Introduction

When it comes to ensuring safety and performance in various industries, the coefficient of friction test equipment plays a crucial role. One such advanced tool is the Coefficient of Friction Tester (COF) from Haisen, known for its precision and reliability. This cutting-edge equipment is designed to measure surface friction and provide valuable insights into safety and quality standards across different applications.

Understanding the Importance of Coefficient of Friction Test Equipment

The coefficient of friction test equipment is essential for evaluating the grip and traction between two surfaces, making it vital for ensuring safety in aviation, automotive, and material testing industries. With Haisen's BHM01/02 Surface Friction Tester, businesses can accurately measure the frictional properties of various materials and surfaces, leading to improved safety measures and enhanced product quality.

Key Features of Haisen's BHM01/02 Surface Friction Tester

Haisen's COF tester stands out with its safety design that maintains original vehicle systems for optimal performance during testing. It also boasts high-precision components and an industrial-grade laptop with a Chinese interface for reliable operation. The inclusion of specialized test tires compliant with aviation standards further enhances its accuracy in measuring surface friction.

Applications of Advanced Coefficient of Friction Test Equipment

The applications of advanced coefficient of friction test equipment are diverse, ranging from airport runway pavement friction coefficient testing to continuous friction measurement in the automotive industry. Haisen's COF tester has been instrumental in ensuring material safety and quality across various sectors by providing accurate data on surface friction characteristics.

The Role of Coefficient of Friction Test Equipment

As the demand for safer airport runways increases, the use of coefficient of friction test equipment such as the Continuous Friction Coefficient Tester becomes crucial. By accurately measuring the pavement friction coefficient, airports can ensure safe landing and takeoff conditions for aircraft, minimizing the risk of accidents and improving overall safety.

Impact on Airport Runway Safety

The Continuous Friction Coefficient Tester plays a vital role in maintaining airport runway safety by providing real-time data on pavement friction. This allows airport authorities to identify areas with low friction coefficients and take necessary measures to improve traction, reducing the risk of skidding during aircraft operations. With advanced equipment like Haisen's Airport Surface Friction Test Equipment, airports can enhance safety measures and prevent potential accidents.

Importance in Automotive Industry

In the automotive industry, coefficient of friction testing equipment is essential for ensuring vehicle safety and performance. Continuous friction measuring equipment enables manufacturers to evaluate tire-road interaction and optimize vehicle handling characteristics. By utilizing advanced technology like Haisen's Friction Testing Equipment, automotive companies can enhance vehicle stability and maneuverability, ultimately improving overall driving experience and safety on the roads.

Significance in Material Testing

The significance of coefficient of friction test equipment extends to material testing across various industries. From evaluating packaging materials for slip resistance to assessing industrial flooring for workplace safety, accurate measurement of the coefficient of friction is crucial. With reliable equipment like Haisen's Coefficient of Friction Tester (COF), businesses can ensure product quality, minimize risks related to slippery surfaces, and maintain a safe working environment for employees.

Additionally, the coefficient of friction test equipment is essential for evaluating the performance of materials in extreme conditions. Whether it's testing the slip resistance of materials in wet environments or assessing the durability of flooring in high-traffic areas, accurate measurement of friction coefficients helps businesses make informed decisions about material selection. This can lead to cost savings by avoiding frequent replacements and repairs, as well as ensuring that products meet safety standards and regulations.

Haisen's BHM01/02 Surface Friction Tester Features

Safety Design and Original Vehicle Systems

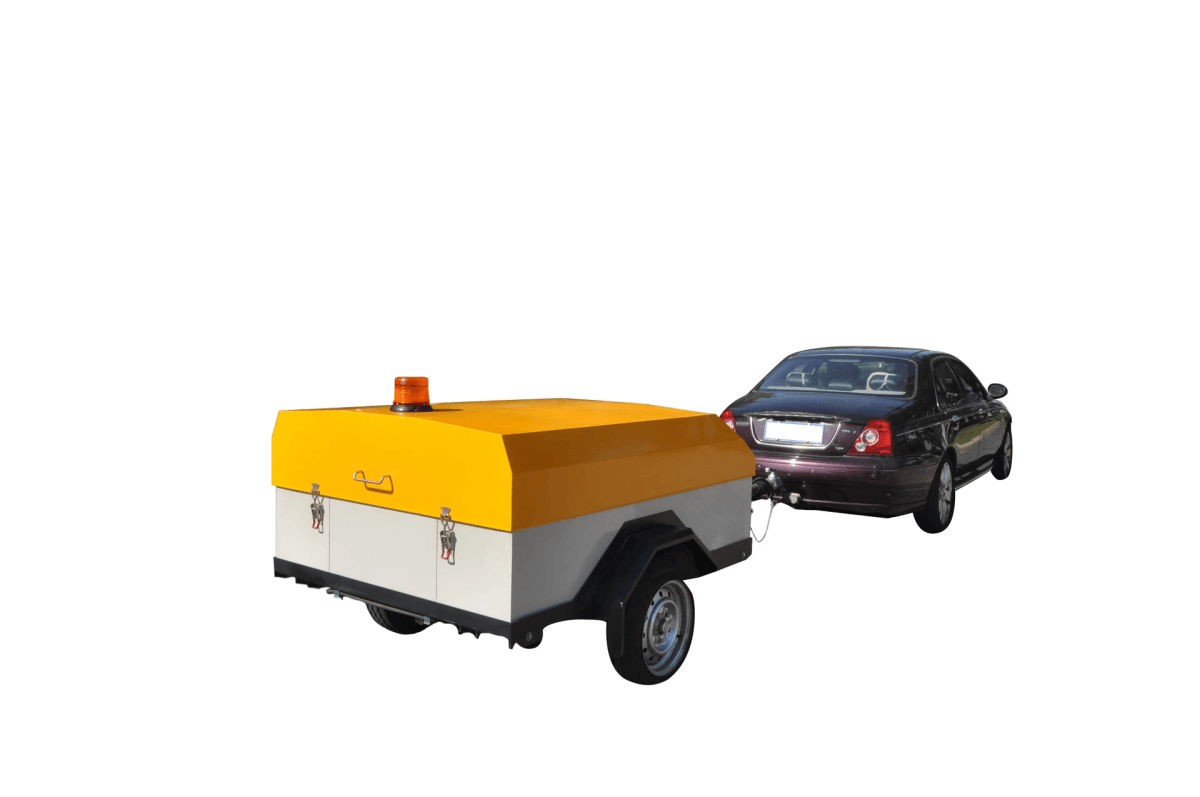

Haisen's BHM01/02 Surface Friction Tester maintains original vehicle systems for safety and performance, with a reinforced trunk for testing equipment. This ensures that the COF tester is securely installed and does not compromise the vehicle's integrity during testing, providing reliable and accurate results for friction testing equipment.

Reliability with High-Precision Components

The COF tester uses high-precision components and an industrial-grade laptop with a Chinese interface for reliable operation. This guarantees the accuracy of the friction measurements, making it a trustworthy tool for various applications in airport runway pavement friction coefficient testing, continuous friction measuring equipment, and more.

Calibration and Specialized Test Tires

Haisen's BHM01/02 Surface Friction Tester features an accurate and easy-to-use external electronic calibration device to ensure precise measurements. In addition, it uses specialized tires compliant with CAAC, ICAO, and FAA standards, with 0.7MPa pressure, making it suitable for a wide range of friction testing applications.

Furthermore, the specialized tires used in Haisen's BHM01/02 Surface Friction Tester are designed to withstand the rigorous demands of airport runway testing. With a pressure of 0.7MPa, these tires provide reliable and consistent performance across various surface conditions, ensuring accurate friction measurements in any environment. This level of durability and precision makes the tester an essential tool for maintaining aviation safety standards and optimizing runway maintenance.

Applications of Coefficient of Friction Test Equipment

Airport Runway Pavement Friction Coefficient Testing

The Airport runway pavement friction coefficient tester, such as Haisen's BHM01/02 Surface Friction Tester, plays a crucial role in ensuring the safety of airport runways. By accurately measuring the friction coefficient of the pavement, it helps airport authorities to identify potential hazards and take necessary measures to maintain safe landing and takeoff conditions for aircraft. This advanced friction testing equipment is essential for preventing accidents and ensuring smooth operations at airports.

Continuous Friction Measurement in Automotive Industry

In the automotive industry, continuous friction measuring equipment is indispensable for evaluating the performance of tires and road surfaces. Haisen's COF tester provides reliable data on the friction coefficient between tires and different road conditions, enabling manufacturers to develop safer and more efficient vehicles. With precise measurements and high-tech features, this equipment contributes to enhancing vehicle stability, handling, and overall safety on the roads.

Furthermore, continuous friction measurement equipment plays a crucial role in ensuring the safety and quality of materials used in automotive manufacturing. By accurately assessing the friction coefficient between tires and various road surfaces, manufacturers can select the most suitable materials for optimal performance and durability. This not only leads to the production of high-quality vehicles but also reduces the risk of accidents caused by inadequate traction or unstable handling.

Importance in Ensuring Material Safety and Quality

The use of coefficient of friction test equipment goes beyond aviation and automotive sectors; it also plays a vital role in ensuring material safety and quality across various industries. From evaluating the slip resistance of flooring materials to assessing the friction properties of packaging materials, this testing equipment helps businesses adhere to safety standards and deliver high-quality products to consumers. With Haisen's advanced technology, manufacturers can conduct thorough testing to guarantee that their materials meet regulatory requirements.

In addition to evaluating slip resistance and friction properties, coefficient of friction test equipment is also crucial for testing the durability and performance of materials in various environmental conditions. Whether it's simulating the wear and tear on automotive components or assessing the impact of moisture on packaging materials, this testing equipment helps manufacturers identify potential weaknesses and make necessary improvements to enhance material safety and quality. By utilizing Haisen's advanced technology, businesses can ensure that their products are not only safe for consumers but also durable enough to withstand real-world usage.

Advantages of Using Advanced Friction Testing Equipment

Enhanced Safety Measures in Aviation

The use of advanced coefficient of friction test equipment, such as the Haisen BHM01/02 Surface Friction Tester, has significantly enhanced safety measures in aviation. By accurately measuring the friction coefficient on airport runway pavement, this equipment ensures optimal conditions for takeoff and landing, reducing the risk of skidding and accidents. With over 200 units in use at various airports, including high-altitude locations, the Haisen tester has proven to be a vital tool in maintaining safe aviation operations.

The Haisen BHM01/02 Surface Friction Tester has not only revolutionized safety measures in aviation but has also had a significant impact on the automotive sector. By accurately measuring the friction coefficient on road surfaces, this advanced equipment has enabled car manufacturers to enhance the performance of their vehicles. With the ability to test various road conditions, including wet and icy surfaces, the Haisen tester ensures that automobiles have optimal traction, reducing the risk of accidents and improving overall driving safety.

Improved Performance in Automotive Sector

In the automotive industry, continuous friction measuring equipment plays a crucial role in improving performance and safety. The Haisen tester, with its original vehicle systems and high-precision components, provides reliable data for optimizing tire design and road surface materials. This leads to enhanced traction control systems and improved vehicle handling, ultimately contributing to safer driving conditions on the road.

Furthermore, the data collected from continuous friction measuring equipment can also be used to improve fuel efficiency in vehicles. By analyzing the interaction between tire design and road surface materials, manufacturers can develop tires that reduce rolling resistance and improve overall fuel economy. This not only benefits drivers by saving them money at the pump, but also contributes to a more environmentally friendly automotive industry.

Quality Assurance in Material Testing

For material testing purposes, coefficient of friction test equipment like the Airport Surface Friction Test Equipment is essential for ensuring quality and safety standards are met. The Haisen tester's specialized tires compliant with CAAC, ICAO, and FAA regulations allow for accurate testing of various materials under different conditions. This ensures that materials used in construction and manufacturing meet required friction coefficients for optimal performance and safety.

With its advanced technology and proven track record in enhancing safety measures in aviation, improving automotive performance, and ensuring quality assurance in material testing, the Haisen BHM01/02 Surface Friction Tester stands as a reliable solution for various industries reliant on accurate coefficient of friction measurements.

Conclusion

As we look towards the future of friction testing equipment, it's clear that advanced technology will continue to play a crucial role in ensuring safety across various industries. Implementing cutting-edge features such as those found in Haisen's BHM01/02 Surface Friction Tester will be essential for staying ahead of the curve and maintaining high standards of safety and performance.

The Future of Friction Testing Equipment

With rapid advancements in technology, the future of coefficient of friction test equipment is set to bring even greater precision and efficiency. As demands for accuracy and reliability continue to rise, we can expect to see innovations that further enhance the capabilities of friction testing equipment, ultimately leading to safer environments across aviation, automotive, and material testing sectors.

As demands for accuracy and reliability continue to rise, the integration of advanced technology such as artificial intelligence and machine learning is poised to revolutionize the way friction testing equipment operates. By utilizing these cutting-edge technologies, friction testing equipment will be able to analyze data in real time, identify patterns, and make predictive maintenance recommendations, ultimately leading to improved safety measures in various industries. This shift towards smart friction testing equipment will not only enhance precision and efficiency but also streamline operations, reduce downtime, and minimize the risk of accidents.

Implementing Advanced Technology for Safety

The importance of implementing advanced technology for safety cannot be overstated. By leveraging state-of-the-art features such as safety design, reliability with high-precision components, and specialized test tires like those offered by Haisen's COF tester, industries can proactively address potential risks and ensure optimal safety standards are met.

By investing in reliable friction testing equipment, industries can ensure that their products meet the highest safety standards. This equipment allows for precise measurement of the coefficient of friction, which is crucial in determining the slip resistance of various surfaces. With accurate data from reliable testing equipment, companies can make informed decisions about product design and materials to minimize potential hazards and enhance overall safety.

Importance of Investing in Reliable Friction Testing Equipment

Investing in reliable friction testing equipment is paramount for maintaining operational excellence and upholding stringent safety regulations. As industries strive to achieve optimal performance and quality assurance, having access to advanced tools like airport runway pavement friction coefficient testers or continuous friction measuring equipment becomes indispensable in ensuring reliable data collection and analysis.