Introduction

When it comes to airport operations, ensuring the safety of runway surfaces is paramount. This is where coefficient of friction testing equipment plays a crucial role in measuring airport runway friction levels. Haisen's BHM01/02 Surface Friction Tester is at the forefront of this technology, offering advanced features to enhance runway safety and compliance.

Understanding the Importance of Runway Safety

Runway safety is essential for safe landing and takeoff, as well as overall aircraft performance. Measuring airport runway friction levels through coefficient of friction testing equipment ensures that the surface can handle various weather conditions and comply with aviation regulations.

The Need for Advanced Friction Testing Equipment

Advanced friction testing equipment such as Haisen's BHM01/02 Surface Friction Tester is necessary to conduct runway surface friction testing accurately and efficiently. This equipment plays a critical role in maintaining safe airport operations and complying with industry standards.

Key Features of Haisen's BHM01/02 Surface Friction Tester

Haisen's BHM01/02 Surface Friction Tester boasts safety design and reliability, with high-precision components and specialized test tires compliant with aviation regulations. It also features computer control for continuous testing and a water system for high-altitude testing.

The Significance of Coefficient of Friction Testing Equipment

Measuring Airport Runway Friction Levels is crucial for ensuring safe landing and takeoff. With advanced coefficient of friction testing equipment like Haisen's BHM01/02 Surface Friction Tester, airports can accurately assess runway conditions to prevent skidding and ensure the safety of aircraft operations.

Ensuring Safe Landing and Takeoff

Runway friction testing is essential for determining the grip levels on airport surfaces, which directly impact the ability of aircraft to land and take off safely. By using specialized test tires and computer control, Haisen's BHM01/02 Surface Friction Tester provides accurate measurements to help maintain optimal runway conditions. This is crucial for ensuring that aircraft can operate efficiently and safely in various weather conditions, including rain, snow, or ice. Without proper friction levels, planes may experience difficulty braking or accelerating, putting passengers and crew at risk.

Impact on Aircraft Performance

The coefficient of friction on an air track directly affects aircraft performance during critical phases of flight. By utilizing advanced friction testing equipment, airports can ensure that runway surfaces meet the necessary standards for minimizing braking distances and maintaining control during landing and takeoff.

Compliance with Aviation Regulations

To comply with aviation regulations, airports must conduct regular runway surface friction testing to ensure that the coefficient of friction meets required standards. Haisen's BHM01/02 Surface Friction Tester offers reliable calibration capabilities, allowing airports to adhere to regulatory requirements while ensuring the safety of aircraft operations.

In addition to ensuring compliance with aviation regulations, regular runway surface friction testing also helps airports maintain high safety standards and reduce the risk of accidents. By using Haisen's BHM01/02 Surface Friction Tester, airports can proactively identify and address any potential issues with runway friction, ultimately enhancing the overall safety of aircraft operations. This proactive approach not only helps airports meet regulatory requirements but also demonstrates a commitment to prioritizing the safety of passengers and crew.

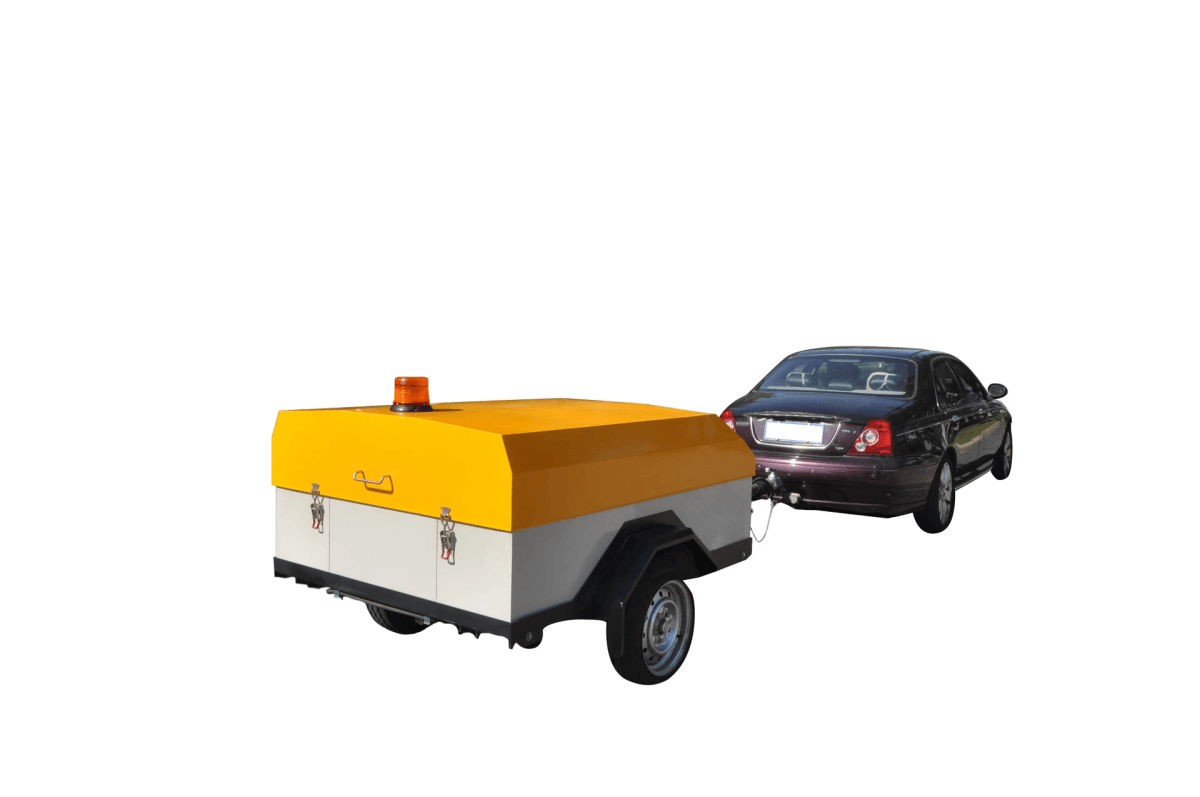

Haisen's BHM01/02 Surface Friction Tester Features

Haisen's BHM01/02 Surface Friction Tester is designed with safety and reliability in mind, maintaining original vehicle systems for safety and performance, with a reinforced trunk for testing equipment. This advanced coefficient of friction testing equipment uses high-precision components and an industrial-grade laptop with a Chinese interface for reliable operation, ensuring accurate results every time.

Safety Design and Reliability

The safety design of Haisen's BHM01/02 Surface Friction Tester ensures that it maintains the original vehicle systems for safety and performance, while also incorporating a reinforced trunk specifically designed for the testing equipment. This innovative approach prioritizes the safety of airport operations while providing reliable and accurate friction testing results.

The BHM01/02 Surface Friction Tester also features advanced acceleration capabilities, allowing for precise and efficient testing of runway surfaces. This ensures that airports can quickly and accurately assess the friction levels of their runways, leading to improved safety and performance for all aircraft. Additionally, the tester's calibration capabilities guarantee that the equipment is always operating at optimal levels, providing consistent and reliable results for airport operators.

Acceleration and Calibration Capabilities

With acceleration capabilities that allow vehicles like Ford Taurus 2.7T and Honda Acura to reach 96 km/h within 200 meters, Haisen's BHM01/02 Surface Friction Tester provides efficient and effective testing procedures. Additionally, the equipment features an accurate and easy-to-use external electronic calibration device, ensuring precise measurements at all times.

Furthermore, the BHM01/02 Surface Friction Tester is equipped with specialized test tires that are designed to simulate real-world driving conditions, ensuring accurate and reliable results. These test tires are carefully engineered to provide consistent and repeatable measurements, allowing for precise assessment of surface friction levels. With these specialized test tires, the BHM01/02 Surface Friction Tester offers a comprehensive solution for evaluating road surface conditions.

Specialized Test Tires and Computer Control

Haisen's BHM01/02 Surface Friction Tester utilizes specialized tires compliant with CAAC, ICAO, and FAA standards, featuring 0.7MPa pressure to ensure accurate friction testing on airport runways. The equipment is also equipped with computer control operated by a Chinese Windows OS laptop pre-programmed for continuous testing, making it user-friendly and efficient in conducting runway friction tests.

Furthermore, the specialized tires of the BHM01/02 Surface Friction Tester are designed to withstand the high pressures and speeds encountered during runway testing, ensuring accurate and reliable results. The computer control system allows for precise monitoring and adjustment of testing parameters, giving operators full control over the testing process. This advanced technology not only improves the accuracy of friction testing but also enhances overall safety and efficiency in airport operations.

The Role of Advanced Friction Testing Equipment in Airport Operations

Measuring Airport Runway Friction Levels is crucial for ensuring safe takeoff and landing of aircraft. With advanced coefficient of friction testing equipment like Haisen's BHM01/02 Surface Friction Tester, airports can accurately assess the condition of their runway surfaces to enhance safety measures.

Enhancing Runway Safety Measures

What is runway friction testing? It is a method used to measure the level of grip between an aircraft's tires and the runway surface. By conducting regular tests with specialized equipment like Haisen's BHM01/02, airports can identify areas that require maintenance or improvement to ensure optimal friction levels for safe aircraft operations.

Runway friction testing also helps airports to comply with regulatory requirements for maintaining safe runway conditions. By regularly monitoring and assessing friction levels, airports can demonstrate their commitment to safety and ensure that they meet the standards set by aviation authorities. This proactive approach not only enhances safety but also improves the overall efficiency of aircraft operations by reducing the risk of runway-related incidents and delays.

Improving Efficiency of Aircraft Operations

The coefficient of friction on an air track directly impacts the performance and efficiency of aircraft operations. With reliable and precise testing equipment, airport authorities can proactively address any issues related to runway surface friction, leading to smoother takeoffs and landings, as well as improved overall operational efficiency.

By addressing issues related to runway surface friction, airport authorities can also enhance overall airport safety and compliance. A higher coefficient of friction reduces the risk of skidding and hydroplaning during adverse weather conditions, making takeoffs and landings safer for both passengers and crew. Additionally, maintaining optimal runway surface friction levels ensures that airports are in compliance with industry safety standards, reducing the likelihood of accidents or incidents.

Impact on Overall Airport Safety and Compliance

How do you test the coefficient of friction? Advanced friction testing equipment like Haisen's BHM01/02 provides accurate measurements that help airports comply with aviation regulations by maintaining optimal runway surface friction levels. This ensures the safety and compliance of airport operations while also minimizing potential risks associated with low-friction surfaces.

Investing in advanced coefficient of friction testing equipment also allows airports to proactively identify and address potential runway surface issues before they escalate into safety hazards. By regularly testing the coefficient of friction, airports can detect any decreases in surface grip and take prompt corrective actions to maintain optimal safety levels. This proactive approach not only enhances overall airport safety but also demonstrates a commitment to compliance with aviation regulations, earning the trust and confidence of passengers and airlines.

Applications and Benefits of Haisen's BHM01/02 Surface Friction Tester

Water System and High-Altitude Testing

Haisen's BHM01/02 Surface Friction Tester is equipped with a robust water system, including a 580L/620L tank, allowing for comprehensive testing over distances of up to 7000 meters. This feature enables accurate assessment of runway friction levels in various weather conditions, including wet runways and high-altitude locations.

Additionally, the water system of the BHM01/02 Surface Friction Tester is designed to withstand high-altitude testing, ensuring accurate results even in challenging conditions. This capability makes it an invaluable tool for airports located in mountainous regions or at high elevations, where traditional friction testers may struggle to provide reliable data. With this advanced water system, Haisen's friction tester sets a new standard for precision and reliability in runway friction assessment at high altitudes.

Achievements and Success Stories

With over 200 units in use at airports worldwide, including high-altitude locations, Haisen's BHM01/02 Surface Friction Tester has demonstrated its effectiveness in ensuring safe landing and takeoff conditions for aircraft. The reliability and precision of the equipment have contributed to its widespread adoption and success in enhancing runway safety measures. As the demand for safer aviation operations continues to grow, Haisen is committed to further developing the capabilities of its Surface Friction Tester. This includes exploring advanced sensor technologies and data analysis techniques to provide even more accurate and real-time information to airport authorities and airline operators.

Future Developments and Enhancements

As a leader in coefficient of friction testing equipment, Haisen is committed to continuous improvement and innovation. Future developments may involve advanced technological enhancements to further improve accuracy and efficiency in measuring airport runway friction levels, ensuring the highest standards of safety for aircraft operations. One potential area of focus for Haisen is the development of real-time data analysis capabilities, allowing for immediate adjustments to be made based on changing runway conditions. Additionally, the integration of machine learning algorithms could enable the equipment to adapt and optimize its measurements over time, providing even more precise and reliable results. These advancements will not only benefit airport operations but also contribute to the overall advancement of friction testing technology in various industries.

Conclusion

Investing in Advanced Runway Coefficient of Friction Testing Equipment

As airports strive to maintain safe runway conditions, investing in advanced coefficient of friction testing equipment like Haisen's BHM01/02 Surface Friction Tester is crucial. With its safety design and reliability, it ensures accurate measurements of runway surface friction levels, contributing to enhanced airport safety. In addition, the Haisen BHM01/02 Surface Friction Tester is user-friendly and easy to operate, making it an ideal choice for airport maintenance teams. Its portability also allows for quick and efficient testing across multiple runway surfaces without disrupting regular airport operations.

Ensuring the Safety and Compliance of Airport Operations

Measuring airport runway friction levels is essential for ensuring safe landing and takeoff, as well as compliance with aviation regulations. The use of specialized test tires and computer control in Haisen's BHM01/02 Surface Friction Tester provides reliable data for maintaining safe runway conditions.

Furthermore, advancements in runway safety technology are also focusing on real-time monitoring and reporting of friction levels. This allows airport authorities to quickly identify and address any areas of concern, reducing the risk of accidents and delays. With the integration of data analytics and predictive maintenance, airports can proactively manage runway conditions to ensure optimal safety for all aircraft operations.

The Future of Runway Safety Technology

As technology continues to advance, the future of runway safety technology looks promising. With the innovative features of Haisen's BHM01/02 Surface Friction Tester, such as water system and high-altitude testing capabilities, airports can expect further enhancements in ensuring safe and efficient aircraft operations. Additionally, the ability of this advanced friction tester to provide real-time data and analysis will allow airports to make proactive decisions in maintaining safe runway conditions. Furthermore, the integration of artificial intelligence and machine learning into runway safety technology will enable predictive maintenance, reducing downtime and enhancing overall operational efficiency for airports.