Introduction

Accurate friction testing is crucial for ensuring the safety of vehicles on roads and airport runways. Friction coefficient testers play a vital role in measuring the grip between tires and surfaces, providing essential data for maintaining safe driving conditions. Friction test equipment enhances safety by enabling authorities to monitor and manage friction levels effectively.

What is a Friction Coefficient Tester?

A friction coefficient tester is a specialized device that measures frictional resistance between a tire and the road surface or runway. It provides valuable data on the grip level available, helping prevent accidents and ensure optimal driving conditions.

Importance of Accurate Friction Testing

Accurate friction testing is essential for determining the effectiveness of anti-skid measures, such as de-icing chemicals or rubber removal on airport runways. It also helps identify potential road hazards, such as oil spills or worn-out surfaces, contributing to overall road safety.

How Friction Test Equipment Enhances Safety

Friction test equipment enhances safety by allowing authorities to proactively monitor and manage friction levels on roads and airport runways. This ensures that vehicles can operate safely in various weather conditions while reducing the risk of accidents due to low traction.

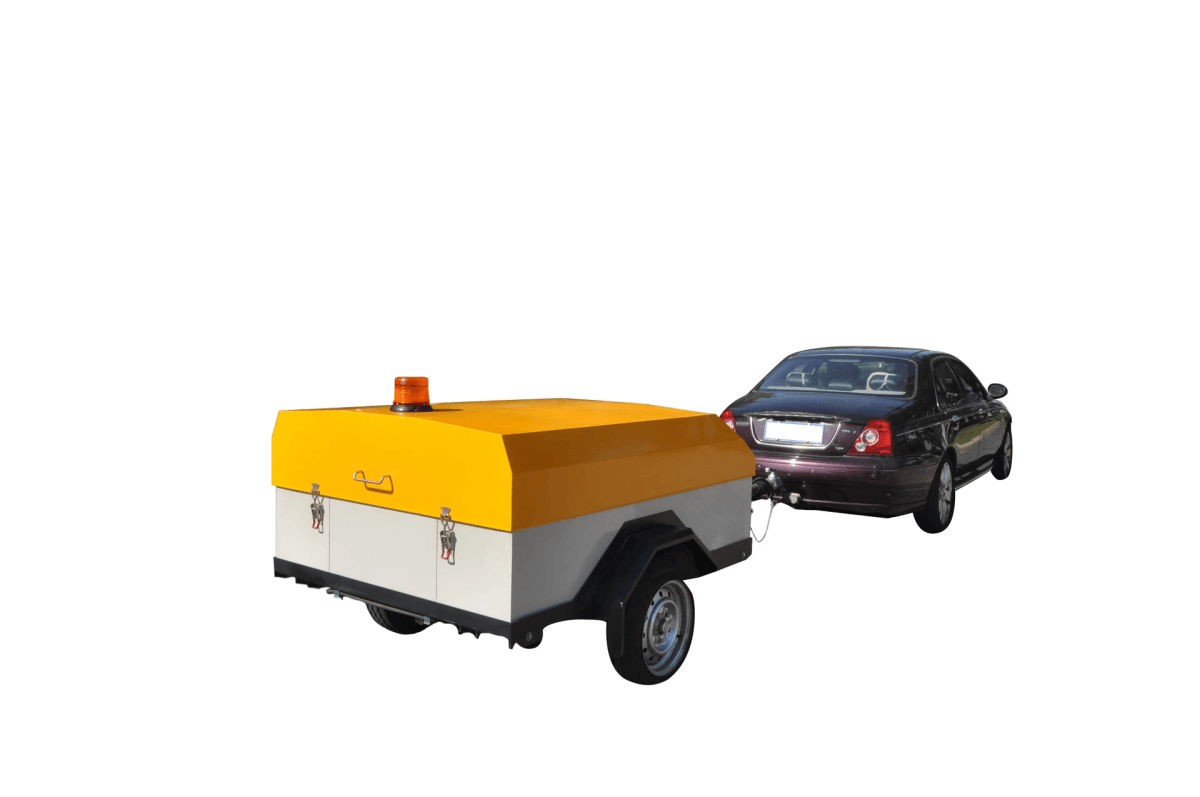

The Haisen BHM01/02 Surface Friction Tester

The Haisen BHM01/02 Surface Friction Tester is a state-of-the-art friction coefficient tester that sets the standard for road and runway friction testing equipment. Its safety design and equipment reinforcement ensure reliable and accurate results, making it the top choice for airport authorities worldwide.

Safety Design and Equipment Reinforcement

The Haisen BHM01/02 is engineered with safety as the paramount consideration, incorporating reinforced components capable of enduring rigorous continuous testing. This robust construction and advanced safety features safeguard operators and equipment, providing airport authorities with unparalleled peace of mind.

The Haisen BHM01/02 is equipped with high-precision components to ensure reliable and precise performance in all testing conditions. This unwavering commitment to quality and meticulous craftsmanship guarantees consistent and accurate results, making it an indispensable asset for airport operations.

Key features of the Haisen BHM01/02 include:

- Reinforced components for enhanced durability

- Advanced safety features for operator and equipment protection

- High-precision components for reliable and accurate results

With its focus on safety, reliability, and accuracy, the Haisen BHM01/02 is ideal for airport authorities seeking a robust and dependable testing solution.

Reliability and High-Precision Components

Equipped with high-precision components, the Haisen BHM01/02 delivers reliable and consistent friction test results, which are crucial for ensuring safe landing and takeoff conditions on airport runways. Its advanced technology guarantees accuracy, making it a trusted tool for assessing runway friction levels.

Furthermore, the high-precision components of the Haisen BHM01/02 allow for quick and efficient testing of runway friction levels, saving valuable time for airport maintenance crews. This means potential issues can be identified and addressed promptly, ensuring that runways are always in optimal condition for safe aircraft operations. The reliability of the test results also provides peace of mind to airport authorities and pilots, knowing that they can trust the accuracy of the data provided by this advanced technology.

Acceleration Capabilities of Tested Vehicles

The Haisen BHM01/02 boasts impressive acceleration capabilities, allowing it to accurately measure the friction coefficient of various surfaces under real-world conditions. This capability enables airport authorities to conduct comprehensive tests on different runway surfaces, ensuring optimal safety for aircraft operations.

The Haisen BHM01/02's advanced acceleration capabilities also make it an invaluable tool for testing the performance of different tire designs on various surfaces. By accurately measuring the friction coefficient, this vehicle testing equipment provides valuable data for tire manufacturers to improve their products and enhance overall safety on the road. Furthermore, the ability to conduct tests under real-world conditions ensures that the results are highly reliable and applicable to everyday driving scenarios.

Calibration and Testing Accuracy

Easy-to-Use External Calibration Device

The Haisen BHM01/02 Surface Friction Tester has an easy-to-use external calibration device, making it simple for operators to ensure accurate and reliable testing results. This feature allows for quick and efficient calibration, saving valuable time and ensuring the equipment continuously operates at peak performance. The external calibration device also provides peace of mind, knowing that the friction tester consistently delivers precise measurements, essential for maintaining safe runway conditions for aircraft operations. This user-friendly calibration tool allows airport personnel to confidently and accurately test friction.

Specialized Tires Compliant with Aviation Regulations

The Haisen BHM01/02 Surface Friction Tester has specialized tires that meet all aviation regulations for friction testing. These tires are designed to provide accurate and consistent results on various runway surfaces, ensuring the data collected is reliable and compliant with industry standards. Using these specialized tires also minimizes the risk of damage to the runway surface, making them a safe and efficient choice for friction testing equipment. Additionally, the tires are specifically engineered to withstand the high speeds and forces involved in friction testing, further enhancing the overall performance and reliability of the Haisen BHM01/02 Surface Friction Tester.

Achievements and Track Record at Various Airports

The Haisen BHM01/02 Surface Friction Tester boasts a proven track record of success at numerous airports worldwide. This state-of-the-art equipment has consistently delivered accurate and reliable friction testing results from major international hubs to smaller regional airfields.

Key benefits of the Haisen BHM01/02 include:

- Enhanced safety: Precise friction measurements help identify potential hazards and mitigate risks.

- Improved efficiency: Accurate data enables optimized runway maintenance and operations.

- User-friendly operation: The intuitive interface facilitates efficient data collection and analysis.

- Real-time results: Instantaneous data provides up-to-date information for informed decision-making.

Airport authorities and aviation professionals worldwide have praised the Haisen tester's ability to enhance safety and efficiency on runways, taxiways, and aprons. With its impressive achievements and advanced capabilities, the Haisen BHM01/02 has become a trusted tool for maintaining safe operating conditions in the aviation industry.

The Haisen BHM01/02 is more than just a friction tester; it's a cornerstone of airport safety and efficiency.

Computerized Control and Data Collection

Regarding reliable operation, the Haisen BHM01/02 Surface Friction Tester stands out with its user-friendly Chinese interface. This feature ensures that airport personnel can easily navigate the testing process, leading to accurate and efficient results. With clear instructions and intuitive controls, the friction coefficient tester simplifies the otherwise complex task of runway friction testing.

Chinese Interface for Reliable Operation

The pre-programmed laptop included with the Haisen BHM01/02 Surface Friction Tester allows continuous testing without interruptions. This ensures seamless and comprehensive data collection, providing airport authorities with a complete overview of runway conditions. The laptop's advanced software also enables real-time analysis of friction test results, allowing for immediate adjustments if necessary.

In addition, the laptop's Chinese interface ensures reliable operation in any testing environment. The user-friendly interface allows for easy navigation and control, making it simple for operators to conduct tests with precision and accuracy. This feature is particularly beneficial for airport authorities who may have staff members with varying technical expertise, as it streamlines the testing process and minimizes the risk of errors.

Pre-programmed Laptop for Continuous Testing

To extend testing ranges and ensure thorough assessments, the friction tester comes equipped with a water system that provides consistent and reliable wet surface conditions for testing. This feature allows airport personnel to simulate various weather conditions, including rain or snow, providing valuable insights into runway performance under different circumstances.

Water System for Extended Testing Ranges

By incorporating a user-friendly Chinese interface, a pre-programmed laptop for continuous testing, and a water system for extended testing ranges, the Haisen BHM01/02 Surface Friction Tester is an innovative and reliable tool for accurate airport friction testing. With these advanced features, airport authorities can confidently ensure safe landing and takeoff conditions for all aircraft using their runways.

In addition to its advanced features, the Haisen BHM01/02 Surface Friction Tester also boasts a water system for extended testing ranges, allowing for more comprehensive and accurate testing of runway surfaces. This innovative system ensures that airport authorities can assess friction levels across a wider range of conditions, including wet surfaces, providing a more thorough understanding of runway safety. By incorporating this water system, the Haisen BHM01/02 sets itself apart as a versatile and reliable tool for ensuring safe landing and takeoff conditions for all aircraft.

Comparison with Other Friction Testers

The advantages are apparent when comparing the Haisen BHM01/02 with other friction testers. Unlike traditional road friction testers, the Haisen BHM01/02 offers unparalleled accuracy and reliability in runway friction testing equipment. Its advanced technology outperforms competitors like Sarsys and ASFT friction testers, providing precise data for enhanced safety.

The Haisen BHM01/02 is specifically designed for airport use, offering unique features that cater to the specific needs of aviation authorities. Its high-precision components and reliable performance make it the go-to choice for runway friction testing. Specialized tires compliant with aviation regulations ensure accurate results that meet industry standards.

Compared to other friction testers, the Haisen BHM01/02 stands out for its user-friendly interface and intuitive operation, making it easy for airport personnel to conduct friction tests efficiently. Its quick data processing capabilities and seamless integration with airport systems further enhance its appeal, allowing for swift decision-making based on accurate test results. This sets it apart from other testers that may lack the same level of user-friendliness and compatibility with airport operations.

Airport authorities worldwide have praised the Haisen BHM01/02 for its exceptional performance and reliability in runway friction testing. From major international airports to smaller regional ones, users have reported increased efficiency and accuracy when using this state-of-the-art friction coefficient tester. Their testimonials highlight the impact of this equipment on enhancing aviation safety.

With its superior capabilities and positive feedback from industry professionals, the Haisen BHM01/02 sets a new standard in runway friction testing equipment. Its advanced features and real-world performance make it a top choice for airport authorities looking to enhance safety through reliable friction testing technology.

Future of Friction Testing Technology

As technology continues to advance, exciting innovations in road friction testing equipment are on the horizon. Companies like Sarsys are developing state-of-the-art friction testers that offer even greater precision and reliability, ensuring the safety of drivers on the road.

Innovations in Road Friction Testing Equipment

These new road friction testers boast cutting-edge features such as advanced sensor technology and real-time data collection, providing accurate measurements of surface conditions. With improved accuracy and efficiency, these testers will revolutionize road maintenance and enhance safety for all drivers.

Impact of Friction Tester Airport Usage on Aviation Safety

The use of friction testers at airports has already significantly impacted aviation safety. By providing accurate runway friction data; the ASFT friction tester has helped prevent accidents and ensure smooth takeoffs and landings for countless flights, making it an indispensable tool for airport authorities.

The impact of friction testers at airports has been so significant that there is a push for further developments in runway friction testing technology. With advancements in sensor technology and data analysis, the next generation of friction testers is expected to provide even more precise and real-time data on runway conditions. This will enable airport authorities to proactively address potential safety hazards and ensure optimal runway performance, further enhancing aviation safety.

Anticipated Developments in Runway Friction Testing

There is great anticipation for further developments in runway friction testing equipment. With ongoing research and development, we can expect advancements that offer enhanced precision and efficiency, raising the bar for aviation safety standards. One exciting potential growth area is integrating advanced sensor technology into friction testing equipment. This could provide real-time data on runway conditions, allowing immediate adjustments to be made in response to changing weather or traffic patterns.

Enhance Aviation Safety with Reliable Friction Testing Technology

Regarding best practices for runway friction testing, the Haisen BHM01/02 surface friction tester stands out as a reliable and high-precision option. Its safety design, calibration accuracy, and computerized control make it the ideal choice for airport authorities looking to enhance aviation safety through reliable friction testing technology.

Best Practices for Runway Friction Testing

The Haisen BHM01/02 surface friction tester is a top airport runway friction testing equipment choice. It offers several key advantages:

- Easy-to-use external calibration devices ensure accurate and consistent testing results.

- Specialized tires that comply with aviation regulations provide reliable measurements.

- A water system allows for extended testing ranges, accommodating various weather conditions.

This equipment empowers airports to assess runway conditions precisely and maintain optimal aircraft safety.

Choosing the Right Friction Coefficient Tester

When selecting a friction coefficient tester, reliability, precision, and safety features must be considered. The Haisen BHM01/02 outshines competitors with its safety design, high-precision components, and acceleration capabilities of tested vehicles—essential factors in choosing the right friction test equipment.

Reliable friction testing technology is paramount in enhancing aviation safety. The Haisen BHM01/02 surface friction tester has garnered real-world testimonials from airport authorities who have experienced its benefits firsthand. Its impact on aviation safety is undeniable, making it the top choice for runway friction testing.

Furthermore, the Haisen BHM01/02 surface friction tester has advanced technology that provides accurate and reliable data in various weather conditions. This ensures that airport authorities can make informed decisions regarding runway maintenance and aircraft operations, ultimately contributing to a safer aviation environment. With its user-friendly interface and efficient testing process, the Haisen BHM01/02 has become indispensable for enhancing aviation safety worldwide.