the butterfly valve actuator is a pivotal component in modern industrial applications, providing efficient flow control across various sectors. Understanding what a butterfly valve actuator is and its role in valve functionality can significantly enhance operational efficiency. By recognizing the purpose of the butterfly valve and the function of motorized butterfly valves, industries can make informed decisions that align with their specific needs.

Key Takeaways on Butterfly Valve Actuators

Butterfly valve actuators play an essential role in regulating fluid flow within pipelines, making them indispensable in many industrial processes. What is a butterfly valve actuator? It is a device that enables precise control over the opening and closing of a butterfly valve, ensuring optimal performance. The advantages of using these actuators include reduced energy consumption and improved reliability compared to traditional manual systems.

Making Informed Choices for Industrial Needs

When selecting an actuator for your valves, it's crucial to consider factors such as type, application, and operational environment. What is an actuator in a valve? It serves as the mechanism that controls the positioning of the valve's disc or ball to manage fluid flow effectively. By understanding what is the purpose of the butterfly valve and evaluating your options—whether electric, pneumatic, or hydraulic—you can ensure that you choose an actuator that meets your specific operational requirements.

Future Trends in Actuation Technology

The future of actuation technology looks promising with advancements aimed at increasing efficiency and automation across industries. Innovations are likely to focus on enhancing connectivity features for remote monitoring and control while improving energy efficiency standards for devices like motorized butterfly valves. As industries evolve, understanding what is the function of motorized butterfly valves will be critical for staying ahead in this rapidly changing landscape.