Introduction

Are you in the market for a reliable and efficient actuator for your industrial operations? Look no further than the electric rotary actuator, a motorized device that converts electrical energy into mechanical motion to control valves. Whether you're in petrochemical, metallurgy, shipbuilding, or power generation, choosing the best electric actuator is crucial for optimal performance and safety.

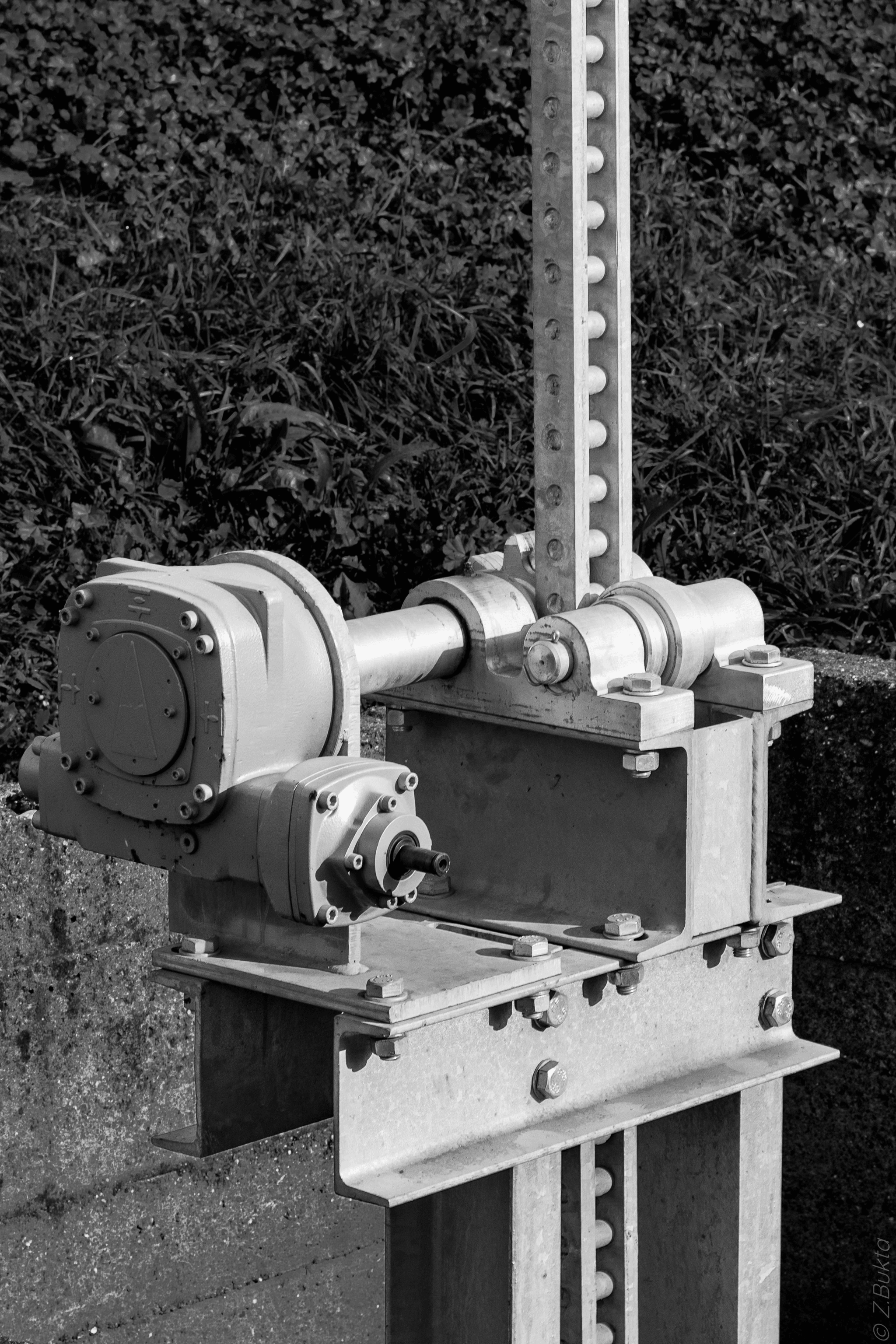

Overview of Electric Rotary Actuators

Electric rotary actuators are widely used in various industries to automate valve operations. Unlike linear actuators that move in a straight line, rotary actuators provide rotational motion to control the position of valves. These electromechanical devices play a vital role in regulating flow rates and pressures in industrial processes.

Importance of Choosing the Best Actuator

Selecting the right electric actuator valve is essential for ensuring smooth and precise control of valves in industrial settings. The wrong choice can lead to inefficiencies, safety hazards, and costly maintenance issues down the line. It's crucial to consider key factors such as compatibility with valve types, remote control capabilities, precision, and durability when making a selection.

Key Considerations for Actuator Selection

When choosing an electric linear actuator or rotary actuator, it's important to assess its precision and accuracy in controlling valve positions. Remote control capabilities are also essential for seamless operation in various industrial applications. Additionally, durability and reliability are key factors to ensure long-term performance while maintaining safety standards.

Top Electric Rotary Actuator Options

When it comes to choosing the best electric rotary actuator for your industrial needs, there are several top options that stand out in terms of performance and reliability.

Haisen's Part-Turn Valve Electric Actuator

Haisen's part-turn valve electric actuator is a robust and efficient choice for applications requiring precise control and automation. With its motorized design, this electric actuator delivers smooth and accurate operation, making it ideal for actuator valve systems in various industries.

AUMA Electric Actuator

The AUMA electric actuator offers advanced electromechanical linear actuator technology, providing exceptional performance and durability. Its precision engineering and remote control capabilities make it a top choice for demanding industrial environments where reliability is crucial.

Rotork IQ Part-Turn Actuator

The Rotork IQ part-turn actuator is known for its superior quality and compatibility with a wide range of valve types. This electric linear actuator is designed to deliver precise positioning and efficient operation, making it a popular choice for industrial applications requiring optimal performance.

Bernard Controls Quarter-Turn Electric Actuator

Bernard Controls' quarter-turn electric actuator is renowned for its durability and versatility in handling various valve types. With its robust construction and reliable motorized design, this rotary actuator is well-suited for demanding industrial settings where consistent performance is essential.

Emerson Bettis EHO Actuator

Emerson Bettis' EHO actuator stands out for its energy-efficient operation and advanced control features. This electric rotary actuator offers smooth and reliable performance, making it an excellent choice for applications where precision and accuracy are paramount.

Key Features to Look For

When selecting an electric rotary actuator, precision and accuracy are crucial factors to consider. The actuator should be able to precisely control the valve's position, allowing for accurate flow regulation in various industrial processes.

Precision and Accuracy

Look for an electric actuator that offers precise and accurate positioning, ensuring optimal performance and efficiency in your operations. Whether it's controlling the flow of fluids or gases, a high level of precision is essential for smooth and reliable functionality.

Remote Control Capabilities

Remote control capabilities enable seamless operation and monitoring of the actuator valve from a distance. This feature allows for convenient adjustments and troubleshooting without the need for physical intervention, saving time and resources in industrial settings.

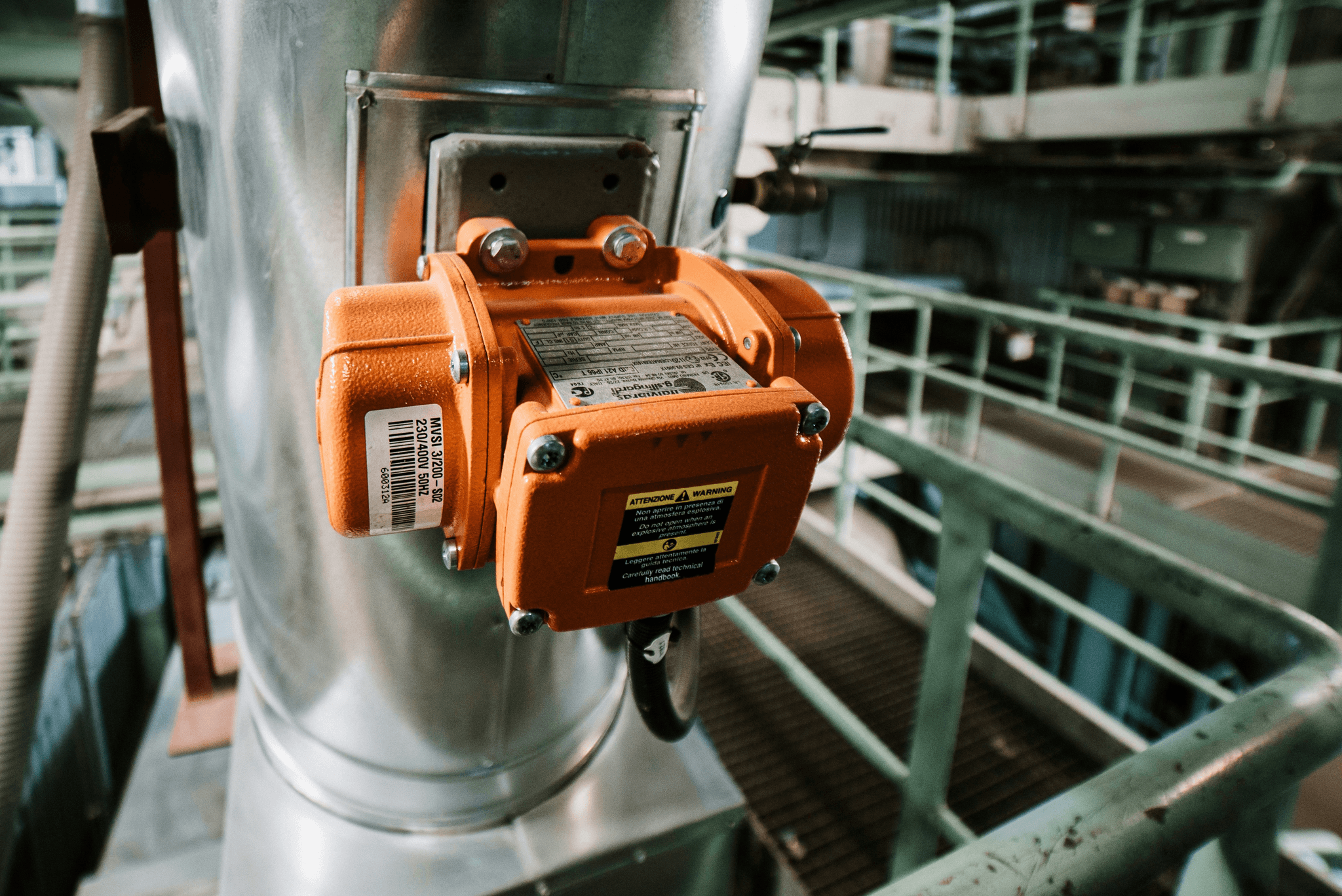

Durability and Reliability

The durability and reliability of an electric rotary actuator are vital considerations for long-term performance. Look for actuators that are built to withstand harsh environmental conditions, frequent use, and heavy loads, ensuring minimal downtime and maintenance costs.

Compatibility with Valve Types

Ensure that the chosen electric actuator is compatible with a wide range of valve types commonly used in industrial applications. Versatility in valve compatibility allows for greater flexibility in system design and implementation.

Safety Features for Industrial Use

Safety features such as overload protection, emergency stop functions, and fail-safe mechanisms are essential for industrial environments where human safety is paramount. Choose an electric rotary actuator that prioritizes safety to mitigate potential risks during operation.

Applications in Various Industries

When it comes to the petrochemical industry, electric rotary actuators play a crucial role in controlling valves for the processing of various chemicals and materials. These actuators offer precise and reliable control over the flow of substances, ensuring safety and efficiency in operations.

Petrochemical

In metallurgy, the use of electric linear actuators is essential for controlling valves in high-temperature and high-pressure environments. These actuators provide the necessary force and precision to regulate the flow of molten metals and other materials, contributing to the overall efficiency and safety of metallurgical processes.

Metallurgy

Shipbuilding relies on motorized actuators for valve control in critical systems such as ballast tanks, fuel systems, and ventilation. Electric actuators ensure smooth and accurate operation, contributing to the safety and functionality of various onboard systems in marine vessels.

Shipbuilding

In the food and beverage industry, electromechanical linear actuators are used for precise control over valves in processing equipment such as mixers, conveyors, and packaging machinery. These actuators contribute to consistent product quality and adherence to strict hygiene standards.

Food and Beverage

Power generation facilities utilize rotary actuators for valve automation in steam turbines, cooling systems, and power distribution networks. Electric actuators ensure reliable operation under demanding conditions, contributing to the overall efficiency and safety of power generation processes.

Advantages of Electric Actuators

Energy Efficiency

Electric rotary actuators offer superior energy efficiency compared to traditional pneumatic or hydraulic actuators. By utilizing electric power, these actuators can minimize energy waste and reduce operating costs in industrial settings. With precise control over energy consumption, electric actuators are an environmentally friendly and cost-effective choice for various applications.

Low Maintenance

One of the key advantages of electric rotary actuators is their low maintenance requirements. Unlike traditional hydraulic or pneumatic systems, electric actuators do not require regular fluid changes or complex maintenance procedures. This results in reduced downtime and lower maintenance costs, making them a practical choice for industrial operations seeking efficiency and reliability.

Smooth Operation

Electric rotary actuators provide smooth and precise motion control, ensuring accurate positioning and seamless operation in diverse industrial environments. With advanced motorized technology, these actuators deliver consistent performance without the need for manual adjustments or frequent recalibration. This smooth operation enhances overall productivity and quality in manufacturing processes.

Environmental Friendliness

As industries increasingly prioritize sustainability, electric rotary actuators offer a more environmentally friendly alternative to traditional actuator options. By eliminating the use of hydraulic fluids or compressed air, these actuators contribute to a cleaner working environment with reduced emissions and waste generation. Their eco-friendly design aligns with modern environmental standards and regulations.

Cost-Effectiveness

In addition to energy savings and low maintenance requirements, electric rotary actuators present a cost-effective solution for industrial automation needs. Their long-term durability and reliability translate into reduced replacement costs and enhanced operational efficiency over time. With minimal ongoing expenses, these actuator systems prove to be a wise investment for businesses aiming to optimize their resources.

Future Trends in Electric Actuators

As technology continues to advance, the integration of electric rotary actuators with IoT (Internet of Things) technology is becoming increasingly prevalent. This allows for real-time monitoring and control of actuator valves, enhancing operational efficiency and predictive maintenance capabilities. With advanced control systems, electric actuators can now be programmed to perform complex tasks with precision and accuracy, further expanding their applications across various industries.

Integration with IoT Technology

In the near future, electric rotary actuators are expected to be seamlessly integrated with IoT technology, allowing for remote monitoring and control through connected devices. This will enable operators to access real-time data on actuator performance and valve operation, leading to proactive maintenance and improved reliability in industrial processes.

Advanced Control Systems

The development of advanced control systems for electric actuators will revolutionize their capabilities, enabling more sophisticated motion control and automation. These systems will offer enhanced programmability and customization options, allowing for precise positioning and seamless integration with other industrial equipment.

Sustainable Manufacturing Practices

As the demand for sustainable manufacturing practices grows, electric linear actuators are poised to play a pivotal role in reducing energy consumption and minimizing environmental impact. Their energy-efficient operation and low maintenance requirements make them an ideal choice for companies striving towards sustainability in their operations. Additionally, the versatility of electric linear actuators allows for precise control and automation, further contributing to energy savings and reducing waste in manufacturing processes. With the ability to integrate seamlessly into existing systems, electric linear actuators offer a practical solution for companies looking to enhance their sustainability efforts without disrupting their current operations.

Market Growth and Demand

The market for electric actuators is expected to experience significant growth due to increasing industrial automation trends across various sectors such as petrochemicals, metallurgy, shipbuilding, food and beverage, as well as power generation. This surge in demand reflects the growing recognition of the advantages offered by electric actuators over traditional pneumatic or hydraulic alternatives.

The increasing focus on sustainability and energy efficiency in industrial operations has also contributed to the growing demand for electric actuators. With the ability to operate with greater precision and control, electric actuators offer significant energy savings compared to their pneumatic and hydraulic counterparts. This aligns with the global push for greener technologies and reduced carbon footprint, making electric actuators a preferred choice for companies looking to improve their environmental impact.

Innovations in Actuator Design

Innovations in actuator design are driving improvements in performance, reliability, and versatility. From compact motorized actuators to electromechanical linear actuators capable of precise linear motion control, manufacturers are constantly pushing the boundaries of what electric actuators can achieve in terms of efficiency and adaptability.

In addition to enhancing performance and reliability, advancements in actuator design are also focused on reducing energy consumption and minimizing environmental impact. Manufacturers are exploring new materials and technologies to create more efficient actuators that require less power to operate, thereby contributing to sustainability efforts in various industries. By prioritizing energy efficiency in actuator design, companies can not only lower operating costs but also reduce their carbon footprint, aligning with the growing demand for eco-friendly solutions.

Conclusion

When it comes to choosing the right electric actuator for your needs, it's crucial to consider factors such as precision, durability, and compatibility with valve types. Investing in quality and reliability is key to ensuring smooth industrial operations, while also future-proofing your systems against potential obsolescence. By embracing electric rotary actuators and other motorized options, you can optimize energy efficiency and minimize maintenance costs. So, don't hesitate to explore the latest innovations in actuator design and stay ahead of the curve!

Choosing the Right Electric Actuator for Your Needs

Selecting the ideal electric actuator valve or linear actuator involves careful consideration of your specific requirements. Whether you're looking for an electromechanical linear actuator or a rotary actuator, prioritize precision and compatibility with your existing systems. By understanding the unique demands of your industry, you can make an informed decision that aligns with your operational goals.

Investing in Quality and Reliability

Quality and reliability should be non-negotiable when it comes to investing in electric actuators. Look for reputable manufacturers that offer durable products with advanced control systems and safety features tailored to industrial use. By prioritizing these aspects, you can minimize downtime and ensure consistent performance across various applications.

Future-proofing Your Industrial Operations

In a rapidly evolving industrial landscape, future-proofing your operations is essential for long-term success. Embracing sustainable manufacturing practices and integrating IoT technology into your electric actuators can enhance efficiency while reducing environmental impact. Keep an eye on market trends and innovations to stay ahead of the competition.