Introduction

When it comes to ensuring safe runway conditions, friction measurement plays a crucial role in maintaining the safety of aircraft operations. By accurately measuring the friction between the runway surface and aircraft tires, potential hazards can be identified and mitigated, ultimately enhancing overall runway safety. As advanced technology continues to evolve, so do the methods for testing and measuring friction on airport runways. The introduction of innovative equipment such as the BHM01/02 Surface Friction Tester has significantly contributed to improving runway safety by providing reliable and accurate measurements.

Importance of Friction Measurement in Runway Safety

The importance of friction measurement in ensuring runway safety cannot be overstated. Accurate friction measurements enable airport authorities and aviation professionals to assess the surface conditions of runways, allowing them to take necessary precautions for safe takeoffs and landings. By understanding how friction is measured and its impact on aircraft performance, airport personnel can proactively address potential safety concerns, ultimately reducing the risk of accidents or incidents on runways.

Evolution of Advanced Friction Testing Methods

Over time, there has been a significant evolution in advanced friction testing methods used in aviation operations. From traditional methods to more sophisticated techniques, such as Runway Friction Tester (RFT) testing, there has been a continuous effort to enhance the accuracy and reliability of friction measurements on airport runways. These advancements have not only improved overall runway safety but have also contributed to optimizing aircraft performance during critical maneuvers.

The Role of BHM01/02 Surface Friction Tester in Runway Safety

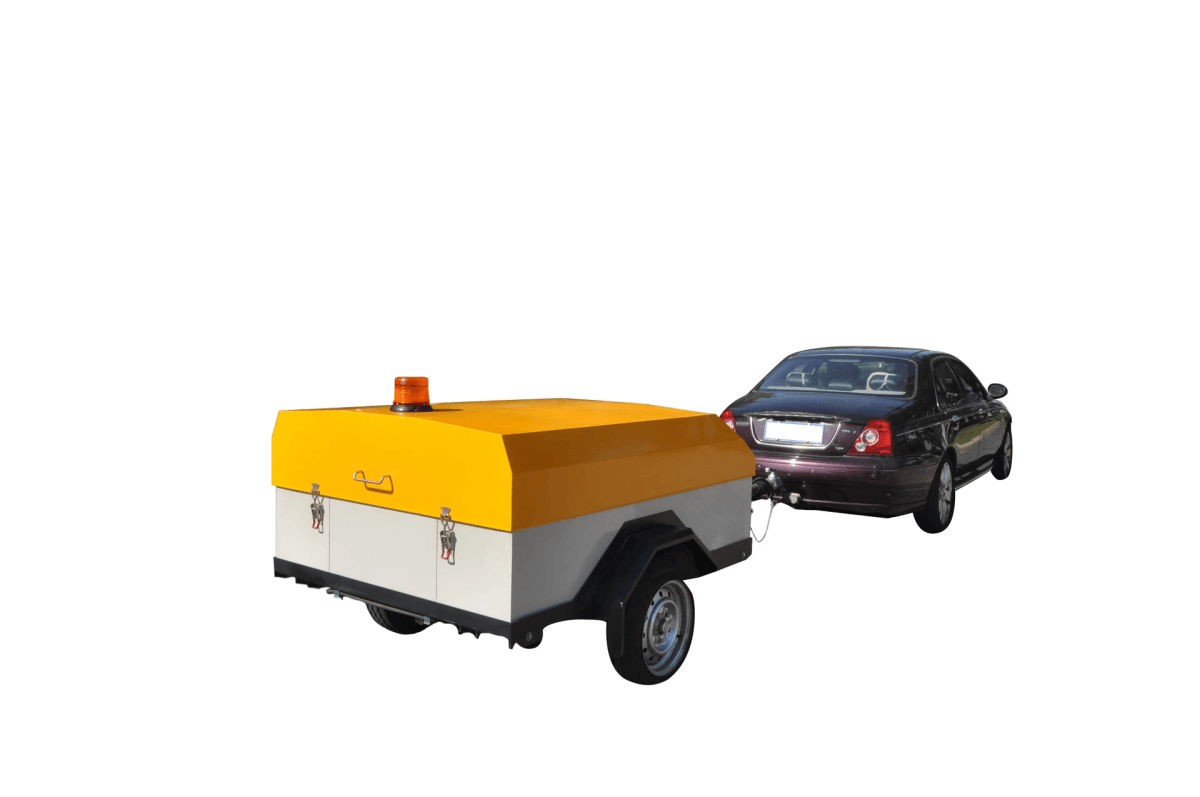

The BHM01/02 Surface Friction Tester has emerged as a pivotal tool in ensuring runway safety through accurate friction measurement. With its safety design that maintains original vehicle systems while reinforcing the trunk for testing equipment, this innovative tester prioritizes both safety and performance. Additionally, its reliability is upheld by high-precision components and an industrial-grade laptop with a Chinese interface for dependable operation.

Understanding Friction Measurement

Friction measurement is the process of assessing the resistance between two surfaces in contact, crucial for ensuring safe runway conditions. Accurate friction measurement allows for the evaluation of surface conditions and potential hazards, making it a critical component of runway safety protocols.

What is Friction Measurement and Why It Matters

Friction measurement involves quantifying the force required to move one surface relative to another, providing essential data for assessing runway safety. By measuring friction, aviation authorities can identify areas with low traction, reducing the risk of accidents due to slippery runways and ensuring safe takeoffs and landings.

The Science Behind Friction Measurement

The science behind friction measurement lies in understanding the interaction between surfaces and the forces that influence their resistance to motion. This includes factors such as surface texture, contaminants, and environmental conditions that can impact friction levels on runways.

Key Parameters for Accurate Friction Testing

Key parameters for accurate friction testing include the use of reliable equipment such as the Haisen BHM01/02 Surface Friction Tester. This advanced machine utilizes high-precision components and specialized tires compliant with aviation standards to ensure precise and consistent results in measuring runway friction.

Advanced Methods for Measuring Friction

When it comes to advanced methods for measuring friction, Haisen's BHM01/02 Surface Friction Tester stands out as a reliable and high-precision solution. This state-of-the-art equipment is designed with safety in mind, maintaining the original vehicle systems for safety and performance while also featuring a reinforced trunk for testing equipment. With its industrial-grade laptop and high-precision components, this friction tester ensures reliable operation and accurate results.

A key aspect of using reliable equipment for accurate friction measurement is the calibration process. Haisen's BHM01/02 Surface Friction Tester features an accurate and easy-to-use external electronic calibration device, ensuring that the measurements are precise and consistent. Additionally, the specialized tires used in this friction testing machine are compliant with CAAC, ICAO, and FAA standards, with 0.7MPa pressure, further enhancing the reliability of the testing process.

Maximizing safety with high-precision components is essential in friction measurement to ensure that accurate results are obtained without compromising on safety standards. The BHM01/02 Surface Friction Tester achieves this by using components that meet stringent quality standards, allowing for precise measurements while maintaining a safe testing environment.

RFT Testing and Evaluation

RFT testing plays a crucial role in ensuring runway safety by accurately measuring friction levels to prevent skidding and sliding during takeoff and landing. With the use of advanced friction testing methods, such as the BHM01/02 Surface Friction Tester, airports can maintain optimal runway conditions for safe aircraft operations.

The Impact of RFT Testing on Runway Safety

Measuring friction is essential for maintaining safe runway conditions, as it directly impacts an aircraft's ability to decelerate or accelerate during critical phases of flight. Accurate friction measurement helps in preventing hydroplaning, ensuring effective braking action, and reducing the risk of runway excursions, ultimately enhancing overall aviation safety.

Evaluating Friction Tester Machine Performance

The performance of a friction tester machine is crucial in obtaining reliable friction measurements for runway safety. The BHM01/02 Surface Friction Tester from Haisen is designed with high-precision components and advanced safety features to ensure accurate and consistent results, making it a dependable tool for evaluating and maintaining optimal runway conditions.

Understanding the Role of RFT Full Form in Software Testing

In software testing, RFT stands for Rational Functional Tester, which is a tool used to automate functional and regression testing of software applications. While this may not be directly related to runway safety, it's important to understand the different contexts in which RFT is used across various industries.

Best Practices for Friction Measurement

When it comes to ensuring accuracy in friction testing, using reliable equipment is key. The Haisen BHM01/02 Surface Friction Tester is designed with safety and reliability in mind, featuring high-precision components and industrial-grade laptop for dependable operation. With a reinforced trunk for testing equipment and specialized tires compliant with industry standards, the Haisen tester ensures accurate and consistent results for friction measurement.

Ensuring Accuracy in Friction Testing

Accurate friction testing is crucial for maintaining safe runway conditions. The Haisen BHM01/02 Surface Friction Tester employs advanced technology to measure friction accurately, providing essential data for assessing runway safety. With its reliable components and precise calibration, this tester ensures that friction measurements are consistent and dependable, contributing to enhanced aviation safety.

Importance of Regular Calibration in Friction Measurement

Regular calibration of friction testing equipment is essential to maintain accuracy in measurements. The Haisen tester features an external electronic calibration device that is accurate and easy to use, ensuring that the machine is always calibrated correctly for precise friction testing. This regular calibration helps to uphold the integrity of the data obtained from the tester, providing reliable information for runway safety assessments.

Selecting the Right Friction Testing Machine for Your Needs

Selecting the right friction testing machine is crucial for obtaining accurate measurements. The Haisen BHM01/02 Surface Friction Tester offers a comprehensive solution with its safety design, reliability, and precision components. Its compatibility with industry standards such as CAAC, ICAO, and FAA makes it an ideal choice for airports looking to invest in a high-quality friction testing machine that meets their specific needs.

Future of Friction Measurement Technology

As technology continues to advance, so does the innovation in friction testing equipment. Companies like Haisen are at the forefront of developing state-of-the-art friction tester machines that offer unparalleled accuracy and reliability in measuring runway friction. These advanced equipment are designed to meet the evolving needs of the aviation industry, ensuring that runways remain safe for aircraft operations.

Innovations in Friction Testing Equipment

Haisen's friction testing equipment is equipped with safety design features that maintain original vehicle systems for safety and performance, while also having a reinforced trunk for testing equipment. The reliability of these machines is evident through their use of high-precision components and an industrial-grade laptop with a Chinese interface for reliable operation. This ensures that accurate and consistent friction measurements can be obtained, contributing to enhanced runway safety.

Role of AI in Advancing Friction Measurement

Artificial intelligence (AI) is playing a significant role in advancing friction measurement technology. With AI integration, friction tester machines can analyze data more efficiently, identify patterns, and provide insights that contribute to improved accuracy in measuring runway friction. This advancement allows for better decision-making in maintaining safe runway conditions and optimizing aircraft operations.

Adapting Friction Measurement to Evolving Industry Standards

As industry standards continue to evolve, it's crucial for friction measurement technology to adapt accordingly. Friction tester machines need to meet the requirements set by organizations such as CAAC, ICAO, and FAA, ensuring that they comply with the latest regulations for accurate and reliable measurements. Adapting to these standards guarantees that airports can maintain safe operating conditions on their runways.

Conclusion

In conclusion, the accurate measurement of friction is crucial for ensuring safe runway conditions and enhancing overall aviation operations. By utilizing advanced technology such as the Haisen BHM01/02 Surface Friction Tester, airports can rely on reliable and high-precision components to measure friction accurately. The RFT testing and evaluation process plays a vital role in maintaining runway safety, and selecting the right friction testing machine is essential for achieving accurate results.

Ensuring Safe Runway Conditions Through Accurate Friction Measurement

Accurate friction measurement is essential for ensuring safe runway conditions, as it directly impacts aircraft performance during takeoff and landing. With the use of reliable equipment such as the Haisen BHM01/02 Surface Friction Tester, airports can maintain high standards of safety by accurately measuring friction levels on runways. This allows for proactive maintenance and ensures that runways are always in optimal condition for aircraft operations.

By leveraging advanced technology such as the Haisen BHM01/02 Surface Friction Tester, airports can also gather real-time data on runway conditions, allowing for immediate response to any changes in friction levels. This proactive approach ensures that runways are always safe for aircraft operations, reducing the risk of accidents and delays. Additionally, accurate friction measurement enables airports to make informed decisions about runway maintenance and resurfacing, ultimately saving time and resources in the long run.

Leveraging Advanced Technology for Enhanced Runway Safety

By leveraging advanced technology in friction measurement, airports can enhance runway safety and minimize the risk of accidents due to inadequate friction levels. The Haisen BHM01/02 Surface Friction Tester utilizes high-precision components and industrial-grade laptops to provide reliable operation and accurate results. This cutting-edge technology enables airports to stay ahead of potential safety issues by proactively monitoring and maintaining optimal runway conditions.

By implementing the Haisen BHM01/02 Surface Friction Tester, airports can ensure that runways are maintained at optimal friction levels, reducing the likelihood of accidents caused by slippery surfaces. This advanced technology provides real-time data on runway conditions, allowing airport personnel to take immediate action if friction levels fall below safety standards. With the ability to proactively monitor and address potential safety hazards, airports can uphold their commitment to passenger and aircraft safety, ultimately enhancing their reputation as a reliable and secure travel hub.

The Importance of Friction Measurement in Aviation Operations

Friction measurement plays a critical role in aviation operations by directly impacting aircraft performance, especially during critical phases such as takeoff and landing. Accurate friction testing is essential for ensuring that runways meet industry standards for safety, which ultimately contributes to overall aviation safety. With the right friction testing equipment in place, airports can uphold stringent safety measures and prioritize the well-being of passengers and crew.

Furthermore, friction measurement also plays a crucial role in preventing runway overruns and undershoots, which can have catastrophic consequences for aircraft and passengers. By regularly testing and monitoring the friction levels of runways, airports can identify potential hazards and take proactive measures to address any issues before they escalate. This proactive approach not only enhances aviation safety but also minimizes the risk of accidents or incidents during takeoff and landing.