Introduction

In the world of aviation, the process of aircraft fueling is crucial for ensuring safe and efficient operations. Understanding what fueling in an aircraft entails, including the necessary steps and protocols, can significantly impact flight safety and performance. Proper aircraft refueling is not just a routine task; it’s a vital component that requires attention to detail and adherence to established rules to prevent mishaps.

Understanding the Aircraft Fueling Process

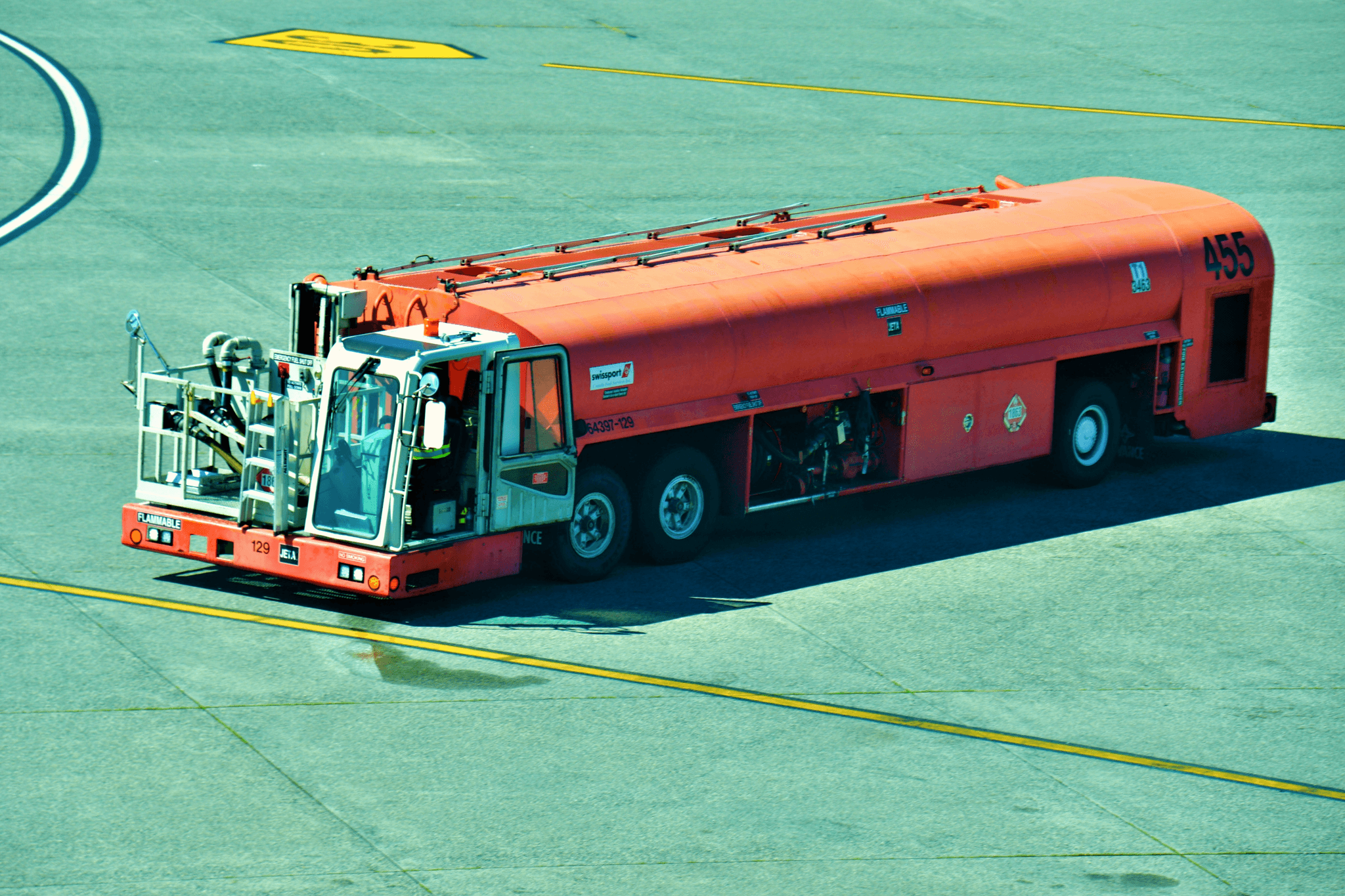

Aircraft fueling involves several critical steps that must be meticulously followed to ensure safety and efficiency. It begins with assessing how much fuel does an airport fuel truck hold, determining the appropriate amount needed for various aircraft types, and preparing the refueling equipment accordingly. By understanding these fundamentals, personnel can effectively manage what are often complex fueling operations.

Importance of Proper Aircraft Refueling

Proper aircraft refueling is essential not only for operational efficiency but also for maintaining safety standards in aviation. When executed correctly, it minimizes risks such as fuel contamination or incorrect fuel quantities—issues that could lead to severe consequences during flight. Additionally, investing in quality refueling equipment like Haisen's Aircraft Pipeline Refueling Truck enhances this process by providing reliable service tailored for different aircraft sizes.

Overview of Common Refueling Mistakes

Despite its importance, several common mistakes occur during aircraft fueling that can compromise safety and efficiency. These include overlooking pre-refueling checks, failing to follow established protocols, or misjudging fuel quantity requirements—all of which can lead to dangerous situations in-flight. By being aware of these pitfalls and understanding rules for aircraft refueling, operators can significantly reduce the likelihood of errors.

Ignoring Pre-Refueling Checks

Before embarking on the critical task of aircraft fueling, it's essential to understand what it entails and why pre-refueling checks are indispensable. Ignoring these checks can lead to severe consequences, including safety hazards and operational inefficiencies. In this section, we will explore the fundamental aspects of fueling in an aircraft, outline necessary inspections before fueling, and highlight common oversights during these crucial checks.

What is fueling in an aircraft?

Fueling in an aircraft is the process of transferring aviation fuel from a fuel source—such as a truck or storage tank—into the aircraft's fuel tanks. This operation is vital for ensuring that the aircraft has enough fuel for its intended flight path. Properly understanding what fueling in an aircraft entails sets the stage for recognizing why meticulous pre-refueling checks are essential.

Necessary inspections before fueling

Before any aircraft refueling can commence, several necessary inspections must be conducted to ensure safety and compliance with established protocols. These include checking fuel quality, inspecting hoses and connections for wear or damage, and confirming that all equipment is functioning correctly. Adhering to these steps for refueling an aircraft not only ensures a smooth operation but also mitigates risks associated with improper fueling practices.

Common oversights during checks

Despite their importance, many personnel overlook critical elements during pre-refueling inspections, leading to potential mishaps later on. Common oversights include neglecting to check for contamination in the fuel or failing to ensure that grounding procedures are followed correctly—both of which can have dire consequences during actual aircraft fueling operations. By fostering a culture of diligence and attention to detail during these initial checks, teams can significantly reduce risks associated with improper refueling practices.

Failing to Follow Refueling Protocols

In the world of aircraft fueling, following established protocols is not just a suggestion; it's a necessity. The rules for aircraft refueling are designed to protect both the personnel involved and the aircraft itself. Ignoring these protocols can lead to serious accidents, costly repairs, and even jeopardize flight safety.

What are the rules for aircraft refueling?

When it comes to fueling in an aircraft, there are several critical rules that must be adhered to. First off, personnel should always wear appropriate protective gear during the refueling process to minimize risks associated with fuel spills or fire hazards. Additionally, ensuring that all equipment used during fueling is in proper working condition is vital; this includes checking hoses, nozzles, and filters for any signs of wear or damage.

Another essential step in understanding what are the steps for refueling an aircraft involves establishing a clear communication protocol among team members. This includes using hand signals or radios to coordinate actions while minimizing distractions from surrounding activities at the airport. Lastly, grounding both the aircraft and fuel truck is crucial for preventing static electricity buildup that could ignite fuel vapors during transfer.

Importance of adhering to standard operating procedures

Adhering to standard operating procedures (SOPs) in aircraft fueling ensures consistency and safety across operations. These procedures outline specific actions that must be taken before, during, and after fueling—helping prevent oversights that could lead to disastrous consequences. For instance, SOPs often include pre-refueling checks like verifying fuel type compatibility and inspecting fuel quality before beginning any transfer.

Moreover, compliance with SOPs helps maintain regulatory standards set by aviation authorities around the world—ensuring that organizations avoid hefty fines or penalties due to non-compliance. By consistently following these guidelines, teams can also foster a culture of safety within their organization where everyone understands their roles during aircraft refueling operations.

Avoiding accidents through proper protocols

Proper protocols serve as a safeguard against accidents during aircraft fueling operations by providing clear guidelines on how tasks should be executed safely and efficiently. For example, knowing how much fuel does an airport fuel truck hold helps operators plan their refueling process better—avoiding situations where they might run out of fuel mid-operation or overfill an aircraft's tank unintentionally.

Additionally, utilizing specialized vehicles like Haisen's Aircraft Pipeline Refueling Truck can greatly enhance safety measures during fueling activities due to its advanced filtration systems designed specifically for aviation needs. With features such as low-altitude dispensers capable of underwing service for various sizes of military aircraft refueling trucks or commercial planes alike—these trucks ensure effective delivery while minimizing risks associated with contamination.

By committing fully to established protocols and investing in high-quality equipment like Haisen's offerings for sale on the market today—aviation professionals can significantly reduce incidents related to improper fueling practices while enhancing overall operational efficiency.

Misjudging Fuel Quantity Requirements

Misjudging fuel quantity requirements can lead to significant operational issues in aircraft fueling. It's crucial to have a clear understanding of how much fuel an airport fuel truck holds and how that translates into the needs of various aircraft types. Failure to accurately assess these requirements can result in delays, increased costs, and even safety hazards.

How much fuel does an airport fuel truck hold?

An airport fuel truck typically holds between 5,000 to 12,000 gallons of aviation fuel, depending on its design and purpose. Understanding this capacity is essential for efficient aircraft fueling operations; it helps ground staff determine how many trips are needed for larger aircraft or multiple refuelings throughout the day. Additionally, knowing the tank size allows for better planning and scheduling when coordinating refueling services.

Calculating fuel needs for different aircraft types

Calculating fuel needs involves assessing the specific requirements of each aircraft type based on its size and mission profile. For instance, larger commercial airliners may require upwards of 30,000 gallons just for a single flight, while smaller general aviation planes might only need a few hundred gallons. This discrepancy underscores the importance of understanding what is fueling in an aircraft: accurate calculations lead to efficient refueling operations that ensure timely departures without unnecessary delays.

Consequences of fuel miscalculations

The consequences of miscalculating fuel requirements can be dire; they range from grounded flights due to insufficient fuel to costly delays caused by excess load or even emergency landings if a plane runs out mid-flight. Moreover, improper management can lead to wasted resources and increased operational costs as more trips are required than initially planned. In extreme cases, such errors could jeopardize passenger safety and tarnish an airline's reputation.

Choosing the Wrong Aircraft Refueling Truck

Selecting the right aircraft refueling truck is crucial for ensuring efficient and safe aircraft fueling operations. An inappropriate choice can lead to delays, increased operational costs, and even safety hazards during fuel transfer. Understanding the features of an ideal refueling truck, comparing options like Haisen's Aircraft Pipeline Refueling Truck, and recognizing the advantages of military aircraft refueling trucks can help streamline this vital process.

Features of an ideal aircraft refueling truck for sale

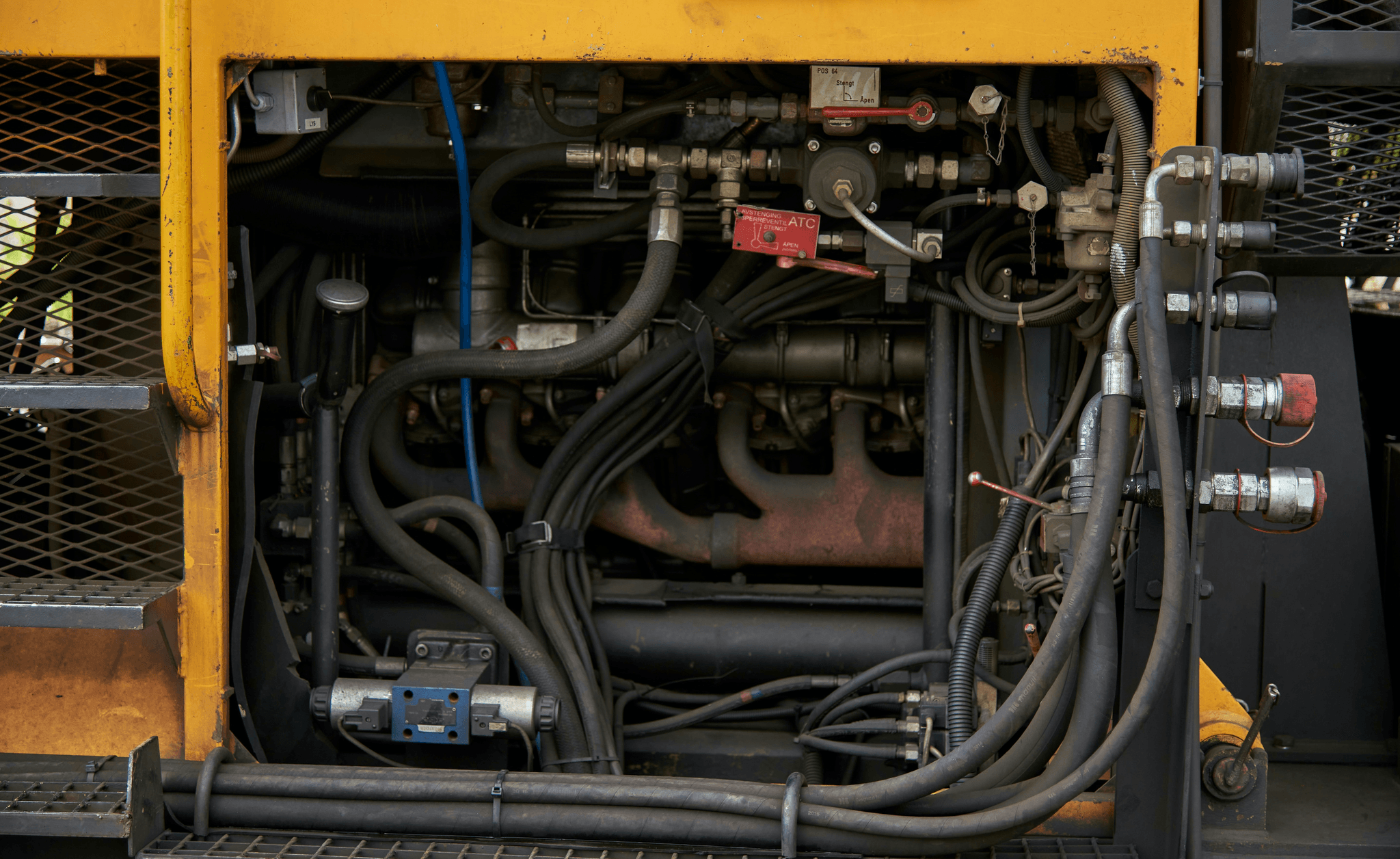

When considering an aircraft refueling truck for sale, several key features should be prioritized to ensure effective fueling operations. First and foremost, a good fuel truck should have a robust filtration system to prevent contamination during the fueling process. Additionally, it should possess a high flow rate capability to minimize downtime while meeting various fuel quantity requirements dictated by different aircraft types.

Moreover, safety measures such as emergency shut-off valves and ground bonding systems are essential to comply with what are the rules for aircraft refueling? These features not only enhance operational efficiency but also protect personnel and equipment from accidents related to fuel handling. In summary, an ideal aircraft refueling truck combines reliability, safety features, and efficiency in its design.

Comparison of Haisen's Aircraft Pipeline Refueling Truck

Haisen's Aircraft Pipeline Refueling Truck stands out in the market due to its sophisticated design that includes a comprehensive piping system along with pneumatic control capabilities. This vehicle is capable of providing effective refueling services at a high flow rate across various types of aircrafts—making it versatile in any airport setting. When compared to other models like the CF5060TJYGX Aircraft Hydrant Dispenser, Haisen's unit offers significant benefits such as being only 2 meters high; this low-altitude design allows for more effective underwing fueling service across a wide range of aircraft sizes.

The filtration system integrated into Haisen’s design removes impurities like dust and moisture during fueling—ensuring that what is fueling in an aircraft meets stringent quality standards. Furthermore, its hydraulic system ensures smooth operation while accurately measuring fuel flow rates throughout the process. Therefore, investing in Haisen’s Aircraft Pipeline Refueling Truck means prioritizing quality while adhering to necessary protocols for safe and efficient operations.

Advantages of military aircraft refueling trucks

Military aircraft refueling trucks offer unique advantages that can significantly enhance both performance and safety during operations. These vehicles are typically designed with rugged durability to withstand harsh environments while maintaining compliance with strict aviation standards regarding what are the steps for refueling an aircraft? Their advanced technology often includes automated systems that streamline fueling processes—reducing human error significantly.

Additionally, military trucks often feature enhanced filtration systems engineered specifically for defense applications where contamination could have dire consequences on mission success. The ability to operate efficiently under various conditions makes military trucks not just reliable but also adaptable—ensuring they meet various operational needs without compromising on quality or safety standards associated with proper aviation practices. Ultimately, investing in military-grade equipment can elevate your overall capabilities when it comes to safe and efficient aircraft fueling.

Overlooking Contamination Prevention

In the realm of aircraft fueling, ensuring the purity of fuel is crucial for safe and efficient operations. Contaminated fuel can lead to severe mechanical failures, jeopardizing both the aircraft and its passengers. Therefore, understanding how to prevent contamination during the refueling process is essential for all aviation professionals.

Filtration systems and their importance

Filtration systems play a pivotal role in maintaining fuel quality during aircraft fueling. These systems are designed to remove impurities such as dirt, water, and microbial growth from the fuel before it enters the aircraft's tanks. Without effective filtration, even minor contamination can lead to significant issues in engine performance and reliability.

When considering what is fueling in an aircraft, it's important to recognize that a well-functioning filtration system acts as the first line of defense against contaminants. High-quality filtration ensures that only clean fuel reaches the engine, which is vital for optimal performance and safety. Aircraft refueling trucks equipped with advanced filtration systems are indispensable tools in maintaining fuel integrity.

How to prevent impurities during fueling

Preventing impurities during fueling involves several proactive steps that must be adhered to rigorously. First off, operators should always inspect refueling equipment before each use; this includes checking hoses and nozzles for any signs of wear or damage that could allow contaminants to enter the system. Additionally, ensuring that storage tanks are regularly cleaned helps minimize potential sources of contamination.

Following established protocols is key when considering what are the rules for aircraft refueling? This includes using proper grounding techniques to avoid static electricity build-up which can disturb settled particles in fuel tanks. Furthermore, training personnel on best practices enhances their ability to identify potential contamination risks during operations.

Impacts of poor fuel quality on aircraft operations

The consequences of poor fuel quality can be dire for both safety and operational efficiency in aviation. Contaminated fuel may cause engine malfunctions or failures mid-flight, leading not only to costly repairs but also endangering lives on board. Additionally, reliance on subpar fuels can result in increased maintenance costs due to fouled injectors or clogged filters.

When examining how much fuel does an airport fuel truck hold? It's important to remember that larger capacities mean more responsibility regarding contamination prevention measures throughout the refueling process. Investing in high-quality equipment like Haisen's Aircraft Pipeline Refueling Truck ensures effective filtration at high flow rates while minimizing risks associated with poor quality fuels.

To sum it up: prioritizing contamination prevention through effective filtration systems and adherence to established protocols will significantly enhance safety during aircraft fueling operations while safeguarding against costly repercussions down the line.

Conclusion

In the world of aircraft fueling, precision and care are paramount. Avoiding common mistakes not only ensures the safety of the aircraft but also enhances operational efficiency. A thorough understanding of what fueling in an aircraft entails, alongside adherence to established protocols, can make a significant difference in successful operations.

Avoiding Mistakes for Safe Aircraft Operations

To ensure safe aircraft operations, it is crucial to avoid mistakes during the refueling process. Common oversights—like skipping pre-refueling checks or misjudging fuel quantity requirements—can lead to dire consequences. By understanding what are the rules for aircraft refueling and following them diligently, personnel can significantly reduce risks associated with improper fueling practices.

Investing in Quality Refueling Equipment

Investing in quality refueling equipment is essential for maintaining safety and efficiency in aircraft fueling operations. The right equipment, such as Haisen's Aircraft Pipeline Refueling Truck, offers advanced filtration systems that prevent contamination during fueling processes. When looking for an aircraft refueling truck for sale, it's important to consider features that enhance performance and reliability.

Commitment to Ongoing Training and Compliance

A commitment to ongoing training and compliance is vital for those involved in aircraft fueling activities. Regular training sessions help staff stay updated on what are the steps for refueling an aircraft effectively while reinforcing the importance of adhering to protocols and standards. This proactive approach not only mitigates risks but also fosters a culture of safety within aviation operations.