Introduction

In the bustling world of aviation, the importance of a well-functioning refuel plane truck cannot be overstated. Refueler trucks are the unsung heroes that ensure aircraft are ready for takeoff, yet common oversights in their operation can lead to inefficiencies and safety hazards. Understanding these pitfalls is crucial for anyone involved in aircraft operations, as it sets the stage for effective refueling procedures and highlights the need for top-notch quality equipment.

Common Oversights with Refuel Plane Trucks

One of the most frequent mistakes made with refuel plane trucks is neglecting routine equipment checks before use. This oversight can lead to delays or even dangerous situations during refueling operations. Additionally, misjudging fuel needs based on aircraft size can result in either overfilling or underfilling—both of which create unnecessary complications and potential safety risks.

Importance of Proper Refueling Procedures

Proper refueling procedures are essential not just for efficiency but also for ensuring safety during operations. Knowing how commercial planes are refueled involves understanding both the technical aspects and adherence to stringent protocols that protect personnel and equipment alike. A well-executed procedure minimizes downtime and maximizes flight readiness, making it vital for airports aiming to maintain smooth operations.

Key Features of Top-Notch Refueler Trucks

Top-notch quality and innovative aircraft refueling trucks come equipped with advanced features designed to enhance performance and safety. For instance, Haisen's Aircraft Pipeline Refueling Truck boasts a sophisticated piping system alongside a hydraulic control system that allows for high flow rates while filtering out impurities from fuel. Such capabilities ensure that every operation runs smoothly, allowing airport staff to focus on what matters most: getting planes back in the air efficiently.

Understanding Refuel Plane Truck Mechanics

How Haisen Refueler Trucks Operate

Haisen refueler trucks are engineered to deliver fuel efficiently through a sophisticated system designed for high flow rates. These trucks feature a robust chassis, an intricate piping system, and advanced pneumatic control mechanisms that work in harmony to provide seamless fuel transfer. When you ask, How are commercial planes refueled? the answer often involves such specialized equipment that ensures quick turnaround times while maintaining safety protocols.

The operation begins with the truck positioning itself near the aircraft, where it connects its dispensing nozzle to the plane's fueling port. During this process, impurities like dust and moisture are filtered out to ensure only clean fuel enters the aircraft's tanks. This meticulous operation is essential for answering questions like How much fuel does an airport fuel truck hold? since each refuel plane truck is designed with specific capacities tailored to various aircraft needs.

Essential Components of Refueler Trucks

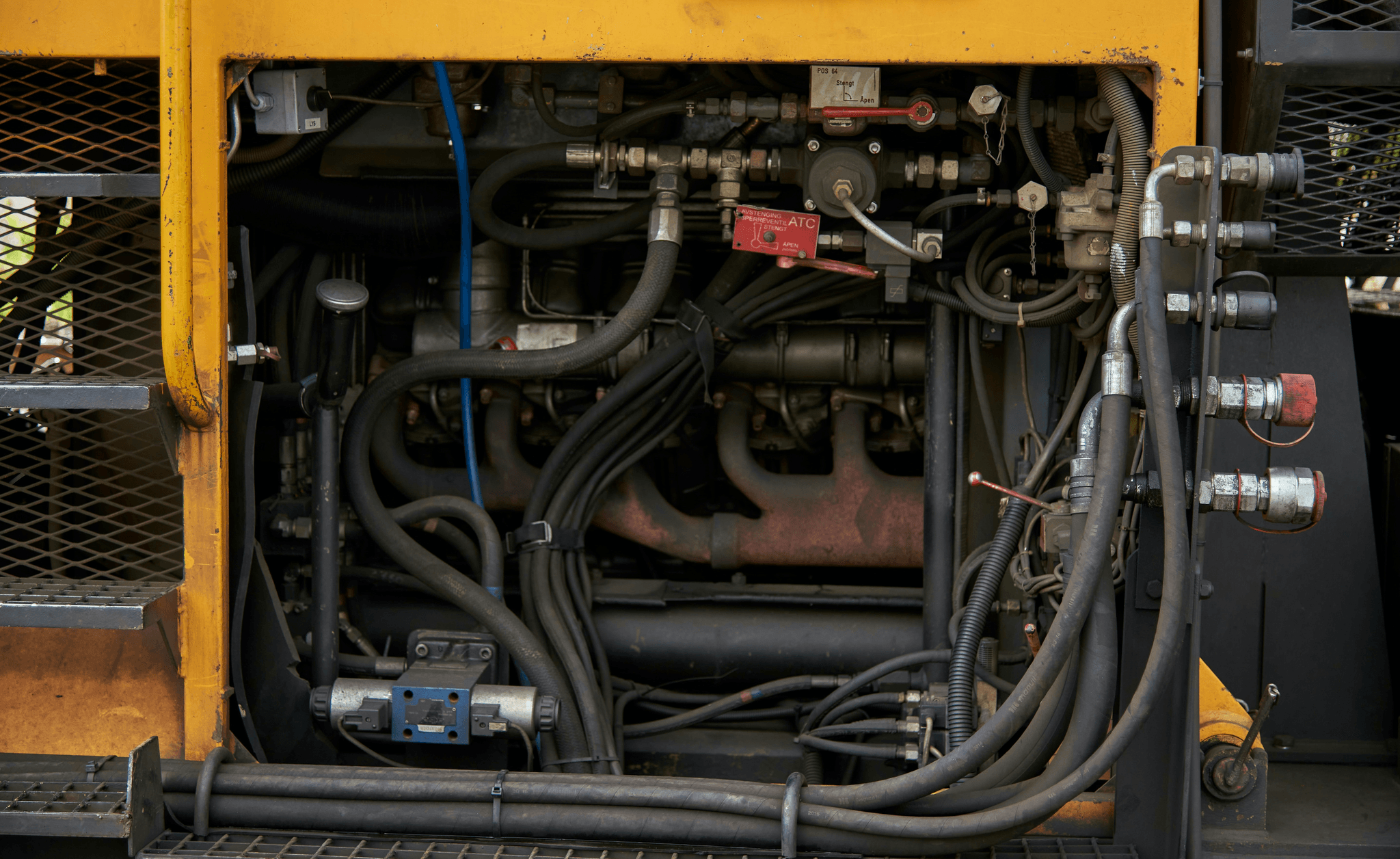

To fully appreciate how a refuel plane truck operates, it's important to understand its essential components. Haisen’s trucks include vital systems such as hydraulic and electrical systems that facilitate smooth operation during fueling tasks. Each component plays a pivotal role in ensuring that the truck functions reliably under pressure while meeting industry standards.

The hydraulic system helps control movement and pressure during fueling operations, while the electrical system manages all electronic functions from monitoring flow rates to operational alerts. This integration of technology allows for precise measurements during fueling—an aspect critical for efficiency in commercial aviation operations. Without these top-notch components working together seamlessly, questions about What is the procedure for refueling an aircraft? would become more complex than necessary.

Importance of Regular Maintenance

Regular maintenance of refueler trucks cannot be overstated; it’s akin to giving your car regular check-ups—neglect can lead to disastrous outcomes! Ensuring that all parts function optimally not only extends the lifespan of your equipment but also guarantees safety during operations—especially when considering how long it takes to refuel a cargo plane or any other type of aircraft.

A well-maintained Haisen refuel plane truck will consistently perform at high efficiency levels while minimizing downtime due to repairs or malfunctions. Operators should keep an eye on key indicators like filter cleanliness and fluid levels as part of their routine checks; this proactive approach prevents costly mistakes down the line and promotes overall operational effectiveness.

Refueling Procedures for Commercial Aircraft

Refueling commercial aircraft is a precise and systematic process that ensures safety and efficiency. Understanding how to operate a refuel plane truck effectively is crucial for ground staff, as it directly impacts flight schedules and operational costs. This section will delve into the step-by-step guide to refueling, the mechanics behind how commercial planes are refueled, and the essential safety measures that must be adhered to during this critical procedure.

Step-by-Step Guide to Refueling

The refueling process begins with the arrival of the refuel plane truck at the designated parking area of the aircraft. Ground staff must first conduct a thorough inspection of the truck to ensure all systems are functioning properly and that there are no leaks or malfunctions. Following this, they will connect the fueling hose from the truck to the aircraft's fuel port while ensuring proper grounding to prevent static electricity buildup.

Next, it's essential to monitor fuel levels during transfer; knowing how much fuel does an airport fuel truck hold helps in planning efficient operations. The operator should maintain communication with cockpit personnel throughout this process, providing updates on fuel quantity being transferred. Once fueling is complete, staff will disconnect hoses carefully, conduct a final check for any spills or leaks, and document all necessary data related to fuel type and amount used.

How Are Commercial Planes Refueled?

Commercial planes are typically refueled using specialized equipment like Haisen's Aircraft Pipeline Refueling Truck, which is designed for high-flow rate operations across various aircraft types. These top-notch quality and innovative aircraft refueling trucks feature advanced filtration systems that remove impurities from fuel before it enters an aircraft’s tank—ensuring only clean fuel is used during flights.

The procedure involves transferring jet fuel from storage tanks through underground pipelines or directly from a refueler truck into an aircraft's tanks via its fueling ports. Ground crew members play multiple roles: they operate valves on both ends of the fueling system while also monitoring pressure gauges to ensure safe transfer rates. This teamwork ensures that each operation runs smoothly without delays—a vital aspect when considering how long does it take to refuel a cargo plane.

Ensuring Safety During Refueling

Safety protocols during refueling cannot be overstated; they protect both personnel and equipment involved in this critical operation. First off, ground crew must wear appropriate personal protective equipment (PPE) such as gloves and goggles when handling fuels—this minimizes exposure risks associated with jet fuels or other aviation liquids used in operations.

Furthermore, constant monitoring of environmental conditions such as wind speed and direction is crucial; these factors can influence potential hazards like fires or spills around flammable materials present near a refueler truck site. Lastly, adherence to established safety protocols—including maintaining clear communication between team members—is key in preventing accidents during what could otherwise be routine procedures like What is the procedure for refueling of an aircraft?

Fuel Capacity and Efficiency

When it comes to refuel plane trucks, understanding fuel capacity and efficiency is crucial for smooth operations at any airport. Refueler trucks are engineered to hold substantial amounts of fuel while ensuring that the refueling process is both quick and efficient. This section will delve into how much fuel these trucks can carry, ways to maximize efficiency during operations, and how to accurately calculate the fuel needs for different types of aircraft.

How Much Fuel Does an Airport Fuel Truck Hold?

The capacity of an airport fuel truck can vary significantly based on its design and purpose. Typically, a standard refuel plane truck can hold anywhere from 5,000 to 12,000 gallons of aviation fuel, allowing it to service multiple aircraft in one go. This large capacity ensures that refueler trucks can handle the demands of busy airports without frequent trips back to the storage facility.

Understanding how much fuel an airport fuel truck holds is essential for planning purposes—especially when considering peak travel times or specific aircraft requirements. For instance, larger commercial planes may require more frequent refueling than smaller jets or cargo planes, making the role of a high-capacity refueler truck critical in maintaining operational efficiency. In addition, knowing the tank size helps ground crew calculate how many flights a single truck can support before needing a refill.

Maximizing Fuel Efficiency During Operations

Maximizing fuel efficiency during operations is not just about having a well-designed refuel plane truck; it's also about implementing best practices throughout the process. One effective strategy involves scheduling regular maintenance checks on equipment like pumps and hoses to ensure they operate at optimal levels without leaks or malfunctions. Additionally, educating staff on efficient fueling techniques can significantly reduce waste and improve turnaround times.

Another key aspect is utilizing technology such as flow meters and automated systems that monitor usage in real-time while dispensing fuel into aircraft tanks. These innovations help ensure accurate measurements are taken during each fueling operation—crucial for avoiding over-fueling or under-fueling scenarios which could lead to delays or safety issues later on. Ultimately, top-notch quality and innovative aircraft refueling trucks equipped with advanced features play a vital role in maximizing overall operational efficiency.

Calculating Fuel Needs for Different Aircraft

Calculating the specific fuel needs for different aircraft types requires knowledge of various factors including size, weight, distance traveled, and current load conditions. Each commercial plane has its own unique specifications which dictate how much aviation fuel it requires during each flight cycle; thus understanding these details is essential for effective planning using your refuel plane truck fleet.

Ground crews must also factor in additional elements such as weather conditions that might affect flight performance or emergency reserves that need to be accounted for when determining total fueling requirements prior to departure. By closely monitoring these variables alongside historical data from previous flights—like “How long does it take to refuel a cargo plane?”—teams can develop accurate fueling strategies tailored specifically to each type of aircraft they service.

In conclusion, mastering the intricacies involved in calculating necessary fuels ensures not only smoother operations but also enhances safety measures across all aspects of commercial aviation logistics involving Refueler Trucks.

Time Management in Refueling

In the fast-paced world of aviation, time management is crucial when it comes to refueling operations. A well-organized refuel plane truck operation can significantly reduce downtime for aircraft, allowing them to get back in the air swiftly. Efficient refueling not only enhances overall operational efficiency but also contributes to customer satisfaction and profitability for airlines.

How Long Does It Take to Refuel a Cargo Plane?

The duration required to refuel a cargo plane can vary based on several factors, including the size of the aircraft and the capacity of the refueler trucks used. On average, it takes anywhere from 30 minutes to an hour to complete this process, depending on how much fuel is needed and whether any additional checks are performed during refueling. Understanding these timeframes helps ground staff better plan their operations and ensures that they can meet tight schedules effectively.

Streamlining Refueling for Quick Turnarounds

To streamline fuel operations for quick turnarounds, utilizing top-notch quality and innovative aircraft refueling trucks is essential. These advanced refueler trucks are designed with high flow rates and efficient dispensing systems that minimize downtime during the fueling process. By implementing best practices such as pre-fueling checks and coordinated communication among ground crew members, airports can significantly reduce the time taken for each operation while ensuring that safety protocols are adhered to.

Training Staff for Efficient Operations

Investing in comprehensive training programs for staff involved in aircraft fueling operations cannot be overstated. Well-trained personnel not only understand how commercial planes are refueled but also become adept at managing equipment like Haisen's Aircraft Pipeline Refueling Truck efficiently. Regular drills focusing on procedures such as How long does it take to refuel a cargo plane? or What is the procedure for refueling of an aircraft? ensure that staff remain sharp and responsive during real-world operations.

Common Mistakes to Avoid

When operating refuel plane trucks, it's essential to be aware of common pitfalls that can lead to inefficiencies or even dangerous situations. Many individuals underestimate the importance of thorough equipment checks before use, misjudge fuel requirements based on aircraft size, and overlook critical safety protocols. By identifying and addressing these mistakes, operators can enhance the efficiency and safety of their refueling operations.

Neglecting Equipment Checks Before Use

One of the most significant oversights in operating refueler trucks is neglecting equipment checks before use. A quick inspection can help identify potential issues with hoses, pumps, or valves that could lead to leaks or malfunctions during the refueling process. Ensuring that all components are in top-notch condition not only guarantees smoother operations but also helps prevent costly downtime when dealing with repairs.

Additionally, understanding how much fuel an airport fuel truck holds is crucial for planning purposes. If a truck is not adequately inspected and maintained, it may not operate at its full capacity when needed most. Regular checks foster reliability and ensure that operators can confidently address any situation without compromising safety.

Misjudging Fuel Needs for Aircraft Size

Another common mistake involves misjudging fuel needs based on aircraft size during the refueling process. Operators must have a clear understanding of how commercial planes are refueled and the specific fuel capacities required for various models. This knowledge is crucial because underestimating or overestimating fuel needs can lead to delays in takeoff or unnecessary expenditure.

For instance, knowing how long it takes to refuel a cargo plane will help operators plan their fueling schedules more effectively. Different aircraft have varying capacities; thus, using a one-size-fits-all approach may leave some planes under-fueled while others are over-fueled unnecessarily. Proper training and awareness regarding these nuances will significantly improve overall efficiency in operations involving top-notch quality and innovative aircraft refueling trucks.

Ignoring Safety Protocols

Ignoring safety protocols while operating a refuel plane truck can result in catastrophic consequences—both for personnel and the aircraft being serviced. It’s vital for operators to be well-versed in established procedures for handling aviation fuels safely; this includes wearing appropriate protective gear and following guidelines during fueling operations meticulously. Safety should never be an afterthought; it must always be prioritized to avoid accidents.

Moreover, every operator should understand what is the procedure for refueling an aircraft properly so as not to create hazardous situations inadvertently. Training staff on emergency response measures further enhances safety during fueling activities by ensuring everyone knows how to react if something goes awry—after all, prevention is better than cure!

In conclusion, avoiding these common mistakes ensures efficient operation with Haisen's Aircraft Pipeline Refueling Truck or any other high-quality alternative available on the market today.

Conclusion

In the world of aviation, mastering the operations of a refuel plane truck is paramount for safety and efficiency. Understanding the intricacies of how these machines function not only enhances operational performance but also minimizes risks associated with aircraft refueling. By adhering to best practices and investing time in training, personnel can ensure that they are well-equipped to handle various scenarios that may arise during refueling.

Mastering Refueler Truck Operations

To truly master refueler truck operations, it’s essential to familiarize oneself with the specific mechanics involved in each vehicle type, particularly Haisen's Aircraft Pipeline Refueling Truck. This innovative truck boasts advanced features such as a sophisticated piping system and an efficient filtration mechanism that ensures clean fuel delivery, making it essential for effective aircraft service. Moreover, understanding how much fuel does an airport fuel truck hold can help operators plan better and avoid unnecessary delays during busy flight schedules.

Enhancing Efficiency in Aircraft Refueling

Enhancing efficiency in aircraft refueling goes beyond just knowing how are commercial planes refueled; it involves implementing streamlined procedures that cut down on time without compromising safety. For instance, establishing clear protocols for equipment checks can prevent mishaps and ensure that every refuel plane truck is ready for action when needed. Additionally, by training staff on how long does it take to refuel a cargo plane under various conditions, airports can optimize turnaround times and keep flights running smoothly.

Investing in Quality Refueler Trucks

Investing in top-notch quality and innovative aircraft refueling trucks is crucial for any airport aiming to maintain high operational standards. Quality trucks like Haisen's not only provide reliable service but also come equipped with features designed to meet diverse fueling needs across different aircraft sizes efficiently. In the long run, opting for superior equipment translates into fewer breakdowns and lower maintenance costs—an investment worth making in any bustling aviation hub.